Optical flat on:

[Wikipedia]

[Google]

[Amazon]

An optical flat is an optical-grade piece of glass

An optical flat is an optical-grade piece of glass

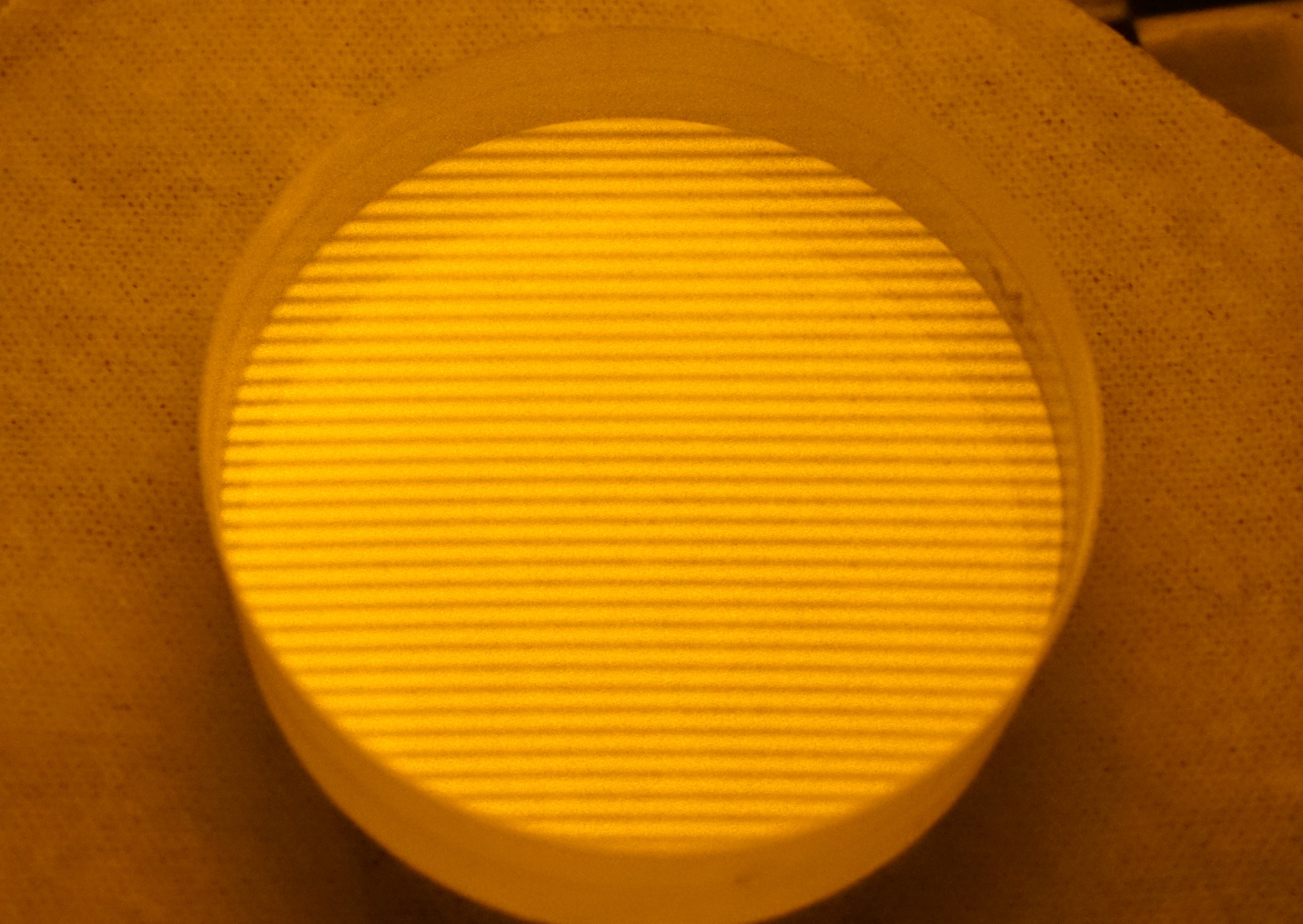

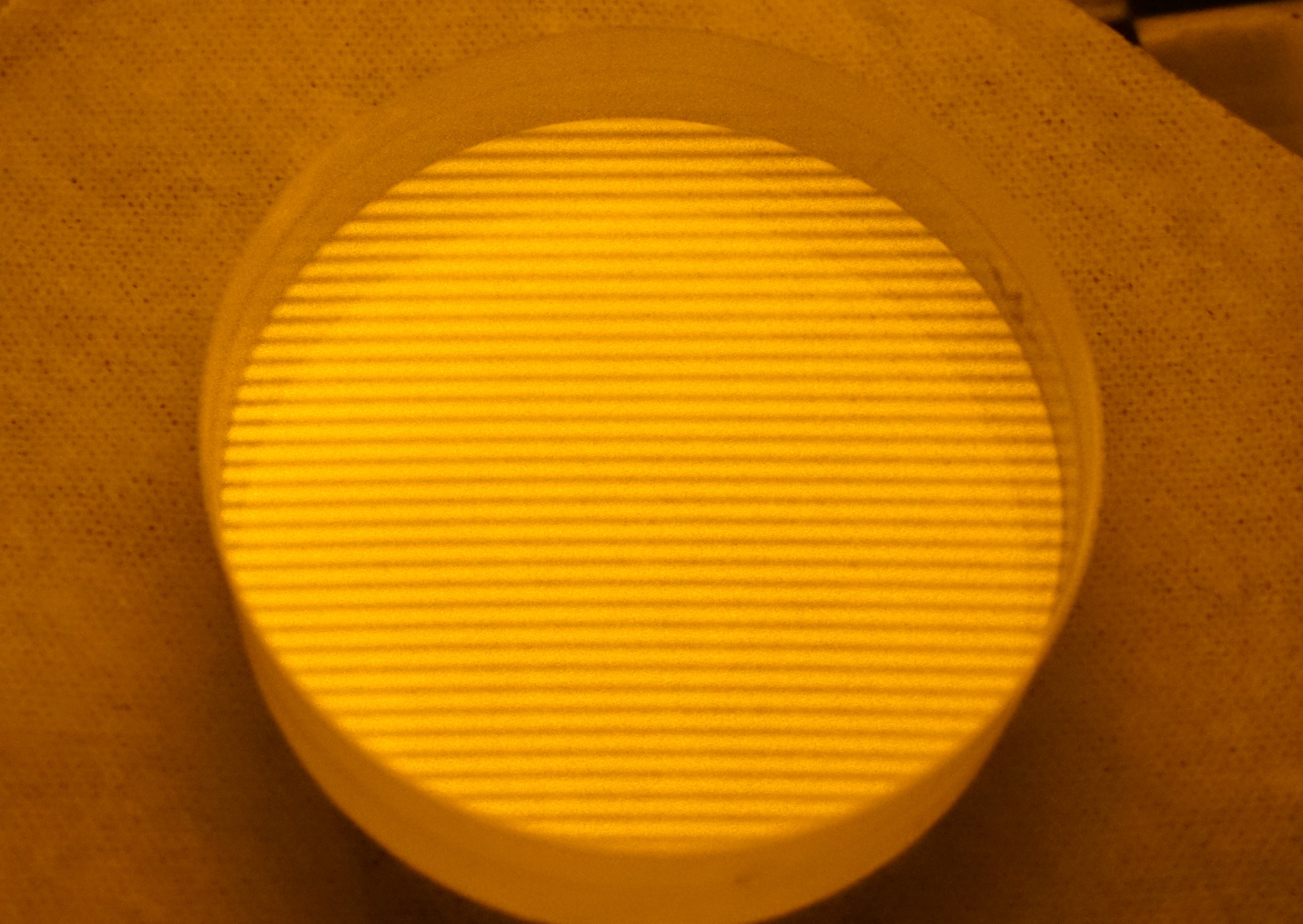

An optical flat is usually placed upon a flat surface to be tested. If the surface is clean and reflective enough, rainbow colored bands of interference fringes will form when the test piece is illuminated with white light. However, if a monochromatic light is used to illuminate the work piece, such as helium, low-pressure sodium, or a laser, then a series of dark and light interference fringes will form. These interference fringes determine the flatness of the work piece, relative to the optical flat, to within a fraction of the wavelength of the light. If both surfaces are perfectly the same flatness and parallel to each other, no interference fringes will form. However, there is usually some air trapped between the surfaces. If the surfaces are flat, but a tiny optical wedge of air exists between them, then straight, parallel interference fringes will form, indicating the angle of the wedge (i.e.: more, thinner fringes indicate a steeper wedge while fewer but wider fringes indicate less of a wedge). The shape of the fringes also indicate the shape of the test surface, because fringes with a bend, a contour, or rings indicate high and low points on the surface, such as rounded edges, hills or valleys, or convex and concave surfaces.

An optical flat is usually placed upon a flat surface to be tested. If the surface is clean and reflective enough, rainbow colored bands of interference fringes will form when the test piece is illuminated with white light. However, if a monochromatic light is used to illuminate the work piece, such as helium, low-pressure sodium, or a laser, then a series of dark and light interference fringes will form. These