Iron Age metallurgy on:

[Wikipedia]

[Google]

[Amazon]

Ferrous metallurgy is the metallurgy of

Ferrous metallurgy is the metallurgy of

Iron was extracted from

Iron was extracted from

One of the earliest smelted iron artifacts, a dagger with an iron blade found in a Hattic tomb in

One of the earliest smelted iron artifacts, a dagger with an iron blade found in a Hattic tomb in

Online version

accessed on 2010-02-11. About 1500 BC, increasing numbers of non-meteoritic, smelted iron objects appeared in

The history of ferrous metallurgy in the Indian subcontinent began in the 2nd millennium BC. Archaeological sites in

The history of ferrous metallurgy in the Indian subcontinent began in the 2nd millennium BC. Archaeological sites in  Perhaps as early as 500 BC, although certainly by 200 AD, high-quality steel was produced in southern India by the

Perhaps as early as 500 BC, although certainly by 200 AD, high-quality steel was produced in southern India by the

Historians debate whether bloomery-based ironworking ever spread to China from the Middle East. One theory suggests that metallurgy was introduced through Central Asia.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 8. In 2008, two iron fragments were excavated at the Mogou site, in Gansu. They have been dated to the 14th century BC, belonging to the period of Siwa culture, suggesting an independent Chinese origin. One of the fragments was made of bloomery iron rather than meteoritic iron.p. xl, Historical Dictionary of Ancient Greek Warfare, J, Woronoff & I. Spence

The earliest iron artifacts made from bloomeries in China date to end of the 9th century BC. Cast iron was used in ancient China for warfare, agriculture and architecture. Around 500 BC, metalworkers in the southern state of Wu achieved a temperature of 1130 °C. At this temperature, iron combines with 4.3% carbon and melts. The liquid iron can be

Historians debate whether bloomery-based ironworking ever spread to China from the Middle East. One theory suggests that metallurgy was introduced through Central Asia.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 8. In 2008, two iron fragments were excavated at the Mogou site, in Gansu. They have been dated to the 14th century BC, belonging to the period of Siwa culture, suggesting an independent Chinese origin. One of the fragments was made of bloomery iron rather than meteoritic iron.p. xl, Historical Dictionary of Ancient Greek Warfare, J, Woronoff & I. Spence

The earliest iron artifacts made from bloomeries in China date to end of the 9th century BC. Cast iron was used in ancient China for warfare, agriculture and architecture. Around 500 BC, metalworkers in the southern state of Wu achieved a temperature of 1130 °C. At this temperature, iron combines with 4.3% carbon and melts. The liquid iron can be  During the

During the

Iron working was introduced to

Iron working was introduced to

Though there is some uncertainty, some archaeologists believe that iron metallurgy was developed independently in sub-Saharan Africa (possibly in West Africa).Eggert (2014). pp

Though there is some uncertainty, some archaeologists believe that iron metallurgy was developed independently in sub-Saharan Africa (possibly in West Africa).Eggert (2014). pp

51

��59. Inhabitants of Termit, in eastern

53

��54. Similarly, smelting in bloomery-type furnaces appear in the

Mechanical Engineering

) The first forge driven by a

The preferred method of iron production in Europe until the development of the puddling process in 1783–84. Cast iron development lagged in Europe because wrought iron was the desired product and the intermediate step of producing cast iron involved an expensive blast furnace and further refining of pig iron to cast iron, which then required a labor and capital intensive conversion to wrought iron.

Through a good portion of the Middle Ages, in Western Europe, iron was still being made by the working of iron blooms into wrought iron. Some of the earliest casting of iron in Europe occurred in Sweden, in two sites,

The preferred method of iron production in Europe until the development of the puddling process in 1783–84. Cast iron development lagged in Europe because wrought iron was the desired product and the intermediate step of producing cast iron involved an expensive blast furnace and further refining of pig iron to cast iron, which then required a labor and capital intensive conversion to wrought iron.

Through a good portion of the Middle Ages, in Western Europe, iron was still being made by the working of iron blooms into wrought iron. Some of the earliest casting of iron in Europe occurred in Sweden, in two sites,

It was only after this that economically viable means of converting pig iron to bar iron began to be devised. A process known as

It was only after this that economically viable means of converting pig iron to bar iron began to be devised. A process known as

Apart from some production of puddled steel, English steel continued to be made by the cementation process, sometimes followed by remelting to produce crucible steel. These were batch-based processes whose raw material was bar iron, particularly Swedish oregrounds iron.

The problem of mass-producing cheap steel was solved in 1855 by Henry Bessemer, with the introduction of the

Apart from some production of puddled steel, English steel continued to be made by the cementation process, sometimes followed by remelting to produce crucible steel. These were batch-based processes whose raw material was bar iron, particularly Swedish oregrounds iron.

The problem of mass-producing cheap steel was solved in 1855 by Henry Bessemer, with the introduction of the

The steel industry is often considered an indicator of economic progress, because of the critical role played by steel in infrastructural and overall

The steel industry is often considered an indicator of economic progress, because of the critical role played by steel in infrastructural and overall

Ferrous metallurgy is the metallurgy of

Ferrous metallurgy is the metallurgy of iron

Iron () is a chemical element with Symbol (chemistry), symbol Fe (from la, Wikt:ferrum, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 element, group 8 of the periodic table. It is, Abundanc ...

and its alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

s. The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt

Egypt ( ar, مصر , ), officially the Arab Republic of Egypt, is a transcontinental country spanning the northeast corner of Africa and southwest corner of Asia via a land bridge formed by the Sinai Peninsula. It is bordered by the Medit ...

, were made from meteoritic iron-nickel. It is not known when or where the smelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a ...

of iron from ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically containing metals, that can be mined, treated and sold at a profit.Encyclopædia Britannica. "Ore". Encyclopædia Britannica Online. Retrieved 7 Apr ...

s began, but by the end of the 2nd millennium BC iron was being produced from iron ores in the region from Greece to India,Riederer, Josef; Wartke, Ralf-B.: "Iron", Cancik, Hubert; Schneider, Helmuth (eds.): Brill's New Pauly, Brill 2009Early Antiquity By I.M. Drakonoff. 1991. University of Chicago Press

The University of Chicago Press is the largest and one of the oldest university presses in the United States. It is operated by the University of Chicago and publishes a wide variety of academic titles, including ''The Chicago Manual of Style'', ...

. . p. 372 and Sub-Saharan Africa. The use of wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

(worked iron) was known by the 1st millennium BC, and its spread defined the Iron Age

The Iron Age is the final epoch of the three-age division of the prehistory and protohistory of humanity. It was preceded by the Stone Age ( Paleolithic, Mesolithic, Neolithic) and the Bronze Age ( Chalcolithic). The concept has been mostl ...

. During the medieval period, smiths in Europe found a way of producing wrought iron from cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

(in this context known as pig iron) using finery forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery ...

s. All these processes required charcoal as fuel.

By the 4th century BC southern India had started exporting Wootz steel

Wootz steel, also known as Seric steel, is a crucible steel characterized by a pattern of bands and high carbon content. These bands are formed by sheets of microscopic carbides within a tempered martensite or pearlite matrix in higher carbon ...

(with a carbon content between pig iron and wrought iron) to ancient China, Africa, the Middle East and Europe. Archaeological evidence of cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

appears in 5th-century BC China. New methods of producing it by carburizing

Carburising, carburizing (chiefly American English), or carburisation is a heat treatment process in which iron or steel absorbs carbon while the metal is heated in the presence of a carbon-bearing material, such as charcoal or carbon monoxide. ...

bars of iron in the cementation process were devised in the 17th century. During the Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

, new methods of producing bar iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" t ...

by substituting coke for charcoal emerged, and these were later applied to produce steel, ushering in a new era of greatly increased use of iron and steel that some contemporaries described as a new "Iron Age". In the late 1850s Henry Bessemer

Sir Henry Bessemer (19 January 1813 – 15 March 1898) was an English inventor, whose steel-making process would become the most important technique for making steel in the nineteenth century for almost one hundred years from 1856 to 1950. H ...

invented a new steelmaking process which involved blowing air through molten pig-iron to burn off carbon, and so producing mild steel. This and other 19th-century and later steel-making processes have displaced wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

. Today, wrought iron is no longer produced on a commercial scale, having been displaced by the functionally equivalent mild or low-carbon steel.

