A heat exchanger is a system used to transfer heat between a source and a

working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in

space heating

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HV ...

,

refrigeration

The term refrigeration refers to the process of removing heat from an enclosed space or substance for the purpose of lowering the temperature.International Dictionary of Refrigeration, http://dictionary.iifiir.org/search.phpASHRAE Terminology, ht ...

,

air conditioning

Air conditioning, often abbreviated as A/C or AC, is the process of removing heat from an enclosed space to achieve a more comfortable interior environment (sometimes referred to as 'comfort cooling') and in some cases also strictly controlling ...

,

power station

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

Many ...

s,

chemical plants,

petrochemical plants,

petroleum refineries,

natural-gas processing

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing impurities, contaminants and higher molecular mass hydrocarbons to produce what is known as ''pipeline quality'' dry natural gas. Natural gas ...

, and

sewage treatment

Sewage treatment (or domestic wastewater treatment, municipal wastewater treatment) is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding e ...

. The classic example of a heat exchanger is found in an

internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal c ...

in which a circulating fluid known as

engine coolant flows through

radiator coils and

air

The atmosphere of Earth is the layer of gases, known collectively as air, retained by Earth's gravity that surrounds the planet and forms its planetary atmosphere. The atmosphere of Earth protects life on Earth by creating pressure allowing f ...

flows past the coils, which cools the coolant and heats the incoming

air

The atmosphere of Earth is the layer of gases, known collectively as air, retained by Earth's gravity that surrounds the planet and forms its planetary atmosphere. The atmosphere of Earth protects life on Earth by creating pressure allowing f ...

. Another example is the

heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, th ...

, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

Flow arrangement

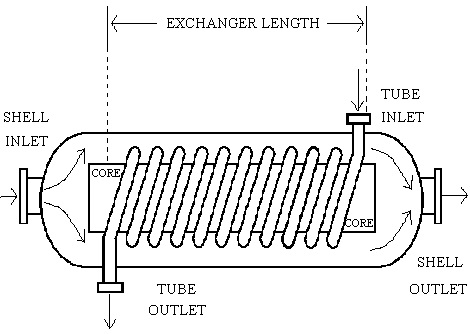

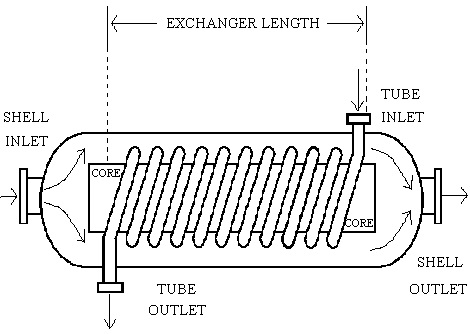

Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this ty ...

, single pass (1–1 parallel flow)

Image:Heat_exc_2-1.png, Fig. 2: Shell and tube heat exchanger, 2-pass tube side (1–2 crossflow)

Image:Heat_exc_2-2.png, Fig. 3: Shell and tube heat exchanger, 2-pass shell side, 2-pass tube side (2-2 countercurrent)

There are three primary classifications of heat exchangers according to their flow arrangement. In ''parallel-flow'' heat exchangers, the two fluids enter the exchanger at the same end, and travel in parallel to one another to the other side. =In ''counter-flow'' heat exchangers the fluids enter the exchanger from opposite ends. The counter current design is the most efficient, in that it can transfer the most heat from the heat (transfer) medium per unit mass due to the fact that the average temperature difference along any unit length is ''higher''=. See

countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each ...

. In a ''cross-flow'' heat exchanger, the fluids travel roughly perpendicular to one another through the exchanger.

For efficiency, heat exchangers are designed to maximize the surface area of the wall between the two fluids, while minimizing resistance to fluid flow through the exchanger. The exchanger's performance can also be affected by the addition of fins or corrugations in one or both directions, which increase surface area and may channel fluid flow or induce turbulence.

The driving temperature across the heat transfer surface varies with position, but an appropriate mean temperature can be defined. In most simple systems this is the "

log mean temperature difference" (LMTD). Sometimes direct knowledge of the LMTD is not available and the

NTU method is used.

Types

Double pipe heat exchangers are the simplest exchangers used in industries. On one hand, these heat exchangers are cheap for both design and maintenance, making them a good choice for small industries. On the other hand, their low efficiency coupled with the high space occupied in large scales, has led modern industries to use more efficient heat exchangers like shell and tube or plate. However, since double pipe heat exchangers are simple, they are used to teach heat exchanger design basics to students as the fundamental rules for all heat exchangers are the same.

1. Double-pipe heat exchanger

(a) When the other fluid flows into the annular gap between two tubes, one fluid flows through the smaller pipe. The flow may be a current flow or parallel flow in a double pipe heat exchanger.

(b) Parallel flow, where at the same point, the hot and cold liquids join, flow in the same direction and exit at the same end.

(c) Counter flow, where at opposite ends, hot and cold fluids join, flow in the opposite direction and exit at opposite ends.

The figure above illustrates the parallel and counter-flow flow directions of the fluid exchanger. If this is done under comparable conditions, more heat is transferred to the counter-flow device than to the parallel flow heat exchanger. Owing to the large temperature differential arising from the high thermal voltage, the temperature profiles of the two heat exchangers display two significant disadvantages in the parallel-flow design. Which indicates that the partnership is a distinct disadvantage if it is intended a design is to increase the cold fluid temperature.

Where two fluids are expected to be taken to exactly the same temperature, the parallel flow configuration is beneficial. While the counter flow heat exchanger has more significant advantages compared to parallel flow design. Where it can reduce thermal stress and produce more uniform rate of heat transfer.

2. Shell-and-tube heat exchanger

In a shell-and-tube heat exchanger, two fluids at different temperatures flow through the heat exchanger. One of the fluids flows through the tube side and the other fluid flows outside the tubes, but inside the shell (shell side).

Baffles are used to support the tubes, direct the fluid flow to the tubes in an approximately natural manner, and maximize the turbulence of the shell fluid. There are many various kinds of baffles, and the choice of baffle form, spacing, and geometry depends on the allowable flow rate of the drop in shell-side force, the need for tube support, and the flow-induced vibrations. There are several variations of shell-and-tube exchangers available; the differences lie in the arrangement of flow configurations and details of construction.

In application to cool air with shell-and-tube technology (such as

intercooler /

charge air cooler

An intercooler is a heat exchanger used to cool a gas after compression. Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines.

Internal combustion engines

Most ...

for

combustion engines), fins can be added on the tubes to increase heat transfer area on air side and create a tubes & fins configuration.

3. Plate Heat Exchanger

A plate heat exchanger contains an amount of thin shaped heat transfer plates bundled together. The gasket arrangement of each pair of plates provides two separate channel system. Each pair of plates form a channel where the fluid can flow through. The pairs are attached by welding and bolting methods. The following shows the components in the heat exchanger.