interference fringes determine the flatness of the work piece, relative to the optical flat, to within a fraction of the wavelength of the light. If both surfaces are perfectly the same flatness and parallel to each other, no interference fringes will form. However, there is usually some air trapped between the surfaces. If the surfaces are flat, but a tiny optical wedge of air exists between them, then straight, parallel interference fringes will form, indicating the angle of the wedge (i.e.: more, thinner fringes indicate a steeper wedge while fewer but wider fringes indicate less of a wedge). The shape of the fringes also indicate the shape of the test surface, because fringes with a bend, a contour, or rings indicate high and low points on the surface, such as rounded edges, hills or valleys, or convex and concave surfaces.

The fringes act very much like the lines on a

The fringes act very much like the lines on a

An optical flat is an optical-grade piece of glass

An optical flat is an optical-grade piece of glass lapped

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first step ...

and polished to be extremely flat on one or both sides, usually within a few tens of nanometres (billionths of a metre). They are used with a monochromatic light {{Short description, Electromagnetic radiation with a single constant frequency

In physics, monochromatic radiation is electromagnetic radiation with a single constant frequency. When that frequency is part of the visible spectrum (or near it) the ...

to determine the flatness (surface accuracy) of other surfaces, whether optical, metallic, ceramic, or otherwise, by interference

Interference is the act of interfering, invading, or poaching. Interference may also refer to:

Communications

* Interference (communication), anything which alters, modifies, or disrupts a message

* Adjacent-channel interference, caused by extr ...

