Turbine Blade Convoy Passing through Edenfield.jpg on:

[Wikipedia]

[Google]

[Amazon]

A turbine ( or ) (from the Greek , ''tyrbē'', or

A turbine ( or ) (from the Greek , ''tyrbē'', or

* Water turbines

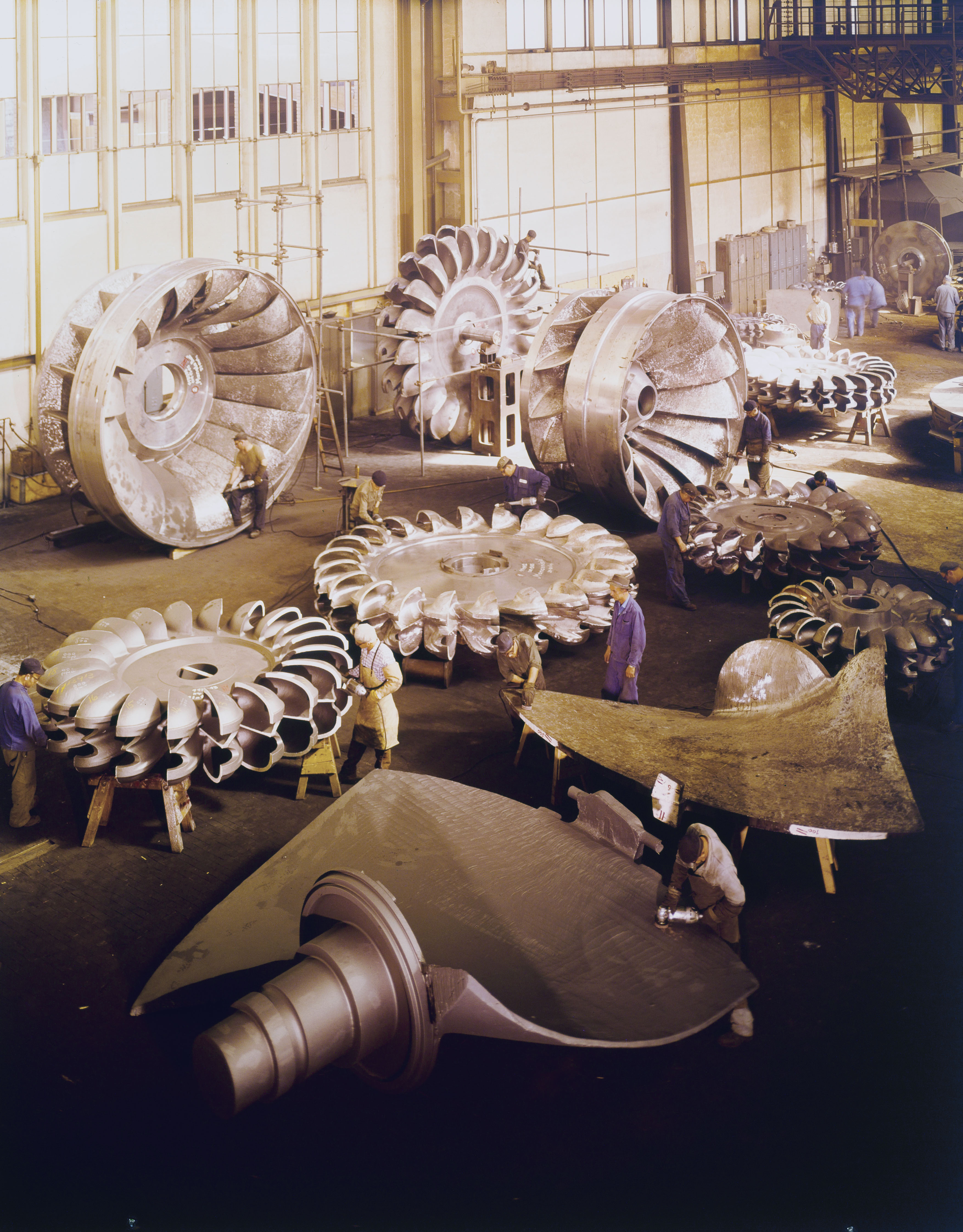

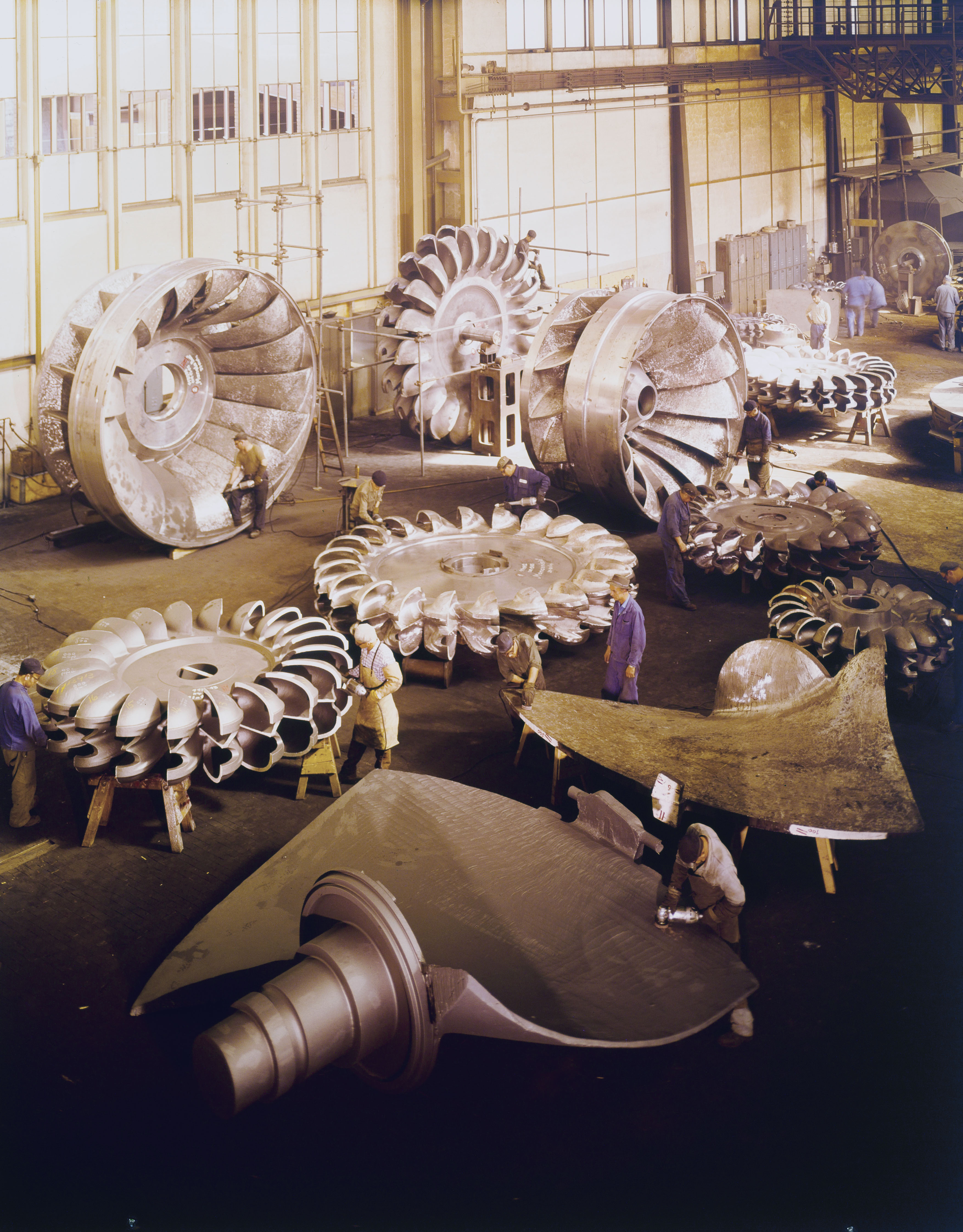

** Pelton wheel, Pelton turbine, a type of impulse water turbine.

** Francis turbine, a type of widely used water turbine.

** Kaplan turbine, a variation of the Francis Turbine.

** Turgo turbine, a modified form of the Pelton wheel.

** Cross-flow turbine, also known as Banki-Michell turbine, or Ossberger turbine.

*

* Water turbines

** Pelton wheel, Pelton turbine, a type of impulse water turbine.

** Francis turbine, a type of widely used water turbine.

** Kaplan turbine, a variation of the Francis Turbine.

** Turgo turbine, a modified form of the Pelton wheel.

** Cross-flow turbine, also known as Banki-Michell turbine, or Ossberger turbine.

*

Turbines

{{Authority control Turbines, Jet engines Power engineering Gas technologies

A turbine ( or ) (from the Greek , ''tyrbē'', or

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin

Latin (, or , ) is a classical language belonging to the Italic branch of the Indo-European languages. Latin was originally a dialect spoken in the lower Tiber area (then known as Latium) around present-day Rome, but through the power of the ...

''turbo'', meaning vortex

In fluid dynamics, a vortex ( : vortices or vortexes) is a region in a fluid in which the flow revolves around an axis line, which may be straight or curved. Vortices form in stirred fluids, and may be observed in smoke rings, whirlpools in ...

) is a rotary mechanical device that extracts energy