The largest and most modern underground iron ore mine in the world operates in Kiruna, Norrbotten County, Lapland. The mine, owned by Luossavaara-Kiirunavaara AB, a large Swedish mining-company, has an annual production capacity of over 26 million tonnes of iron ore.

Meteoric iron

iron–nickel alloy

An iron–nickel alloy or nickel–iron alloy, abbreviated FeNi or NiFe, is a group of alloys consisting primarily of the elements nickel (Ni) and iron (Fe). It is the main constituent of the "iron" planetary cores and iron meteorites. In chem ...

s, which comprise about 6% of all meteorites that fall on the Earth

Earth is the third planet from the Sun and the only astronomical object known to harbor life. While large volumes of water can be found throughout the Solar System, only Earth sustains liquid surface water. About 71% of Earth's surfa ...

. That source can often be identified with certainty because of the unique crystal

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macro ...

line features (Widmanstätten pattern

Widmanstätten patterns, also known as Thomson structures, are figures of long nickel–iron crystals, found in the octahedrite iron meteorites and some pallasites. They consist of a fine interleaving of kamacite and taenite bands or ribbons ...

s) of that material, which are preserved when the metal is worked cold or at low temperature. Those artifacts include, for example, a bead

A bead is a small, decorative object that is formed in a variety of shapes and sizes of a material such as stone, bone, shell, glass, plastic, wood, or pearl and with a small hole for threading or stringing. Beads range in size from under ...

from the 5th millennium BC found in Iran

Iran, officially the Islamic Republic of Iran, and also called Persia, is a country located in Western Asia. It is bordered by Iraq and Turkey to the west, by Azerbaijan and Armenia to the northwest, by the Caspian Sea and Turkmeni ...

and spear tips and ornaments from ancient Egypt and Sumer around 4000 BC.Tylecote (1992). p. 3.

These early uses appear to have been largely ceremonial or decorative. Meteoric iron is very rare, and the metal was probably very expensive, perhaps more expensive than gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile me ...

. The early Hittites

The Hittites () were an Anatolian people who played an important role in establishing first a kingdom in Kussara (before 1750 BC), then the Kanesh or Nesha kingdom (c. 1750–1650 BC), and next an empire centered on Hattusa in north-centra ...

are known to have barter

In trade, barter (derived from ''baretor'') is a system of exchange in which participants in a transaction directly exchange goods or services for other goods or services without using a medium of exchange, such as money. Economists disti ...

ed iron (meteoric or smelted) for silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

, at a rate of 40 times the iron's weight, with the Old Assyrian Empire

The Old Assyrian period was the second stage of Assyrian history, covering the history of the city of Assur from its rise as an independent city-state under Puzur-Ashur I 2025 BC to the foundation of a larger Assyrian territorial state after th ...

in the first centuries of the second millennium BC.

Meteoric iron was also fashioned into tools in the Arctic

The Arctic ( or ) is a polar region located at the northernmost part of Earth. The Arctic consists of the Arctic Ocean, adjacent seas, and parts of Canada (Yukon, Northwest Territories, Nunavut), Danish Realm (Greenland), Finland, Iceland, N ...

, about the year 1000, when the Thule people

The Thule (, , ) or proto-Inuit were the ancestors of all modern Inuit. They developed in coastal Alaska by the year 1000 and expanded eastward across northern Canada, reaching Greenland by the 13th century. In the process, they replaced people o ...

of Greenland

Greenland ( kl, Kalaallit Nunaat, ; da, Grønland, ) is an island country in North America that is part of the Kingdom of Denmark. It is located between the Arctic and Atlantic oceans, east of the Canadian Arctic Archipelago. Greenland i ...

began making harpoon

A harpoon is a long spear-like instrument and tool used in fishing, whaling, sealing, and other marine hunting to catch and injure large fish or marine mammals such as seals and whales. It accomplishes this task by impaling the target animal ...

s, knives, ulu

An ulu ( iu, ᐅᓗ, plural: ''uluit'', 'woman's knife') is an all-purpose knife traditionally used by Inuit, Iñupiat, Yupik peoples, Yupik, and Aleut women. It is utilized in applications as diverse as skinning and cleaning animals, cutting a c ...

s and other edged tools from pieces of the Cape York meteorite

The Cape York meteorite, also known as the Innaanganeq meteorite, is one of the largest known iron meteorites, classified as a medium octahedrite in chemical group IIIAB. In addition to many small fragments, at least eight large fragments with a ...

. Typically pea-size bits of metal were cold-hammered into disks and fitted to a bone handle. These artifacts were also used as trade goods with other Arctic peoples: tools made from the Cape York meteorite have been found in archaeological sites more than distant. When the American polar explorer Robert Peary shipped the largest piece of the meteorite to the American Museum of Natural History in New York City

New York, often called New York City or NYC, is the most populous city in the United States. With a 2020 population of 8,804,190 distributed over , New York City is also the most densely populated major city in the Un ...

in 1897, it still weighed over 33 ton

Ton is the name of any one of several units of measure. It has a long history and has acquired several meanings and uses.

Mainly it describes units of weight. Confusion can arise because ''ton'' can mean

* the long ton, which is 2,240 pounds

...

s. Another example of a late use of meteoric iron is an adze

An adze (; alternative spelling: adz) is an ancient and versatile cutting tool similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. Adzes have been used since the Stone Age. They are used for smoothing ...

from around 1000 AD found in Sweden.

Native iron

Native

Native may refer to:

People

* Jus soli, citizenship by right of birth

* Indigenous peoples, peoples with a set of specific rights based on their historical ties to a particular territory

** Native Americans (disambiguation)

In arts and entert ...

iron in the metallic state occurs rarely as small inclusions in certain basalt

Basalt (; ) is an aphanitic (fine-grained) extrusive igneous rock formed from the rapid cooling of low-viscosity lava rich in magnesium and iron (mafic lava) exposed at or very near the surface of a rocky planet or moon. More than 90 ...

rocks. Besides meteoritic iron, Thule people of Greenland have used native iron from the Disko region.

Iron smelting and the Iron Age

Iron smelting—the extraction of usable metal fromoxidized

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a ...

iron ores—is more difficult than tin

Tin is a chemical element with the symbol Sn (from la, stannum) and atomic number 50. Tin is a silvery-coloured metal.

Tin is soft enough to be cut with little force and a bar of tin can be bent by hand with little effort. When bent, t ...

and copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

smelting. While these metals and their alloys can be cold-worked or melted in relatively simple furnaces (such as the kilns used for pottery

Pottery is the process and the products of forming vessels and other objects with clay and other ceramic materials, which are fired at high temperatures to give them a hard and durable form. Major types include earthenware, stoneware and ...

) and cast into molds, smelted iron requires hot-working and can be melted only in specially designed furnaces. Iron is a common impurity in copper ores and iron ore was sometimes used as a flux, thus it is not surprising that humans mastered the technology of smelted iron only after several millennia of bronze metallurgy.

The place and time for the discovery of iron smelting is not known, partly because of the difficulty of distinguishing metal extracted from nickel-containing ores from hot-worked meteoritic iron. The archaeological evidence seems to point to the Middle East area, during the Bronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second prin ...

in the 3rd millennium BC. However, wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

artifacts remained a rarity until the 12th century BC.

The Iron Age

The Iron Age is the final epoch of the three-age division of the prehistory and protohistory of humanity. It was preceded by the Stone Age ( Paleolithic, Mesolithic, Neolithic) and the Bronze Age ( Chalcolithic). The concept has been mostl ...

is conventionally defined by the widespread replacement of bronze weapons and tools with those of iron and steel.Waldbaum (1978). pp. 56–58. That transition happened at different times in different places, as the technology spread. Mesopotamia was fully into the Iron Age by 900 BC. Although Egypt produced iron artifacts, bronze remained dominant until its conquest by Assyria in 663 BC. The Iron Age began in India about 1200 BC, in Central Europe about 800 BC, and in China about 300 BC. Around 500 BC, the Nubia

Nubia () (Nobiin: Nobīn, ) is a region along the Nile river encompassing the area between the first cataract of the Nile (just south of Aswan in southern Egypt) and the confluence of the Blue and White Niles (in Khartoum in central Sudan), or ...

ns, who had learned from the Assyrians the use of iron and were expelled from Egypt, became major manufacturers and exporters of iron.

Ancient Near East

Anatolia

Anatolia, tr, Anadolu Yarımadası), and the Anatolian plateau, also known as Asia Minor, is a large peninsula in Western Asia and the westernmost protrusion of the Asian continent. It constitutes the major part of modern-day Turkey. The ...