. When an optical flat is placed on another surface and illuminated, the light waves reflect off both the bottom surface of the flat and the surface it is resting on. This causes a phenomenon similar to thin-film interference

Thin-film interference is a natural phenomenon in which light waves reflected by the upper and lower boundaries of a thin film interfere with one another, either enhancing or reducing the reflected light. When the thickness of the film is an ...

. The reflected waves interfere, creating a pattern of interference fringe

In physics, interference is a phenomenon in which two waves combine by adding their displacement together at every single point in space and time, to form a resultant wave of greater, lower, or the same amplitude. Constructive and destructive ...

s visible as light and dark bands. The spacing between the fringes is smaller where the gap is changing more rapidly, indicating a departure from flatness in one of the two surfaces. This is comparable to the contour lines one would find on a map. A flat surface is indicated by a pattern of straight, parallel fringes with equal spacing, while other patterns indicate uneven surfaces. Two adjacent fringes indicate a difference in elevation of one-half wavelength

In physics, the wavelength is the spatial period of a periodic wave—the distance over which the wave's shape repeats.

It is the distance between consecutive corresponding points of the same phase on the wave, such as two adjacent crests, t ...

of the light used, so by counting the fringes, differences in elevation of the surface can be measured to better than one micrometre.

Usually only one of the two surfaces of an optical flat is made flat to the specified tolerance, and this surface is indicated by an arrow on the edge of the glass.

Optical flats are sometimes given an optical coating and used as precision mirror

A mirror or looking glass is an object that reflects an image. Light that bounces off a mirror will show an image of whatever is in front of it, when focused through the lens of the eye or a camera. Mirrors reverse the direction of the im ...

s or optical windows for special purposes, such as in a Fabry–Pérot interferometer or laser cavity An optical cavity, resonating cavity or optical resonator is an arrangement of mirrors or other optical elements that forms a cavity resonator for light waves. Optical cavities are a major component of lasers, surrounding the gain medium and prov ...

. Optical flats have uses in spectrophotometry

Spectrophotometry is a branch of electromagnetic spectroscopy concerned with the quantitative measurement of the reflection or transmission properties of a material as a function of wavelength. Spectrophotometry uses photometers, known as sp ...

as well.

Flatness testing

Preparation

Both the optical flat and the surface to be tested need to be extremely clean. The tiniest bit of dust settling between the surfaces can ruin the results. Even the thickness of a streak or a fingerprint on the surfaces can be enough to change the width of the gap between them. Before the test, the surfaces are usually cleaned very thoroughly. Most commonly,acetone

Acetone (2-propanone or dimethyl ketone), is an organic compound with the formula . It is the simplest and smallest ketone (). It is a colorless, highly volatile and flammable liquid with a characteristic pungent odour.

Acetone is miscib ...

is used as the cleaning agent, because it dissolves most oils and it evaporates completely, leaving no residue. Typically, the surface will be cleaned using the "drag" method, in which a lint-free, scratch-free tissue is wetted, stretched, and dragged across the surface, pulling any impurities along with it. This process is usually performed dozens of times, ensuring that the surface is completely free of impurities. A new tissue will need to be used each time, to prevent recontamination of the surfaces from previously removed dust and oils.

Testing is often done in a clean-room or another dust-free environment, keeping the dust from settling on the surfaces between cleaning and assembly. Sometimes, the surfaces may be assembled by sliding them together, helping to scrape off any dust that might happen to land on the flat. The testing is usually done in a temperature-controlled environment to prevent any distortions in the glass, and needs to be performed on a very stable work-surface. After testing, the flats are usually cleaned again and stored in a protective case, and are often kept in a temperature-controlled environment until used again.

Lighting

For the best test-results, a monochromatic light, consisting of only a single wavelength, is used to illuminate the flats. To show the fringes properly, several factors need to be taken into account when setting up the light source, such as the angle of incidence between the light and the observer, theangular size

The angular diameter, angular size, apparent diameter, or apparent size is an angular distance describing how large a sphere or circle appears from a given point of view. In the vision sciences, it is called the visual angle, and in optics, it is ...

of the light source in relation to the pupil of the eye, and the homogeneity of the light source when reflected off of the glass.

Many sources for monochromatic light can be used. Most lasers emit light of a very narrow bandwidth, and often provide a suitable light source. A helium–neon laser

A helium–neon laser or He-Ne laser, is a type of gas laser whose high energetic medium gain medium consists of a mixture of 10:1 ratio of helium and neon at a total pressure of about 1 torr inside of a small electrical discharge. The bes ...

emits light at 632 nanometres (red), while a frequency doubled

Second-harmonic generation (SHG, also called frequency doubling) is a nonlinear optical process in which two photons with the same frequency interact with a nonlinear material, are "combined", and generate a new photon with twice the energy of ...

Nd:YAG laser emits light at 532 nm (green). Various laser diode

The laser diode chip removed and placed on the eye of a needle for scale

A laser diode (LD, also injection laser diode or ILD, or diode laser) is a semiconductor device similar to a light-emitting diode in which a diode pumped directly with e ...

s and diode-pumped solid-state laser

A diode-pumped solid-state laser (DPSSL) is a solid-state laser made by pumping a solid gain medium, for example, a ruby or a neodymium-doped YAG crystal, with a laser diode.

