Food packaging on:

[Wikipedia]

[Google]

[Amazon]

Food packaging is a packaging system specifically designed for food and represents one of the most important aspects among the processes involved in the food industry, as it provides protection from chemical, biological and physical alterations. The main goal of food packaging is to provide a practical means of protecting and delivering food goods at a reasonable cost while meeting the needs and expectations of both consumers and industries. Additionally, current trends like sustainability, environmental impact reduction, and

Food packaging is a packaging system specifically designed for food and represents one of the most important aspects among the processes involved in the food industry, as it provides protection from chemical, biological and physical alterations. The main goal of food packaging is to provide a practical means of protecting and delivering food goods at a reasonable cost while meeting the needs and expectations of both consumers and industries. Additionally, current trends like sustainability, environmental impact reduction, and

Cake mix in plastic packet photo.JPG, Bagged cake mix

File:Biscuit components.jpg, Biscuit components: plastic bottles, paper bag

File:JNR Vegetable-oil Container.jpg, Container for bulk vegetable oil

File:Freezer (5194456668).jpg, Frozen processed food freezer in supermarket

File:A 4 Litre Cask of Australian White Wine.jpg, Bag in box;

A choice of packaging machinery requires consideration of technical capabilities, labor requirements, worker safety, maintainability, serviceability, reliability, ability to integrate into the packaging line, capital cost, floorspace, flexibility (change-over, materials, etc.), energy usage,

A choice of packaging machinery requires consideration of technical capabilities, labor requirements, worker safety, maintainability, serviceability, reliability, ability to integrate into the packaging line, capital cost, floorspace, flexibility (change-over, materials, etc.), energy usage,