, dated from 2500 BC.Richard Cowen, ''The Age of Iron'', Chapter 5 in a series of essays on Geology, History, and People prepares for a course of the University of California at DavisOnline version

accessed on 2010-02-11. About 1500 BC, increasing numbers of non-meteoritic, smelted iron objects appeared in

Mesopotamia

Mesopotamia ''Mesopotamíā''; ar, بِلَاد ٱلرَّافِدَيْن or ; syc, ܐܪܡ ܢܗܪ̈ܝܢ, or , ) is a historical region of Western Asia situated within the Tigris–Euphrates river system, in the northern part of the ...

, Anatolia and Egypt. Nineteen meteoric iron objects were found in the tomb

A tomb ( grc-gre, τύμβος ''tumbos'') is a repository for the remains of the dead. It is generally any structurally enclosed interment space or burial chamber, of varying sizes. Placing a corpse into a tomb can be called ''immureme ...

of Egypt

Egypt ( ar, مصر , ), officially the Arab Republic of Egypt, is a transcontinental country spanning the northeast corner of Africa and southwest corner of Asia via a land bridge formed by the Sinai Peninsula. It is bordered by the Medit ...

ian ruler Tutankhamun

Tutankhamun (, egy, twt-ꜥnḫ-jmn), Egyptological pronunciation Tutankhamen () (), sometimes referred to as King Tut, was an Egyptian pharaoh who was the last of his royal family to rule during the end of the Eighteenth Dynasty (ruled ...

, who died in 1323 BC, including an iron dagger with a golden hilt, an Eye of Horus, the mummy's head-stand and sixteen models of an artisan's tools. An Ancient Egyptian sword bearing the name of pharaoh Merneptah

Merneptah or Merenptah (reigned July or August 1213 BC – May 2, 1203 BC) was the fourth pharaoh of the Nineteenth Dynasty of Ancient Egypt. He ruled Egypt for almost ten years, from late July or early August 1213 BC until his death on May 2, ...

as well as a battle axe

A battle axe (also battle-axe, battle ax, or battle-ax) is an axe specifically designed for combat. Battle axes were specialized versions of utility axes. Many were suitable for use in one hand, while others were larger and were deployed two-ha ...

with an iron blade and gold-decorated bronze shaft were both found in the excavation of Ugarit

)

, image =Ugarit Corbel.jpg

, image_size=300

, alt =

, caption = Entrance to the Royal Palace of Ugarit

, map_type = Near East#Syria

, map_alt =

, map_size = 300

, relief=yes

, location = Latakia Governorate, Syria

, region = ...

.

Although iron objects dating from the Bronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second prin ...

have been found across the Eastern Mediterranean, bronzework appears to have greatly predominated during this period.Waldbaum (1978): 23. As the technology spread, iron came to replace bronze as the dominant metal used for tools and weapons across the Eastern Mediterranean (the Levant

The Levant () is an approximate historical geographical term referring to a large area in the Eastern Mediterranean region of Western Asia. In its narrowest sense, which is in use today in archaeology and other cultural contexts, it is ...

, Cyprus

Cyprus ; tr, Kıbrıs (), officially the Republic of Cyprus,, , lit: Republic of Cyprus is an island country located south of the Anatolian Peninsula in the eastern Mediterranean Sea. Its continental position is disputed; while it is ge ...

, Greece

Greece,, or , romanized: ', officially the Hellenic Republic, is a country in Southeast Europe. It is situated on the southern tip of the Balkans, and is located at the crossroads of Europe, Asia, and Africa. Greece shares land borders ...

, Crete

Crete ( el, Κρήτη, translit=, Modern: , Ancient: ) is the largest and most populous of the Greek islands, the 88th largest island in the world and the fifth largest island in the Mediterranean Sea, after Sicily, Sardinia, Cyprus, ...

, Anatolia and Egypt).

Iron was originally smelted in bloomeries, furnaces where bellows

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtig ...

were used to force air through a pile of iron ore and burning charcoal. The carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

produced by the charcoal reduced the iron oxide from the ore to metallic iron. The bloomery, however, was not hot enough to melt the iron, so the metal collected in the bottom of the furnace as a spongy mass, or ''bloom''. Workers then repeatedly beat and folded it to force out the molten slag. This laborious, time-consuming process produced wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

, a malleable but fairly soft alloy.

Concurrent with the transition from bronze to iron was the discovery of carburization, the process of adding carbon to wrought iron. While the iron bloom contained some carbon, the subsequent hot-working oxidized

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a ...

most of it. Smiths in the Middle East discovered that wrought iron could be turned into a much harder product by heating the finished piece in a bed of charcoal, and then quench

In materials science, quenching is the rapid cooling of a workpiece in water, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as p ...

ing it in water or oil. This procedure turned the outer layers of the piece into steel, an alloy of iron and iron carbide

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in front ...

s, with an inner core of less brittle iron.

Theories on the origin of iron smelting

The development of iron smelting was traditionally attributed to theHittites

The Hittites () were an Anatolian people who played an important role in establishing first a kingdom in Kussara (before 1750 BC), then the Kanesh or Nesha kingdom (c. 1750–1650 BC), and next an empire centered on Hattusa in north-centra ...

of Anatolia of the Late Bronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second prin ...

.Muhly, James D. 'Metalworking/Mining in the Levant' pp. 174–183 in ''Near Eastern Archaeology'' ed. Suzanne Richard (2003), pp. 179–180. It was believed that they maintained a monopoly on iron working, and that their empire had been based on that advantage. According to that theory, the ancient Sea Peoples

The Sea Peoples are a hypothesized seafaring confederation that attacked ancient Egypt and other regions in the East Mediterranean prior to and during the Late Bronze Age collapse (1200–900 BCE).. Quote: "First coined in 1881 by the Fren ...

, who invaded the Eastern Mediterranean and destroyed the Hittite empire at the end of the Late Bronze Age, were responsible for spreading the knowledge through that region. This theory is no longer held in the mainstream of scholarship, since there is no archaeological evidence of the alleged Hittite monopoly. While there are some iron objects from Bronze Age Anatolia, the number is comparable to iron objects found in Egypt and other places of the same time period, and only a small number of those objects were weapons.

A more recent theory claims that the development of iron technology was driven by the disruption of the copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

and tin

Tin is a chemical element with the symbol Sn (from la, stannum) and atomic number 50. Tin is a silvery-coloured metal.

Tin is soft enough to be cut with little force and a bar of tin can be bent by hand with little effort. When bent, t ...

trade routes, due to the collapse of the empires at the end of the Late Bronze Age. These metals, especially tin, were not widely available and metal workers had to transport them over long distances, whereas iron ores were widely available. However, no known archaeological evidence suggests a shortage of bronze or tin in the Early Iron Age. Bronze objects remained abundant, and these objects have the same percentage of tin as those from the Late Bronze Age.

Indian subcontinent

Gangetic plains

The Indo-Gangetic Plain, also known as the North Indian River Plain, is a fertile plain encompassing northern regions of the Indian subcontinent, including most of northern and eastern India, around half of Pakistan, virtually all of Ba ...

have yielded iron implements dated between 1800 and 1200 BC. By the early 13th century BC, iron smelting was practiced on a large scale in India. In Southern India

South India, also known as Dakshina Bharata or Peninsular India, consists of the peninsular southern part of India. It encompasses the Indian states of Andhra Pradesh, Karnataka, Kerala, Tamil Nadu, and Telangana, as well as the union territ ...

(present day Mysore

Mysore (), officially Mysuru (), is a city in the southern part of the state of Karnataka, India. Mysore city is geographically located between 12° 18′ 26″ north latitude and 76° 38′ 59″ east longitude. It is located at an altitude of ...

) iron was in use 12th to 11th centuries BC. The technology of iron metallurgy advanced in the politically stable Maurya

The Maurya Empire, or the Mauryan Empire, was a geographically extensive Iron Age historical power in the Indian subcontinent based in Magadha, having been founded by Chandragupta Maurya in 322 BCE, and existing in loose-knit fashion until 1 ...

period and during a period of peaceful settlements in the 1st millennium BC.

Iron artifacts such as spikes

The SPIKES protocol is a method used in clinical medicine to break bad news to patients and families. As receiving bad news can cause distress and anxiety, clinicians need to deliver the news carefully. By using the SPIKES method for introducing a ...

