Oil production plant on:

[Wikipedia]

[Google]

[Amazon]

An oil production plant is a facility which processes production fluids from

Oil from the first stage separator may be cooled or heated in a

Oil from the first stage separator may be cooled or heated in a

oil well

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas ma ...

s in order to separate out key components and prepare them for export. Typical oil well production fluids are a mixture of oil, gas and produced water

Produced water is a term used in the oil industry or geothermal industry to describe water that is produced as a byproduct during the extraction of oil and natural gas, or used as a medium for heat extraction. Produced water is the kind of brackis ...

. An oil production plant is distinct from an oil depot

An oil terminal (also called a tank farm, tankfarm, oil installation or oil depot) is an industrial facility for the storage of oil, petroleum and petrochemical products, and from which these products are transported to end users or other stor ...

, which does not have processing facilities.

Oil production plant may be associated with onshore or offshore oil fields.

Many permanent offshore installations have full oil production facilities.Magnus Process Flow Diagrams 1983; NW Hutton Process Flow Diagrams 1987; Shearwater Process Flow Diagrams 2005 Smaller platforms and subsea wells export production fluids to the nearest production facility, which may be on a nearby offshore processing installation or an onshore terminal. The produced oil may sometimes be ''stabilised'' (a form of distillation

Distillation, or classical distillation, is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation, usually inside an apparatus known as a still. Dry distillation is the he ...

) which reduces vapour pressure and sweetens "sour" crude oil by removing hydrogen sulphide, thereby making the crude oil suitable for storage and transport. offshore installations deliver oil and gas to onshore terminals which may further process the fluids prior to sale or delivery to oil refineries.

Onshore oil production

The configuration of onshore oil production facilities depends on the size of the oil field. For simple fields comprising a single well or a few wells, an oil storage tank may be sufficient. The tank is emptied periodically by road tanker and transferred to an oil refinery. For larger production rates a rail tanker transfer facility may be appropriate. For larger fields a full three-phase processing facility is required. Three-phase separators separate the well fluids into its three constituent phases: oil, gas and produced water. Oil may be transferred by road or rail tanker or by pipeline to an oil refinery. Gas may be used on the site to run gas engines to produce electricity or can be piped to local users. Excess gas is burned in a ground flare. Produced water may be re-injected into the reservoir. ''See for example: Wytch Farm''Offshore oil processing options

There is a wide variety of options for the processing of produced oil. These range from minimal offshore processing with all produced fluids sent to an onshore facility, to full offshore processing to make products to a specification suitable for sale or use with no further onshore processing. The decision on what facilities to provide depends on a number of factors: * the optimal size of the offshore installation * whether an onshore terminal is required or available * what export routes (pipelines, tankers) are available * the project constraints in terms of cost, schedule, and resources * the impact or implications for future projects TheGulf of Mexico

The Gulf of Mexico ( es, Golfo de México) is an ocean basin and a marginal sea of the Atlantic Ocean, largely surrounded by the North American continent. It is bounded on the northeast, north and northwest by the Gulf Coast of the United ...

and the North Sea

The North Sea lies between Great Britain, Norway, Denmark, Germany, the Netherlands and Belgium. An epeiric sea on the European continental shelf, it connects to the Atlantic Ocean through the English Channel in the south and the Norwegian ...

are two mature producing areas that have taken different approaches to the facilities provided. These are summarised in the following table:Adapted from Bothamley 2004

Export options

The export options for oil and gas and the deployment around the world are as follows: * Stabilised crude oil ** Reid Vapor Pressure RVP < 11 psi (0.76 bar) **Basic Sediment & Water BS&W < 1% by volume) **Gulf of Mexico, Canada East Coast, West Africa,Indonesia

Indonesia, officially the Republic of Indonesia, is a country in Southeast Asia and Oceania between the Indian and Pacific oceans. It consists of over 17,000 islands, including Sumatra, Java, Sulawesi, and parts of Borneo and New Gui ...

.

* Unstabilised wet crude

**True vapour pressure 150 psia (10.3 bara)

** BS&W 2%

**North Sea, Azerbaijan

Azerbaijan (, ; az, Azərbaycan ), officially the Republic of Azerbaijan, , also sometimes officially called the Azerbaijan Republic is a transcontinental country located at the boundary of Eastern Europe and Western Asia. It is a part of th ...