In single channels the configuration of the gaskets enables flow through. Thus, this allows the main and secondary media in counter-current flow. A gasket plate heat exchanger has a heat region from corrugated plates. The gasket function as seal between plates and they are located between frame and pressure plates. Fluid flows in a counter current direction throughout the heat exchanger. An efficient thermal performance is produced. Plates are produced in different depths, sizes and corrugated shapes. There are different types of plates available including plate and frame, plate and shell and spiral plate heat exchangers. The distribution area guarantees the flow of fluid to the whole heat transfer surface. This helps to prevent stagnant area that can cause accumulation of unwanted material on solid surfaces. High flow turbulence between plates results in a greater transfer of heat and a decrease in pressure.

4. Condensers and Boilers

Heat exchangers using a two-phase heat transfer system are condensers, boilers and evaporators. Condensers are instruments that take and cool hot gas or vapor to the point of condensation and transform the gas into a liquid form. The point at which liquid transforms to gas is called vaporization and vice versa is called condensation. Surface condenser is the most common type of condenser where it includes a water supply device. Figure 5 below displays a two-pass surface condenser.

The pressure of steam at the turbine outlet is low where the steam density is very low where the flow rate is very high. To prevent a decrease in pressure in the movement of steam from the turbine to condenser, the condenser unit is placed underneath and connected to the turbine. Inside the tubes the cooling water runs in a parallel way, while steam moves in a vertical downward position from the wide opening at the top and travel through the tube.

Furthermore, boilers are categorized as initial application of heat exchangers. The word steam generator was regularly used to describe a boiler unit where a hot liquid stream is the source of heat rather than the combustion products. Depending on the dimensions and configurations the boilers are manufactured. Several boilers are only able to produce hot fluid while on the other hand the others are manufactured for steam production.

Shell and tube heat exchanger

Shell and tube heat exchangers consist of a series of tubes which contain fluid that must be either heated or cooled. A second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, etc. Shell and tube heat exchangers are typically used for high-pressure applications (with pressures greater than 30 bar and temperatures greater than 260 °C).

[Saunders, E. A. (1988). Heat Exchanges: Selection, Design and Construction. New York: Longman Scientific and Technical.] This is because the shell and tube heat exchangers are robust due to their shape.

Several thermal design features must be considered when designing the tubes in the shell and tube heat exchangers:

There can be many variations on the shell and tube design. Typically, the ends of each tube are connected to

plenums (sometimes called water boxes) through holes in tubesheets. The tubes may be straight or bent in the shape of a U, called U-tubes.

* Tube diameter: Using a small tube diameter makes the heat exchanger both economical and compact. However, it is more likely for the heat exchanger to foul up faster and the small size makes mechanical cleaning of the fouling difficult. To prevail over the fouling and cleaning problems, larger tube diameters can be used. Thus to determine the tube diameter, the available space, cost and fouling nature of the fluids must be considered.

* Tube thickness: The thickness of the wall of the tubes is usually determined to ensure:

** There is enough room for corrosion

** That flow-induced vibration has resistance

** Axial strength

** Availability of spare parts

** Hoop strength (to withstand internal tube pressure)

** Buckling strength (to withstand overpressure in the shell)

* Tube length: heat exchangers are usually cheaper when they have a smaller shell diameter and a long tube length. Thus, typically there is an aim to make the heat exchanger as long as physically possible whilst not exceeding production capabilities. However, there are many limitations for this, including space available at the installation site and the need to ensure tubes are available in lengths that are twice the required length (so they can be withdrawn and replaced). Also, long, thin tubes are difficult to take out and replace.

* Tube pitch: when designing the tubes, it is practical to ensure that the tube pitch (i.e., the centre-centre distance of adjoining tubes) is not less than 1.25 times the tubes' outside diameter. A larger tube pitch leads to a larger overall shell diameter, which leads to a more expensive heat exchanger.

* Tube corrugation: this type of tubes, mainly used for the inner tubes, increases the turbulence of the fluids and the effect is very important in the heat transfer giving a better performance.

* Tube Layout: refers to how tubes are positioned within the shell. There are four main types of tube layout, which are, triangular (30°), rotated triangular (60°), square (90°) and rotated square (45°). The triangular patterns are employed to give greater heat transfer as they force the fluid to flow in a more turbulent fashion around the piping. Square patterns are employed where high fouling is experienced and cleaning is more regular.

* Baffle Design:

baffles are used in shell and tube heat exchangers to direct fluid across the tube bundle. They run perpendicularly to the shell and hold the bundle, preventing the tubes from sagging over a long length. They can also prevent the tubes from vibrating. The most common type of baffle is the segmental baffle. The semicircular segmental baffles are oriented at 180 degrees to the adjacent baffles forcing the fluid to flow upward and downwards between the tube bundle. Baffle spacing is of large thermodynamic concern when designing shell and tube heat exchangers. Baffles must be spaced with consideration for the conversion of pressure drop and heat transfer. For thermo economic optimization it is suggested that the baffles be spaced no closer than 20% of the shell's inner diameter. Having baffles spaced too closely causes a greater pressure drop because of flow redirection. Consequently, having the baffles spaced too far apart means that there may be cooler spots in the corners between baffles. It is also important to ensure the baffles are spaced close enough that the tubes do not sag. The other main type of baffle is the disc and doughnut baffle, which consists of two concentric baffles. An outer, wider baffle looks like a doughnut, whilst the inner baffle is shaped like a disk. This type of baffle forces the fluid to pass around each side of the disk then through the doughnut baffle generating a different type of fluid flow.

*Tubes & fins Design: in application to cool air with shell-and-tube technology (such as

intercooler /

charge air cooler

An intercooler is a heat exchanger used to cool a gas after compression. Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines.

Internal combustion engines

Most ...

for

combustion engines), the difference in heat transfer between air and cold fluid can be such that there is a need to increase heat transfer area on air side. For this function fins can be added on the tubes to increase heat transfer area on air side and create a tubes & fins configuration.

Fixed tube liquid-cooled heat exchangers especially suitable for marine and harsh applications can be assembled with brass shells, copper tubes, brass baffles, and forged brass integral end hubs. ''(See:

Copper in heat exchangers).''

Plate heat exchangers

Another type of heat exchanger is the

plate heat exchanger A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fl ...

. These exchangers are composed of many thin, slightly separated plates that have very large surface areas and small fluid flow passages for heat transfer. Advances in

gasket

Some seals and gaskets

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to c ...

and

brazing

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

Brazing differs from we ...

technology have made the plate-type heat exchanger increasingly practical. In

HVAC applications, large heat exchangers of this type are called ''plate-and-frame''; when used in open loops, these heat exchangers are normally of the gasket type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently bonded plate heat exchangers, such as dip-brazed, vacuum-brazed, and welded plate varieties, and they are often specified for closed-loop applications such as

refrigeration

The term refrigeration refers to the process of removing heat from an enclosed space or substance for the purpose of lowering the temperature.International Dictionary of Refrigeration, http://dictionary.iifiir.org/search.phpASHRAE Terminology, ht ...