, knives

A knife ( : knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced ...

, dagger

A dagger is a fighting knife with a very sharp point and usually two sharp edges, typically designed or capable of being used as a thrusting or stabbing weapon.State v. Martin, 633 S.W.2d 80 (Mo. 1982): This is the dictionary or popular-use de ...

s, arrow-heads, bowls, spoon

A spoon is a utensil consisting of a shallow bowl (also known as a head), oval or round, at the end of a handle. A type of cutlery (sometimes called flatware in the United States), especially as part of a place setting, it is used primarily f ...

s, saucepan

Cookware and bakeware is food preparation equipment, such as cooking pots, pans, baking sheets etc. used in kitchens. Cookware is used on a stove or range cooktop, while bakeware is used in an oven. Some utensils are considered both cookware ...

s, axe

An axe ( sometimes ax in American English; see spelling differences) is an implement that has been used for millennia to shape, split and cut wood, to harvest timber, as a weapon, and as a ceremonial or heraldic symbol. The axe has ma ...

s, chisels, tongs

Tongs are a type of tool used to grip and lift objects instead of holding them directly with hands. There are many forms of tongs adapted to their specific use.

The first pair of tongs belongs to the Egyptians. Tongs likely started off as ...

, door fittings, etc., dated from 600 to 200 BC, have been discovered at several archaeological sites of India.Marco Ceccarelli (2000). ''International Symposium on History of Machines and Mechanisms: Proceedings HMM Symposium''. Springer. . p. 218 The Greek historian Herodotus

Herodotus ( ; grc, , }; BC) was an ancient Greek historian and geographer

A geographer is a physical scientist, social scientist or humanist whose area of study is geography, the study of Earth's natural environment and human society ...

wrote the first western

Western may refer to:

Places

*Western, Nebraska, a village in the US

*Western, New York, a town in the US

*Western Creek, Tasmania, a locality in Australia

*Western Junction, Tasmania, a locality in Australia

*Western world, countries that id ...

account of the use of iron in India. The Indian mythological texts, the Upanishad

The Upanishads (; sa, उपनिषद् ) are late Vedic Sanskrit texts that supplied the basis of later Hindu philosophy.Wendy Doniger (1990), ''Textual Sources for the Study of Hinduism'', 1st Edition, University of Chicago Press, , ...

s, have mentions of weaving, pottery and metallurgy, as well. The Romans

Roman or Romans most often refers to:

*Rome, the capital city of Italy

* Ancient Rome, Roman civilization from 8th century BC to 5th century AD

*Roman people, the people of ancient Rome

*''Epistle to the Romans'', shortened to ''Romans'', a lette ...

had high regard for the excellence of steel from India in the time of the Gupta Empire

The Gupta Empire was an ancient Indian empire which existed from the early 4th century CE to late 6th century CE. At its zenith, from approximately 319 to 467 CE, it covered much of the Indian subcontinent. This period is considered as the Gold ...

.

Perhaps as early as 500 BC, although certainly by 200 AD, high-quality steel was produced in southern India by the

Perhaps as early as 500 BC, although certainly by 200 AD, high-quality steel was produced in southern India by the crucible technique

Crucible steel is steel made by melting pig iron (cast iron), iron, and sometimes steel, often along with sand, glass, ashes, and other fluxes, in a crucible. In ancient times steel and iron were impossible to melt using charcoal or coal fires ...

. In this system, high-purity wrought iron, charcoal, and glass were mixed in a crucible and heated until the iron melted and absorbed the carbon. Iron chain was used in Indian suspension bridges as early as the 4th century.

Wootz steel

Wootz steel, also known as Seric steel, is a crucible steel characterized by a pattern of bands and high carbon content. These bands are formed by sheets of microscopic carbides within a tempered martensite or pearlite matrix in higher carbon ...

was produced in India and Sri Lanka from around 300 BC. Wootz steel is famous from Classical Antiquity

Classical antiquity (also the classical era, classical period or classical age) is the period of cultural history between the 8th century BC and the 5th century AD centred on the Mediterranean Sea, comprising the interlocking civilizations of ...

for its durability and ability to hold an edge. When asked by King Porus

Porus or Poros ( grc, Πῶρος ; 326–321 BC) was an ancient Indian king whose territory spanned the region between the Jhelum River (Hydaspes) and Chenab River (Acesines), in the Punjab region of the Indian subcontinent. He is only men ...

to select a gift, Alexander

Alexander is a male given name. The most prominent bearer of the name is Alexander the Great, the king of the Ancient Greek kingdom of Macedonia who created one of the largest empires in ancient history.

Variants listed here are Aleksandar, Al ...

is said to have chosen, over gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile me ...

or silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

, thirty pounds of steel. Wootz steel was originally a complex alloy with iron as its main component together with various trace element

__NOTOC__

A trace element, also called minor element, is a chemical element whose concentration (or other measure of amount) is very low (a "trace amount"). They are classified into two groups: essential and non-essential. Essential trace elements ...

s. Recent studies have suggested that its qualities may have been due to the formation of carbon nanotubes

A scanning tunneling microscopy image of a single-walled carbon nanotube

Rotating single-walled zigzag carbon nanotube

A carbon nanotube (CNT) is a tube made of carbon with diameters typically measured in nanometers.

''Single-wall carbon na ...

in the metal. According to Will Durant

William James Durant (; November 5, 1885 – November 7, 1981) was an American writer, historian, and philosopher. He became best known for his work '' The Story of Civilization'', which contains 11 volumes and details the history of eastern a ...

, the technology passed to the Persians

The Persians are an Iranian ethnic group who comprise over half of the population of Iran. They share a common cultural system and are native speakers of the Persian language as well as of the languages that are closely related to Persian.

...

and from them to Arab

The Arabs (singular: Arab; singular ar, عَرَبِيٌّ, DIN 31635: , , plural ar, عَرَب, DIN 31635: , Arabic pronunciation: ), also known as the Arab people, are an ethnic group mainly inhabiting the Arab world in Western Asia, ...

s who spread it through the Middle East.Will Durant (), ''The Story of Civilization

''The Story of Civilization'' (1935–1975), by husband and wife Will and Ariel Durant, is an 11-volume set of books covering both Eastern and Western civilizations for the general reader, with a particular emphasis on European (Western) history ...

I: Our Oriental Heritage'' In the 16th century, the Dutch

Dutch commonly refers to:

* Something of, from, or related to the Netherlands

* Dutch people ()

* Dutch language ()

Dutch may also refer to:

Places

* Dutch, West Virginia, a community in the United States

* Pennsylvania Dutch Country

People E ...

carried the technology from South India to Europe, where it was mass-produced.

Steel was produced in Sri Lanka from 300 BC by furnaces blown by the monsoon winds. The furnaces were dug into the crests of hills, and the wind was diverted into the air vents by long trenches. This arrangement created a zone of high pressure at the entrance, and a zone of low pressure at the top of the furnace. The flow is believed to have allowed higher temperatures than bellows-driven furnaces could produce, resulting in better-quality iron. Steel made in Sri Lanka was traded extensively within the region and in the Islamic world.

One of the world's foremost metallurgical curiosities is an iron pillar located in the Qutb complex

The Qutb Minar complex are monuments and buildings from the Delhi Sultanate at Mehrauli in Delhi, India. Construction of the Qutub Minar "victory tower" in the complex, named after the religious figure Sufi Saint Khwaja Qutbuddin Bakhtiar Kaki, ...

in Delhi

Delhi, officially the National Capital Territory (NCT) of Delhi, is a city and a union territory of India containing New Delhi, the capital of India. Straddling the Yamuna river, primarily its western or right bank, Delhi shares borders ...

. The pillar is made of wrought iron (98% Fe), is almost seven meters high and weighs more than six tonnes. The pillar was erected by Chandragupta II Vikramaditya and has withstood 1,600 years of exposure to heavy rains with relatively little corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

.