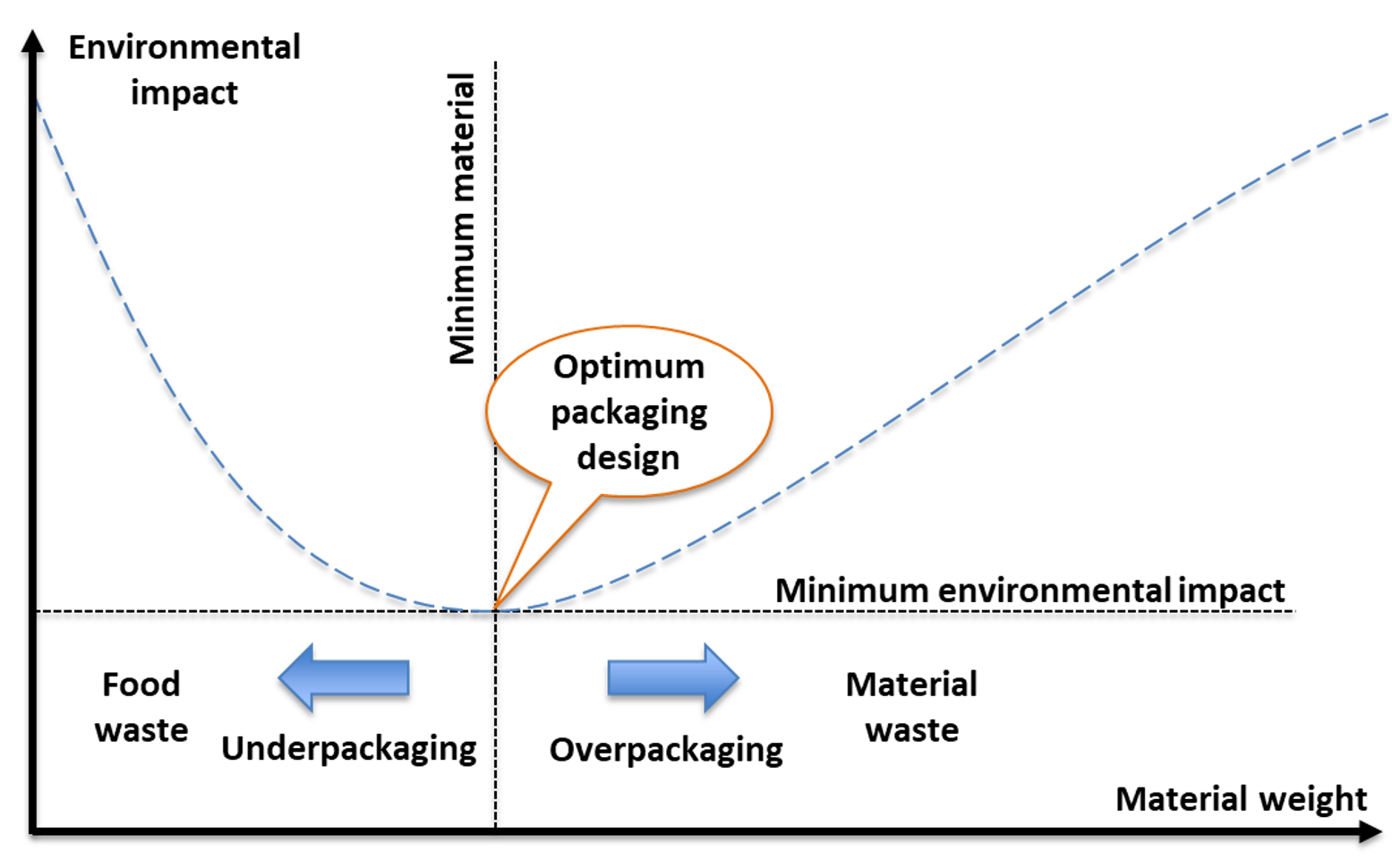

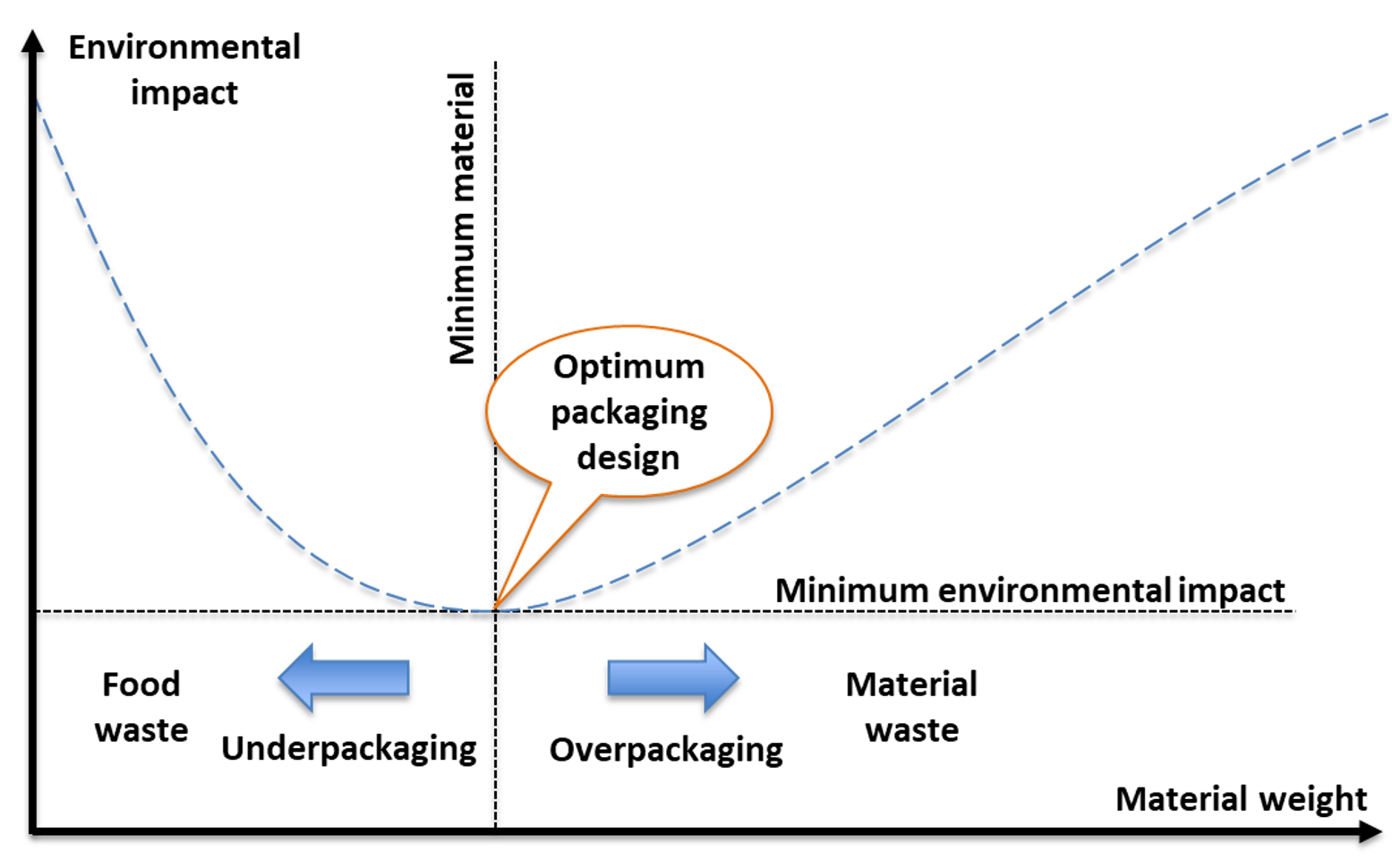

In the last decades, the growing demand from the consumers and governments for more sustainable and eco-friendly packaging design has driven the food industry to re-design and propose alternative packaging solutions. However, in designing a brand new packaging system, several variables need to be taken in consideration. An ideal packaging design should only use the right amount of the appropriate materials to provide the desired performance for a specific product. As shown in the optimum packaging design chart, the variety of situations in which product losses occur increases as the material weight or volume is decreased. Such trend will eventually reach a situation in which the loss outweighs the cost savings from using less packing material. Beyond that point, any packing reduction increases the overall quantity of waste in the system, rendering it a false benefit. The goal of the optimal packaging design is to identify a weight below which the package can no longer be sold since it does not satisfy the specifications, while considering the environmental impact connected to the materials selection.

In the last decades, the growing demand from the consumers and governments for more sustainable and eco-friendly packaging design has driven the food industry to re-design and propose alternative packaging solutions. However, in designing a brand new packaging system, several variables need to be taken in consideration. An ideal packaging design should only use the right amount of the appropriate materials to provide the desired performance for a specific product. As shown in the optimum packaging design chart, the variety of situations in which product losses occur increases as the material weight or volume is decreased. Such trend will eventually reach a situation in which the loss outweighs the cost savings from using less packing material. Beyond that point, any packing reduction increases the overall quantity of waste in the system, rendering it a false benefit. The goal of the optimal packaging design is to identify a weight below which the package can no longer be sold since it does not satisfy the specifications, while considering the environmental impact connected to the materials selection.

The product's quality and safety are the package's most important responsibility. However, there have been growing demands for packaging to be designed, manufactured, consumed, and recycled in a more sustainable fashion due to the increasing pollution connected with packaging and food wastes. It has been estimated that only 10.33% of all municipal solid waste (MSW), which makes up to 30.3% of the total waste, is recycled into new products globally.

However, depending on the level of packaging and the materials that are being used during their manufacturing, the end-of-life of a package may differ completely. Despite the fact that a recycling process is usually the desired path, lots of complications may lead to less sustainable destines.

The oxygen transmission rate of a gas through the packaging is defined as the amount of oxygen permeating per unit of permeable area and unit of time in a packaging system considering standardized test conditions (23 °C and 1 atm partial pressure difference). It is an effective tool to estimate the barrier properties of a certain material. The determination of the OTR is usually carried out by means of a steady-state and isostatic method, reported by the

The oxygen transmission rate of a gas through the packaging is defined as the amount of oxygen permeating per unit of permeable area and unit of time in a packaging system considering standardized test conditions (23 °C and 1 atm partial pressure difference). It is an effective tool to estimate the barrier properties of a certain material. The determination of the OTR is usually carried out by means of a steady-state and isostatic method, reported by the

Concurrently to the oxygen barrier property, the permeability of water vapor through a food packaging system should be minimized to effectively prevent physical and chemical changes connected to an excessive moisture content.The moisture barrier properties of a material can be assessed by measuring the water vapour transmission rate (WVTR), which can be defined as the amount of water vapour per unit of area and unit of time passing through the packaging film.

The WVTR measurements, like the OTR, adhere to the standards for standardized tests as outlined in the ASTM E96 (standard methods for water vapor transmission of materials). An impermeable test dish (such as a stainless steel cup) and a test chamber where temperature and relative humidity (RH) can be adjusted in accordance with the standard specification, make up the basic instrumentation used in such tests.

Although both oxygen and water vapour represent the most studied permeants in food packaging application, other gases such as carbon dioxide (CO2) and nitrogen (N2) have also great relevance in the preservation of food products. In fact, N2 and CO2 have been employed in modified atmosphere packaging (MAP) technology to establish the correct conditions inside the package's headspace to lessen food spoiling.