. Plate heat exchangers also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with "chevron", dimpled, or other patterns, where others may have machined fins and/or grooves.

When compared to shell and tube exchangers, the stacked-plate arrangement typically has lower volume and cost. Another difference between the two is that plate exchangers typically serve low to medium pressure fluids, compared to medium and high pressures of shell and tube. A third and important difference is that plate exchangers employ more countercurrent flow rather than cross current flow, which allows lower approach temperature differences, high temperature changes, and increased efficiencies.

Plate and shell heat exchanger

A third type of heat exchanger is a plate and shell heat exchanger, which combines plate heat exchanger with shell and tube heat exchanger technologies. The heart of the heat exchanger contains a fully welded circular plate pack made by pressing and cutting round plates and welding them together. Nozzles carry flow in and out of the platepack (the 'Plate side' flowpath). The fully welded platepack is assembled into an outer shell that creates a second flowpath ( the 'Shell side'). Plate and shell technology offers high heat transfer, high pressure, high

operating temperature, compact size, low fouling and close approach temperature. In particular, it does completely without gaskets, which provides security against leakage at high pressures and temperatures.

Adiabatic wheel heat exchanger

A fourth type of heat exchanger uses an intermediate fluid or solid store to hold heat, which is then moved to the other side of the heat exchanger to be released. Two examples of this are adiabatic wheels, which consist of a large wheel with fine threads rotating through the hot and cold fluids, and fluid heat exchangers.

Plate fin heat exchanger

This type of heat exchanger uses "sandwiched" passages containing fins to increase the effectiveness of the unit. The designs include crossflow and counterflow coupled with various fin configurations such as straight fins, offset fins and wavy fins.

Plate and fin heat exchangers are usually made of aluminum alloys, which provide high heat transfer efficiency. The material enables the system to operate at a lower temperature difference and reduce the weight of the equipment. Plate and fin heat exchangers are mostly used for low temperature services such as natural gas,

helium

Helium (from el, ἥλιος, helios, lit=sun) is a chemical element with the symbol He and atomic number 2. It is a colorless, odorless, tasteless, non-toxic, inert, monatomic gas and the first in the noble gas group in the periodic table. ...

and

oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

liquefaction plants, air separation plants and transport industries such as motor and

aircraft engines.

Advantages of plate and fin heat exchangers:

* High heat transfer efficiency especially in gas treatment

* Larger heat transfer area

* Approximately 5 times lighter in weight than that of shell and tube heat exchanger.

* Able to withstand high pressure

Disadvantages of plate and fin heat exchangers:

* Might cause clogging as the pathways are very narrow

* Difficult to clean the pathways

* Aluminium alloys are susceptible to

Mercury Liquid Embrittlement Failure

Finned tube heat exchanger

The usage of fins in a tube-based heat exchanger is common when one of the working fluids is a low-pressure gas, and is typical for heat exchangers that operate using ambient air, such as automotive

radiators

Radiators are heat exchangers used to transfer thermal energy from one medium to another for the purpose of cooling and heating. The majority of radiators are constructed to function in cars, buildings, and electronics.

A radiator is always a ...

and

HVAC air

condensers. Fins dramatically increase the surface area with which heat can be exchanged, which improves the efficiency of conducting heat to a fluid with very low

thermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

, such as air. The fins are typically made from aluminium or copper since they must conduct heat from the tube along the length of the fins, which are usually very thin.

The main construction types of finned tube exchangers are:

* A stack of evenly-spaced metal plates act as the fins and the tubes are pressed through pre-cut holes in the fins, good thermal contact usually being achieved by deformation of the fins around the tube. This is typical construction for

HVAC air coils and large

refrigeration

The term refrigeration refers to the process of removing heat from an enclosed space or substance for the purpose of lowering the temperature.International Dictionary of Refrigeration, http://dictionary.iifiir.org/search.phpASHRAE Terminology, ht ...

condensers.

* Fins are spiral-wound onto individual tubes as a continuous strip, the tubes can then be assembled in banks, bent in a serpentine pattern, or wound into large spirals.

* Zig-zag metal strips are sandwiched between flat rectangular tubes, often being

solder

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable ...

ed or

brazed together for good thermal and mechanical strength. This is common in low-pressure heat exchangers such as water-cooling

radiators

Radiators are heat exchangers used to transfer thermal energy from one medium to another for the purpose of cooling and heating. The majority of radiators are constructed to function in cars, buildings, and electronics.

A radiator is always a ...

. Regular flat tubes will expand and deform if exposed to high pressures but flat

microchannel

Micro Channel architecture, or the Micro Channel bus, is a proprietary 16- or 32-bit parallel computer bus introduced by IBM in 1987 which was used on PS/2 and other computers until the mid-1990s. Its name is commonly abbreviated as "MCA", alth ...

tubes allow this construction to be used for high pressures.

Stacked-fin or spiral-wound construction can be used for the tubes inside shell-and-tube heat exchangers when high efficiency thermal transfer to a gas is required.

In electronics cooling,

heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, th ...

s, particularly those using

heat pipe

A heat pipe is a heat-transfer device that employs phase transition to transfer heat between two solid interfaces.

At the hot interface of a heat pipe, a volatile liquid in contact with a thermally conductive solid surface turns into a vapor b ...

s, can have a stacked-fin construction.

Pillow plate heat exchanger

A

pillow plate heat exchanger is commonly used in the dairy industry for cooling milk in large direct-expansion stainless steel

bulk tank {{no footnotes, date=June 2013

In dairy farming a bulk milk cooling tank is a large storage tank for cooling and holding milk at a cold temperature until it can be picked up by a milk hauler.

The bulk milk cooling tank is an important piece of dai ...

s. Nearly the entire surface area of a tank can be integrated with this heat exchanger, without gaps that would occur between pipes welded to the exterior of the tank. Pillow plates can also be constructed as flat plates that are stacked inside a tank. The relatively flat surface of the plates allows easy cleaning, especially in sterile applications.

The pillow plate can be constructed using either a thin sheet of metal welded to the thicker surface of a tank or vessel, or two thin sheets welded together. The surface of the plate is welded with a regular pattern of dots or a serpentine pattern of weld lines. After welding the enclosed space is pressurised with sufficient force to cause the thin metal to bulge out around the welds, providing a space for heat exchanger liquids to flow, and creating a characteristic appearance of a swelled pillow formed out of metal.

Waste heat recovery units

A

waste heat recovery unit (WHRU) is a heat exchanger that recovers heat from a hot gas stream while transferring it to a working medium, typically water or oils. The hot gas stream can be the exhaust gas from a gas turbine or a diesel engine or a waste gas from industry or refinery.