China

Historians debate whether bloomery-based ironworking ever spread to China from the Middle East. One theory suggests that metallurgy was introduced through Central Asia.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 8. In 2008, two iron fragments were excavated at the Mogou site, in Gansu. They have been dated to the 14th century BC, belonging to the period of Siwa culture, suggesting an independent Chinese origin. One of the fragments was made of bloomery iron rather than meteoritic iron.p. xl, Historical Dictionary of Ancient Greek Warfare, J, Woronoff & I. Spence

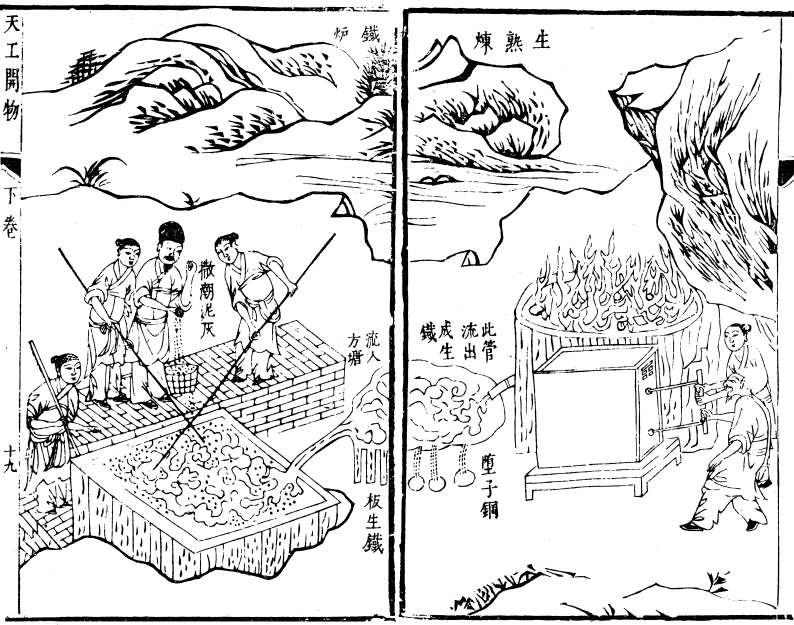

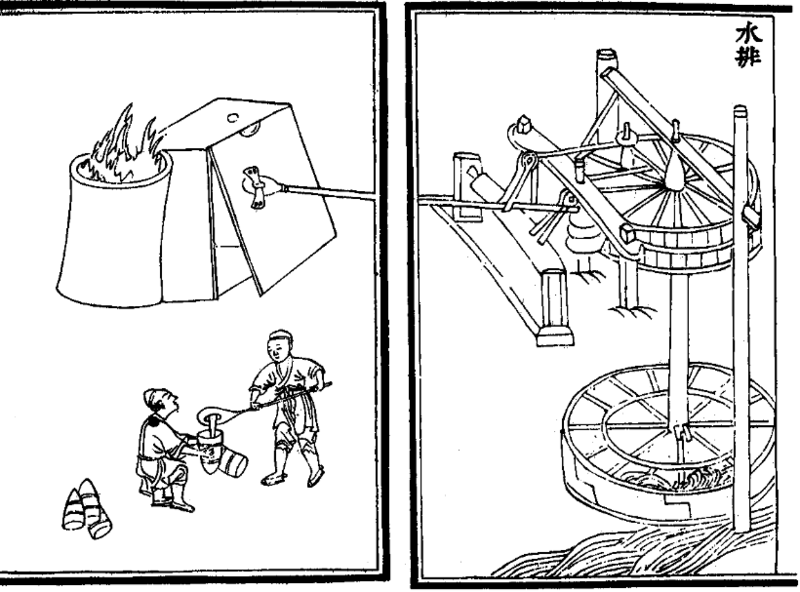

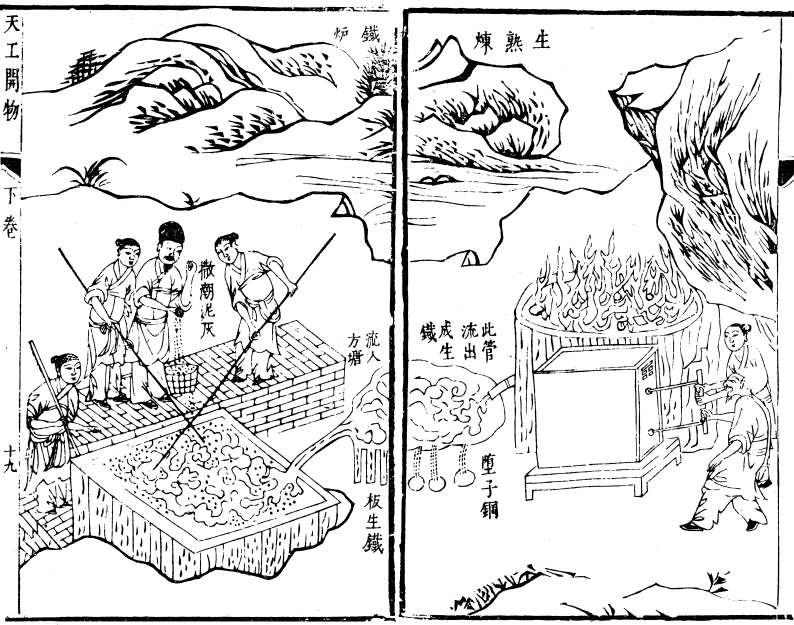

The earliest iron artifacts made from bloomeries in China date to end of the 9th century BC. Cast iron was used in ancient China for warfare, agriculture and architecture. Around 500 BC, metalworkers in the southern state of Wu achieved a temperature of 1130 °C. At this temperature, iron combines with 4.3% carbon and melts. The liquid iron can be

Historians debate whether bloomery-based ironworking ever spread to China from the Middle East. One theory suggests that metallurgy was introduced through Central Asia.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 8. In 2008, two iron fragments were excavated at the Mogou site, in Gansu. They have been dated to the 14th century BC, belonging to the period of Siwa culture, suggesting an independent Chinese origin. One of the fragments was made of bloomery iron rather than meteoritic iron.p. xl, Historical Dictionary of Ancient Greek Warfare, J, Woronoff & I. Spence

The earliest iron artifacts made from bloomeries in China date to end of the 9th century BC. Cast iron was used in ancient China for warfare, agriculture and architecture. Around 500 BC, metalworkers in the southern state of Wu achieved a temperature of 1130 °C. At this temperature, iron combines with 4.3% carbon and melts. The liquid iron can be cast

Cast may refer to:

Music

* Cast (band), an English alternative rock band

* Cast (Mexican band), a progressive Mexican rock band

* The Cast, a Scottish musical duo: Mairi Campbell and Dave Francis

* ''Cast'', a 2012 album by Trespassers William

...

into molds, a method far less laborious than individually forging each piece of iron from a bloom.

Cast iron is rather brittle and unsuitable for striking implements. It can, however, be ''decarburized'' to steel or wrought iron by heating it in air for several days. In China, these iron working methods spread northward, and by 300 BC, iron was the material of choice throughout China for most tools and weapons. A mass grave in Hebei

Hebei or , (; alternately Hopeh) is a northern province of China. Hebei is China's sixth most populous province, with over 75 million people. Shijiazhuang is the capital city. The province is 96% Han Chinese, 3% Manchu, 0.8% Hui, and 0 ...

province, dated to the early 3rd century BC, contains several soldiers buried with their weapons and other equipment. The artifacts recovered from this grave are variously made of wrought iron, cast iron, malleabilized cast iron, and quench-hardened steel, with only a few, probably ornamental, bronze weapons.

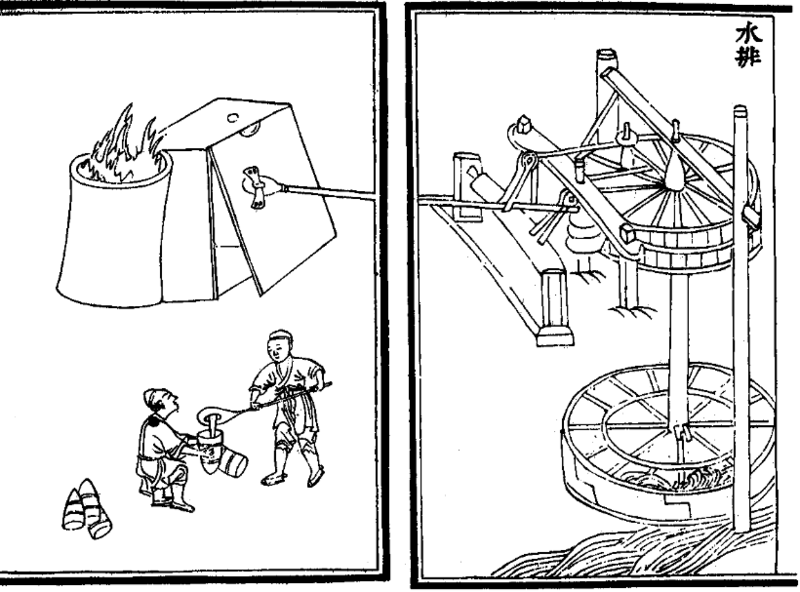

During the

During the Han Dynasty

The Han dynasty (, ; ) was an imperial dynasty of China (202 BC – 9 AD, 25–220 AD), established by Liu Bang (Emperor Gao) and ruled by the House of Liu. The dynasty was preceded by the short-lived Qin dynasty (221–207 BC) and a warr ...