Concurrently to the oxygen barrier property, the permeability of water vapor through a food packaging system should be minimized to effectively prevent physical and chemical changes connected to an excessive moisture content.The moisture barrier properties of a material can be assessed by measuring the water vapour transmission rate (WVTR), which can be defined as the amount of water vapour per unit of area and unit of time passing through the packaging film.

The WVTR measurements, like the OTR, adhere to the standards for standardized tests as outlined in the ASTM E96 (standard methods for water vapor transmission of materials). An impermeable test dish (such as a stainless steel cup) and a test chamber where temperature and relative humidity (RH) can be adjusted in accordance with the standard specification, make up the basic instrumentation used in such tests.

Although both oxygen and water vapour represent the most studied permeants in food packaging application, other gases such as carbon dioxide (CO2) and nitrogen (N2) have also great relevance in the preservation of food products. In fact, N2 and CO2 have been employed in modified atmosphere packaging (MAP) technology to establish the correct conditions inside the package's headspace to lessen food spoiling.

Poly(hydroxyalkanoates) for Food Packaging:

Application and Attempts towards Implementation {{DEFAULTSORT:Food Packaging Food science Retail packaging

Food packaging is a packaging system specifically designed for food and represents one of the most important aspects among the processes involved in the food industry, as it provides protection from chemical, biological and physical alterations. The main goal of food packaging is to provide a practical means of protecting and delivering food goods at a reasonable cost while meeting the needs and expectations of both consumers and industries. Additionally, current trends like sustainability, environmental impact reduction, and

Food packaging is a packaging system specifically designed for food and represents one of the most important aspects among the processes involved in the food industry, as it provides protection from chemical, biological and physical alterations. The main goal of food packaging is to provide a practical means of protecting and delivering food goods at a reasonable cost while meeting the needs and expectations of both consumers and industries. Additionally, current trends like sustainability, environmental impact reduction, and shelf-life

Shelf life is the length of time that a commodity may be stored without becoming unfit for use, consumption, or sale. In other words, it might refer to whether a commodity should no longer be on a pantry shelf (unfit for use), or no longer on a ...

extension have gradually become among the most important aspects in designing a packaging system.

History

Packaging of food products has seen a vast transformation in technology usage and application from the stone age to the industrial revolution: 7000 BC: The adoption of pottery and glass which saw industrialization around 1500 BC. 1700s: The first manufacturing production of tinplate was introduced in England (1699) and in France (1720). Afterwards, the Dutch navy start to use such packaging to prolong the preservation of food products. 1804: Nicolas Appert, in response to inquiries into extending the shelf life of food for the French Army, employed glass bottles along with thermal food treatment. Glass has been replaced by metal cans in this application. However, there is still an ongoing debate about who first introduced the use of tinplates as food packaging. 1870: The use of paper board was launched and corrugated materials patented. 1880s: First cereal packaged in a folding box by Quaker Oats. 1890s: The crown cap for glass bottles was patented by William Painter. 1960s: Development of the two-piece drawn and wall-ironed metal cans in the US, along with the ring-pull opener and the Tetra Brik Aseptic carton package. 1970s: The barcode system was introduced in the retail and manufacturing industry. PET plastic blow-mold bottle technology, which is widely used in the beverage industry, was introduced. 1990s: The application of digital printing on food packages became widely adopted. Plastic packaging saw its inaugural use duringWorld War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the World War II by country, vast majority of the world's countries—including all of the great power ...

, even though materials employed in its manufacturing (such as cellulose nitrate, styrene and vinyl chloride) were discovered in the 1800s.

Functions

Packaging and package's labeling have several objectives: * Physical protection - The food enclosed in the package may require protection fromshock

Shock may refer to:

Common uses Collective noun

*Shock, a historic commercial term for a group of 60, see English numerals#Special names

* Stook, or shock of grain, stacked sheaves

Healthcare

* Shock (circulatory), circulatory medical emerge ...

, vibration

Vibration is a mechanical phenomenon whereby oscillations occur about an equilibrium point. The word comes from Latin ''vibrationem'' ("shaking, brandishing"). The oscillations may be periodic, such as the motion of a pendulum—or random, su ...

, compression, temperature, bacteria, etc.

* Barrier protection - A barrier from oxygen, water vapor, dust, etc., is often required. Permeation is a critical factor in design. Keeping the contents clean, fresh, and safe for the intended shelf life is a primary function. Modified atmospheres or controlled atmospheres are also maintained in some food packages. Some packages contain desiccants, oxygen absorbers or ethylene absorbers to help extend shelf life.

* Containment or agglomeration - Small items are typically grouped together in one package to allow efficient handling. Liquids, powders, and granular materials need containment.

* Information transmission - Packages and labels communicate how to use, transport, recycle, or dispose of the package or product. Some types of information are required by governments.

* Marketing - The packaging and labels can be used by marketers to encourage potential buyers to purchase the product. Aesthetically pleasing and eye-appealing food presentations can encourage people to consider the contents. Package design has been an important and constantly evolving phenomenon for several decades. Marketing communications and graphic design are applied to the surface of the package and (in many cases) also to the point of sale display. The colour of the package plays a significant role in evoking emotions that persuade the consumer to make the purchase.

* Security - Packaging can play an important role in reducing the security risks of shipment. Packages can be made with improved tamper resistance to deter tampering, and can also have tamper-evident features to help indicate tampering. Packages can be engineered to help reduce the risks of package pilferage; some package constructions are more resistant to pilferage and some have pilfer-indicating seals. Packages may include authentication seals to help indicate that the package and contents are not counterfeit. Packages also can include anti-theft devices, such as dye packs, RFID tags, or electronic article surveillance tags, that can be activated or detected by devices at exit points and require specialized tools to deactivate. Using packaging in this way is a means of retail loss prevention

Retail loss prevention (also known as Retail asset protection) is a set of practices employed by retail companies to preserve profit. Profit preservation is any business activity specifically designed to reduce preventable losses. A preventable ...

.

* Convenience - Packages can have features which add convenience in distribution Distribution may refer to:

Mathematics

* Distribution (mathematics), generalized functions used to formulate solutions of partial differential equations

*Probability distribution, the probability of a particular value or value range of a vari ...

, handling, stacking, display, sale, opening, reclosing, use, and reuse.

* Portion control - Single-serving packaging has a precise amount of contents to control usage. Bulk commodities (such as salt) can be divided into packages that are a more suitable size for individual households. It also aids the control of inventory: selling sealed one-liter bottles of milk, rather than having people bring their own bottles to fill themselves.