Large systems with high volume and temperature gas streams, typical in industry, can benefit from steam

Rankine cycle

The Rankine cycle is an idealized thermodynamic cycle describing the process by which certain heat engines, such as steam turbines or reciprocating steam engines, allow mechanical work to be extracted from a fluid as it moves between a heat sourc ...

(SRC) in a waste heat recovery unit, but these cycles are too expensive for small systems. The recovery of heat from low temperature systems requires different working fluids than steam.

An organic Rankine cycle (ORC) waste heat recovery unit can be more efficient at low temperature range using

refrigerants that boil at lower temperatures than water. Typical organic refrigerants are

ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogenous wa ...

,

pentafluoropropane (R-245fa and R-245ca), and

toluene

Toluene (), also known as toluol (), is a substituted aromatic hydrocarbon. It is a colorless, water-insoluble liquid with the smell associated with paint thinners. It is a mono-substituted benzene derivative, consisting of a methyl group (CH3) a ...

.

The refrigerant is boiled by the heat source in the

evaporator

An evaporator is a device used to turn the liquid form of a chemical substance, such as water, into a vapor.

Uses

Air conditioning and refrigeration

Some air conditioners and refrigerators use a compressed liquid with a low boiling point, su ...

to produce super-heated vapor. This fluid is expanded in the turbine to convert thermal energy to kinetic energy, that is converted to electricity in the electrical generator. This energy transfer process decreases the temperature of the refrigerant that, in turn, condenses. The cycle is closed and completed using a pump to send the fluid back to the evaporator.

Dynamic scraped surface heat exchanger

Another type of heat exchanger is called "

(dynamic) scraped surface heat exchanger". This is mainly used for heating or cooling with high-

viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

products,

crystallization processes,

evaporation and high-

fouling

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms ( biofouling) or a non-living substance (inorganic or organic). Fouling is usually distinguished from other sur ...

applications. Long running times are achieved due to the continuous scraping of the surface, thus avoiding fouling and achieving a sustainable heat transfer rate during the process.

Phase-change heat exchangers

In addition to heating up or cooling down fluids in just a single

phase, heat exchangers can be used either to heat a

liquid to evaporate (or boil) it or used as

condensers to cool a

vapor

In physics, a vapor (American English) or vapour (British English and Canadian English; see spelling differences) is a substance in the gas phase at a temperature lower than its critical temperature,R. H. Petrucci, W. S. Harwood, and F. G. Her ...

and

condense

Condensation is the change of the state of matter from the gas phase into the liquid phase, and is the reverse of vaporization. The word most often refers to the water cycle. It can also be defined as the change in the state of water vapor to ...

it to a liquid. In

chemical plants and

refineries,

reboilers used to heat incoming feed for

distillation

Distillation, or classical distillation, is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation, usually inside an apparatus known as a still. Dry distillation is the heat ...

towers are often heat exchangers.

Distillation set-ups typically use condensers to condense distillate vapors back into liquid.

Power plant

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the electricity generation, generation of electric power. Power stations are generally connected to an el ...

s that use

steam-driven

turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating ...

s commonly use heat exchangers to boil

water

Water (chemical formula ) is an Inorganic compound, inorganic, transparent, tasteless, odorless, and Color of water, nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living ...

into

steam. Heat exchangers or similar units for producing steam from water are often called

boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centr ...

s or steam generators.

In the nuclear power plants called

pressurized water reactor

A pressurized water reactor (PWR) is a type of light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants (with notable exceptions being the UK, Japan and Canada). In a PWR, the primary coolant (water) i ...

s, special large heat exchangers pass heat from the primary (reactor plant) system to the secondary (steam plant) system, producing steam from water in the process. These are called

steam generators

A steam generator is a form of low water-content boiler, similar to a flash steam boiler. The usual construction is as a spiral coil of water-tube, arranged as a single, or monotube, coil. Circulation is once-through and pumped under pressure, ...

. All fossil-fueled and nuclear power plants using steam-driven turbines have

surface condenser

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid stat ...

s to convert the exhaust steam from the turbines into condensate (water) for re-use.

To

conserve energy and

cooling capacity

Cooling capacity is the measure of a cooling system's ability to remove heat. It is equivalent to the heat supplied to the evaporator/boiler part of the refrigeration cycle and may be called the "rate of refrigeration" or "refrigeration capacity". ...

in chemical and other plants, regenerative heat exchangers can transfer heat from a stream that must be cooled to another stream that must be heated, such as distillate cooling and reboiler feed pre-heating.

This term can also refer to heat exchangers that contain a material within their structure that has a change of phase. This is usually a solid to liquid phase due to the small volume difference between these states. This change of phase effectively acts as a buffer because it occurs at a constant temperature but still allows for the heat exchanger to accept additional heat. One example where this has been investigated is for use in high power aircraft electronics.

Heat exchangers functioning in multiphase flow regimes may be subject to the

Ledinegg instability.

Direct contact heat exchangers

Direct contact heat exchangers involve heat transfer between hot and cold streams of two phases in the absence of a separating wall. Thus such heat exchangers can be classified as:

* Gas – liquid

*

Immiscible liquid – liquid

* Solid-liquid or solid – gas

Most direct contact heat exchangers fall under the Gas – Liquid category, where heat is transferred between a gas and liquid in the form of drops, films or sprays.

Such types of heat exchangers are used predominantly in

air conditioning

Air conditioning, often abbreviated as A/C or AC, is the process of removing heat from an enclosed space to achieve a more comfortable interior environment (sometimes referred to as 'comfort cooling') and in some cases also strictly controlling ...

,

humidification, industrial hot water heating,

water cooling

Cooling tower and water discharge of a nuclear power plant

Water cooling is a method of heat removal from components and industrial equipment. Evaporative cooling using water is often more efficient than air cooling. Water is inexpensive and non ...

and condensing plants.

Microchannel heat exchangers

Microchannel heat exchangers are multi-pass parallel flow heat exchangers consisting of three main elements: manifolds (inlet and outlet), multi-port tubes with the hydraulic diameters smaller than 1mm, and fins. All the elements usually brazed together using controllable atmosphere brazing process. Microchannel heat exchangers are characterized by high heat transfer ratio, low refrigerant charges, compact size, and lower airside pressure drops compared to finned tube heat exchangers. Microchannel heat exchangers are widely used in automotive industry as the car radiators, and as condenser, evaporator, and cooling/heating coils in HVAC industry.