In physics, energy (from Ancient Greek: ἐνέργεια, ''enérgeia'', “activity”) is the quantitative property that is transferred to a body or to a physical system, recognizable in the performance of work and in the form of hea ...

from a fluid flow and converts it into useful work

Work may refer to:

* Work (human activity), intentional activity people perform to support themselves, others, or the community

** Manual labour, physical work done by humans

** House work, housework, or homemaking

** Working animal, an animal t ...

. The work produced by a turbine can be used for generating electrical power when combined with a generator.Munson, Bruce Roy, T. H. Okiishi, and Wade W. Huebsch. "Turbomachines." Fundamentals of Fluid Mechanics. 6th ed. Hoboken, NJ: J. Wiley & Sons, 2009. Print. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Early turbine examples are windmill

A windmill is a structure that converts wind power into rotational energy using vanes called sails or blades, specifically to mill grain (gristmills), but the term is also extended to windpumps, wind turbines, and other applications, in some ...

s and waterwheels.

Gas

Gas is one of the four fundamental states of matter (the others being solid, liquid, and plasma).

A pure gas may be made up of individual atoms (e.g. a noble gas like neon), elemental molecules made from one type of atom (e.g. oxygen), or ...

, steam, and water

Water (chemical formula ) is an Inorganic compound, inorganic, transparent, tasteless, odorless, and Color of water, nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living ...

turbines have a casing around the blades that contains and controls the working fluid. Credit for invention of the steam turbine is given both to Anglo-Irish engineer Sir Charles Parsons