, Gulf of Suez

The Gulf of Suez ( ar, خليج السويس, khalīǧ as-suwais; formerly , ', "Sea of Calm") is a gulf at the northern end of the Red Sea, to the west of the Sinai Peninsula. Situated to the east of the Sinai Peninsula is the smaller Gulf of ...

, Trinidad

Trinidad is the larger and more populous of the two major islands of Trinidad and Tobago. The island lies off the northeastern coast of Venezuela and sits on the continental shelf of South America. It is often referred to as the southernmos ...

.

Gas disposal may take one or more of the following routes:

In the Central and Northern North Sea gas is delivered to St Fergus or Teesside terminals by a small number of large diameter (36 inch, 91.4 cm) gas pipelines. These operate at 1600 – 2500 psig (110 – 172 bar) in the dense phase i.e. above the critical pressure. Operation in the dense phase provides a number of advantages:

* it is more efficient to transport gas at high pressure over long distances

* it eliminates the problem of multiphase flow

* it eliminates the need to treat gas by hydrocarbon dewpointing

These advantages are offset by the additional compression required and thicker walled, more expensive, pipelines are necessary.

Plant configuration

A further consideration is the number of separation trains and the number of stages of separation. Trains of process facilities operate in parallel, and stages are operated in a sequential series. The number of trains depends on flowrates, the availability of plant, and the available plot area. Single trains are capable of handling 150,000 to 200,000 barrels of oil per day (23,847 – 31,797 m3/day). Vessel sizes can be up to 14 to 19 feet (4.27 to 5.79 m) diameter and up to 30 feet (9.14 m) long. Vessels on Gulf of Mexico deepwater installations are 12 to 14 feet (3.66 to 4.27 m) diameter and 60 to 70 feet (4.27 to 21.34 m) long. The number of stages of separation depends on: * wellhead pressure * the gas/oil ratio * the vapor pressure specification of the crude oil export stream First stage separators in the Gulf of Mexico typically operate at 1500 to 1800 psi (103.4 to 124.1 bar), they operate as 2-phase liquid and vapour separators with a liquid residence time of 1 to 2 minutes. Produced water is removed in the low pressure (LP) 3-phase separator. This operates at 150 –250 psi (10.3 – 17.2 bar). In the North Sea first stage separators generally operate at < 750 psi (< 51.72 bar). These are operated as 3-phase (vapour, oil and water) separators and are sized to provide 3 – 5 minutes of liquid residence time. Pressures are set to maximise gas separation at as a high a pressure as possible. Up to 5 stages of separation are common in the Gulf of Mexico and up to 4 stages on platforms in the North Sea. The throughput, number of trains, separation stages and first stage separator pressure for a range of historic offshore installations is shown in the table.Materials of construction

A range of materials of construction are used for oil processing plant.Carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, coba ...

is extensively used as it is inexpensive. However, it is unsuitable for corrosive service where a number of corrosion resistant alloys and other materials are required. The table illustrates typical materials for service on a plant that processes sour fluids.

Process description

The oil train

The production plant can be considered to begin after the production wing valve on theoil well

An oil well is a drillhole boring in Earth that is designed to bring petroleum oil hydrocarbons to the surface. Usually some natural gas is released as associated petroleum gas along with the oil. A well that is designed to produce only gas ma ...

Christmas tree

A Christmas tree is a decorated tree, usually an evergreen conifer, such as a spruce, pine or fir, or an artificial tree of similar appearance, associated with the celebration of Christmas. The custom was further developed in early modern ...

. The reservoir

A reservoir (; from French ''réservoir'' ) is an enlarged lake behind a dam. Such a dam may be either artificial, built to store fresh water or it may be a natural formation.

Reservoirs can be created in a number of ways, including contr ...

fluids from each well are piped through a flowline to a choke valve, which regulates the rate of flow and reduces the pressure of the fluids. The flowlines from each well are gathered together at one or more inlet manifolds. These are provided for each train or operate at different pressures to match the wellhead pressure with various separator pressures. High pressure manifolds are routed into a first stage separator, which separates the three fluid phases. Produced water

Produced water is a term used in the oil industry or geothermal industry to describe water that is produced as a byproduct during the extraction of oil and natural gas, or used as a medium for heat extraction. Produced water is the kind of brackis ...

