Rheometer on:

[Wikipedia]

[Google]

[Amazon]

A rheometer is a laboratory device used to measure the way in which a dense

A rheometer is a laboratory device used to measure the way in which a dense

Four basic shearing planes can be defined according to their geometry,

* Couette drag plate flow

* Cylindrical flow

* Poiseuille flow in a tube and

* Plate-plate flow

The various types of shear rheometers then use one or a combination of these geometries.

Four basic shearing planes can be defined according to their geometry,

* Couette drag plate flow

* Cylindrical flow

* Poiseuille flow in a tube and

* Plate-plate flow

The various types of shear rheometers then use one or a combination of these geometries.

See Dynamic Shear Rheometer by Cooper Research TechnologyPresentation on alternative uses of rheometers

{{Webarchive, url=https://web.archive.org/web/20190915161424/http://www.campoly.com/files/3313/6813/2733/Rheometers__not_just_for_rheology_any_more.pdf , date=15 September 2019 Fluid dynamics Measuring instruments Tribology

A rheometer is a laboratory device used to measure the way in which a dense

A rheometer is a laboratory device used to measure the way in which a dense fluid

In physics, a fluid is a liquid, gas, or other material that continuously deforms (''flows'') under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are substances which cannot resist any shear ...

(a liquid

A liquid is a nearly incompressible fluid that conforms to the shape of its container but retains a (nearly) constant volume independent of pressure. As such, it is one of the four fundamental states of matter (the others being solid, gas, a ...

, suspension

Suspension or suspended may refer to:

Science and engineering

* Suspension (topology), in mathematics

* Suspension (dynamical systems), in mathematics

* Suspension of a ring, in mathematics

* Suspension (chemistry), small solid particles suspend ...

or slurry) flows in response to applied forces. It is used for those fluids which cannot be defined by a single value of viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

and therefore require more parameters to be set and measured than is the case for a viscometer

A viscometer (also called viscosimeter) is an instrument used to measure the viscosity of a fluid. For liquids with viscosities which vary with flow conditions, an instrument called a rheometer is used. Thus, a rheometer can be considered as a spe ...

. It measures the rheology

Rheology (; ) is the study of the flow of matter, primarily in a fluid ( liquid or gas) state, but also as "soft solids" or solids under conditions in which they respond with plastic flow rather than deforming elastically in response to an appl ...

of the fluid.

There are two distinctively different types of ''rheometers''. Rheometers that control the applied shear stress

Shear stress, often denoted by (Greek: tau), is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the ot ...

or shear strain are called rotational or shear rheometers, whereas rheometers that apply extensional stress

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elonga ...

or extensional strain are extensional rheometers.

Rotational or shear type rheometers are usually designed as either a native strain-controlled instrument (control and apply a user-defined shear strain which can then measure the resulting shear stress) or a native stress-controlled instrument (control and apply a user-defined shear stress

Stress may refer to:

Science and medicine

* Stress (biology), an organism's response to a stressor such as an environmental condition

* Stress (linguistics), relative emphasis or prominence given to a syllable in a word, or to a word in a phrase ...

and measure the resulting shear strain).

Meanings and origin

The word rheometer comes from the Greek, and means a device for measuring main flow. In the 19th century it was commonly used for devices to measure electric current, until the word was supplanted bygalvanometer

A galvanometer is an electromechanical measuring instrument for electric current. Early galvanometers were uncalibrated, but improved versions, called ammeters, were calibrated and could measure the flow of current more precisely.

A galvanom ...

and ammeter

An ammeter (abbreviation of ''Ampere meter'') is an instrument used to measure the current in a circuit. Electric currents are measured in amperes (A), hence the name. For direct measurement, the ammeter is connected in series with the circuit ...