Sir Charles Algernon Parsons, (13 June 1854 – 11 February 1931) was an Anglo-Irish engineer, best known for his invention of the compound steam turbine, and as the eponym of C. A. Parsons and Company. He worked as an engineer on ...

(1854–1931) for invention of the reaction turbine, and to Swedish engineer Gustaf de Laval

Karl Gustaf Patrik de Laval (; 9 May 1845 – 2 February 1913) was a Swedish engineer and inventor who made important contributions to the design of steam turbines and centrifugal separation machinery for dairy.

Life

Gustaf de Laval was born at ...

(1845–1913) for invention of the impulse turbine. Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction

In turbomachinery, degree of reaction or reaction ratio (R) is defined as the ratio of the static pressure rise in the rotating blades of a compressor (or drop in turbine blades) to the static pressure rise in the compressor stage (or drop in a tu ...

and impulse from the blade root to its periphery. Hero of Alexandria

Hero of Alexandria (; grc-gre, Ἥρων ὁ Ἀλεξανδρεύς, ''Heron ho Alexandreus'', also known as Heron of Alexandria ; 60 AD) was a Greek mathematician and engineer who was active in his native city of Alexandria, Roman Egypt. He ...

demonstrated the turbine principle in an aeolipile

An aeolipile, aeolipyle, or eolipile, from the Greek "αιολουπυλη", also known as a Hero's engine, is a simple, bladeless radial steam turbine which spins when the central water container is heated. Torque is produced by steam jets exi ...

in the first century AD and Vitruvius

Vitruvius (; c. 80–70 BC – after c. 15 BC) was a Roman architect and engineer during the 1st century BC, known for his multi-volume work entitled '' De architectura''. He originated the idea that all buildings should have three attribut ...

mentioned them around 70 BC.