DPSSLs have advantages in compactness and efficiency over other types ...

s emit light in red, yellow, green, blue or violet. Dye laser

A dye laser is a laser that uses an organic dye as the lasing medium, usually as a liquid solution. Compared to gases and most solid state lasing media, a dye can usually be used for a much wider range of wavelengths, often spanning 50 to 100 ...

s can be tuned to emit nearly any color. However, lasers also experience a phenomenon called laser speckle

Speckle, speckle pattern, or speckle noise is a granular noise texture degrading the quality as a consequence of interference among wavefronts in coherent imaging

Imaging is the representation or reproduction of an object's form; especially ...

, which shows up in the fringes.

Several gas or metal-vapor lamps can also be used. When operated at low pressure and current, these lamps generally produce light in various spectral line

A spectral line is a dark or bright line in an otherwise uniform and continuous spectrum, resulting from emission or absorption of light in a narrow frequency range, compared with the nearby frequencies. Spectral lines are often used to iden ...

s, with one or two lines being most predominant. Because these lines are very narrow, the lamps can be combined with narrow-bandwidth filters to isolate the strongest line. A helium-discharge lamp will produce a line at 587.6 nm (yellow), while a mercury-vapor lamp

A mercury-vapor lamp is a gas-discharge lamp that uses an electric arc through vaporized mercury to produce light. The arc discharge is generally confined to a small fused quartz arc tube mounted within a larger soda lime or borosilicate gl ...

produces a line at 546.1 (yellowish green). Cadmium

Cadmium is a chemical element with the symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12, zinc and mercury. Like zinc, it demonstrates oxidation state +2 in most of ...

vapor produces a line at 643.8 nm (red), but low pressure sodium produces a line at 589.3 nm (yellow). Of all the lights, low pressure sodium is the only one that produces a single line, requiring no filter.

The fringes only appear in the reflection of the light source, so the optical flat must be viewed from the exact angle of incidence that the light shines upon it. If viewed from a zero degree angle (from directly above), the light must also be at a zero degree angle. As the viewing angle changes, the lighting angle must also change. The light must be positioned so that its reflection can be seen covering the entire surface. Also, the angular size of the light source needs to be many times greater than the eye. For example, if an incandescent light is used, the fringes may only show up in the reflection of the filament. By moving the lamp much closer to the flat, the angular size becomes larger and the filament may appear to cover the entire flat, giving clearer readings. Sometimes, a diffuser

Diffuser may refer to:

Aerodynamics

* Diffuser (automotive), a shaped section of a car's underbody which improves the car's aerodynamic properties

* Part of a jet engine air intake, especially when operated at supersonic speeds

* The channel bet ...

may be used, such as the powder coating inside frosted bulbs, to provide a homogenous reflection off the glass. Typically, the measurements will be more accurate when the light source is as close to the flat as possible, but the eye is as far away as possible.

How interference fringes form

The diagram at right shows an optical flat resting on a surface to be tested. Unless the two surfaces are perfectly flat, there will be a small gap between them ''(shown)'', which will vary with the contour of the surface. Monochromatic light ''(red)'' shines through the glass flat and reflects from both the bottom surface of the optical flat and the top surface of the test piece, and the two reflected rays combine and superpose. However, the ray reflecting off the bottom surface travels a longer path. The additional path length is equal to twice the gap between the surfaces. In addition, the ray reflecting off the bottom surface undergoes a 180° phase reversal, while the internal reflection of the other ray from the underside of the optical flat causes no phase reversal. The brightness of the reflected light depends on the difference in the path length of the two rays: If the gap between the surfaces is not constant, this interference results in a pattern of bright and dark lines or bands called "''interference fringes''" being observed on the surface. These are similar tocontour line

A contour line (also isoline, isopleth, or isarithm) of a function of two variables is a curve along which the function has a constant value, so that the curve joins points of equal value. It is a plane section of the three-dimensional grap ...

s on maps, revealing the height differences of the bottom test surface. The gap between the surfaces is constant along a fringe. The path length difference between two adjacent bright or dark fringes is one wavelength of the light, so the difference in the gap between the surfaces is one-half wavelength. Since the wavelength of light is so small, this technique can measure very small departures from flatness. For example, the wavelength of red light is about 700 nm, so the difference in height between two fringes is half that, or 350 nm, about 1/100 the diameter of a human hair.

Mathematical derivation

The variation in brightness of the reflected light as a function of gap width can be found by deriving the formula for the sum of the two reflected waves. Assume that the ''z''-axis is oriented in the direction of the reflected rays. Assume for simplicity that the intensity ''A'' of the two reflected light rays is the same (this is almost never true, but the result of differences in intensity is just a smaller contrast between light and dark fringes). The equation for the electric field of the sinusoidal light ray reflected from the top surface traveling along the z-axis is : where is the peak amplitude, λ is the wavelength, and is theangular frequency

In physics, angular frequency "''ω''" (also referred to by the terms angular speed, circular frequency, orbital frequency, radian frequency, and pulsatance) is a scalar measure of rotation rate. It refers to the angular displacement per unit tim ...

of the wave. The ray reflected from the bottom surface will be delayed by the additional path length and the 180° phase reversal at the reflection, causing a phase shift

In physics and mathematics, the phase of a periodic function F of some real variable t (such as time) is an angle-like quantity representing the fraction of the cycle covered up to t. It is denoted \phi(t) and expressed in such a scale that it ...

