Silk mill on:

[Wikipedia]

[Google]

[Amazon]

A silk mill is a factory that makes

A silk mill is a factory that makes

* Auburn Button Works and Logan Silk Mills, Auburn in Cayuga County, New York * Ashley and Bailey Company Silk Mill (also known as Franklin Silk Mill and Leinhardt Brothers Furniture Warehouse), a historic silk mill located at West York, York County ''Note:'' This includes * Bellemonte Silk Mill, Hawley, Wayne County *

A silk mill is a factory that makes

A silk mill is a factory that makes silk

Silk is a natural protein fiber, some forms of which can be woven into textiles. The protein fiber of silk is composed mainly of fibroin and is produced by certain insect larvae to form cocoons. The best-known silk is obtained from the ...

for garments using a process called silk throwing

Silk throwing is the industrial process wherein silk that has been reeled into skeins, is cleaned, receives a twist and is wound onto bobbins. The yarn is now twisted together with threads, in a process known as ''doubling''. Colloquially silk thr ...

. Traditionally, silk mills were concentrated in Japan, England, New Jersey, Pennsylvania, Italy and Switzerland.

The silk throwing process

Silk is a naturally produced fibre obtained from many species of the silk moth. In 1700 the favoured silk was produced by a moth (Bombyx mori

The domestic silk moth (''Bombyx mori''), is an insect from the moth family Bombycidae. It is the closest relative of ''Bombyx mandarina'', the wild silk moth. The silkworm is the larva or caterpillar of a silk moth. It is an economically imp ...

), that spun a cocoon to protect the larvae. The larvae fed on mulberry leaves grown in Italy. Silk fibres from the Bombyx mori silkworm have a triangular cross section with rounded corners, 5–10 μm wide. The silk is a protein, fibroin

Fibroin is an insoluble protein present in silk produced by numerous insects, such as the larvae of ''Bombyx mori'', and other moth genera such as '' Antheraea'', '' Cricula'', '' Samia'' and '' Gonometa''. Silk in its raw state consists of tw ...

, that was cemented in place by the use of gum, another protein, sericin.

The cocoons were harvested and placed in troughs of hot water to dissolve the gum and allowed the single thread to be wound into a skein. The skeins were placed into bales and taken to the mill for processing. Three sorts of yarn could be produced: ''no-twist'' which was suitable for weft, ''tram'' that had received a slight twist making it easier to handle, and ''organzine'' which had a greater twist and was suitable for use as warp.''

''Reeling'' is the industrial process where silk that has been wound into skeins, is cleaned, receives a twist and is wound onto bobbins.

''Silk throwing'' is the process where the thread from the bobbins is twisted again to form ''tram'' and or ''organzine''. The yarn is twisted together into threads, in a process known as ''doubling''. Colloquially silk throwing can be used to refer to the whole process: reeling, throwing and doubling.

History

The Italians were the first to build mills that contained anything more than a set ofspinning wheel

A spinning wheel is a device for spinning thread or yarn from fibres. It was fundamental to the cotton textile industry prior to the Industrial Revolution. It laid the foundations for later machinery such as the spinning jenny and spinning f ...

s. Thomas Cotchett's mill, was built in Derby in 1704, and was a failure.

John Lombe had visited the successful silk throwing mill in Piedmont

it, Piemontese

, population_note =

, population_blank1_title =

, population_blank1 =

, demographics_type1 =

, demographics1_footnotes =

, demographics1_title1 =

, demographics1_info1 =

, demographics1_title2 ...

in 1716, an early example of industrial espionage. He returned to Derby with the necessary knowledge, with details of the Italian silk throwing machines – the and the – and some Italian craftsmen. He designed the mill, and with his half-brother Thomas Lombe (born 1685) instructed George Sorocold

George Sorocold (c. 1668 – c. 1738) was an English civil engineer of the eighteenth century notable for pioneering work on water supplies and hydraulic power systems around Great Britain.

Biography

Sorocold was born in Lancashire in 1666, t ...

to build it and fit it with the new machines. Lombe's Mill was the first successful silk throwing mill in England and probably the first fully mechanised factory in the world. Between 1717 and 1721 George built the mill, beside the River Derwent to the south of Cotchett's failed Mill to house machines for "doubling" or twisting silk

Silk is a natural protein fiber, some forms of which can be woven into textiles. The protein fiber of silk is composed mainly of fibroin and is produced by certain insect larvae to form cocoons. The best-known silk is obtained from the ...

into thread. The machines required large buildings and a power source. An undershot water wheel turned by the mill fleam

A fleam, also flem, flew, flue, fleame, or phleam, was a handheld instrument used for bloodletting.