The word "turbine" was coined in 1822 by the French mining engineer Claude Burdin

Claude Burdin (; 19 March 1788 – 12 November 1873) was a French engineer.

Born in Lépin-le-Lac, Savoie, when it was known as the Duchy of Savoy, he was professor at the school of mines, École nationale supérieure des mines de Saint-� ...

from the Greek , ''tyrbē'', meaning "vortex

In fluid dynamics, a vortex ( : vortices or vortexes) is a region in a fluid in which the flow revolves around an axis line, which may be straight or curved. Vortices form in stirred fluids, and may be observed in smoke rings, whirlpools in ...

" or "whirling", in a memo, "Des turbines hydrauliques ou machines rotatoires à grande vitesse", which he submitted to the Académie royale des sciences

The French Academy of Sciences (French: ''Académie des sciences'') is a learned society, founded in 1666 by Louis XIV at the suggestion of Jean-Baptiste Colbert, to encourage and protect the spirit of French scientific research. It was at the ...

in Paris. Benoit Fourneyron, a former student of Claude Burdin, built the first practical water turbine.

Operation theory

A working fluid contains potential energy (pressure head) andkinetic energy

In physics, the kinetic energy of an object is the energy that it possesses due to its motion.

It is defined as the work needed to accelerate a body of a given mass from rest to its stated velocity. Having gained this energy during its acc ...

(velocity head). The fluid may be compressible

In thermodynamics and fluid mechanics, the compressibility (also known as the coefficient of compressibility or, if the temperature is held constant, the isothermal compressibility) is a measure of the instantaneous relative volume change of a f ...

or incompressible

In fluid mechanics or more generally continuum mechanics, incompressible flow ( isochoric flow) refers to a flow in which the material density is constant within a fluid parcel—an infinitesimal volume that moves with the flow velocity. An eq ...

. Several physical principles are employed by turbines to collect this energy:

Impulse

Impulse or Impulsive may refer to:

Science

* Impulse (physics), in mechanics, the change of momentum of an object; the integral of a force with respect to time

* Impulse noise (disambiguation)

* Specific impulse, the change in momentum per uni ...

turbines change the direction of flow of a high velocity fluid or gas jet. The resulting impulse spins the turbine and leaves the fluid flow with diminished kinetic energy. There is no pressure change of the fluid or gas in the turbine blade

...

s (the moving blades), as in the case of a steam or gas turbine, all the pressure drop takes place in the stationary blades (the nozzles). Before reaching the turbine, the fluid's ''pressure head'' is changed to ''velocity head'' by accelerating the fluid with a nozzle. Pelton wheel

The Pelton wheel or Pelton Turbine is an impulse-type water turbine invented by American inventor Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse of moving water, as opposed to water's dead weight like the tra ...

s and de Laval turbines use this process exclusively. Impulse turbines do not require a pressure casement around the rotor since the fluid jet is created by the nozzle prior to reaching the blades on the rotor. Newton's second law

Newton's laws of motion are three basic laws of classical mechanics that describe the relationship between the motion of an object and the forces acting on it. These laws can be paraphrased as follows:

# A body remains at rest, or in moti ...

describes the transfer of energy for impulse turbines. Impulse turbines are most efficient for use in cases where the flow is low and the inlet pressure is high.

Reaction

Reaction may refer to a process or to a response to an action, event, or exposure:

Physics and chemistry

*Chemical reaction

*Nuclear reaction

* Reaction (physics), as defined by Newton's third law

*Chain reaction (disambiguation).

Biology and m ...

turbines develop torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

by reacting to the gas or fluid's pressure or mass. The pressure of the gas or fluid changes as it passes through the turbine rotor blades. A pressure casement is needed to contain the working fluid as it acts on the turbine stage(s) or the turbine must be fully immersed in the fluid flow (such as with wind turbines). The casing contains and directs the working fluid and, for water turbines, maintains the suction imparted by the draft tube

Draft Tube is a diverging tube fitted at the exit of runner of turbine and used to utilize the kinetic energy available with water at the exit of runner. '.