, the densest phase, settles out at the bottom of the separator, oil floats on the top of the produced water phase, and gas occupies the upper part of the separator. The separator is sized to provide a liquid residence time of 3 to 5 minutes which is sufficient for light crude oil (>35° API) as produced in the North Sea. In the Gulf of Mexico the first stage separator operates as a 2-phase (gas and liquid) vessel, it is sized to provide a liquid residence time of 1 to 2 minutes.

heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct conta ...

to aid further separation. North Sea fields tend to operate at higher temperatures so heating may not be required. Gulf of Mexico fields tend to operate at lower temperatures so heat is required to achieve export vapor and BS&W specifications. Typical operating temperatures are 140 – 160 °F (60 – 71 °C).

Oil is then routed either to a second stage separator, operating at a lower pressure than the first stage to further separate oil/gas/water, or to a coalescer

A coalescer is a device which induces coalescence in a medium. They are primarily used to separate emulsions into their components via various processes, operating in reverse to an emulsifier.

Coalescers are of two main types: mechanical and elec ...

to further remove water. Several stages of separation, operating at successively lower pressures, aim to reduce the amount of dissolved gas and hence reduces the flash point

The flash point of a material is the "lowest liquid temperature at which, under certain standardized conditions, a liquid gives off vapours in a quantity such as to be capable of forming an ignitable vapour/air mixture". (EN 60079-10-1)

The fl ...

of the oil to meet the export oil specification. For higher oil flowrates parallel trains of separators may be necessary to handle the flow and to provide a turn-down capability. The final stage of separation may be an electrostatic coalescer. These can achieve a 0.5% by volume water content, typical design fluxes are in the order of 200 bopd/ft2.

A test separator (see diagram) enables the performance of individual wells to be determined. An individual well is connected to the test header which routes fluids to the test separator. Three phase separation into oil, vapour and produced water takes place. The flowrates of these phases are accurately measured as the fluids flow to lower pressure points in the oil train. The flowrates determine the performance of the well in terms of the maximum flow of the well, the gas-oil ratio, and the water cut of the fluids.

Some oil fields are sour, with high levels of carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

(CO2) and hydrogen sulphide

Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hydride gas, and is poisonous, corrosive, and flammable, with trace amounts in ambient atmosphere having a characteristic foul odor of rotten eggs. The unde ...

(H2S). Operation of separation at high temperature drives these gases to the vapour phase. However, crude may still contain sour compounds above a typical H2S-in-crude specification limit of < 10 ppmw. A trayed column is used with sour crude fed in the top of the column and stripping gas introduced into the bottom of the column.

From the final stage of separation, or from the coaleser, oil may be cooled to meet export specifications or to limit thermal stresses on the oil export riser. Oil is metered to accurately measure the flowrate and then pumped via a pipeline to the onshore terminal. Some installations such as concrete gravity-base structures and floating production storage and offloading, FPSOs, have integral oil storage tanks which are continuously filled with oil and periodically discharged into oil tanker

An oil tanker, also known as a petroleum tanker, is a ship designed for the bulk transport of oil or its products. There are two basic types of oil tankers: crude tankers and product tankers. Crude tankers move large quantities of unrefined ...

s.

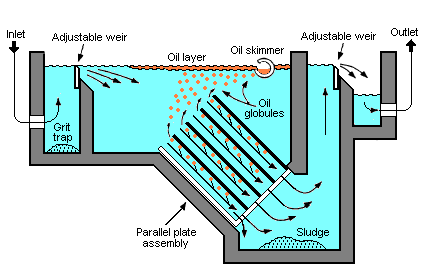

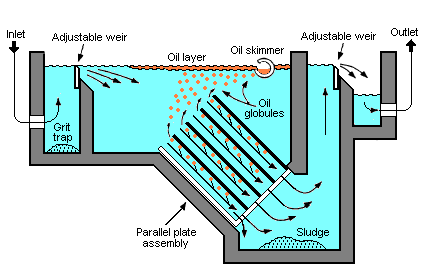

Produced water

Produced water from the separator(s) and coalescer is routed to a produced waterdegasser

A degasser is a device used in the upstream oil industry to remove dissolved and entrained gases from a liquid. In drilling it is used to remove gasses from drilling fluid which could otherwise form bubbles. In a produced water treatment plant it ...

operating at near atmospheric pressure to remove dissolved gas from the water. In the early days of the offshore industry parallel plate separator units were used to clean produced water prior to overboard disposal. Hydrocyclones, which are more compact, were introduced in the 1980s. A hydrocyclone Hydrocyclones are a type of cyclonic separators that separate product phases mainly on basis of differences in gravity with aqueous solutions as the primary feed fluid.