Micro heat exchangers, Micro-scale heat exchangers, or microstructured heat exchangers are heat exchangers in which (at least one)

fluid flows in lateral confinements with typical dimensions below 1 mm. The most typical such confinement are

microchannels, which are channels with a

hydraulic diameter The hydraulic diameter, , is a commonly used term when handling flow in non-circular tubes and channels. Using this term, one can calculate many things in the same way as for a round tube. When the cross-section is uniform along the tube or channel ...

below 1 mm. Microchannel heat exchangers can be made from metal or ceramics. Microchannel heat exchangers can be used for many applications including:

* high-performance aircraft

gas turbine engines

*

heat pumps

A heat pump is a device that can heat a building (or part of a building) by transferring thermal energy from the outside using a refrigeration cycle. Many heat pumps can also operate in the opposite direction, cooling the building by removing h ...

*

Microprocessor

A microprocessor is a computer processor where the data processing logic and control is included on a single integrated circuit, or a small number of integrated circuits. The microprocessor contains the arithmetic, logic, and control circ ...

and

microchip

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

cooling

Cooling is removal of heat, usually resulting in a lower temperature and/or phase change. Temperature lowering achieved by any other means may also be called cooling.ASHRAE Terminology, https://www.ashrae.org/technical-resources/free-resources/as ...

*

air conditioning

Air conditioning, often abbreviated as A/C or AC, is the process of removing heat from an enclosed space to achieve a more comfortable interior environment (sometimes referred to as 'comfort cooling') and in some cases also strictly controlling ...

HVAC and refrigeration air coils

One of the widest uses of heat exchangers is for refrigeration and

air conditioning

Air conditioning, often abbreviated as A/C or AC, is the process of removing heat from an enclosed space to achieve a more comfortable interior environment (sometimes referred to as 'comfort cooling') and in some cases also strictly controlling ...

. This class of heat exchangers is commonly called ''air coils'', or just ''coils'' due to their often-serpentine internal tubing, or

condensers in the case of

refrigeration

The term refrigeration refers to the process of removing heat from an enclosed space or substance for the purpose of lowering the temperature.International Dictionary of Refrigeration, http://dictionary.iifiir.org/search.phpASHRAE Terminology, ht ...

, and are typically of the finned tube type. Liquid-to-air, or air-to-liquid

HVAC coils are typically of modified crossflow arrangement. In vehicles, heat coils are often called

heater core

A heater core is a radiator-like device used in heating the cabin of a vehicle. Hot coolant from the vehicle's engine is passed through a winding tube of the core, a heat exchanger between coolant and cabin air. Fins attached to the core tubes ser ...

s.

On the liquid side of these heat exchangers, the common fluids are water, a water-glycol solution, steam, or a

refrigerant. For ''heating coils'', hot water and steam are the most common, and this heated fluid is supplied by

boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centr ...

s, for example. For ''cooling coils'', chilled water and refrigerant are most common. Chilled water is supplied from a

chiller

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another p ...

that is potentially located very far away, but refrigerant must come from a nearby condensing unit. When a refrigerant is used, the cooling coil is the

evaporator

An evaporator is a device used to turn the liquid form of a chemical substance, such as water, into a vapor.

Uses

Air conditioning and refrigeration

Some air conditioners and refrigerators use a compressed liquid with a low boiling point, su ...

, and the heating coil is the

condenser in the

vapor-compression refrigeration

Vapour-compression refrigeration or vapor-compression refrigeration system (VCRS), in which the refrigerant undergoes phase changes, is one of the many refrigeration cycles and is the most widely used method for air conditioning of buildings ...

cycle. HVAC coils that use this direct-expansion of refrigerants are commonly called ''DX coils''. Some ''DX coils'' are "microchannel" type.

On the air side of HVAC coils a significant difference exists between those used for heating, and those for cooling. Due to

psychrometrics

Psychrometrics (or psychrometry, ; also called hygrometry) is the field of engineering concerned with the physical and thermodynamic properties of gas-vapor mixtures.

Common applications

Although the principles of psychrometry apply to any ...

, air that is cooled often has moisture condensing out of it, except with extremely dry air flows. Heating some air increases that airflow's capacity to hold water. So heating coils need not consider moisture condensation on their air-side, but cooling coils ''must'' be adequately designed and selected to handle their particular ''latent'' (moisture) as well as the ''sensible'' (cooling) loads. The water that is removed is called ''condensate''.

For many climates, water or steam HVAC coils can be exposed to freezing conditions. Because water expands upon freezing, these somewhat expensive and difficult to replace thin-walled heat exchangers can easily be damaged or destroyed by just one freeze. As such, freeze protection of coils is a major concern of HVAC designers, installers, and operators.

The introduction of indentations placed within the heat exchange fins controlled condensation, allowing water molecules to remain in the cooled air.

The heat exchangers in direct-combustion

furnaces, typical in many residences, are not 'coils'. They are, instead, gas-to-air heat exchangers that are typically made of stamped steel sheet metal. The combustion products pass on one side of these heat exchangers, and air to heat on the other. A ''cracked heat exchanger'' is therefore a dangerous situation that requires immediate attention because combustion products may enter living space.

Helical-coil heat exchangers

Although double-pipe heat exchangers are the simplest to design, the better choice in the following cases would be the helical-coil heat exchanger (HCHE):

* The main advantage of the HCHE, like that for the Spiral heat exchanger (SHE), is its highly efficient use of space, especially when it's limited and not enough straight pipe can be laid.

* Under conditions of low flowrates (or

laminar flow), such that the typical shell-and-tube exchangers have low heat-transfer coefficients and becoming uneconomical.

* When there is low pressure in one of the fluids, usually from accumulated pressure drops in other process equipment.

* When one of the fluids has components in multiple phases (solids, liquids, and gases), which tends to create mechanical problems during operations, such as plugging of small-diameter tubes.

Cleaning of helical coils for these multiple-phase fluids can prove to be more difficult than its shell and tube counterpart; however the helical coil unit would require cleaning less often.

These have been used in the nuclear industry as a method for exchanging heat in a

sodium system for large

liquid metal fast breeder reactor

A liquid metal cooled nuclear reactor, liquid metal fast reactor or LMFR is an advanced type of nuclear reactor where the primary coolant is a liquid metal. Liquid metal cooled reactors were first adapted for nuclear submarine use and have been s ...

s since the early 1970s, using an HCHE device invented by

Charles E. Boardman and

John H. Germer. There are several simple methods for designing HCHE for all types of manufacturing industries, such as using the

Ramachandra K. Patil (et al.) method from

India

India, officially the Republic of India (Hindi: ), is a country in South Asia. It is the seventh-largest country by area, the second-most populous country, and the most populous democracy in the world. Bounded by the Indian Ocean on the so ...

and the

Scott S. Haraburda method from the

United States

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country primarily located in North America. It consists of 50 states, a federal district, five major unincorporated territori ...

.

However, these are based upon assumptions of estimating inside heat transfer coefficient, predicting flow around the outside of the coil, and upon constant heat flux.