This draft tube at the end of the turbine increases the pressure of the exiting flu ...

. Francis turbines and most steam turbines use this concept. For compressible working fluids, multiple turbine stages are usually used to harness the expanding gas efficiently. Newton's third law

Newton's laws of motion are three basic laws of classical mechanics that describe the relationship between the motion of an object and the forces acting on it. These laws can be paraphrased as follows:

# A body remains at rest, or in moti ...

describes the transfer of energy for reaction turbines. Reaction turbines are better suited to higher flow velocities or applications where the fluid head (upstream pressure) is low.

In the case of steam turbines, such as would be used for marine applications or for land-based electricity generation, a Parsons-type reaction turbine would require approximately double the number of blade rows as a de Laval-type impulse turbine, for the same degree of thermal energy conversion. Whilst this makes the Parsons turbine much longer and heavier, the overall efficiency of a reaction turbine is slightly higher than the equivalent impulse turbine for the same thermal energy conversion.

In practice, modern turbine designs use both reaction and impulse concepts to varying degrees whenever possible. Wind turbine

A wind turbine is a device that converts the kinetic energy of wind into electrical energy. Hundreds of thousands of large turbines, in installations known as wind farms, now generate over 650 gigawatts of power, with 60 GW added each yea ...

s use an airfoil to generate a reaction lift

Lift or LIFT may refer to:

Physical devices

* Elevator, or lift, a device used for raising and lowering people or goods

** Paternoster lift, a type of lift using a continuous chain of cars which do not stop

** Patient lift, or Hoyer lift, mobil ...

from the moving fluid and impart it to the rotor. Wind turbines also gain some energy from the impulse of the wind, by deflecting it at an angle. Turbines with multiple stages may use either reaction or impulse blading at high pressure. Steam turbines were traditionally more impulse but continue to move towards reaction designs similar to those used in gas turbines. At low pressure the operating fluid medium expands in volume for small reductions in pressure. Under these conditions, blading becomes strictly a reaction type design with the base of the blade solely impulse. The reason is due to the effect of the rotation speed for each blade. As the volume increases, the blade height increases, and the base of the blade spins at a slower speed relative to the tip. This change in speed forces a designer to change from impulse at the base, to a high reaction-style tip.

Classical turbine design methods were developed in the mid 19th century. Vector analysis related the fluid flow with turbine shape and rotation. Graphical calculation methods were used at first. Formulae for the basic dimensions of turbine parts are well documented and a highly efficient machine can be reliably designed for any fluid flow condition. Some of the calculations are empirical or 'rule of thumb' formulae, and others are based on classical mechanics

Classical mechanics is a physical theory describing the motion of macroscopic objects, from projectiles to parts of machinery, and astronomical objects, such as spacecraft, planets, stars, and galaxies. For objects governed by classi ...

. As with most engineering calculations, simplifying assumptions were made.

Velocity triangle In turbomachinery, a velocity triangle or a velocity diagram is a triangle representing the various components of velocities of the working fluid in a turbomachine. Velocity triangles may be drawn for both the inlet and outlet sections of any turbo ...

s can be used to calculate the basic performance of a turbine stage. Gas exits the stationary turbine nozzle guide vanes at absolute velocity ''V''a1. The rotor rotates at velocity ''U''. Relative to the rotor, the velocity of the gas as it impinges on the rotor entrance is ''V''r1. The gas is turned by the rotor and exits, relative to the rotor, at velocity ''V''r2. However, in absolute terms the rotor exit velocity is ''V''a2. The velocity triangles are constructed using these various velocity vectors. Velocity triangles can be constructed at any section through the blading (for example: hub, tip, midsection and so on) but are usually shown at the mean stage radius. Mean performance for the stage can be calculated from the velocity triangles, at this radius, using the Euler equation:

:

Hence:

:

where:

: is the specific enthalpy drop across stage

: is the turbine entry total (or stagnation) temperature

: is the turbine rotor peripheral velocity

: is the change in whirl velocity

The turbine pressure ratio is a function of and the turbine efficiency.