Types

Packaging design may vary largely depending on the function that are fashioned into different types of packages and containers, and depending on the food products and their function, such as: Since almost all food products is packed in some fashion, food packaging is both fundamental and pervasive. Additionally, by enabling the creation and standardization of brands, it provides the opportunity to realized significant advertising, extensive distribution, and mass merchandising. Therefore, a distinction between the various type (or level) of packaging needs to be made.Primary packaging

Primary packaging is directly in contact with the food products, creating the ideal headspace for them while providing protection from external alteration. Additionally, primary packaging, also known as retail packaging or consumer units, is responsible for the marketing aspects of food packaging. Typically, the packaging materials used in the primary level include cardboard cartons, plastic trays, glass bottle and multi-layerd structure (Tetra Pak

Tetra Pak is a Swedish–Swiss multinational food packaging and processing company with head offices in Lund, Sweden, and Pully, Switzerland. The company offers packaging, filling machines and processing for dairy, beverages, cheese, ice cre ...

).

Secondary packaging

Secondary packaging contains a number of primary packages into one box being made usually out ofcorrugated cardboard

Corrugated fiberboard or corrugated cardboard is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugate ...

. Thus, the secondary level is a physical distribution carrier for the primary packages, making more easy to handle during the transportation. Occasionally it can be used as an aid in retail outlets or super market for the display of basic goods.

Tertiary packaging

The outermost package, known as tertiary packaging, makes it easier to handle, store, and distribute both primary and secondary packages in bulk safely, providing further protection of the product while creating an easy way to transport large quantities of materials. The most familiar type of tertiary packaging comprises a wrapped pallet of corrugated case.Gallery

box wine

Boxed wine (cask wine) is wine sold in a bag inside a box. The box is made of cardboard or corrugated fiberboard, which supports a plastic bladder filled with wine. The wine flows out from a plastic push-release valve.

History

The process for ...

Dg milk containers.jpg, Glass milk bottle and paperboard milk carton

File:Pyramidal silk tea bag.jpg, Silk tea bag

File:Sacos de café, Casa do Bandeirante 1.JPG, Coffee beans in burlap bags, gunny sacks

File:Boy Scouts Pick Fruit For Jam- Life on a Fruit-picking Camp Near Cambridge, England, UK, 1943 D16205.jpg, Bushel baskets of fruit

File:English breakfast tea tin.jpg, Tea tin, can with removable cover

File:USMC-03767.jpg, Folding cartons of cereal

File:Yoohoo-boxes.jpg, Drink boxes

File:Food and packaging.jpg, Packaged apples

File:HK Westwood Wellcome Shop packaged iced Seafood 烏頭魚 mullet fish April-2012.jpg, Fresh fish in plastic shrink-wrapped tray

File:Boneless Pork Loin Chops-01.jpg, Shrink-wrapped frozen pork

Image:MREsingleveggie.gif, Military MRE

A Meal, Ready-to-Eat (MRE) is a self-contained, individual field ration in lightweight packaging purchased by the United States Department of Defense for its service members for use in combat or field conditions where other food is not availa ...

, bean and rice burrito in retort pouch

A retort pouch or retortable pouch is a type of food packaging made from a laminate of flexible plastic and metal foils. It allows the sterile packaging of a wide variety of food and drink handled by aseptic processing, and is used as an alternativ ...

File:Typical Polish set of spices.jpg, Condiments and spices

Image:Can(Easy Open Can).JPG, Aluminum can

An Aluminum can (British English: Tin can) is a single-use container for packaging made primarily of aluminum.

It is commonly used for food and beverages such as milk and soup but also for products such as oil, chemicals, and other liquids. Gl ...

with an easy-open, full pull-out end

File:Dip & Squeeze ketchup.jpg, A Dip & Squeeze ketchup container

Packaging machines

quality

Quality may refer to:

Concepts

*Quality (business), the ''non-inferiority'' or ''superiority'' of something

*Quality (philosophy), an attribute or a property

*Quality (physics), in response theory

* Energy quality, used in various science discipl ...

of outgoing packages, qualifications (for food, pharmaceuticals, etc.), throughput, efficiency, productivity, and ergonomics

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

, at a minimum.

Packaging machines may be of the following general types:

* Autocoding label and date verification

* Blister

A blister is a small pocket of body fluid ( lymph, serum, plasma, blood, or pus) within the upper layers of the skin, usually caused by forceful rubbing ( friction), burning, freezing, chemical exposure or infection. Most blisters are filled ...

, skin and vacuum packaging machines

* Capping, over-capping, lidding, closing, seaming and sealing machines

* Cartoning machines

A cartoning machine or cartoner, is a packaging machine that forms cartons: erect, close, folded, side seamed and sealed cartons.Control EngineeringAutomation in Packaging Benchmark Study Retrieved 10 May 2010.

Packaging machines which form a car ...

* Case and tray forming, packing, unpacking, closing and sealing Machines

* Check weighing machines

* Cleaning, sterilizing, cooling and drying machines

* Conveying and accumulating machines

* Feeding, orienting, and placing machines

* Filling machines for liquid and powdered products

* Package filling and closing Machines

* Form, fill and seal machines

* Inspecting, detecting and checkweighing machines

* Pallet

A pallet (also called a skid) is a flat transport structure, which supports goods in a stable fashion while being lifted by a forklift, a pallet jack, a front loader, a jacking device, or an erect crane. A pallet is the structural founda ...

izing, depalletizing, and pallet unitizing machines

* Labeling, marking, and other product identification machines

* Wrapping machines

* Converting machines

Reducing food packaging

Reduced packaging and sustainable packaging are becoming more frequent. The motivations can be government regulations, consumer pressure, retailer pressure, and cost control. Reduced packaging often saves packaging costs. In the UK, aLocal Government Association

The Local Government Association (LGA) is the national membership body for local authorities. Its core membership is made up of 339 English councils and the 22 Welsh councils through the Welsh Local Government Association.

The LGA is p ...

survey produced by the British Market Research Bureau compared a range of outlets to buy 29 common food items, and found that small local retailers and market traders "produced less packaging and more that could be recycled than the larger supermarkets

A supermarket is a self-service shop offering a wide variety of food, beverages and household products, organized into sections. This kind of store is larger and has a wider selection than earlier grocery stores, but is smaller and more l ...

."

In the last decades, the growing demand from the consumers and governments for more sustainable and eco-friendly packaging design has driven the food industry to re-design and propose alternative packaging solutions. However, in designing a brand new packaging system, several variables need to be taken in consideration. An ideal packaging design should only use the right amount of the appropriate materials to provide the desired performance for a specific product. As shown in the optimum packaging design chart, the variety of situations in which product losses occur increases as the material weight or volume is decreased. Such trend will eventually reach a situation in which the loss outweighs the cost savings from using less packing material. Beyond that point, any packing reduction increases the overall quantity of waste in the system, rendering it a false benefit. The goal of the optimal packaging design is to identify a weight below which the package can no longer be sold since it does not satisfy the specifications, while considering the environmental impact connected to the materials selection.