Spiral heat exchangers

A modification to the perpendicular flow of the typical HCHE involves the replacement of shell with another coiled tube, allowing the two fluids to flow parallel to one another, and which requires the use of different design calculations. These are the

Spiral Heat Exchangers (SHE), which may refer to a

helical

Helical may refer to:

* Helix, the mathematical concept for the shape

* Helical engine, a proposed spacecraft propulsion drive

* Helical spring, a coilspring

* Helical plc, a British property company, once a maker of steel bar stock

* Helicoil

A t ...

(coiled) tube configuration, more generally, the term refers to a pair of flat surfaces that are coiled to form the two channels in a counter-flow arrangement. Each of the two channels has one long curved path. A pair of fluid ports are connected

tangent

In geometry, the tangent line (or simply tangent) to a plane curve at a given point is the straight line that "just touches" the curve at that point. Leibniz defined it as the line through a pair of infinitely close points on the curve. Mo ...

ially to the outer arms of the spiral, and axial ports are common, but optional.

The main advantage of the SHE is its highly efficient use of space. This attribute is often leveraged and partially reallocated to gain other improvements in performance, according to well known tradeoffs in heat exchanger design. (A notable tradeoff is capital cost vs operating cost.) A compact SHE may be used to have a smaller footprint and thus lower all-around capital costs, or an oversized SHE may be used to have less

pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

drop, less pumping

energy

In physics, energy (from Ancient Greek: ἐνέργεια, ''enérgeia'', “activity”) is the quantitative property that is transferred to a body or to a physical system, recognizable in the performance of work and in the form of hea ...

, higher

thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For a ...

, and lower energy costs.

Construction

The distance between the sheets in the spiral channels is maintained by using spacer studs that were welded prior to rolling. Once the main spiral pack has been rolled, alternate top and bottom edges are welded and each end closed by a gasketed flat or conical cover bolted to the body. This ensures no mixing of the two fluids occurs. Any leakage is from the periphery cover to the atmosphere, or to a passage that contains the same fluid.

Self cleaning

Spiral heat exchangers are often used in the heating of fluids that contain solids and thus tend to foul the inside of the heat exchanger. The low pressure drop lets the SHE handle fouling more easily. The SHE uses a “self cleaning” mechanism, whereby fouled surfaces cause a localized increase in fluid velocity, thus increasing the

drag (or fluid

friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of ...

) on the fouled surface, thus helping to dislodge the blockage and keep the heat exchanger clean. "The internal walls that make up the heat transfer surface are often rather thick, which makes the SHE very robust, and able to last a long time in demanding environments."

They are also easily cleaned, opening out like an

oven where any buildup of foulant can be removed by

pressure washing

Pressure washing or power washing is the use of high-pressure water spray to remove loose paint, mold, grime, dust, mud, and dirt from surfaces and objects such as buildings, vehicles and concrete surfaces. The volume of a mechanical pressure w ...

.

Self-cleaning water filters are used to keep the system clean and running without the need to shut down or replace cartridges and bags.

Flow arrangements

There are three main types of flows in a spiral heat exchanger:

* Counter-current Flow: Fluids flow in opposite directions. These are used for liquid-liquid, condensing and gas cooling applications. Units are usually mounted vertically when condensing vapour and mounted horizontally when handling high concentrations of solids.

* Spiral Flow/Cross Flow: One fluid is in spiral flow and the other in a cross flow. Spiral flow passages are welded at each side for this type of spiral heat exchanger. This type of flow is suitable for handling low density gas, which passes through the cross flow, avoiding pressure loss. It can be used for liquid-liquid applications if one liquid has a considerably greater flow rate than the other.

* Distributed Vapour/Spiral flow: This design is that of a condenser, and is usually mounted vertically. It is designed to cater for the sub-cooling of both condensate and non-condensables. The coolant moves in a spiral and leaves via the top. Hot gases that enter leave as condensate via the bottom outlet.

Applications

The Spiral heat exchanger is good for applications such as pasteurization, digester heating, heat recovery, pre-heating (see:

recuperator

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat. ...

), and effluent cooling. For sludge treatment, SHEs are generally smaller than other types of heat exchangers. These are used to transfer the heat.

Selection

Due to the many variables involved, selecting optimal heat exchangers is challenging. Hand calculations are possible, but many iterations are typically needed. As such, heat exchangers are most often selected via computer programs, either by system designers, who are typically

engineer

Engineers, as practitioners of engineering, are professionals who invent, design, analyze, build and test machines, complex systems, structures, gadgets and materials to fulfill functional objectives and requirements while considering the limit ...

s, or by equipment vendors.

To select an appropriate heat exchanger, the system designers (or equipment vendors) would firstly consider the design limitations for each heat exchanger type.

Though cost is often the primary criterion, several other selection criteria are important:

* High/low pressure limits

* Thermal performance

* Temperature ranges

* Product mix (liquid/liquid, particulates or high-solids liquid)

* Pressure drops across the exchanger

* Fluid flow capacity

* Cleanability, maintenance and repair

* Materials required for construction

* Ability and ease of future expansion

* Material selection, such as

copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

,

aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

,

carbon steel,

stainless steel,

nickel alloys

This is a list of named alloys grouped alphabetically by base metal. Within these headings, the alloys are also grouped alphabetically. Some of the main alloying elements are optionally listed after the alloy names.

Alloys by base metal

Alumini ...

,

ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain ...

,

polymer

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

, and

titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

.

Small-diameter coil technologies are becoming more popular in modern air conditioning and refrigeration systems because they have better rates of heat transfer than conventional sized condenser and evaporator coils with round copper tubes and aluminum or copper fin that have been the standard in the HVAC industry. Small diameter coils can withstand the higher pressures required by the new generation of environmentally friendlier refrigerants. Two small diameter coil technologies are currently available for air conditioning and refrigeration products:

copper microgroove and brazed aluminum microchannel.

Choosing the right heat exchanger (HX) requires some knowledge of the different heat exchanger types, as well as the environment where the unit must operate. Typically in the manufacturing industry, several differing types of heat exchangers are used for just one process or system to derive the final product. For example, a kettle HX for pre-heating, a double pipe HX for the ‘carrier’ fluid and a plate and frame HX for final cooling. With sufficient knowledge of heat exchanger types and operating requirements, an appropriate selection can be made to optimise the process.

Monitoring and maintenance

Online monitoring of commercial heat exchangers is done by tracking the overall heat transfer coefficient. The overall heat transfer coefficient tends to decline over time due to fouling.

By periodically calculating the overall heat transfer coefficient from exchanger flow rates and temperatures, the owner of the heat exchanger can estimate when cleaning the heat exchanger is economically attractive.

Integrity inspection of plate and tubular heat exchanger can be tested in situ by the conductivity or helium gas methods. These methods confirm the integrity of the plates or tubes to prevent any cross contamination and the condition of the gaskets.