with respect to the top ray

:

where is the phase difference between the waves in radian

The radian, denoted by the symbol rad, is the unit of angle in the International System of Units (SI) and is the standard unit of angular measure used in many areas of mathematics. The unit was formerly an SI supplementary unit (before tha ...

s. The two waves will superpose and add: the sum of the electric fields of the two waves is

:

Using the trigonometric identity

In trigonometry, trigonometric identities are equalities that involve trigonometric functions and are true for every value of the occurring variables for which both sides of the equality are defined. Geometrically, these are identities involvin ...

for the sum of two cosines: , this can be written

:

This represents a wave at the original wavelength whose amplitude is proportional to the cosine of , so the brightness of the reflected light is an oscillating, sinusoidal function of the gap width ''d''. The phase difference is equal to the sum of the phase shift due to the path length difference 2''d'' and the additional 180° phase shift at the reflection

:

so the electric field of the resulting wave will be

:

This represents an oscillating wave whose magnitude varies sinusoidally between and zero as increases.

*''Constructive interference'': The brightness will be maximum where , which occurs when

*:

*''Destructive interference'': The brightness will be zero (or in the more general case minimum) where , which occurs when

*:

Thus the bright and dark fringes alternate, with the separation between two adjacent bright or dark fringes representing a change in the gap length of one half wavelength (λ/2).

Precision and errors

Counterintuitively, the fringes do not exist within the gap or the flat itself. The interference fringes actually form when the light waves all converge at the eye or camera, forming the image. Because the image is the compilation of all converging wavefronts interfering with each other, the flatness of the test piece can only be measured relative to the flatness of the optical flat. Any deviations on the flat will be added to the deviations on the test surface. Therefore, a surface polished to a flatness of λ/4 cannot be effectively tested with a λ/4 flat, as it is not possible to determine where the errors lie, but its contours can be revealed by testing with more accurate surfaces like a λ/20 or λ/50 optical flat. This also means that both the lighting and viewing angle have an effect on the accuracy of the results. When lighted or viewed at an angle, the distance that the light must travel across the gap is longer than when viewed and illuminated straight on. Thus, as the angle of incidence becomes steeper, the fringes will also appear to move and change. A zero degree angle of incidence is usually the most desirable angle, both for lighting and viewing. Unfortunately, this is usually impossible to achieve with the naked eye. Many interferometers usebeamsplitter

A beam splitter or ''beamsplitter'' is an optical device that splits a beam of light into a transmitted and a reflected beam. It is a crucial part of many optical experimental and measurement systems, such as interferometers, also finding wid ...

s to obtain such an angle. Because the results are relative to the wavelength of the light, accuracy can also be increased by using light of shorter wavelengths, although the 632 nm line from a helium–neon laser is often used as the standard.

No surface is ever completely flat. Therefore, any errors or irregularities that exist on the optical flat will affect the results of the test. Optical flats are extremely sensitive to temperature changes, which can cause temporary surface deviations resulting from uneven thermal expansion

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions.

Temperature is a monotonic function of the average molecular kinetic ...

. The glass often experiences poor thermal conduction, taking a long time to reach thermal equilibrium

Two physical systems are in thermal equilibrium if there is no net flow of thermal energy between them when they are connected by a path permeable to heat. Thermal equilibrium obeys the zeroth law of thermodynamics. A system is said to be i ...

. Merely handling the flats can transfer enough heat to offset the results, so glasses such as fused silica

Fused quartz, fused silica or quartz glass is a glass consisting of almost pure silica (silicon dioxide, SiO2) in amorphous (non- crystalline) form. This differs from all other commercial glasses in which other ingredients are added which ch ...

or borosilicate

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10−6 K−1 at 20 °C), ma ...

are used, which have very low coefficients of thermal expansion. The glass needs to be hard and very stable, and is usually very thick to prevent flexing. When measuring on the nanometre scale, the slightest bit of pressure can cause the glass to flex enough to distort the results. Therefore, a very flat and stable work-surface is also needed, on which the test can be performed, preventing both the flat and the test-piece from sagging under their combined weight, Often, a precision-ground surface plate

A surface plate is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup. The surface plate is often used as the baseline for all measurements to a workpiece, theref ...

is used as a work surface, providing a steady table-top for testing upon. To provide an even flatter surface, sometimes the test may be performed on top of another optical flat, with the test surface sandwiched in the middle.

Absolute flatness

Absolute flatness is the flatness of an object when measured against anabsolute scale

There is no single definition of an absolute scale. In statistics and measurement theory, it is simply a ratio scale in which the unit of measurement is fixed, and values are obtained by counting. According to another definition it is a system of ...

, in which the reference flat (standard) is completely free of irregularities. The flatness of any optical flat is relative to the flatness of the original standard Standard may refer to:

Symbols

* Colours, standards and guidons, kinds of military signs

* Standard (emblem), a type of a large symbol or emblem used for identification

Norms, conventions or requirements

* Standard (metrology), an object th ...

that was used to calibrate it. Therefore, because both surfaces have some irregularities, there are few ways to know the true, absolute flatness of any optical flat. The only surface that can achieve nearly absolute flatness is a liquid surface, such as mercury, and can sometimes achieve flatness readings to within λ/100, which equates to a deviation of only 6.32 nm (632 nm/100). However, liquid flats are very difficult to use and align properly, so they are typically only used when preparing a standard flat for calibrating other flats.