. It was also used for the measurement of the flow of liquids, in medical practice (flow of blood) and in civil engineering (flow of water). This latter use persisted to the second half of the 20th century in some areas. Following the coining of the term rheology

Rheology (; ) is the study of the flow of matter, primarily in a fluid ( liquid or gas) state, but also as "soft solids" or solids under conditions in which they respond with plastic flow rather than deforming elastically in response to an appl ...

the word came to be applied to instruments for measuring the character rather than quantity of flow, and the other meanings are obsolete. (Principal Source: Oxford English Dictionary

The ''Oxford English Dictionary'' (''OED'') is the first and foundational historical dictionary of the English language, published by Oxford University Press (OUP). It traces the historical development of the English language, providing a com ...

) The principle and working of rheometers is described in several texts.

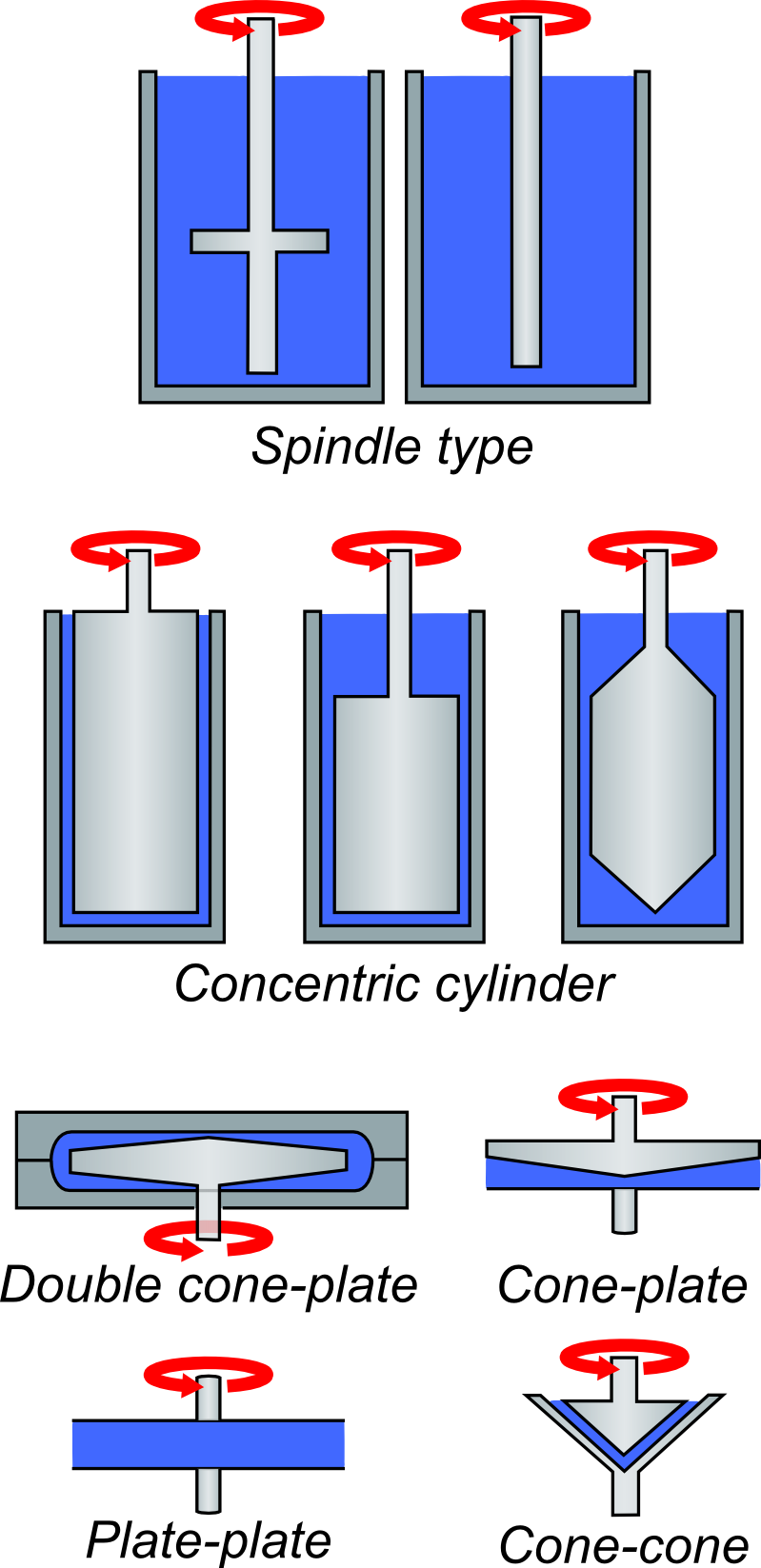

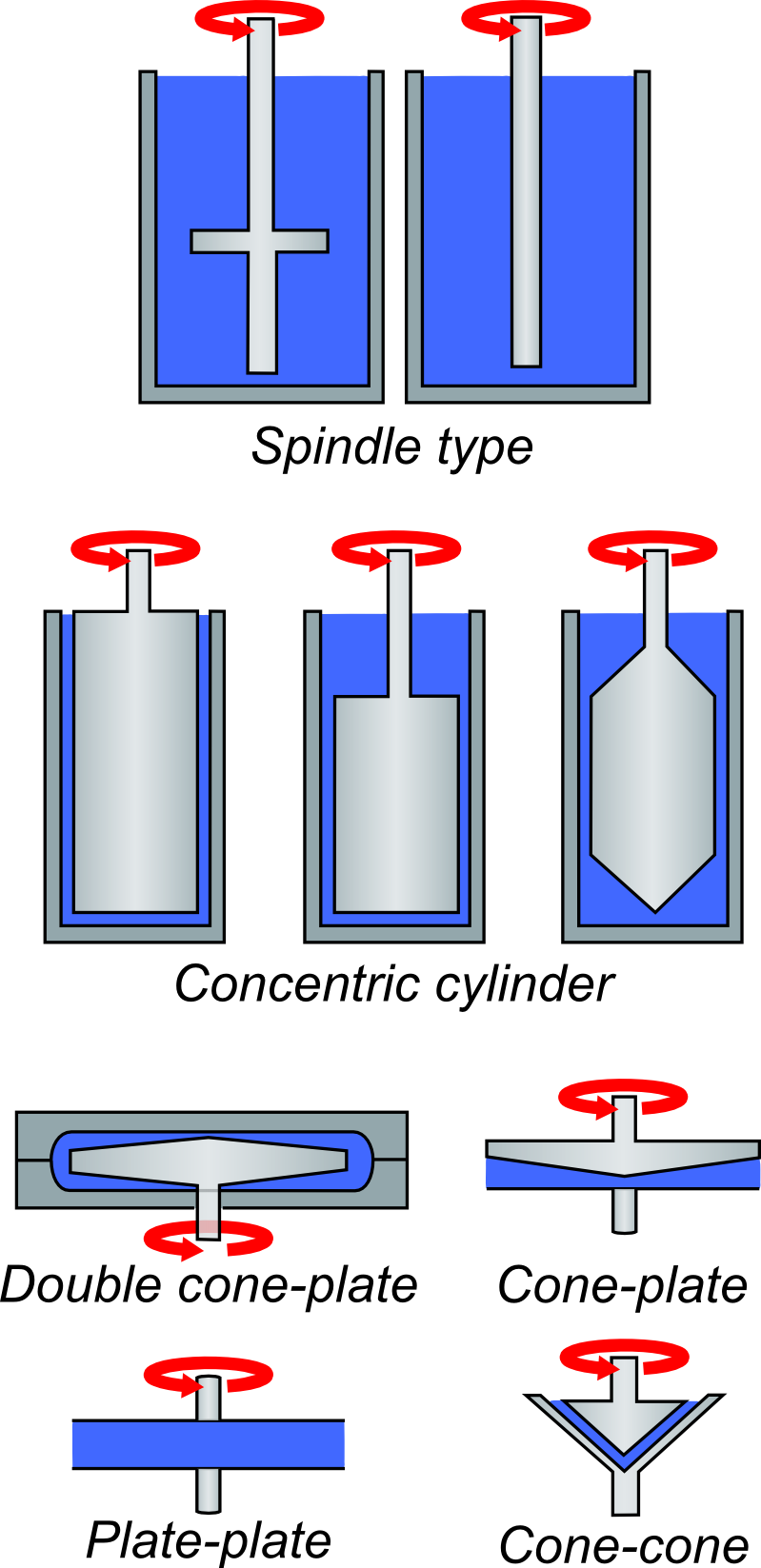

Types of shear rheometer

Shearing geometries

Four basic shearing planes can be defined according to their geometry,

* Couette drag plate flow

* Cylindrical flow

* Poiseuille flow in a tube and

* Plate-plate flow

The various types of shear rheometers then use one or a combination of these geometries.

Four basic shearing planes can be defined according to their geometry,

* Couette drag plate flow

* Cylindrical flow

* Poiseuille flow in a tube and

* Plate-plate flow

The various types of shear rheometers then use one or a combination of these geometries.

Linear shear