As opposed to dry or dust cyclones, which separate solids from gasses, hydrocy ...

removes entrained oil and solids from produced water which then passes to the degasser and can then either be re-injected into the reservoir

A reservoir (; from French ''réservoir'' ) is an enlarged lake behind a dam. Such a dam may be either artificial, built to store fresh water or it may be a natural formation.

Reservoirs can be created in a number of ways, including contr ...

or dumped overboard. Induced gas flotation

Induced gas flotation (IGF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by injecting gas bubbles into the water or wastewater in a flota ...

plant is used when the hydrocyclone / degasser plant cannot achieve the oil-in-water specification. For overboard disposal the water should have an oil content of less than about 30 parts per million (ppm) oil-in-water. On North Sea installations the higher operating temperatures allow an oil-in-water concentration of > 20 ppmw to be achieved.

The gas train

The associated gas from the top of the separator(s) is also known as flash gas or wet gas as it is saturated with water and liquid hydrocarbons. The gas is typically routed through scrubbers,compressor

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

Compressors are similar to pumps: both increase the pressure on a fluid and both can tr ...

s and coolers

A cooler, portable ice chest, ice box, cool box, chilly bin (in New Zealand), or esky ( Australia) is an insulated box used to keep food or drink cool.

Ice cubes are most commonly placed in it to help the contents inside stay cool. Ice packs ...

to raise the pressure of the gas and to remove liquids. Scrubbers are vertical vessels that allow the removal and separation of liquids from a gas stream. Coolers are located after a compressor to remove the heat of compression. Centrifugal compressors are often used offshore. They are more compact and lighter than reciprocating machines and maintenance costs are less. The latter are used where only small volumes of gas are handled. Centrifugal compressors my be driven by gas turbines or electric motors.

The dry gas may be exported, used for gas lift

Gas lift or bubble pumps use the artificial lift technique of raising a fluid such as water or oil by introducing bubbles of compressed air, water vapor or other vaporous bubbles into the outlet tube. This has the effect of reducing the hydrost ...

, flared, used as fuel for the installation's power generators, or after further compression re-injected into the reservoir

A reservoir (; from French ''réservoir'' ) is an enlarged lake behind a dam. Such a dam may be either artificial, built to store fresh water or it may be a natural formation.

Reservoirs can be created in a number of ways, including contr ...

. Export gas is metered to accurately measure the flowrate before being sent to the onshore terminal via gas pipeline. Other treatment processes may be required.

Gas dehydration

Gas may be dried to reduce the water content to meet sales specification, to prevent condensation of water in the pipeline and the formation of slugs, or to avoid the formation of hydrates in the export pipeline. Gas is dried by counter-current contact with triethylene glycol in aglycol dehydration Glycol dehydration is a liquid desiccant system for the removal of water from natural gas and natural gas liquids (NGL). It is the most common and economical means of water removal from these streams. Glycols typically seen in industry include tri ...

tower. Typically dried gas has a water content of 2.5 to 7 lb of water /MMSCF. Glycol contactors generally operate at 1100–1200 psi (75 to 83 bar). Water-rich glycol is regenerated by heating and stripping off the water. Enhanced regeneration uses DRIZO or Coldfinger to improve the regeneration performance. Contactor towers formerly comprised bubble cap trays, since the 1980s structured packing has been used which provides the equivalent of 3 to 4 theoretical trays required to meet a water content of <4 lb/MMSCF.

Hydrocarbon dewpointing

The export hydrocarbon dew-point specification (typically 100 barg at 5 °C) may be met by chilling the gas to remove the higher alkanes (butane

Butane () or ''n''-butane is an alkane with the formula C4H10. Butane is a gas at room temperature and atmospheric pressure. Butane is a highly flammable, colorless, easily liquefied gas that quickly vaporizes at room temperature. The name but ...