The other method for determining absolute flatness is the "three-flat test." In this test, three flats of equal size and shape are tested against each other. By analyzing the patterns and their different phase shift

In physics and mathematics, the phase of a periodic function F of some real variable t (such as time) is an angle-like quantity representing the fraction of the cycle covered up to t. It is denoted \phi(t) and expressed in such a scale that it ...

s, the absolute contours of each surface can be extrapolated. This usually requires at least twelve individual tests, checking each flat against every other flat in at least two different orientations. To eliminate any errors, the flats sometimes may be tested while resting on edge, rather than lying flat, helping to prevent sagging.

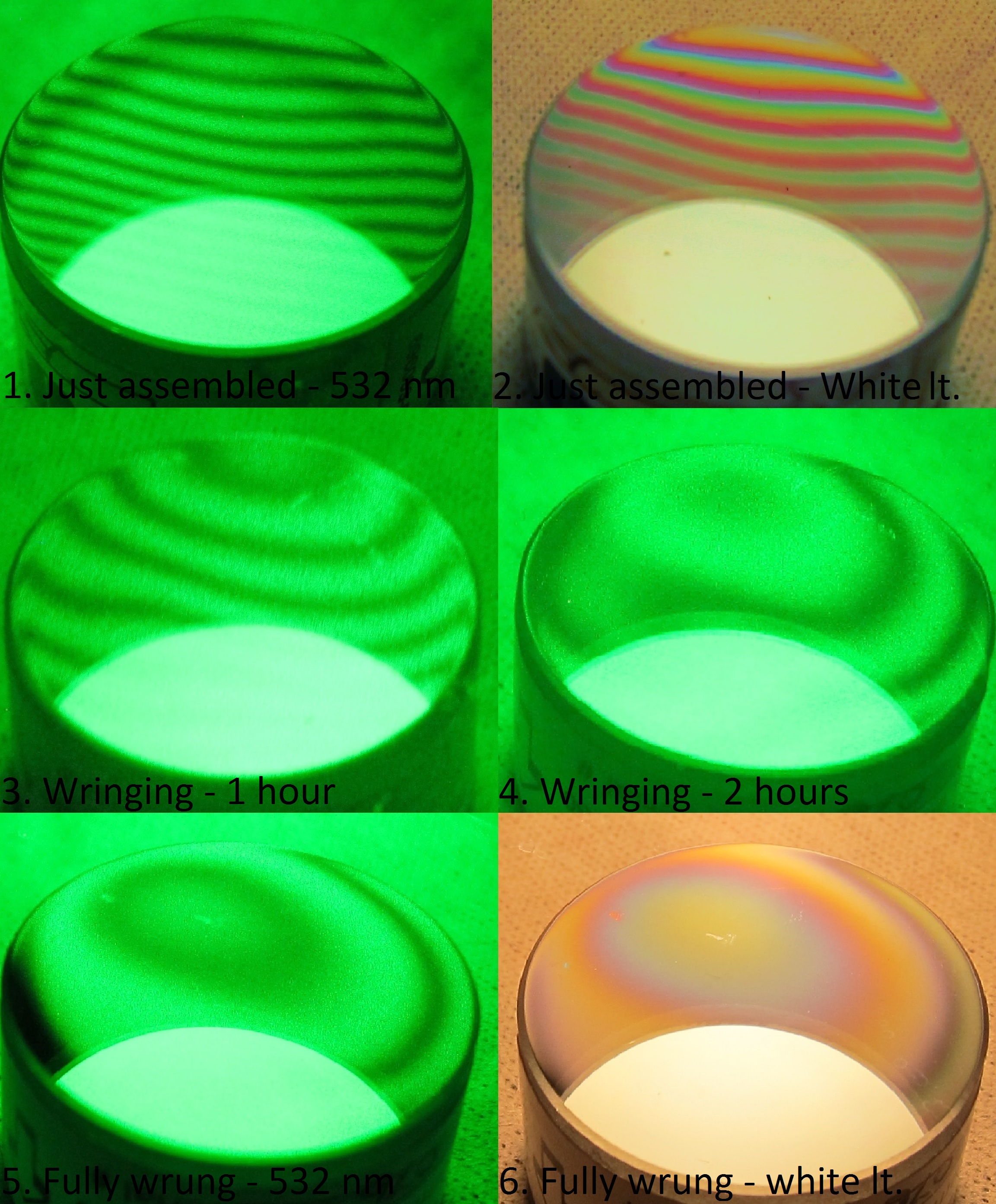

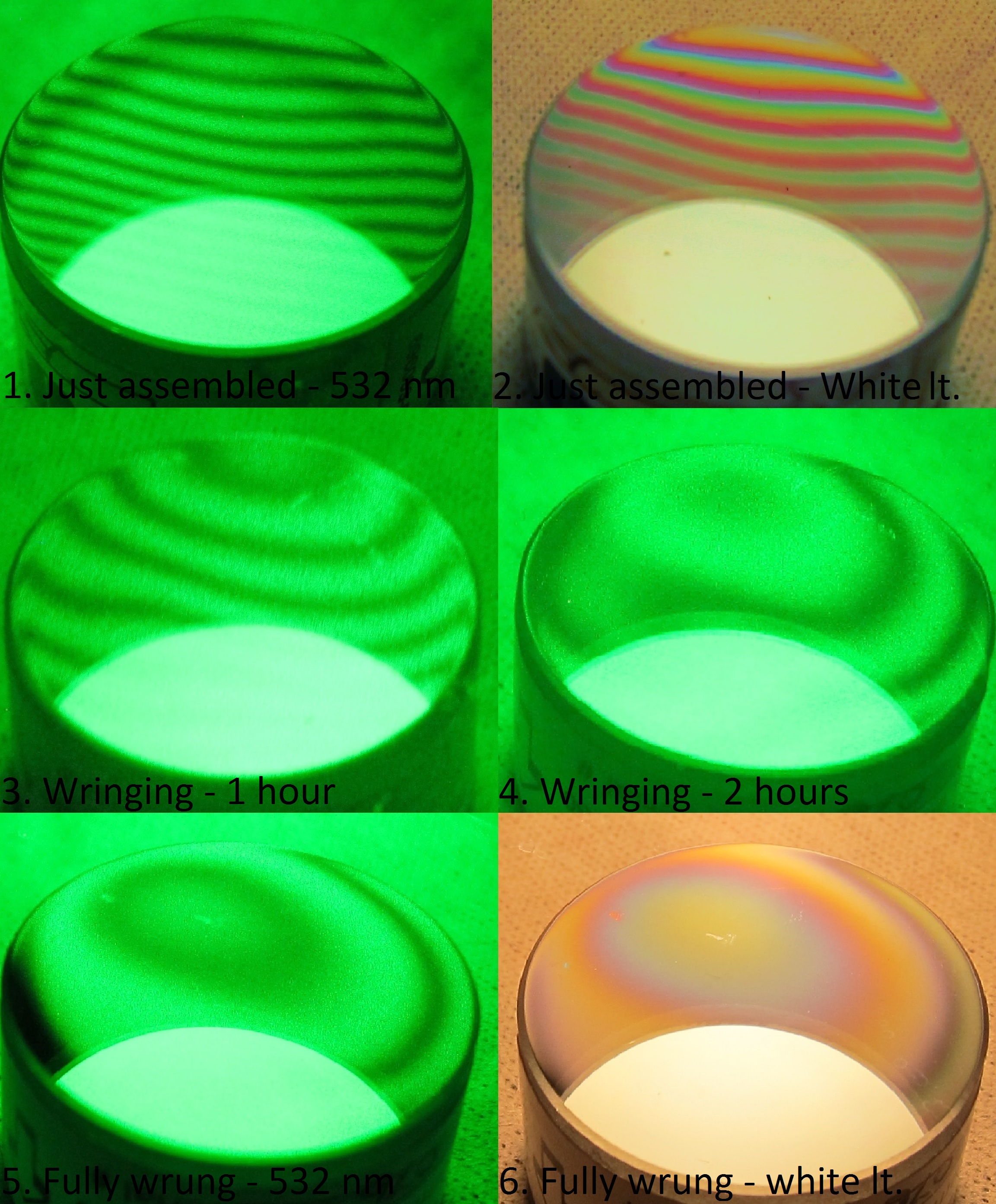

Wringing

Wringing occurs when nearly all of the air becomes forced out from between the surfaces, causing the surfaces to lock together, partly through the vacuum between them. The flatter the surfaces; the better they will wring together, especially when the flatness extends all the way to the edges. If two surfaces are very flat, they may become wrung together so tightly that a lot of force may be needed to separate them. The interference fringes typically only form once the optical flat begins to wring to the testing surface. If the surfaces are clean and very flat, they will begin to wring almost immediately after the first contact. After wringing begins, as air is slowly forced out from between the surfaces, an optical wedge forms between the surfaces. The interference fringes form perpendicular to this wedge. As the air is forced out, the fringes will appear to move toward the thickest gap, spreading out and becoming wider but fewer. As the air is forced out, the vacuum holding the surfaces together becomes stronger. The optical flat should usually never be allowed to fully wring to the surface, otherwise it can be scratched