History

This name for handheld venipuncture devices first appears in Anglo-Saxon manuscripts around 1000. The name is most likely derived from ...

served the purpose.

John Lombe was given a 14-year patent to protect the design of the throwing machines. The King of Sardinia reacted badly to the commercial challenge, placing an embargo on the export of raw silk. John's elder brother, Sir Thomas Lombe, took over the business. When the patents lapsed in 1732, other mills were built in Stockport and Macclesfield.

: "The original Italian works of five storeys high housed 26 Italian winding engines that spun the raw silk on each of the upper three floors whilst the lower two storeys contained eight spinning mills producing basic thread and four twist mills."

The throwing machines were two storeys high and pierced the first floor. The winding machines were situated on the top three floors. All the machines were powered by Sorocold's seven-metre diameter, two-metre wide external undershot waterwheel. That drove a line shaft

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to e ...

that ran the length of the mill. The and took their power from the shaft. The mill was heated to process the silk, and this was explained in the 1718 patent: It was reported that Lombe used a fire engine (steam engine) to pump hot air round the mill .

The circular spinning machines (also known as 'throwing machines'), were the most significant innovation of the factory. Together with the single source of power (water), and the large size and organisation of the workforce for the period (200-400, according to contemporary sources), the total process of production from raw silk to fine quality thread has led the Lombes' silk mill to be described as the first successful use of the factory system in Britain.

United States

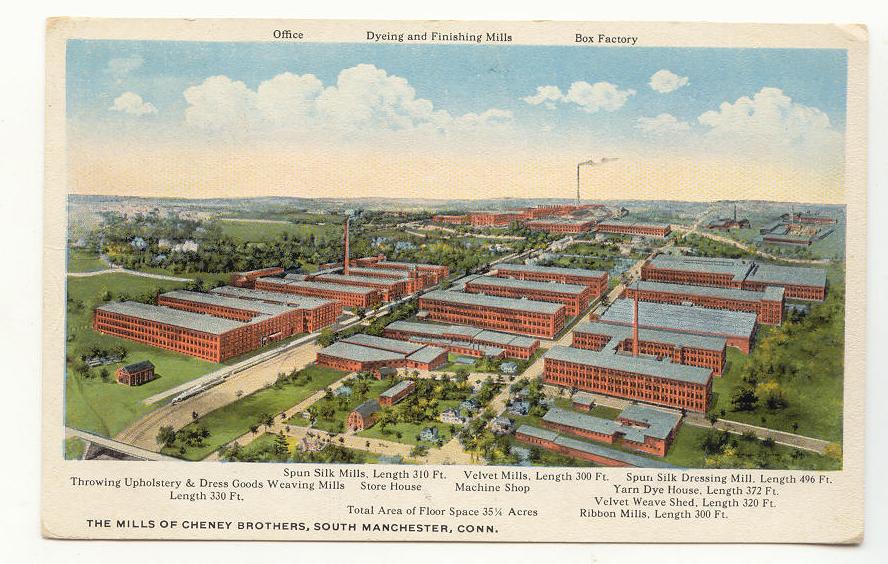

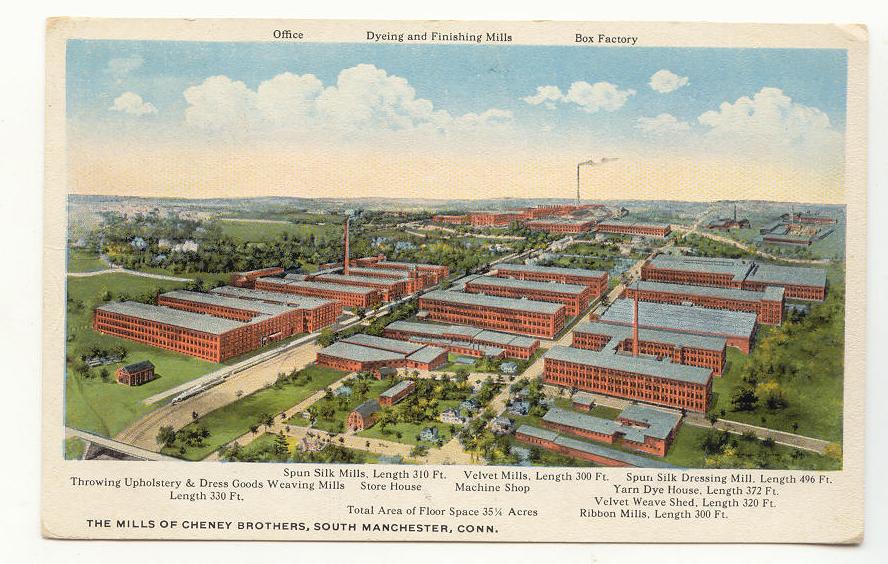

The history of industrial silk in the United States is largely tied to several smaller urban centres in the Northeast region. Beginning in the 1830s,Manchester, Connecticut