(202 BC–220 AD), the government established ironworking as a state monopoly (repealed during the latter half of the dynasty and returned to private entrepreneurship) and built a series of large blast furnaces in Henan

Henan (; or ; ; alternatively Honan) is a landlocked province of China, in the central part of the country. Henan is often referred to as Zhongyuan or Zhongzhou (), which literally means "central plain" or "midland", although the name is al ...

province, each capable of producing several tons of iron per day. By this time, Chinese metallurgists had discovered how to fine molten pig iron, stirring it in the open air until it lost its carbon and could be hammered (wrought). (In modern Mandarin-Chinese

Chinese can refer to:

* Something related to China

* Chinese people, people of Chinese nationality, citizenship, and/or ethnicity

**''Zhonghua minzu'', the supra-ethnic concept of the Chinese nation

** List of ethnic groups in China, people of ...

, this process is now called ''chao'', literally stir frying; pig iron is known as 'raw iron', while wrought iron is known as 'cooked iron'.) By the 1st century BC, Chinese metallurgists had found that wrought iron and cast iron could be melted together to yield an alloy of intermediate carbon content, that is, steel. According to legend, the sword of Liu Bang

Emperor Gaozu of Han (256 – 1 June 195 BC), born Liu Bang () with courtesy name Ji (季), was the founder and first emperor of the Han dynasty, reigning in 202–195 BC. His temple name was "Taizu" while his posthumous name was Empe ...

, the first Han emperor, was made in this fashion. Some texts of the era mention "harmonizing the hard and the soft" in the context of ironworking; the phrase may refer to this process. The ancient city of Wan (Nanyang

Nanyang is the romanization of two common Chinese place names. It may refer to:

Written as 南洋 (Southern Ocean)

* Nanyang (region), a Chinese term denoting the Southeast Asian lands surrounding the South China Sea

;China

* Nanyang Fleet, Qing ...

) from the Han period forward was a major center of the iron and steel industry. Along with their original methods of forging steel, the Chinese had also adopted the production methods of creating Wootz steel, an idea imported from India to China by the 5th century AD. During the Han Dynasty, the Chinese were also the first to apply hydraulic

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counte ...

power (i.e. a waterwheel) in working the bellows of the blast furnace. This was recorded in the year 31 AD, as an innovation by the Chinese mechanical engineer and politician Du Shi

Du Shi (, d. 38'' Book of Later Han'', vol. 31Crespigny, 183.) was a Chinese hydrologist, inventor, mechanical engineer, metallurgist, and politician of the Eastern Han Dynasty. Du Shi is credited with being the first to apply hydraulic power ( ...

, Prefect

Prefect (from the Latin ''praefectus'', substantive adjectival form of ''praeficere'': "put in front", meaning in charge) is a magisterial title of varying definition, but essentially refers to the leader of an administrative area.

A prefect's ...

of Nanyang. Although Du Shi was the first to apply water power to bellows in metallurgy, the first drawn and printed illustration of its operation with water power appeared in 1313 AD, in the Yuan Dynasty era text called the ''Nong Shu''.

In the 11th century, there is evidence of the production of steel in Song China

The Song dynasty (; ; 960–1279) was an imperial dynasty of China that began in 960 and lasted until 1279. The dynasty was founded by Emperor Taizu of Song following his usurpation of the throne of the Later Zhou. The Song conquered the rest ...

using two techniques: a "berganesque" method that produced inferior, heterogeneous steel and a precursor to the modern Bessemer process that utilized partial decarbonization via repeated forging under a cold blast. By the 11th century, there was a large amount of deforestation in China due to the iron industry's demands for charcoal. (2006). 158. By this time however, the Chinese had learned to use bituminous coke to replace charcoal, and with this switch in resources many acres of prime timberland in China were spared.

Iron Age Europe

Iron working was introduced to

Iron working was introduced to Greece

Greece,, or , romanized: ', officially the Hellenic Republic, is a country in Southeast Europe. It is situated on the southern tip of the Balkans, and is located at the crossroads of Europe, Asia, and Africa. Greece shares land borders ...

in the late 10th century BC. The earliest marks of Iron Age in Central Europe are artifacts from the Hallstatt C

The Hallstatt culture was the predominant Western and Central European culture of Late Bronze Age (Hallstatt A, Hallstatt B) from the 12th to 8th centuries BC and Early Iron Age Europe (Hallstatt C, Hallstatt D) from the 8th to 6th centuries B ...

culture (8th century BC). Throughout the 7th to 6th centuries BC, iron artifacts remained luxury items reserved for an elite. This changed dramatically shortly after 500 BC with the rise of the La Tène culture

The La Tène culture (; ) was a European Iron Age culture. It developed and flourished during the late Iron Age (from about 450 BC to the Roman conquest in the 1st century BC), succeeding the early Iron Age Hallstatt culture without any defi ...

, from which time iron metallurgy also became common in Northern Europe and Britain

Britain most often refers to:

* The United Kingdom, a sovereign state in Europe comprising the island of Great Britain, the north-eastern part of the island of Ireland and many smaller islands

* Great Britain, the largest island in the United King ...

. The spread of ironworking in Central and Western Europe is associated with Celtic expansion. By the 1st century BC, Noric steel

Noric steel was a steel from Noricum, a Celtic kingdom located in modern Austria and Slovenia.

The proverbial hardness of Noric steel is expressed by Ovid: ''"...durior ..ferro quod noricus excoquit ignis..."'' which roughly translates to "...har ...

was famous for its quality and sought-after by the Roman military

The military of ancient Rome, according to Titus Livius, one of the more illustrious historians of Rome over the centuries, was a key element in the rise of Rome over "above seven hundred years" from a small settlement in Latium to the capital o ...

.

The annual iron output of the Roman Empire

The Roman Empire ( la, Imperium Romanum ; grc-gre, Βασιλεία τῶν Ῥωμαίων, Basileía tôn Rhōmaíōn) was the post- Republican period of ancient Rome. As a polity, it included large territorial holdings around the Mediter ...

is estimated at 84,750 t.

Sub-Saharan Africa

Though there is some uncertainty, some archaeologists believe that iron metallurgy was developed independently in sub-Saharan Africa (possibly in West Africa).Eggert (2014). pp

Though there is some uncertainty, some archaeologists believe that iron metallurgy was developed independently in sub-Saharan Africa (possibly in West Africa).Eggert (2014). pp51

��59. Inhabitants of Termit, in eastern

Niger

)

, official_languages =

, languages_type = National languagesAïr Mountains

The Aïr Mountains or Aïr Massif ( tmh, Ayăr; Hausa: Eastern ''Azbin'', Western ''Abzin'') is a triangular massif, located in northern Niger, within the Sahara. Part of the West Saharan montane xeric woodlands ecoregion, the ...

in Niger

)

, official_languages =

, languages_type = National languagesNsukka

Nsukka is a town and a Local Government Area in Enugu State, Nigeria. Nsukka shares a common border as a town with Edem, Opi (archaeological site), Ede-Oballa, and Obimo.

The postal code of the area is 410001 and 410002 respectively re ...

region of southeast Nigeria

Nigeria ( ), , ig, Naìjíríyà, yo, Nàìjíríà, pcm, Naijá , ff, Naajeeriya, kcg, Naijeriya officially the Federal Republic of Nigeria, is a country in West Africa. It is situated between the Sahel to the north and the Gulf o ...

in what is now Igboland: dating to 2000 BC at the site of Lejja

Lejja is a community comprising 33 villages in Enugu State of South-Eastern Nigeria. It is populated by the Igbo people and located about 14 Kilometers from Nsukka. It is the location of a prehistoric archaeological site which contains iron smeltin ...