Mechanical integrity monitoring of heat exchanger

tubes

Tube or tubes may refer to:

* ''Tube'' (2003 film), a 2003 Korean film

* ''The Tube'' (TV series), a music related TV series by Channel 4 in the United Kingdom

* "Tubes" (Peter Dale), performer on the Soccer AM television show

* Tube (band), a ...

may be conducted through

Nondestructive methods such as

eddy current

Eddy currents (also called Foucault's currents) are loops of electrical current induced within conductors by a changing magnetic field in the conductor according to Faraday's law of induction or by the relative motion of a conductor in a magnet ...

testing.

Fouling

Fouling

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms ( biofouling) or a non-living substance (inorganic or organic). Fouling is usually distinguished from other sur ...

occurs when impurities deposit on the heat exchange surface.

Deposition of these

impurities can decrease heat transfer effectiveness significantly over time and are caused by:

* Low wall shear stress

* Low fluid velocities

* High fluid velocities

* Reaction product solid precipitation

* Precipitation of dissolved impurities due to elevated wall temperatures

The rate of heat exchanger fouling is determined by the rate of particle deposition less re-entrainment/suppression. This model was originally proposed in 1959 by Kern and Seaton.

Crude Oil Exchanger Fouling. In commercial crude oil refining, crude oil is heated from to prior to entering the distillation column. A series of shell and tube heat exchangers typically exchange heat between crude oil and other oil streams to heat the crude to prior to heating in a furnace. Fouling occurs on the crude side of these exchangers due to asphaltene insolubility. The nature of asphaltene solubility in crude oil was successfully modeled by Wiehe and Kennedy. The precipitation of insoluble asphaltenes in crude preheat trains has been successfully modeled as a first order reaction by Ebert and Panchal who expanded on the work of Kern and Seaton.

Cooling Water Fouling.

Cooling water systems are susceptible to fouling. Cooling water typically has a high total dissolved solids content and suspended colloidal solids. Localized precipitation of dissolved solids occurs at the heat exchange surface due to wall temperatures higher than bulk fluid temperature. Low fluid velocities (less than 3 ft/s) allow suspended solids to settle on the heat exchange surface. Cooling water is typically on the tube side of a shell and tube exchanger because it's easy to clean. To prevent fouling, designers typically ensure that cooling water velocity is greater than and bulk fluid temperature is maintained less than . Other approaches to control fouling control combine the "blind" application of

biocides and anti-scale chemicals with periodic lab testing.

Maintenance

Plate and frame heat exchangers can be disassembled and cleaned periodically. Tubular heat exchangers can be cleaned by such methods as acid cleaning,

sandblasting

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove s ...

,

high-pressure water jet, bullet cleaning, or drill rods.

In large-scale cooling water systems for heat exchangers,

water treatment

Water treatment is any process that improves the quality of water to make it appropriate for a specific end-use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, inc ...

such as purification, addition of

chemical

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., w ...

s, and testing, is used to minimize fouling of the heat exchange equipment. Other water treatment is also used in steam systems for power plants, etc. to minimize fouling and corrosion of the heat exchange and other equipment.

A variety of companies have started using water borne oscillations technology to prevent

biofouling

Biofouling or biological fouling is the accumulation of microorganisms, plants, algae, or small animals where it is not wanted on surfaces such as ship and submarine hulls, devices such as water inlets, pipework, grates, ponds, and rivers that ...

. Without the use of chemicals, this type of technology has helped in providing a low-pressure drop in heat exchangers.

Design and manufacturing regulations

The design and manufacturing of heat exchangers has numerous regulations, which vary according to the region in which they will be used.

Design and manufacturing codes include:

ASME Boiler and Pressure Vessel Code

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

(US);

PD 5500 (UK); BS 1566 (UK);

EN 13445 (EU); CODAP (French); Pressure Equipment Safety Regulations 2016 (PER) (UK);

Pressure Equipment Directive (EU); NORSOK (Norwegian);

TEMA

Tema is a city on the Bight of Benin and Atlantic coast of Ghana. It is located east of the capital city; Accra, in the region of Greater Accra, and is the capital of the Tema Metropolitan District. As of 2013, Tema is the eleventh most populo ...

; API 12; and API 560.

In nature

Humans

The human nasal passages serve as a heat exchanger, with cool air being inhaled and warm air being exhaled. Its effectiveness can be demonstrated by putting the hand in front of the face and exhaling, first through the nose and then through the mouth. Air exhaled through the nose is substantially cooler. This effect can be enhanced with clothing, by, for example, wearing a scarf over the face while breathing in cold weather.

In species that have external testes (such as human), the artery to the testis is surrounded by a mesh of veins called the

pampiniform plexus

The pampiniform plexus (from Latin ''pampinus'', a tendril, + ''forma'', form) is a venous plexus – a network of many small veins found in the human male spermatic cord, and the suspensory ligament of the ovary. In the male, it is formed by th ...

. This cools the blood heading to the testes, while reheating the returning blood.

Birds, fish, marine mammals

"

Countercurrent" heat exchangers occur naturally in the circulation system of

fish

Fish are aquatic, craniate, gill-bearing animals that lack limbs with digits. Included in this definition are the living hagfish, lampreys, and cartilaginous and bony fish as well as various extinct related groups. Approximately 95% of ...

,

whale

Whales are a widely distributed and diverse group of fully aquatic placental marine mammals. As an informal and colloquial grouping, they correspond to large members of the infraorder Cetacea, i.e. all cetaceans apart from dolphins and ...

s and other

marine mammals. Arteries to the skin carrying warm blood are intertwined with veins from the skin carrying cold blood, causing the warm arterial blood to exchange heat with the cold venous blood. This reduces the overall heat loss in cold water. Heat exchangers are also present in the tongue of

baleen whales as large volume of water flow through their mouths. Wading birds use a similar system to limit heat losses from their body through their legs into the water.

Carotid rete

The carotid rete is a counter-current heat exchanging organ in some

ungulate

Ungulates ( ) are members of the diverse clade Ungulata which primarily consists of large mammals with hooves. These include odd-toed ungulates such as horses, rhinoceroses, and tapirs; and even-toed ungulates such as cattle, pigs, giraffes, ...

s. The blood ascending the

carotid arteries

In anatomy, the left and right common carotid arteries (carotids) (Entry "carotid"

in

Thomson's gazelle

Thomson's gazelle (''Eudorcas thomsonii'') is one of the best known species of gazelles. It is named after explorer Joseph Thomson and is sometimes referred to as a "tommie". It is considered by some to be a subspecies of the red-fronted gazell ...

to maintain its brain almost 3 °C (5.4 °F) cooler than the rest of the body, and therefore aids in tolerating bursts in metabolic heat production such as associated with outrunning

cheetah

The cheetah (''Acinonyx jubatus'') is a large cat native to Africa and central Iran. It is the fastest land animal, estimated to be capable of running at with the fastest reliably recorded speeds being , and as such has evolved specialized ...

s (during which the body temperature exceeds the maximum temperature at which the brain could function).