Modern turbine design carries the calculations further. Computational fluid dynamics

Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems that involve fluid flows. Computers are used to perform the calculations required to simulate ...

dispenses with many of the simplifying assumptions used to derive classical formulas and computer software facilitates optimization. These tools have led to steady improvements in turbine design over the last forty years.

The primary numerical classification of a turbine is its specific speed

Specific speed ''N's'', is used to characterize turbomachinery speed.

Common commercial and industrial practices use dimensioned versions which are of equal utility. Specific speed is most commonly used in pump applications to define the su ...

. This number describes the speed of the turbine at its maximum efficiency with respect to the power and flow rate. The specific speed is derived to be independent of turbine size. Given the fluid flow conditions and the desired shaft output speed, the specific speed can be calculated and an appropriate turbine design selected.

The specific speed, along with some fundamental formulas can be used to reliably scale an existing design of known performance to a new size with corresponding performance.

Off-design performance is normally displayed as a turbine map

Each turbine in a gas turbine engine has an operating map. Complete maps are either based on turbine rig test results or are predicted by a special computer program. Alternatively, the map of a similar turbine can be suitably scaled.

Description

A ...

or characteristic.

The number of blades in the rotor and the number of vanes in the stator are often two different prime number

A prime number (or a prime) is a natural number greater than 1 that is not a product of two smaller natural numbers. A natural number greater than 1 that is not prime is called a composite number. For example, 5 is prime because the only ways ...

s in order to reduce the harmonics and maximize the blade-passing frequency.

Types

* Steam turbines are used to drive electrical generators in thermal power plants which usecoal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

, fuel oil or nuclear fuel. They were once used to directly drive mechanical devices such as ships' propellers (for example the ''Turbinia

''Turbinia'' was the first steam turbine-powered steamship. Built as an experimental vessel in 1894, and easily the fastest ship in the world at that time, ''Turbinia'' was demonstrated dramatically at the Spithead Navy Review in 1897 and set ...

'', the first turbine-powered steam launch), but most such applications now use reduction gears or an intermediate electrical step, where the turbine is used to generate electricity, which then powers an electric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate for ...

connected to the mechanical load. Turbo electric ship machinery was particularly popular in the period immediately before and during World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposing ...

, primarily due to a lack of sufficient gear-cutting facilities in US and UK shipyards.

* Aircraft gas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

engines are sometimes referred to as turbine engines to distinguish between piston engines.

* Transonic

Transonic (or transsonic) flow is air flowing around an object at a speed that generates regions of both subsonic and supersonic airflow around that object. The exact range of speeds depends on the object's critical Mach number, but transoni ...

turbine. The gas flow in most turbines employed in gas turbine engines remains subsonic throughout the expansion process. In a transonic turbine the gas flow becomes supersonic as it exits the nozzle guide vanes, although the downstream velocities normally become subsonic. Transonic turbines operate at a higher pressure ratio than normal but are usually less efficient and uncommon.

* Contra-rotating

Contra-rotating, also referred to as coaxial contra-rotating, is a technique whereby parts of a mechanism rotate in opposite directions about a common axis, usually to minimise the effect of torque. Examples include some aircraft propellers, res ...

turbines. With axial turbine

An axial turbine is a turbine in which the flow of the working fluid is parallel to the shaft, as opposed to radial turbines, where the fluid runs around a shaft, as in a watermill. An axial turbine has a similar construction as an axial compressor ...

s, some efficiency advantage can be obtained if a downstream turbine rotates in the opposite direction to an upstream unit. However, the complication can be counter-productive. A contra-rotating steam turbine, usually known as the Ljungström turbine, was originally invented by Swedish Engineer Fredrik Ljungström

Fredrik Ljungström (16 June 1875 – 18 February 1964) was a Swedish engineer, technical designer, and industrialist.

Considered one of the foremost inventors of Sweden, Fredrik Ljungström accounted for hundreds of technical patents a ...