In the last decades, the growing demand from the consumers and governments for more sustainable and eco-friendly packaging design has driven the food industry to re-design and propose alternative packaging solutions. However, in designing a brand new packaging system, several variables need to be taken in consideration. An ideal packaging design should only use the right amount of the appropriate materials to provide the desired performance for a specific product. As shown in the optimum packaging design chart, the variety of situations in which product losses occur increases as the material weight or volume is decreased. Such trend will eventually reach a situation in which the loss outweighs the cost savings from using less packing material. Beyond that point, any packing reduction increases the overall quantity of waste in the system, rendering it a false benefit. The goal of the optimal packaging design is to identify a weight below which the package can no longer be sold since it does not satisfy the specifications, while considering the environmental impact connected to the materials selection.

Recycling of food packaging

Food packaging is created through the use of a wide variety of plastics and metals, papers, and glass materials. Recycling these products differs from the act of literally reusing them because the recycling process has its own algorithm which includes collecting, sourcing, processing, manufacturing and marketing these products. According to the Environmental Protection Agency of the United States, the recycling rate has been steadily on the rise, with data reporting that in 2005 40% of the food packaging and containers that were created were recycled.The product's quality and safety are the package's most important responsibility. However, there have been growing demands for packaging to be designed, manufactured, consumed, and recycled in a more sustainable fashion due to the increasing pollution connected with packaging and food wastes. It has been estimated that only 10.33% of all municipal solid waste (MSW), which makes up to 30.3% of the total waste, is recycled into new products globally.

However, depending on the level of packaging and the materials that are being used during their manufacturing, the end-of-life of a package may differ completely. Despite the fact that a recycling process is usually the desired path, lots of complications may lead to less sustainable destines.

End-of-use

*Plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adapta ...

: Landfilling, burning, and recycling are all alternatives for plastic packaging at the end of their shelf-life. However, improper disposal and handling lead to higher percentage of plastic waste, which can pollute the environment in a wide spectrum of scenarios. The packaging sector accounts for 40.5% of all plastic produced in Europe, which represents the largest sector in food industry. However, the recycling of such wastege is at a critical low level of roughly 35%. Moreover, it has been estimated that over 20% of the plastic packaging does not reach any recycling process.

*Bioplastic

Bioplastics are plastic materials produced from renewable biomass sources, such as vegetable fats and oils, corn starch, straw, woodchips, sawdust, recycled food waste, etc. Some bioplastics are obtained by processing directly from natural bi ...

: also known as biodegradable polymer or biopolymer, are usually made from renewable feedstock resources like corn and sugar cane, as well as from microorganism of different kind. Typical end-of-life options include the composting or the environmental degradation of bioplastics, which result in resource loss and CO2 production. Complete degradation is also only achievable under rigorous conditions that are infrequently offered by the company. Additionally, some bioplastics are processed similarly to their traditional, fossil-based counterparts, which, if improperly sorted, might cause harmful interferences in other materials' recycling processes.

*Paper and cardboard: are composed of cellulosic fibers bonded together to form a flexible structure. These packaging materials have a long tradition as the ideal solutions for storing dry foods (such as flour, rice, and pasta) as well as being used as secondary or tertiary packaging. Paper and cardboard are often collected separately for recycling; however, some difficulties are faced in the case of the presence of a coating (e.g., plastic or aluminum) or contamination due to food residues. Alternative end-of-life options include incineration and landfill. In theory, paper and board packaging is compostable, but persistent chemicals (like PFAS) may be dispersed in the environment through this practice, thus limiting the potential benefits.

* Metal-based packaging can endure high temperatures and can provides outstanding gas, light, and aromas barriers, leading to a very competitive solutions in a broad range of application. Direct food preservation in the packaging was made possible with the development of the canning method. Coatings, whether organic or inorganic, may lessen the interactions between metal and food. However, it was discovered that many of the chemicals in these coatings migrated into food. The end-of-life alternatives for metal food packaging differ depending on its usage: for example cans and lids can be broken down and recycled multiple times.

*Glass

Glass is a non- crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenchin ...

: is an inorganic packaging that has been used for storing food and beverages. Nowadays, soda-lime glass is the commonly used variation manufactured from raw materials such as soda ash, limestone, and metal. Due to the structural characteristics of glass, the risk of migration into the food is very limited. Glass is incredibly chemically stable and durable when handled carefully (due to its fragile nature). Therefore, this packaging material is an ideal candidate for repeated use, due to these characteristics. Glass can also be recycled multiple times without losing any quality properties.

*Multi-layer packaging: in the food and beverage business, packaging composed of numerous layers of various materials is commonly referred to as multi-layer or multi-material packaging. In many countries, multi-material food packaging is frequently burned or disposed of landfills. Nevertheless, some areas are actively developing separate collections and efficient sorting processes for fiber-based multi-material packaging, such as beverage cartons. On the other hand, multi-layer packaging composed of aluminum and plastic barrier, cannot currently be recycled in an efficient way, and must undergo chemical treatment to be disposed of correctly. In light of these considerations, it is clear how, despite being the state-of-the-art in food packaging application, multi-layer packaging poses a great challenge when considering its end-of-life. An exception is the case of multi-layer packaging consisting of several layers of the same material (or being part of the same category): such solutions in many cases allow for outstanding performance and, at the same time, allow for an easier recycling.

Trends in food packaging

*Numerous reports made by industry associations agree that use of smart indicators will increase. There are a number of different indicators with different benefits for food producers, consumers andretailer

Retail is the sale of goods and services to consumers, in contrast to wholesaling, which is sale to business or institutional customers. A retailer purchases goods in large quantities from manufacturers, directly or through a wholesaler, and ...

s.

*Temperature recorders are used to monitor products shipped in a cold chain

A cold chain is a low temperature-controlled supply chain network. An unbroken cold chain is an uninterrupted series of refrigerated production, storage and distribution activities, along with associated equipment and logistics, which maintain qu ...

and to help validate the cold chain. Digital temperature data loggers measure and record the temperature history of food shipments. They sometimes have temperatures displayed on the indicator or have other outputs (lights, etc.): the data from a shipment can be downloaded (cable, RFID, etc.) to a computer for further analysis. These help identify if there has been temperature abuse of products and can help determine the remaining shelf life. They can also help determine the time of temperature extremes during shipment, so that corrective measures can be taken.