One example of a linear shear rheometer is the Goodyear linear skin rheometer, which is used to test cosmetic cream formulations, and for medical research purposes to quantify the elastic properties of tissue. The device works by attaching a linear probe to the surface of the tissue under test, a controlled cyclical force is applied, and the resultant shear force measured using a load cell. Displacement is measured using an LVDT. Thus the basic stress–strain parameters are captured and analysed to derive the dynamic spring rate of the tissue under tests.Pipe or capillary

Liquid is forced through a tube of constant cross-section and precisely known dimensions under conditions oflaminar flow

In fluid dynamics, laminar flow is characterized by fluid particles following smooth paths in layers, with each layer moving smoothly past the adjacent layers with little or no mixing. At low velocities, the fluid tends to flow without lateral mi ...

. Either the flow-rate or the pressure drop are fixed and the other measured. Knowing the dimensions, the flow-rate can be converted into a value for the shear rate

In physics, shear rate is the rate at which a progressive shearing deformation is applied to some material.

Simple shear

The shear rate for a fluid flowing between two parallel plates, one moving at a constant speed and the other one stationary ...

and the pressure drop into a value for the shear stress

Shear stress, often denoted by (Greek: tau), is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the ot ...

. Varying the pressure or flow allows a flow curve to be determined. When a relatively small amount of fluid is available for rheometric characterization, a microfluidic rheometer with embedded pressure sensors can be used to measure pressure drop for a controlled flow rate.

Capillary rheometers are especially advantageous for characterization of therapeutic protein solutions since it determines the ability to be syringed. Additionally, there is an inverse relationship between the rheometry and solution stability, as well as thermodynamic interactions.