(Eze-Uzomaka 2009) and to 750 BC and at the site of Opi (Holl 2009). The site of Gbabiri (in the Central African Republic) has yielded evidence of iron metallurgy, from a reduction furnace and blacksmith workshop; with earliest dates of 896–773 BC and 907–796 BC respectively.Eggert (2014). pp53

��54. Similarly, smelting in bloomery-type furnaces appear in the

Nok culture

The Nok culture (or Nok civilization) is a population whose material remains are named after the Ham village of Nok in Kaduna State of Nigeria, where their terracotta sculptures were first discovered in 1928. The Nok culture appeared in Nige ...

of central Nigeria by about 550 BC and possibly a few centuries earlier.

There is also evidence that carbon steel was made in Western Tanzania

Tanzania (; ), officially the United Republic of Tanzania ( sw, Jamhuri ya Muungano wa Tanzania), is a country in East Africa within the African Great Lakes region. It borders Uganda to the north; Kenya to the northeast; Comoro Islands ...

by the ancestors of the Haya people

The Haya (or Bahaya) are a Bantu ethnic group based in Kagera Region, northwestern Tanzania, on the western side of Lake Victoria. With over one million people, it is estimated the Haya make up approximately 2% of the population of Tanzania. Hi ...

as early as 2,300 to 2,000 years ago (about 300 BC or soon after) by a complex process of "pre-heating" allowing temperatures inside a furnace to reach 1300 to 1400 °C.

Iron and copper working spread southward through the continent, reaching the Cape

A cape is a clothing accessory or a sleeveless outer garment which drapes the wearer's back, arms, and chest, and connects at the neck.

History

Capes were common in medieval Europe, especially when combined with a hood in the chaperon. Th ...

around AD 200. The widespread use of iron revolutionized the Bantu-speaking farming communities who adopted it, driving out and absorbing the rock tool using hunter-gatherer societies they encountered as they expanded to farm wider areas of savanna

A savanna or savannah is a mixed woodland- grassland (i.e. grassy woodland) ecosystem characterised by the trees being sufficiently widely spaced so that the canopy does not close. The open canopy allows sufficient light to reach the ground to ...

. The technologically superior Bantu-speakers spread across southern Africa and became wealthy and powerful, producing iron for tools and weapons in large, industrial quantities.

The earliest records of bloomery-type furnaces in East Africa are discoveries of smelted iron and carbon in Nubia

Nubia () (Nobiin: Nobīn, ) is a region along the Nile river encompassing the area between the first cataract of the Nile (just south of Aswan in southern Egypt) and the confluence of the Blue and White Niles (in Khartoum in central Sudan), or ...

that date back between the 7th and 6th centuries BC, particularly in Meroe where there are known to have been ancient bloomeries that produced metal tools for the Nubians and Kushites and produced surplus for their economy.

Medieval Islamic world

Iron technology was further advanced by severalinventions in medieval Islam

The following is a list of inventions made in the medieval Islamic world, especially during the Islamic Golden Age, George Saliba (1994), ''A History of Arabic Astronomy: Planetary Theories During the Golden Age of Islam'', pp. 245, 250, 256–5 ...

, during the Islamic Golden Age

The Islamic Golden Age was a period of cultural, economic, and scientific flourishing in the history of Islam, traditionally dated from the 8th century to the 14th century. This period is traditionally understood to have begun during the reign ...

. These included a variety of water-powered and wind-powered

Wind power or wind energy is mostly the use of wind turbines to generate electricity. Wind power is a popular, sustainable, renewable energy source that has a much smaller impact on the environment than burning fossil fuels. Historically, w ...

industrial mills for metal production, including geared gristmill

A gristmill (also: grist mill, corn mill, flour mill, feed mill or feedmill) grinds cereal grain into flour and middlings. The term can refer to either the grinding mechanism or the building that holds it. Grist is grain that has been separat ...

s and forges. By the 11th century, every province throughout the Muslim world

The terms Muslim world and Islamic world commonly refer to the Islamic community, which is also known as the Ummah. This consists of all those who adhere to the religious beliefs and laws of Islam or to societies in which Islam is practiced. I ...

had these industrial mills in operation, from Islamic Spain

Al-Andalus translit. ; an, al-Andalus; ast, al-Ándalus; eu, al-Andalus; ber, ⴰⵏⴷⴰⵍⵓⵙ, label= Berber, translit=Andalus; ca, al-Àndalus; gl, al-Andalus; oc, Al Andalús; pt, al-Ândalus; es, al-Ándalus () was the Mu ...

and North Africa

North Africa, or Northern Africa is a region encompassing the northern portion of the African continent. There is no singularly accepted scope for the region, and it is sometimes defined as stretching from the Atlantic shores of Mauritania in ...

in the west to the Middle East

The Middle East ( ar, الشرق الأوسط, ISO 233: ) is a geopolitical region commonly encompassing Arabia (including the Arabian Peninsula and Bahrain), Asia Minor (Asian part of Turkey except Hatay Province), East Thrace (Europ ...

and Central Asia

Central Asia, also known as Middle Asia, is a subregion, region of Asia that stretches from the Caspian Sea in the west to western China and Mongolia in the east, and from Afghanistan and Iran in the south to Russia in the north. It includes t ...

in the east. There are also 10th-century references to cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

, as well as archeological evidence of blast furnaces being used in the Ayyubid and Mamluk

Mamluk ( ar, مملوك, mamlūk (singular), , ''mamālīk'' (plural), translated as "one who is owned", meaning " slave", also transliterated as ''Mameluke'', ''mamluq'', ''mamluke'', ''mameluk'', ''mameluke'', ''mamaluke'', or ''marmeluke'') ...

empires from the 11th century, thus suggesting a diffusion of Chinese metal technology to the Islamic world.

Gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic ...

ed gristmills were invented by Muslim engineers, and were used for crushing metallic ores before extraction. Gristmills in the Islamic world were often made from both watermill

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of ...

s and windmills. In order to adapt water wheel

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or bucket ...

s for gristmilling purposes, cam

Calmodulin (CaM) (an abbreviation for calcium-modulated protein) is a multifunctional intermediate calcium-binding messenger protein expressed in all eukaryotic cells. It is an intracellular target of the secondary messenger Ca2+, and the bin ...

s were used for raising and releasing trip hammer

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, wikt:decorticate, decorticating and polishing of grain in agriculture. In mining, trip hammers were used f ...

s.Donald Routledge Hill, "Mechanical Engineering in the Medieval Near East", ''Scientific American'', May 1991, pp. 64–69. (cf.

The abbreviation ''cf.'' (short for the la, confer/conferatur, both meaning "compare") is used in writing to refer the reader to other material to make a comparison with the topic being discussed. Style guides recommend that ''cf.'' be used onl ...

Donald Routledge HillMechanical Engineering

) The first forge driven by a

hydropower

Hydropower (from el, ὕδωρ, "water"), also known as water power, is the use of falling or fast-running water to produce electricity or to power machines. This is achieved by converting the gravitational potential or kinetic energy of a w ...

ed water mill rather than manual labour was invented in the 12th century Islamic Spain.Lucas, Adam (2006). ''Wind, Water, Work: Ancient and Medieval Milling Technology''. p. 65. Brill, .

One of the most famous steels produced in the medieval Near East was Damascus steel

Damascus steel was the forged steel of the blades of swords smithed in the Near East from ingots of Wootz steel either imported from Southern India or made in production centres in Sri Lanka, or Khorasan, Iran. These swords are characterized by ...

used for swordmaking, and mostly produced in Damascus, Syria, in the period from 900 to 1750. This was produced using the crucible steel

Crucible steel is steel made by melting pig iron (cast iron), iron, and sometimes steel, often along with sand, glass, ashes, and other fluxes, in a crucible. In ancient times steel and iron were impossible to melt using charcoal or coal fires ...

method, based on the earlier Indian wootz steel

Wootz steel, also known as Seric steel, is a crucible steel characterized by a pattern of bands and high carbon content. These bands are formed by sheets of microscopic carbides within a tempered martensite or pearlite matrix in higher carbon ...