or even broken when separating them. In some cases, if left for many hours, a block of wood may be needed to knock them loose. Testing flatness with an optical flat is typically done as soon a viable interference pattern develops, and then the surfaces are separated before they can fully wring. Because the angle of the wedge is extremely shallow and the gap extremely small, wringing may take a few hours to complete. Sliding the flat in relation to the surface can speed up wringing, but trying to press the air out will have little effect. If the surfaces are insufficiently flat, if any oil films or impurities exist on the surface, or if slight dust-particles land between the surfaces, they may not wring at all. Therefore, the surfaces must be very clean and free of debris to get an accurate measurement.Determining surface shape

The fringes act very much like the lines on a

The fringes act very much like the lines on a topography

Topography is the study of the forms and features of land surfaces. The topography of an area may refer to the land forms and features themselves, or a description or depiction in maps.

Topography is a field of geoscience and planetary sc ...

map, where the fringes are always perpendicular to the wedge between the surfaces. When wringing first begins, there is a large angle in the air wedge and the fringes will resemble grid topography-lines. If the fringes are straight; then the surface is flat. If the surfaces are allowed to fully wring and become parallel, the straight fringes will widen until only a dark fringe remains, and they will disappear completely. If the surface is not flat, the grid lines will have some bends in them, indicating the topography of the surface. Straight fringes with bends in them may indicate a raised elevation or a depression. Straight fringes with a "V" shape in the middle indicate a ridge or valley running across the center, while straight fringes with curves near the ends indicate edges that are either rounded-off or have a raised lip.