* Time temperature indicators integrate the time

Time is the continued sequence of existence and event (philosophy), events that occurs in an apparently irreversible process, irreversible succession from the past, through the present, into the future. It is a component quantity of various me ...

and temperature experienced by the indicator and adjacent foods. Some use chemical reactions that result in a color change, while others use the migration of a dye through a filter media. To the degree that these physical changes in the indicator match the degradation rate of the food, the indicator can help indicate probable food degradation.

*Radio frequency identification

Radio-frequency identification (RFID) uses electromagnetic fields to automatically identify and track tags attached to objects. An RFID system consists of a tiny radio transponder, a radio receiver and transmitter. When triggered by an electroma ...

is applied to food packages for supply chain

In commerce, a supply chain is a network of facilities that procure raw materials, transform them into intermediate goods and then final products to customers through a distribution system. It refers to the network of organizations, people, activ ...

control. It has shown a significant benefit in allowing food producers and retailers to have full real time visibility of their supply chain.

*Plastic packaging being used is usually non-biodegradable due to possible interactions with the food. Also, biodegradable polymers often require special composting

Compost is a mixture of ingredients used as plant fertilizer and to improve soil's physical, chemical and biological properties. It is commonly prepared by decomposing plant, food waste, recycling organic materials and manure. The resulting ...

conditions to properly degrade. Normal sealed landfill

A landfill site, also known as a tip, dump, rubbish dump, garbage dump, or dumping ground, is a site for the disposal of waste materials. Landfill is the oldest and most common form of waste disposal, although the systematic burial of the wast ...

conditions do not promote biodegradation. Biodegradable plastic

Biodegradable plastics are plastics that can be decomposed by the action of living organisms, usually microbes, into water, carbon dioxide, and biomass. Biodegradable plastics are commonly produced with renewable raw materials, micro-organisms ...

s include biodegradable films and coatings synthesized from organic materials and microbial polymers. Some package materials are edible. For example, pharmaceuticals are sometimes in capsules made of gelatin

Gelatin or gelatine (from la, gelatus meaning "stiff" or "frozen") is a translucent, colorless, flavorless food ingredient, commonly derived from collagen taken from animal body parts. It is brittle when dry and rubbery when moist. It may also ...

, starch

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants for energy storage. Worldwide, it is the most common carbohydrate in human die ...

, potato

The potato is a starchy food, a tuber of the plant ''Solanum tuberosum'' and is a root vegetable native to the Americas. The plant is a perennial in the nightshade family Solanaceae.

Wild potato species can be found from the southern Uni ...

or other materials. Newer bioplastics

Bioplastics are plastic materials produced from renewable biomass sources, such as vegetable fats and oils, corn starch, straw, woodchips, sawdust, recycled food waste, etc. Some bioplastics are obtained by processing directly from natural bi ...

, films and products are being developed.

*There is an increasing development and production of food packaging materials containing substances and realising systems intended to extend shelf life: carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

(CO2) emitters; antioxidant

Antioxidants are compounds that inhibit oxidation, a chemical reaction that can produce free radicals. This can lead to polymerization and other chain reactions. They are frequently added to industrial products, such as fuels and lubrica ...

s (e.g. butylated hydroxytoluene

Butylated hydroxytoluene (BHT), also known as dibutylhydroxytoluene, is a lipophilic organic compound, chemically a derivative of phenol, that is useful for its antioxidant properties. BHT is widely used to prevent free radical-mediated oxidat ...

(BHT), butylated hydroxyanisole

Butylated hydroxyanisole (BHA) is a synthetic, waxy, solid petrochemical. Its antioxidant properties have caused it to be widely used as a preservative in food, food packaging, animal feed, cosmetics, pharmaceuticals, rubber, and petroleum produ ...

(BHA), tocopherol

Tocopherols (; TCP) are a class of organic chemical compounds (more precisely, various methylated phenols), many of which have vitamin E activity. Because the vitamin activity was first identified in 1936 from a dietary fertility factor in rat ...

s, hinokitiol); antimicrobial

An antimicrobial is an agent that kills microorganisms or stops their growth. Antimicrobial medicines can be grouped according to the microorganisms they act primarily against. For example, antibiotics are used against bacteria, and antifungals ar ...

enzymes (e.g. lysozyme

Lysozyme (EC 3.2.1.17, muramidase, ''N''-acetylmuramide glycanhydrolase; systematic name peptidoglycan ''N''-acetylmuramoylhydrolase) is an antimicrobial enzyme produced by animals that forms part of the innate immune system. It is a glycoside ...

), polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

s (e.g. ε-polylysine, chitosan

Chitosan is a linear polysaccharide composed of randomly distributed β-(1→4)-linked D-glucosamine (deacetylated unit) and ''N''-acetyl-D-glucosamine (acetylated unit). It is made by treating the chitin shells of shrimp and other crustacean ...

) and nanoparticle

A nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 10 ...

s (e.g. silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

, copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

, gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile ...

, platinum

Platinum is a chemical element with the symbol Pt and atomic number 78. It is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its name originates from Spanish , a diminutive of "silver".

Pla ...

, titanium dioxide

Titanium dioxide, also known as titanium(IV) oxide or titania , is the inorganic compound with the chemical formula . When used as a pigment, it is called titanium white, Pigment White 6 (PW6), or CI 77891. It is a white solid that is insolu ...

, zinc oxide

Zinc oxide is an inorganic compound with the formula . It is a white powder that is insoluble in water. ZnO is used as an additive in numerous materials and products including cosmetics, food supplements, rubbers, plastics, ceramics, glass, cement ...

, magnesium oxide

Magnesium oxide ( Mg O), or magnesia, is a white hygroscopic solid mineral that occurs naturally as periclase and is a source of magnesium (see also oxide). It has an empirical formula of MgO and consists of a lattice of Mg2+ ions and O2� ...

, organically modified nanoclays); bacteriocins (e.g. nisin, natamycin); and essential oil

An essential oil is a concentrated hydrophobic liquid containing volatile (easily evaporated at normal temperatures) chemical compounds from plants. Essential oils are also known as volatile oils, ethereal oils, aetheroleum, or simply as the o ...

s.

*In the last decades, the use of modified atmosphere packaging (MAP) and other variation of this technology has shown growing interest and application in the food packaging industry. The use of a specific gas mixture inside the packaging headspace has proven to be ideal to slow down the metabolic process of food product, thus prolonging the shelf-life of meat, fish, fruits and vegetables.