In industry

Heat exchangers are widely used in industry both for cooling and heating large scale industrial processes. The type and size of heat exchanger used can be tailored to suit a process depending on the type of fluid, its phase, temperature, density, viscosity, pressures, chemical composition and various other thermodynamic properties.

In many industrial processes there is waste of energy or a heat stream that is being exhausted, heat exchangers can be used to recover this heat and put it to use by heating a different stream in the process. This practice saves a lot of money in industry, as the heat supplied to other streams from the heat exchangers would otherwise come from an external source that is more expensive and more harmful to the environment.

Heat exchangers are used in many industries, including:

*

Waste water treatment

*

Refrigeration

The term refrigeration refers to the process of removing heat from an enclosed space or substance for the purpose of lowering the temperature.International Dictionary of Refrigeration, http://dictionary.iifiir.org/search.phpASHRAE Terminology, ht ...

*

Wine

Wine is an alcoholic drink typically made from fermented grapes. Yeast consumes the sugar in the grapes and converts it to ethanol and carbon dioxide, releasing heat in the process. Different varieties of grapes and strains of yeasts are m ...

and

beer

Beer is one of the oldest and the most widely consumed type of alcoholic drink in the world, and the third most popular drink overall after water and tea. It is produced by the brewing and fermentation of starches, mainly derived from ce ...

making

*

Petroleum refining

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefi ...

*

Nuclear power

Nuclear power is the use of nuclear reactions to produce electricity. Nuclear power can be obtained from nuclear fission, nuclear decay and nuclear fusion reactions. Presently, the vast majority of electricity from nuclear power is produced ...

In waste water treatment, heat exchangers play a vital role in maintaining optimal temperatures within

anaerobic digester

Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen. The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermen ...

s to promote the growth of microbes that remove pollutants. Common types of heat exchangers used in this application are the double pipe heat exchanger as well as the plate and frame heat exchanger.

In aircraft

In commercial aircraft heat exchangers are used to take heat from the engine's oil system to heat cold fuel. This improves fuel efficiency, as well as reduces the possibility of water entrapped in the fuel freezing in components.

Current market and forecast

Estimated at US$17.5 billion in 2021, the global demand of heat exchangers is expected to experience robust growth of about 5% annually over the next years. The market value is expected to reach US$27 billion by 2030. With an expanding desire for environmentally friendly options and increased development of offices, retail sectors, and public buildings, market expansion is due to grow.

A model of a simple heat exchanger

A simple heat exchange

might be thought of as two straight pipes with fluid flow, which are thermally connected. Let the pipes be of equal length ''L'', carrying fluids with

heat capacity

Heat capacity or thermal capacity is a physical property of matter, defined as the amount of heat to be supplied to an object to produce a unit change in its temperature. The SI unit of heat capacity is joule per kelvin (J/K).

Heat capacity ...

(energy per unit mass per unit change in temperature) and let the mass flow rate of the fluids through the pipes, both in the same direction, be

(mass per unit time), where the subscript ''i'' applies to pipe 1 or pipe 2.

Temperature profiles for the pipes are

and

where ''x'' is the distance along the pipe. Assume a steady state, so that the temperature profiles are not functions of time. Assume also that the only transfer of heat from a small volume of fluid in one pipe is to the fluid element in the other pipe at the same position, i.e., there is no transfer of heat along a pipe due to temperature differences in that pipe. By

Newton's law of cooling

In the study of heat transfer, Newton's law of cooling is a physical law which states that

The rate of heat loss of a body is directly proportional to the difference in the temperatures between the body and its environment.

The law is frequently q ...

the rate of change in energy of a small volume of fluid is proportional to the difference in temperatures between it and the corresponding element in the other pipe:

:

:

( this is for parallel flow in the same direction and opposite temperature gradients, but for counter-flow heat exchange

countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each ...

the sign is opposite in the second equation in front of

), where

is the thermal energy per unit length and γ is the thermal connection constant per unit length between the two pipes. This change in internal energy results in a change in the temperature of the fluid element. The time rate of change for the fluid element being carried along by the flow is:

:

:

where

is the "thermal mass flow rate". The differential equations governing the heat exchanger may now be written as:

:

:

Note that, since the system is in a steady state, there are no partial derivatives of temperature with respect to time, and since there is no heat transfer along the pipe, there are no second derivatives in ''x'' as is found in the

heat equation. These two coupled first-order

differential equation

In mathematics, a differential equation is an equation that relates one or more unknown functions and their derivatives. In applications, the functions generally represent physical quantities, the derivatives represent their rates of change, an ...

s may be solved to yield:

:

:

where

,

,

:

(this is for parallel-flow, but for counter-flow the sign in front of

is negative, so that if

, for the same "thermal mass flow rate" in both opposite directions, the gradient of temperature is constant and the temperatures linear in position ''x'' with a constant difference

along the exchanger, explaining why the counter current design

countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each ...

is the most efficient )

and ''A'' and ''B'' are two as yet undetermined constants of integration. Let

and

be the temperatures at x=0 and let

and

be the temperatures at the end of the pipe at x=L. Define the average temperatures in each pipe as:

:

:

Using the solutions above, these temperatures are:

::

Choosing any two of the temperatures above eliminates the constants of integration, letting us find the other four temperatures. We find the total energy transferred by integrating the expressions for the time rate of change of internal energy per unit length:

:

:

By the conservation of energy, the sum of the two energies is zero. The quantity

is known as the ''

Log mean temperature difference'', and is a measure of the effectiveness of the heat exchanger in transferring heat energy.

See also

*

Architectural engineering

Architectural engineers apply and theoretical knowledge to the engineering design of buildings and building systems. The goal is to engineer high performance buildings that are sustainable, economically viable and ensure the safety health.

Archi ...

*

Chemical engineering

Chemical engineering is an engineering field which deals with the study of operation and design of chemical plants as well as methods of improving production. Chemical engineers develop economical commercial processes to convert raw materials int ...

*

Cooling tower

A cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat an ...

*

Copper in heat exchangers

*

Heat pipe

A heat pipe is a heat-transfer device that employs phase transition to transfer heat between two solid interfaces.

At the hot interface of a heat pipe, a volatile liquid in contact with a thermally conductive solid surface turns into a vapor b ...

*

Heat pump

A heat pump is a device that can heat a building (or part of a building) by transferring thermal energy from the outside using a refrigeration cycle. Many heat pumps can also operate in the opposite direction, cooling the building by removing ...

*

Heat recovery ventilation

Heat recovery ventilation (HRV), also known as mechanical ventilation heat recovery (MVHR), is an energy recovery ventilation system which works between two air sources at different temperatures. Heat recovery is a method which is used to reduce ...

*

Jacketed vessel

*

Log mean temperature difference (LMTD)

*

Marine heat exchangers

*

Mechanical engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, an ...

*

Micro heat exchanger

*