If the surfaces are not completely flat, as wringing progresses the fringes will widen and continue to bend. When fully wrung, they will resemble contour topography-lines, indicating the deviations on the surface. Rounded fringes indicate gentle sloping or slightly cylindrical surfaces, while tight corners in the fringes indicate sharp angles in the surface. Small, round circles may indicate bumps or depressions, while concentric circles indicate a conical shape. Unevenly spaced concentric circles indicate a convex or concave surface. Before the surfaces fully wring, these fringes will be distorted due to the added angle of the air wedge, changing into the contours as the air is slowly pushed out.

A single dark-fringe has the same gap thickness, following a line that runs the entire length of the fringe. The adjacent bright-fringe will indicate a thickness which is either 1/2 of the wavelength narrower or 1/2 of the wavelength wider. The thinner and closer the fringes are; the steeper the slope is, while wider fringes, spaced further apart, show a shallower slope. Unfortunately, it is impossible to tell whether the fringes are indicating an uphill or downhill slope from just a single view of the fringes alone, because the adjacent fringes can be going either way. A ring of concentric circles can indicate that the surface is either concave or convex, which is an effect similar to the hollow-mask illusion.

There are three ways to test the surface for shape, but the most common is the "finger-pressure test." In this test, slight pressure is applied to the flat, to see which way the fringes move. The fringes will move away from the narrow end of the wedge. If the testing surface is concave, when pressure is applied to the center of the rings, the flat will flex a little and the fringes will appear to move inward. However, if the surface is convex, the flat will be in point-contact with the surface in that spot, so it will have no room to flex. Thus, the fringes will remain stationary, merely growing a little wider. If pressure is applied to the edge of the flat something similar happens. If the surface is convex the flat will rock a little, causing the fringes to move toward the finger. However, if the surface is concave the flat will flex a little, and the fringes will move away from the finger toward the center. Although this is called a "finger" pressure test, a wooden stick or some other instrument is often used to avoid heating the glass (with the mere weight of a toothpick often being enough pressure).

Another method involves exposing the flat to white light, allowing rainbow fringes to form, and then pressing in the center. If the surface is concave, there will be point-contact along the edge, and the outer fringe will turn dark. If the surface is convex, there will be point-contact in the center, and the central fringe will turn dark. Much like tempering colors of steel, the fringes will be slightly brownish at the narrower side of the fringe and blue on the wider side, so if the surface is concave the blue will be on the inside of the rings, but if convex the blue will be on the outside.

The third method involves moving the eye in relation to the flat. When moving the eye from a zero-degree angle of incidence to an oblique angle, the fringes will appear to move. If the testing surface is concave, the fringes will appear to move toward the center. If the surface is convex, the fringes will move away from the center. To get a truly accurate reading of the surface, the test should usually be performed in at least two different directions. As grid lines, the fringes only represent part of a grid, so a valley running across the surface may only show as a slight bend in the fringe if it is running parallel to the valley. However, if the optical flat is rotated 90 degrees and retested, the fringes will run perpendicular to the valley and it will show up as a row of "V" or "U" shaped contours in the fringes. By testing in more than one orientation, a better map of the surface can be made.

Long-term stability

During reasonable care and use, optical flats need to maintain their flatness over long periods of time. Therefore, hard glasses with low coefficients of thermal expansion, such asfused silica

Fused quartz, fused silica or quartz glass is a glass consisting of almost pure silica (silicon dioxide, SiO2) in amorphous (non- crystalline) form. This differs from all other commercial glasses in which other ingredients are added which ch ...

, are often used for the manufacturing material. However, a few laboratory measurements of room temperature, fused-silica optical-flats have shown a motion consistent with a material viscosity on the order of 1017–1018 Pa·s. This equates to a deviation of a few nanometres over the period of a decade. Because the flatness of an optical flat is relative to the flatness of the original test flat, the true (absolute) flatness at the time of manufacture can only be determined by performing an interferometer test using a liquid flat, or by performing a "three flat test", in which the interference patterns produced by three flats are computer-analyzed. A few tests that have been carried out have shown that a deviation sometimes occurs on the fused silica's surface. However, the tests show that the deformation may be sporadic, with only some of the flats deforming during the test period, some partially deforming, and others remaining the same. The cause of the deformation is unknown and would never be visible to the human eye during a lifetime. (A λ/4 flat has a normal surface-deviation of 158 nanometres, while a λ/20 flat has a normal deviation of over 30 nm.) This deformation has only been observed in fused silica, while soda-lime glass still shows a viscosity of 1041Pa·s, which is many orders of magnitude higher.

See also

*Newton's rings

Newton's rings is a phenomenon in which an interference pattern is created by the reflection of light between two surfaces, typically a spherical surface and an adjacent touching flat surface. It is named after Isaac Newton, who investigated the ...

* Optical contact bonding

*Gauge block

Gauge blocks (also known as gage blocks, Johansson gauges, slip gauges, or Jo blocks) are a system for producing precision lengths. The individual gauge block is a metal or ceramic block that has been precision ground and lapped to a specific ...

, another type of component designed for flatness

** Surface plate

A surface plate is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup. The surface plate is often used as the baseline for all measurements to a workpiece, theref ...

References

{{reflist Optical devices