, pentane

Pentane is an organic compound with the formula C5H12—that is, an alkane with five carbon atoms. The term may refer to any of three structural isomers, or to a mixture of them: in the IUPAC nomenclature, however, pentane means exclusively the ...

s, etc.). This may be done by a refrigeration

The term refrigeration refers to the process of removing heat from an enclosed space or substance for the purpose of lowering the temperature.International Dictionary of Refrigeration, http://dictionary.iifiir.org/search.phpASHRAE Terminology, ht ...

system, or passing the gas through a Joule-Thomson valve, or through a turbo-expander to condense out and separate liquids. The natural gas liquids

Natural-gas condensate, also called natural gas liquids, is a low-density mixture of hydrocarbon liquids that are present as gaseous components in the raw natural gas produced from many natural gas fields. Some gas species within the raw natu ...

(NGL) produced may be spiked into the oil export fluids where high vapor pressure fluids are exported. Alternatively NGL fractionating columns may be used to produce a fluid for separate export. NGL fractionation columns are installed in Nkossa West Africa and Ardjuna Indonesia.

Gas sweetening

Dry gas may be further treated to meet export gas specifications. Excesscarbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

(CO2) can be removed by treatment in an amine gas treating process (e.g. Selexol), whereby CO2 is preferentially dissolved in a counter-current flow of amine in a contact tower. Hydrogen sulphide

Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hydride gas, and is poisonous, corrosive, and flammable, with trace amounts in ambient atmosphere having a characteristic foul odor of rotten eggs. The unde ...

can also be removed using amine or by passing the gas through beds of zinc oxide

Zinc oxide is an inorganic compound with the formula . It is a white powder that is insoluble in water. ZnO is used as an additive in numerous materials and products including cosmetics, food supplements, rubbers, plastics, ceramics, glass, cement ...

absorbent.

Onshore terminals

Onshore oil terminals receive oil from offshore installations and treat it to produce products for sale or further processing such as in an oil refinery. Onshore terminals generally have fired heaters followed by separators and coalescers to stabilise the crude and remove any produced water and light hydrocarbons not separated offshore. Onshore separators tend to operate at a lower pressure than the offshore separators and so more gas is evolved. The associated gas is generally compressed, dew-pointed and exported via a dedicated pipeline. If gas export is uneconomical then it may be flared. Onshore terminals frequently have large crude oil storage tanks to allow offshore production to continue if the export route becomes unavailable. Export to theoil refinery

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liq ...

is either by pipeline or tanker.

Onshore gas terminals may have facilities for removal of liquids from the incoming gas stream. Gas treatment processes may include glycol dehydration, gas sweetening, hydrocarbon dew-point control and gas compression before gas distribution to users.

Utility and support systems

In addition to production and gas and oil treatment systems a range of ancillary, support and utility systems are provided to support production and occupation of an offshore installation. Systems include:{{Cite book, title=Engineering Data Book, last=Gas Processors Suppliers Association, publisher=GPSA, year=2004, location=Tulsa, Oklahoma, pages=Section 18 Utilities * Glycol regeneration - water-rich glycol is heated and stripped with dry gas to drive off the water * Amine regeneration - rich amine is heated and stripped with sweet gas to drive off CO2 and H2S * Fuel gas - used to powergas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

s, and to purge relief, vent and flare systems

* Purge gas - to provide blanket gas for tanks and to purge vessels prior to maintenance

* Inert gas - to provide blanket gas for tanks and to purge vessels prior to maintenance

* Diesel fuel

Diesel fuel , also called diesel oil, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a result of compression of the inlet air and ...

- for firewater pump diesel engines and start-up of generators

* Aviation fuel

Aviation fuels are petroleum-based fuels, or petroleum and synthetic fuel blends, used to power aircraft. They have more stringent requirements than fuels used for ground use, such as heating and road transport, and contain additives to enhan ...

- Jet A-1 for helicopter refuelling

* Atmospheric vent - gas disposal for low pressure systems and maintenance purging

* Relief and Flares

A flare, also sometimes called a fusée, fusee, or bengala in some Latin-speaking countries, is a type of pyrotechnic that produces a bright light or intense heat without an explosion. Flares are used for distress signaling, illumination, ...

- safe collection and disposal of excess gas under normal and shutdown conditions

* Pipeline pigging - to clear and monitor pipelines

* Well test facilities - test separator to determine flowrates from individual wells

* Seawater - used for flushing, cooling, washdown

* Firewater - seawater for fire fighting

Firefighting is the act of extinguishing or preventing the spread of unwanted fires from threatening human lives and destroying property and the environment. A person who engages in firefighting is known as a firefighter.

Firefighters typically ...