Dynamic shear rheometer

Adynamic shear rheometer

A dynamic shear rheometer, commonly known as DSR, is used for research and development as well as for quality control in the manufacture of a wide range of materials. Dynamic shear rheometers have been used since 1993 when Superpave was used for c ...

, commonly known as DSR is used for research and development as well as for quality control in the manufacturing of a wide range of materials. Dynamic shear rheometers have been used since 1993 when Superpave was used for characterising and understanding high temperature rheological properties of asphalt binders in both the molten and solid state and is fundamental in order to formulate the chemistry and predict the end-use performance of these materials.

Rotational cylinder

The liquid is placed within theannulus

Annulus (or anulus) or annular indicates a ring- or donut-shaped area or structure. It may refer to:

Human anatomy

* ''Anulus fibrosus disci intervertebralis'', spinal structure

* Annulus of Zinn, a.k.a. annular tendon or ''anulus tendineus com ...

of one cylinder inside another. One of the cylinders is rotated at a set speed. This determines the shear rate

In physics, shear rate is the rate at which a progressive shearing deformation is applied to some material.

Simple shear

The shear rate for a fluid flowing between two parallel plates, one moving at a constant speed and the other one stationary ...

inside the annulus. The liquid tends to drag the other cylinder round, and the force it exerts on that cylinder (torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

) is measured, which can be converted to a shear stress

Shear stress, often denoted by (Greek: tau), is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the ot ...

.