*The design of multi-layer packaging system has been recognized as the state-of-the-art in food packaging application for its versatility, processability and efficacy. Each layer can be made of different materials and provides a key functionality for the whole structure, such as improved mechanical properties, chemical stability, barrier properties and anti-microbial properties. However, the use of such complex structure significantly reduces its recyclability (except for a few cases).

*Recently, the application of protective coating on commercially available packaging materials (such as PET, PP, PLA cardboard or biopolymer) represents a potential solution to deal with the increasing environmental impact due to both food and packaging waste.

*Barcode

A barcode or bar code is a method of representing data in a visual, machine-readable form. Initially, barcodes represented data by varying the widths, spacings and sizes of parallel lines. These barcodes, now commonly referred to as linear or o ...

s have been used for decades in packaging many products. 2D barcodes used in autocoding are increasingly applied to food packaging to ensure that products are correctly packaged and date coded.

*The ability of a package to fully empty or dispense a viscous food is somewhat dependent on the surface energy

In surface science, surface free energy (also interfacial free energy or surface energy) quantifies the disruption of intermolecular bonds that occurs when a surface is created. In solid-state physics, surfaces must be intrinsically less ener ...

of the inner walls of the container. The use of superhydrophobic

Ultrahydrophobic (or superhydrophobic) surfaces are highly hydrophobic, i.e., extremely difficult to wet. The contact angles of a water droplet on an ultrahydrophobic material exceed 150°. This is also referred to as the lotus effect, after the ...

surfaces is useful but can be further improved by using new lubricant-impregnated surfaces.

Food Packaging Barrier Properties

A critical requirement in food packaging is represented by the barrier properties against the permeation of gases, water vapor, and aroma compounds of the packaging system. In fact, the chemical interactions between the products and the environment are the principal reasons for improper shelf-life and spoilage phenomena. Therefore, the evaluation of the gas exchange by means of the permeation of gas molecules is a crucial aspect in designing a product. The permeation of a gas molecule through a packaging system is a physical process made up of three independent phenomena: the adsorption of the molecule to the packaging's outer surface; the diffusion of the molecule through the packaging’s section; and the desorption in the internal headspace. Under the assumption of steady state condition, the physical processes involved in the permeation can be modeled by simple equations. Particularly, the diffusion of a permeant's molecule is dependent to the concentration difference between the two sides of the packaging system, which acts as a driving force, thus creating a diffusive flux following the firstFick's law of diffusion

Fick's laws of diffusion describe diffusion and were derived by Adolf Fick in 1855. They can be used to solve for the diffusion coefficient, . Fick's first law can be used to derive his second law which in turn is identical to the diffusion ...

. Furthermore, other assumptions are needed, such as the absence of chemical interaction between the penetrant and the packaging material and the fact that the diffusion flow must follow only one direction. The adsorption/desorption processes of a permeant's molecule normally exhibit a linear dependency with the partial pressure gradient across the barrier layer while keeping the assumption of steady-state transport condition and exhibiting a concentration lower than the penetrant's maximum solubility, thereby adhering to Henry's law of solubility.

The type of permeant, the barrier layer's thickness, the specific permeabilities of the packaging films against gases or vapors, the packaging's permeable area, the temperature, and the pressure or concentration gradient between the barrier's interior and external sides can all have an impact on a system's permeability.

The gas exchange occurring between the packaging system and the external environment has a significant impact on the quality and safety of food products. Uncontrolled physico-chemical and biological processes such as oxidation of vitamins, excessive microbial growth, and spoilage of the packed food may lead to improper conditions inside the packaging headspace, hence reducing their shelf-life. Therefore, the packaging system should be designed to create the ideal conditions for the selected product, avoiding excessive gas exchange.

Among the permeants that could affect the organoleptic properties of food, oxygen and water vapour represent the most important ones. These permeants affect several bio-chemical processes in food products, such as ripening, degradation, hydration/dehydration, microbial growth, vitamins oxidation; they also have an impact on the organoleptic properties, hence causing off-flavours, excessive weight loss, textural changing and generally shortening the shelf life.

To quantify the barrier properties of a packaging system, both oxygen and water vapour permeation are commonly assessed by measuring the oxygen transmission rate Oxygen transmission rate (OTR) is the measurement of the amount of oxygen gas that passes through a substance over a given period. It is mostly carried out on non-porous materials, where the mode of transport is diffusion, but there are a growing nu ...

(OTR) and water vapor transmission rate (WVTR), respectively.Oxygen barrier property

The oxygen transmission rate of a gas through the packaging is defined as the amount of oxygen permeating per unit of permeable area and unit of time in a packaging system considering standardized test conditions (23 °C and 1 atm partial pressure difference). It is an effective tool to estimate the barrier properties of a certain material. The determination of the OTR is usually carried out by means of a steady-state and isostatic method, reported by the

The oxygen transmission rate of a gas through the packaging is defined as the amount of oxygen permeating per unit of permeable area and unit of time in a packaging system considering standardized test conditions (23 °C and 1 atm partial pressure difference). It is an effective tool to estimate the barrier properties of a certain material. The determination of the OTR is usually carried out by means of a steady-state and isostatic method, reported by the ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, an ...

D 3985 or ASTM F 1307, containing respectively standardized protocol for the measurements of the OTR of several kind of packaging.

The typical instrumentation consists in a permeation cell composed by two distinct chambers separated by the tested material; one of the chambers is then filled with a carrier gas (e.g., nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

), while the other one with oxygen, hence creating the necessary driving force to let the oxygen permeate across the barrier’s material.

Water vapor barrier property

Concurrently to the oxygen barrier property, the permeability of water vapor through a food packaging system should be minimized to effectively prevent physical and chemical changes connected to an excessive moisture content.The moisture barrier properties of a material can be assessed by measuring the water vapour transmission rate (WVTR), which can be defined as the amount of water vapour per unit of area and unit of time passing through the packaging film.

The WVTR measurements, like the OTR, adhere to the standards for standardized tests as outlined in the ASTM E96 (standard methods for water vapor transmission of materials). An impermeable test dish (such as a stainless steel cup) and a test chamber where temperature and relative humidity (RH) can be adjusted in accordance with the standard specification, make up the basic instrumentation used in such tests.

Although both oxygen and water vapour represent the most studied permeants in food packaging application, other gases such as carbon dioxide (CO2) and nitrogen (N2) have also great relevance in the preservation of food products. In fact, N2 and CO2 have been employed in modified atmosphere packaging (MAP) technology to establish the correct conditions inside the package's headspace to lessen food spoiling.

Concurrently to the oxygen barrier property, the permeability of water vapor through a food packaging system should be minimized to effectively prevent physical and chemical changes connected to an excessive moisture content.The moisture barrier properties of a material can be assessed by measuring the water vapour transmission rate (WVTR), which can be defined as the amount of water vapour per unit of area and unit of time passing through the packaging film.