. This process was adopted in the Middle East using locally produced steels. The exact process remains unknown, but it allowed carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of th ...

s to precipitate out as micro particles arranged in sheets or bands within the body of a blade. Carbides are far harder than the surrounding low carbon steel, so swordsmiths could produce an edge that cut hard materials with the precipitated carbides, while the bands of softer steel let the sword as a whole remain tough and flexible. A team of researchers based at the Technical University

An institute of technology (also referred to as: technological university, technical university, university of technology, technological educational institute, technical college, polytechnic university or just polytechnic) is an institution of te ...

of Dresden

Dresden (, ; Upper Saxon: ''Dräsdn''; wen, label= Upper Sorbian, Drježdźany) is the capital city of the German state of Saxony and its second most populous city, after Leipzig. It is the 12th most populous city of Germany, the fourth ...

that uses X-ray

An X-ray, or, much less commonly, X-radiation, is a penetrating form of high-energy electromagnetic radiation. Most X-rays have a wavelength ranging from 10 picometers to 10 nanometers, corresponding to frequencies in the range 30&nb ...

s and electron microscopy to examine Damascus steel discovered the presence of cementite

Cementite (or iron carbide) is a compound of iron and carbon, more precisely an intermediate transition metal carbide with the formula Fe3C. By weight, it is 6.67% carbon and 93.3% iron. It has an orthorhombic crystal structure. It is a hard, bri ...

nanowires

A nanowire is a nanostructure in the form of a wire with the diameter of the order of a nanometre (10−9 metres). More generally, nanowires can be defined as structures that have a thickness or diameter constrained to tens of nanometers or less ...

and carbon nanotubes. Peter Paufler, a member of the Dresden team, says that these nanostructures give Damascus steel its distinctive properties and are a result of the forging process.

Medieval and early modern Europe

There was no fundamental change in the technology of iron production in Europe for many centuries. European metal workers continued to produce iron in bloomeries. However, theMedieval

In the history of Europe, the Middle Ages or medieval period lasted approximately from the late 5th to the late 15th centuries, similar to the post-classical period of global history. It began with the fall of the Western Roman Empire ...

period brought two developments—the use of water power in the bloomery process in various places (outlined above), and the first European production in cast iron.

Powered bloomeries

Sometime in the medieval period, water power was applied to the bloomery process. It is possible that this was at the Cistercian Abbey of Clairvaux as early as 1135, but it was certainly in use in early 13th centuryFrance

France (), officially the French Republic ( ), is a country primarily located in Western Europe. It also comprises of overseas regions and territories in the Americas and the Atlantic, Pacific and Indian Oceans. Its metropolitan area ...

and Sweden. In England

England is a country that is part of the United Kingdom. It shares land borders with Wales to its west and Scotland to its north. The Irish Sea lies northwest and the Celtic Sea to the southwest. It is separated from continental Europe b ...

, the first clear documentary evidence for this is the accounts of a forge of the Bishop of Durham

The Bishop of Durham is the Anglican bishop responsible for the Diocese of Durham in the Province of York. The diocese is one of the oldest in England and its bishop is a member of the House of Lords. Paul Butler has been the Bishop of Durham ...

, near Bedburn in 1408, but that was certainly not the first such ironworks. In the Furness

Furness ( ) is a peninsula and region of Cumbria in northwestern England. Together with the Cartmel Peninsula it forms North Lonsdale, historically an exclave of Lancashire.

The Furness Peninsula, also known as Low Furness, is an area of vill ...

district of England, powered bloomeries were in use into the beginning of the 18th century, and near Garstang

Garstang is an ancient market town and civil parish within the Wyre borough of Lancashire, England. It is north of the city of Preston and the same distance south of Lancaster.

In 2011, the parish had a total resident population of 4,268; ...

until about 1770.

The Catalan Forge was a variety of powered bloomery. Bloomeries with hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

were used in upstate New York in the mid-19th century.

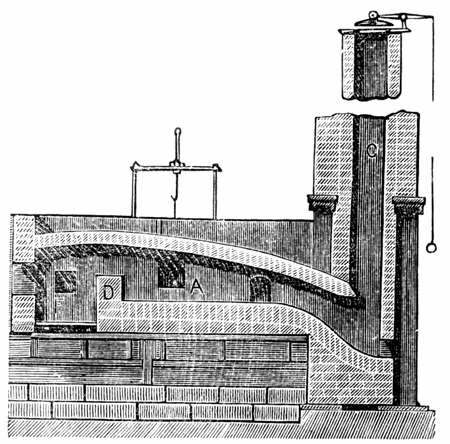

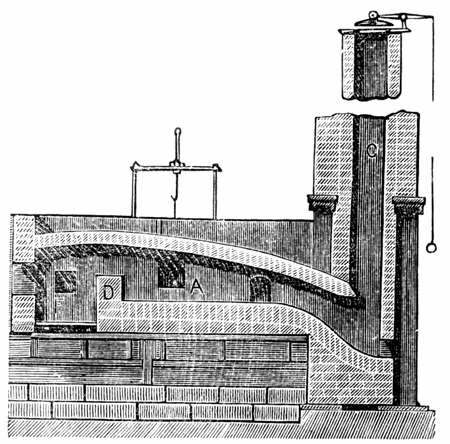

Blast furnace

The preferred method of iron production in Europe until the development of the puddling process in 1783–84. Cast iron development lagged in Europe because wrought iron was the desired product and the intermediate step of producing cast iron involved an expensive blast furnace and further refining of pig iron to cast iron, which then required a labor and capital intensive conversion to wrought iron.

Through a good portion of the Middle Ages, in Western Europe, iron was still being made by the working of iron blooms into wrought iron. Some of the earliest casting of iron in Europe occurred in Sweden, in two sites,

The preferred method of iron production in Europe until the development of the puddling process in 1783–84. Cast iron development lagged in Europe because wrought iron was the desired product and the intermediate step of producing cast iron involved an expensive blast furnace and further refining of pig iron to cast iron, which then required a labor and capital intensive conversion to wrought iron.

Through a good portion of the Middle Ages, in Western Europe, iron was still being made by the working of iron blooms into wrought iron. Some of the earliest casting of iron in Europe occurred in Sweden, in two sites, Lapphyttan

Lapphyttan or Lapphyttejarn in Norberg Municipality, Sweden, may be regarded as the type site for the Medieval Blast Furnace. Its date is probably between 1150 and 1350. It produced cast iron, which was then fined to make ferritic wrought iron c ...

and Vinarhyttan, between 1150 and 1350. Some scholars have speculated the practice followed the Mongol

The Mongols ( mn, Монголчууд, , , ; ; russian: Монголы) are an East Asian ethnic group native to Mongolia, Inner Mongolia in China and the Buryatia Republic of the Russian Federation. The Mongols are the principal member ...

s across Russia

Russia (, , ), or the Russian Federation, is a transcontinental country spanning Eastern Europe and Northern Asia. It is the largest country in the world, with its internationally recognised territory covering , and encompassing one-eig ...

to these sites, but there is no clear proof of this hypothesis, and it would certainly not explain the pre-Mongol datings of many of these iron-production centres. In any event, by the late 14th century, a market for cast iron goods began to form, as a demand developed for cast iron cannonballs.

Finery forge

An alternative method of decarburising pig iron was thefinery forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery ...

, which seems to have been devised in the region around Namur in the 15th century. By the end of that century, this Walloon process

A Walloon forge (or Walloon process) is a type of finery forge that decarbonizes pig iron into wrought iron.

The process was conceived in the Liège region, and from there extended to France, then England around the end of the 15th century. ...

spread to the ''Pay de Bray'' on the eastern boundary of Normandy

Normandy (; french: link=no, Normandie ; nrf, Normaundie, Nouormandie ; from Old French , plural of ''Normant'', originally from the word for "northman" in several Scandinavian languages) is a geographical and cultural region in Northwestern ...

, and then to England, where it became the main method of making wrought iron by 1600. It was introduced to Sweden by Louis de Geer in the early 17th century and was used to make the oregrounds iron

Oregrounds iron was a grade of iron that was regarded as the best grade available in 18th century England. The term was derived from the small Swedish city of Öregrund, the port from which the bar iron was shipped. It was produced using the Wal ...

favoured by English steelmakers.

A variation on this was the German forge. This became the main method of producing bar iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" t ...

in Sweden.

Cementation process

In the early 17th century, ironworkers inWestern Europe

Western Europe is the western region of Europe. The region's countries and territories vary depending on context.

The concept of "the West" appeared in Europe in juxtaposition to "the East" and originally applied to the ancient Mediterranean ...

had developed the cementation process for carburizing

Carburising, carburizing (chiefly American English), or carburisation is a heat treatment process in which iron or steel absorbs carbon while the metal is heated in the presence of a carbon-bearing material, such as charcoal or carbon monoxide. ...

wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...