One version of this is the Fann V-G Viscometer, which runs at two speeds, (300 and 600 rpm) and therefore only gives two points on the flow curve. This is sufficient to define a Bingham plastic

A Bingham plastic is a viscoplastic material that behaves as a rigid body at low stresses but flows as a viscous fluid at high stress. It is named after Eugene C. Bingham who proposed its mathematical form.

It is used as a common mathematical m ...

model which was once widely used in the oil industry

The petroleum industry, also known as the oil industry or the oil patch, includes the global processes of exploration, extraction, refining, transportation (often by oil tankers and pipelines), and marketing of petroleum products. The larges ...

for determining the flow character of drilling fluid

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are als ...

s. In recent years rheometers that spin at 600, 300, 200, 100, 6 & 3 RPM have become more commonplace. This allows for more complex fluids models such as Herschel–Bulkley to be used. Some models allow the speed to be continuously increased and decreased in a programmed fashion, which allows the measurement of time-dependent properties.

Cone and plate

The liquid is placed on horizontal plate and a shallow cone placed into it. The angle between the surface of the cone and the plate is around 1–2 degrees but can vary depending on the types of tests being run. Typically the plate is rotated and the torque on the cone measured. A well-known version of this instrument is the Weissenberg rheogoniometer, in which the movement of the cone is resisted by a thin piece of metal which twists—known as atorsion bar

A torsion bar suspension, also known as a torsion spring suspension, is any vehicle suspension that uses a torsion bar as its main weight-bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end termi ...

. The known response of the torsion bar

A torsion bar suspension, also known as a torsion spring suspension, is any vehicle suspension that uses a torsion bar as its main weight-bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end termi ...

and the degree of twist give the shear stress

Shear stress, often denoted by (Greek: tau), is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the ot ...

, while the rotational speed and cone dimensions give the shear rate

In physics, shear rate is the rate at which a progressive shearing deformation is applied to some material.

Simple shear

The shear rate for a fluid flowing between two parallel plates, one moving at a constant speed and the other one stationary ...

. In principle the Weissenberg rheogoniometer is an absolute method of measurement providing it is accurately set up. Other instruments operating on this principle may be easier to use but require calibration with a known fluid.

Cone and plate rheometers can also be operated in an oscillating mode to measure elastic properties, or in combined rotational and oscillating modes.

Types of extensional rheometer

The development of extensional rheometers has proceeded more slowly than shear rheometers, due to the challenges associated with generating a homogeneous extensional flow. Firstly, interactions of the test fluid or melt with solid interfaces will result in a component of shear flow, which will compromise the results. Secondly, the strain history of all the material elements must be controlled and known. Thirdly, the strain rates and strain levels must be high enough to stretch the polymeric chains beyond their normal radius of gyration, requiring instrumentation with a large range of deformation rates and a large travel distance. Commercially available extensional rheometers have been segregated according to their applicability to viscosity ranges. Materials with a viscosity range from approximately 0.01 to 1 Pa.s. (most polymer solutions) are best characterized with capillary breakup rheometers, opposed jet devices, or contraction flow systems. Materials with a viscosity range from approximately 1 to 1000 Pa.s. are used in filament stretching rheometers. Materials with a high viscosity >1000 Pa.s., such as polymer melts, are best characterized by constant-length devices. Extensional rheometry is commonly performed on materials that are subjected to a tensile deformation. This type of deformation can occur during processing, such as injection molding, fiber spinning, extrusion, blow-molding, and coating flows. It can also occur during use, such as decohesion of adhesives, pumping of hand soaps, and handling of liquid food products. A list of currently and previously marketed commercially available extensional rheometers is shown in the table below.Commercially available extensional rheometers

Rheotens

Rheotens is a fiber spinning rheometer, suitable for polymeric melts. The material is pumped from an upstream tube, and a set of wheels elongates the strand. A force transducer mounted on one of the wheels measures the resultant extensional force. Because of the pre-shear induced as the fluid is transported through the upstream tube, a true extensional viscosity is difficult to obtain. However, the Rheotens is useful to compare the extensional flow properties of a homologous set of materials.CaBER