The WVTR measurements, like the OTR, adhere to the standards for standardized tests as outlined in the ASTM E96 (standard methods for water vapor transmission of materials). An impermeable test dish (such as a stainless steel cup) and a test chamber where temperature and relative humidity (RH) can be adjusted in accordance with the standard specification, make up the basic instrumentation used in such tests.

Although both oxygen and water vapour represent the most studied permeants in food packaging application, other gases such as carbon dioxide (CO2) and nitrogen (N2) have also great relevance in the preservation of food products. In fact, N2 and CO2 have been employed in modified atmosphere packaging (MAP) technology to establish the correct conditions inside the package's headspace to lessen food spoiling.

Food safety and public health

It is critical to maintainfood safety

Food safety (or food hygiene) is used as a scientific method/discipline describing handling, preparation, and storage of food in ways that prevent food-borne illness. The occurrence of two or more cases of a similar illness resulting from ...

during processing, packaging, storage, logistics

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics manages the flow of goods between the point of origin and the point of consumption to meet the requirements of ...

(including cold chain

A cold chain is a low temperature-controlled supply chain network. An unbroken cold chain is an uninterrupted series of refrigerated production, storage and distribution activities, along with associated equipment and logistics, which maintain qu ...

), sale, and use. Conformance to applicable regulations is mandatory. Some are country specific such as the US Food and Drug Administration

The United States Food and Drug Administration (FDA or US FDA) is a federal agency of the Department of Health and Human Services. The FDA is responsible for protecting and promoting public health through the control and supervision of food ...

and the US Department of Agriculture

The United States Department of Agriculture (USDA) is the federal executive department responsible for developing and executing federal laws related to farming, forestry, rural economic development, and food. It aims to meet the needs of comme ...

; others are regional such as the European Food Safety Authority

The European Food Safety Authority (EFSA) is the agency of the European Union (EU) that provides independent scientific advice and communicates on existing and emerging risks associated with the food chain. EFSA was established in February 2002, ...

. Certification programs such as the Global Food Safety Initiative The Global Food Safety Initiative (GFSI) is a private organization working as a "Coalition of Action" from The Consumer Goods Forum (CGF) bringing together retailers and brand owners (manufacturers) from across the CGF membership operating as multis ...

are sometimes used. Food packaging considerations may include: use of hazard analysis and critical control points

Hazard analysis and critical control points, or HACCP (), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs mea ...

, verification and validation

Verification and validation (also abbreviated as V&V) are independent procedures that are used together for checking that a product, service, or system meets requirements and specifications and that it fulfills its intended purpose. These are ...

protocols, Good manufacturing practice

Current good manufacturing practices (cGMP) are those conforming to the guidelines recommended by relevant agencies. Those agencies control the authorization and licensing of the manufacture and sale of food and beverages, cosmetics, pharmaceut ...

s, use of an effective quality management system

A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction (ISO 9001:2015). I ...

, track and trace systems, and requirements for label content. Special food contact materials

Food contact materials are materials that are intended to be in contact with food. These can be things that are quite obvious like a glass or a can for soft drinks as well as machinery in a food factory or a coffee machine.

Food contact materia ...

are used when the package is in direct contact with the food product. Depending on the packaging operation and the food, packaging machinery often needs specified daily wash-down and cleaning procedures.

Health risks of materials and chemicals that are used in food packaging need to be carefully controlled. Carcinogen

A carcinogen is any substance, radionuclide, or radiation that promotes carcinogenesis (the formation of cancer). This may be due to the ability to damage the genome or to the disruption of cellular metabolic processes. Several radioactive sub ...

s, toxic

Toxicity is the degree to which a chemical substance or a particular mixture of substances can damage an organism. Toxicity can refer to the effect on a whole organism, such as an animal, bacterium, or plant, as well as the effect on a sub ...

chemicals, mutagen

In genetics, a mutagen is a physical or chemical agent that permanently changes genetic material, usually DNA, in an organism and thus increases the frequency of mutations above the natural background level. As many mutations can cause cancer i ...

s etc. need to be eliminated from food contact and potential migration into foods. Besides, the consumers need to be aware of certain chemical products that are packaged exactly like food products to attract them. Most of them have pictures of fruits and the containers also resemble food packages. However, they can get consumed by kids or careless adults and lead to poisoning.

Manufacturing

Packaging lines can have a variety of equipment types: integration of automated systems can be a challenge. All aspects of food production, including packaging, are tightly controlled and have regulatory requirements. Uniformity, cleanliness and other requirements are needed to maintainGood Manufacturing Practice

Current good manufacturing practices (cGMP) are those conforming to the guidelines recommended by relevant agencies. Those agencies control the authorization and licensing of the manufacture and sale of food and beverages, cosmetics, pharmaceut ...

s.

Product safety management is vital. A complete Quality Management System

A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction (ISO 9001:2015). I ...

must be in place. Hazard analysis and critical control points

Hazard analysis and critical control points, or HACCP (), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs mea ...

is one methodology which has been proven useful. Verification and validation

Verification and validation (also abbreviated as V&V) are independent procedures that are used together for checking that a product, service, or system meets requirements and specifications and that it fulfills its intended purpose. These are ...

involves collecting documentary evidence of all aspects of compliance. Quality assurance extends beyond the packaging operations through distribution and cold chain management.

See also

Notes and references

Bibliography

* Hans-Jürgen Bässler und Frank Lehmann : ''Containment Technology: Progress in the Pharmaceutical and Food Processing Industry.'' Springer, Berlin 2013, *Heldman, D.R. ed (2003). "Encyclopedia of Agricultural, Food, and Biological Engineering". New York: Marcel Dekker *Potter, N.N. and J.H. Hotchkiss. (1995). "Food Science", Fifth Edition.New York: Chapman & Hall. pp. 478–513. * Robertson, G. L. (2013). "Food Packaging: Principles & Practice". CRC Press. * Selke, S, (1994). "Packaging and the Environment". * Selke, S, (2004) "Plastics Packaging", * Soroka, W. (2009). "Fundamentals of Packaging Technology". Institute of Packaging Professionals. * Stillwell, E. J, (1991) "Packaging for the Environment", A. D. Little, 1991, * Yam, K. L., "Encyclopedia of Packaging Technology", John Wiley & Sons, 2009,External links

*Poly(hydroxyalkanoates) for Food Packaging:

Application and Attempts towards Implementation {{DEFAULTSORT:Food Packaging Food science Retail packaging