* Water injection - deaerated seawater injected into the oil reservoir to drive oil towards production wells and maintain reservoir pressure

* Potable water

Drinking water is water that is used in drink or food preparation; potable water is water that is safe to be used as drinking water. The amount of drinking water required to maintain good health varies, and depends on physical activity level, ...

- drinking water bunkered from supply vessels or made on board by distillation or reverse osmosis

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic ...

of seawater

* Cooling medium - to cool gas and oil streams; comprising either seawater (direct) cooling or a fresh water/glycol mixture (see below)

* Heating medium - to heat gas and oil streams, HVAC; comprising hot oil or a fresh water/glycol mixture (see below)

* Closed (process) drains - to drain process equipment prior to maintenance

* Open drains - drainage from deck areas, hazardous area drains are segregated from non-hazardous area drains, disposed overboard

* Sewage treatment

Sewage treatment (or domestic wastewater treatment, municipal wastewater treatment) is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding en ...

- maceration and overboard disposal of 'black' (toilet) and 'grey' (sink and shower) water

* Plant/service air - for powering air-driven tools, purging vessels

* Instrument air - for operating pneumatic actuated controllers and valves

* Electricity generation

Electricity generation is the process of generating electric power from sources of primary energy. For utilities in the electric power industry, it is the stage prior to its delivery ( transmission, distribution, etc.) to end users or its s ...

- diesel or fuel gas for diesel engine or gas turbine driven electricity generation

* Chemical storage and injection - to aid separation of well fluids and maintain operation of facilities, may include methanol, glycol, corrosion inhibitor, scale inhibitor, oxygen scavenger, H2S scavenger, emulsion breaker, foam breaker, wax inhibitor

* Seal oil and lube oil storage - for compressors, gas turbines and diesel engines

* Hydraulic oil - operation of subsea and subsurface well equipment

* HVAC

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. ...

- for enclosed process plant and accommodation

* Drilling facilities - bulk chemical storage, well drilling equipment

Utilities in detail

Heating medium is generally heated by waste heat recovery from power generation gas turbine exhausts. The temperature required is generally not more than 400 °F (204 °C) and mineral oil based fluids are used. Pressurised hot water, steam, and glycol/water mixtures are also used although temperatures are generally limited to < 300 °F (149 °C). On smaller installations electric heating elements may be the most appropriate option for heating fluids. Process cooling may be performed using air, seawater (known as direct cooling), or cooling medium comprising a 30% glycol (TEG)/water mixture and known as indirect cooling. North Sea installations are generally quite crowded and do not have space for the extensive plot area required for air cooled heat exchangers. Water cooled heat exchangers occupy a relatively small plot area. North Sea installations are often provided with water injection facilities. These require large volumes of seawater to be lifted. The incremental cost of using the seawater for cooling is therefore considerably reduced. Furthermore, the reduced solubility of air in warmed water is an advantage as air has to be stripped out of injection water. The cold North Sea water temperature reduces the size of heat exchangers. Indirect cooling medium cooling is less likely to have corrosion issues than direct seawater cooling which may require more expensive metals such as Copper alloys,Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion i ...

or Inconel. Cooling medium systems have a lower CAPEX

Capital expenditure or capital expense (capex or CAPEX) is the money an organization or corporate entity spends to buy, maintain, or improve its fixed assets, such as buildings, vehicles, equipment, or land. It is considered a capital expenditure ...

. The clean fluid allows printed circuit heat exchangers to be used which offer space and weight savings.

See also

*Petroleum

Petroleum, also known as crude oil, or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, and is found in geological formations. The name ''petroleum'' covers both naturally occurring unprocessed crud ...

*Oil platform

An oil platform (or oil rig, offshore platform, oil production platform, and similar terms) is a large structure with facilities to extract and process petroleum and natural gas that lie in rock formations beneath the seabed. Many oil platfor ...

*Oil industry

The petroleum industry, also known as the oil industry or the oil patch, includes the global processes of exploration, extraction, refining, transportation (often by oil tankers and pipelines), and marketing of petroleum products. The larges ...

*Upstream (oil industry)

The oil and gas industry is usually divided into three major sectors: upstream (or exploration and production - E&P), '' midstream'' and ''downstream''. The upstream sector includes searching for potential underground or underwater crude oil and ...

*Chemical plant

A chemical plant is an industrial process plant that manufactures (or otherwise processes) chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transfo ...

*Oil refinery

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liq ...

* ISO/TC 67

References