The CaBER is a capillary breakup rheometer. A small quantity of material is placed between plates, which are rapidly stretched to a fixed level of strain. The midpoint diameter is monitored as a function of time as the fluid filament necks and breaks up under the combined forces of surface tension, gravity, and viscoelasticity. The extensional viscosity can be extracted from the data as a function of strain and strain rate. This system is useful for low viscosity fluids, inks, paints, adhesives, and biological fluids.FiSER

The FiSER (filament stretching extensional rheometer) is based on the works by Sridhar et al. and Anna et al. In this instrument, a set of linear motors drive a fluid filament apart at an exponentially increasing velocity while measuring force and diameter as a function of time and position. By deforming at an exponentially increasing rate, a constant strain rate can be achieved in the samples (barring endplate flow limitations). This system can monitor the strain-dependent extensional viscosity, as well as stress decay following flow cessation. A detailed presentation on the various uses of filament stretching rheometry can be found on the MIT web site.Sentmanat

The Sentmanat extensional rheometer (SER) is actually a fixture that can be field installed on shear rheometers. A film of polymer is wound on two rotating drums, which apply constant or variable strain rate extensional deformation on the polymer film. The stress is determined from the torque exerted by the drums.Other types of extensional rheometers

Acoustic rheometer

Acoustic rheometer

An acoustic rheometer employs a piezo-electric crystal that can easily launch a successive wave of extensions and contractions into the fluid. It applies an oscillating extensional stress to the system. System response can be interpreted in ter ...

s employ a piezo-electric crystal that can easily launch a successive wave of extensions and contractions into the fluid. This non-contact method applies an oscillating extensional stress. Acoustic rheometers measure the sound speed and attenuation of ultrasound for a set of frequencies in the megahertz range. Sound speed is a measure of system elasticity. It can be converted into fluid compressibility. Attenuation is a measure of viscous properties. It can be converted into viscous longitudinal modulus. In the case of a Newtonian liquid, attenuation yields information on the volume viscosity. This type of rheometer works at much higher frequencies than others. It is suitable for studying effects with much shorter relaxation times than any other rheometer.

Falling plate

A simpler version of the filament stretching rheometer, the falling plate rheometer sandwiches liquid between two solid surfaces. The top plate is fixed, and bottom plate falls under the influence of gravity, drawing out a string of the liquid.Capillary/contraction flow

Other systems involve liquid going through an orifice, expanding from a capillary, or sucked up from a surface into a column by a vacuum. A pressurized capillary rheometer can be used to design thermal treatments of fluid food. This instrumentation could help prevent over and under-processing of fluid food because extrapolation to high temperatures would not be necessary.See also

*Acoustic rheometer

An acoustic rheometer employs a piezo-electric crystal that can easily launch a successive wave of extensions and contractions into the fluid. It applies an oscillating extensional stress to the system. System response can be interpreted in ter ...

*Dynamic shear rheometer

A dynamic shear rheometer, commonly known as DSR, is used for research and development as well as for quality control in the manufacture of a wide range of materials. Dynamic shear rheometers have been used since 1993 when Superpave was used for c ...

*Food rheology

Food rheology is the study of the rheological properties of food, that is, the consistency and flow of food under tightly specified conditions.

The consistency, degree of fluidity, and other mechanical properties are important in understandi ...

*Piezometer

A piezometer is either a device used to measure liquid pressure in a system by measuring the height to which a column of the liquid rises against gravity, or a device which measures the pressure (more precisely, the piezometric head) of groundwa ...

*Rheometry

Rheometry () generically refers to the experimental techniques used to determine the rheological properties of materials, that is the qualitative and quantitative relationships between stresses and strains and their derivatives. The techniques ...

References

External links

See Dynamic Shear Rheometer by Cooper Research Technology

{{Webarchive, url=https://web.archive.org/web/20190915161424/http://www.campoly.com/files/3313/6813/2733/Rheometers__not_just_for_rheology_any_more.pdf , date=15 September 2019 Fluid dynamics Measuring instruments Tribology