Manchester is a town in Hartford County, Connecticut, United States. As of the 2020 United States Census, 2020 census, the town had a total population of 59,713. The urban center of the town is the Manchester (CDP), Connecticut, Manchester census- ...

emerged as the early centre of the silk industry, when the Cheney Brothers became the first to raise silkworms on an industrial scale. With the mulberry tree

''Morus'', a genus of flowering plants in the family Moraceae, consists of diverse species of deciduous trees commonly known as mulberries, growing wild and under cultivation in many temperate world regions. Generally, the genus has 64 identif ...

craze of that decade, other smaller producers began raising silkworms: this economy gained traction around Northampton, Massachusetts and Williamsburg, where a number of small firms and cooperatives emerged. William Skinner, relocated from there to the then-new city of Holyoke after the 1874 flood. Over the next 50 years he and his sons would maintain relations between the American silk industry and its counterparts in Japan, and by 1911, the Skinner Mill complex contained the world's largest silk mill under one roof: Skinner Fabrics had become the largest manufacturer of silk satins internationally. Other efforts later in the 19th century would also bring the new silk industry to Paterson, New Jersey, with several firms hiring European-born textile workers and granting it the nickname "Silk City".

World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposing ...

interrupted the Asian silk trade, and silk prices increased dramatically. U.S. industry began to look for substitutes, which led to the use of synthetics such as nylon

Nylon is a generic designation for a family of synthetic polymers composed of polyamides ( repeating units linked by amide links).The polyamides may be aliphatic or semi-aromatic.

Nylon is a silk-like thermoplastic, generally made from pe ...

. Synthetic silks have also been made from lyocell, a type of cellulose

Cellulose is an organic compound with the formula , a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell w ...

fibre, and are often difficult to distinguish from real silk (see spider silk

Spider silk is a protein fibre spun by spiders. Spiders use their silk to make webs or other structures, which function as sticky nets to catch other animals, or as nests or cocoons to protect their offspring, or to wrap up prey. They can ...

for more on synthetic silks).

Industrial unrest

In New Jersey, disputes between silk mill workers and owners lead to the 1913 Paterson silk strike and the 1926 Passaic Textile Strike .Examples

* American Silk Mills, Paterson, New Jersey, founded in 1905 by Edward Rubin (died 1939), a Russian-born furrier residing in New York City at 22 E. 93rd St.Mortimer J. Adler, ''Philosopher at Large: An Intellectual Autobiography'' (New York: Macmillan, 1977), p. 53.* Auburn Button Works and Logan Silk Mills, Auburn in Cayuga County, New York * Ashley and Bailey Company Silk Mill (also known as Franklin Silk Mill and Leinhardt Brothers Furniture Warehouse), a historic silk mill located at West York, York County ''Note:'' This includes * Bellemonte Silk Mill, Hawley, Wayne County *

Bethlehem Silk Mill

Bethlehem Silk Mill is a historic silk mill complex located in Bethlehem, Northampton County, Pennsylvania. It was built in 1886, and expanded about 1896 and about 1901. The complex once consisted of a total of seven interconnected historic build ...

, Bethlehem, Northampton County

* Diamond Silk Mill (also known as York Silk Manufacturing Company), a historic silk mill located at Springettsbury Township, York County

* Lansdale Silk Hosiery Compy-Interstate Hosiery Mills, Inc., a historic silk mill located at Lansdale, Montgomery County

* Lehigh Valley Silk Mills

The Lehigh Valley Silk Mills were a collection of mills located in the Lehigh Valley region of eastern Pennsylvania in the 19th and 20th centuries.

The industry began in 1881 and thrived throughout the Industrial Revolution. The Lehigh Valley Si ...

, Fountain Hill, Northampton County

* Lister Mills, Bradford, England, built in 1871, known for being the largest silk mill in the world.

* Logwood Mill, Stockport, England, built in 1732

* Lombe's Mill

Lombe's Mill was the first successful silk throwing mill in Britain. It was built on an island on the River Derwent in Derby. It was built after John Lombe visited Piedmont in 1717 and returned to England with details of the Italian silk throwi ...

, Derby, the first successful silk throwing mill in England, built in 1721.

* McCollum and Post Silk Mill, Nazareth, Northampton County

* Old Mill, Congleton, England, built in 1753

* The Royal Button Mill, Macclesfield, England, built in 1744

See also

*Cotton mill

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Although some were driven b ...

References

;Notes ;Bibliography * * * {{Silk fibre * Textile mills Silk production