(1875–1964) in Stockholm, and in partnership with his brother Birger Ljungström he obtained a patent in 1894. The design is essentially a multi-stage radial turbine (or pair of 'nested' turbine rotors) offering great efficiency, four times as large heat drop per stage as in the reaction (Parsons) turbine, extremely compact design and the type met particular success in back pressure power plants. However, contrary to other designs, large steam volumes are handled with difficulty and only a combination with axial flow turbines (DUREX) admits the turbine to be built for power greater than ca 50 MW. In marine applications only about 50 turbo-electric units were ordered (of which a considerable amount were finally sold to land plants) during 1917–19, and during 1920-22 a few turbo-mechanic not very successful units were sold.Ingvar Jung, 1979, The history of the marine turbine, part 1, Royal Institute of Technology, Stockholm, dep of History of technology Only a few turbo-electric marine plants were still in use in the late 1960s (ss Ragne, ss Regin) while most land plants remain in use 2010.

* Statorless turbine. Multi-stage turbines have a set of static (meaning stationary) inlet guide vanes that direct the gas flow onto the rotating rotor blades. In a stator-less turbine the gas flow exiting an upstream rotor impinges onto a downstream rotor without an intermediate set of stator vanes (that rearrange the pressure/velocity energy levels of the flow) being encountered.

* Ceramic turbine. Conventional high-pressure turbine blades (and vanes) are made from nickel based alloys and often use intricate internal air-cooling passages to prevent the metal from overheating. In recent years, experimental ceramic blades have been manufactured and tested in gas turbines, with a view to increasing rotor inlet temperatures and/or, possibly, eliminating air cooling. Ceramic blades are more brittle than their metallic counterparts, and carry a greater risk of catastrophic blade failure. This has tended to limit their use in jet engines and gas turbines to the stator (stationary) blades.

* Ducted fan, Shrouded turbine. Many turbine rotor blades have shrouding at the top, which interlocks with that of adjacent blades, to increase damping and thereby reduce blade flutter. In large land-based electricity generation steam turbines, the shrouding is often complemented, especially in the long blades of a low-pressure turbine, with lacing wires. These wires pass through holes drilled in the blades at suitable distances from the blade root and are usually brazed to the blades at the point where they pass through. Lacing wires reduce blade flutter in the central part of the blades. The introduction of lacing wires substantially reduces the instances of blade failure in large or low-pressure turbines.

* Ducted fan, Shroudless turbine. Modern practice is, wherever possible, to eliminate the rotor shrouding, thus reducing the Centrifugal force, centrifugal load on the blade and the cooling requirements.

* Tesla turbine, Bladeless turbine uses the boundary layer effect and not a fluid impinging upon the blades as in a conventional turbine.

* Water turbines

** Pelton wheel, Pelton turbine, a type of impulse water turbine.

** Francis turbine, a type of widely used water turbine.

** Kaplan turbine, a variation of the Francis Turbine.

** Turgo turbine, a modified form of the Pelton wheel.

** Cross-flow turbine, also known as Banki-Michell turbine, or Ossberger turbine.

*

* Water turbines

** Pelton wheel, Pelton turbine, a type of impulse water turbine.

** Francis turbine, a type of widely used water turbine.

** Kaplan turbine, a variation of the Francis Turbine.

** Turgo turbine, a modified form of the Pelton wheel.

** Cross-flow turbine, also known as Banki-Michell turbine, or Ossberger turbine.

* Wind turbine

A wind turbine is a device that converts the kinetic energy of wind into electrical energy. Hundreds of thousands of large turbines, in installations known as wind farms, now generate over 650 gigawatts of power, with 60 GW added each yea ...

. These normally operate as a single stage without nozzle and interstage guide vanes. An exception is the Éolienne Bollée, which has a stator and a rotor.

* Velocity compound "Curtis". Curtis combined the de Laval and Parsons turbine by using a set of fixed nozzles on the first stage or stator and then a rank of fixed and rotating blade rows, as in the Parsons or de Laval, typically up to ten compared with up to a hundred stages of a Parsons design. The overall efficiency of a Curtis design is less than that of either the Parsons or de Laval designs, but it can be satisfactorily operated through a much wider range of speeds, including successful operation at low speeds and at lower pressures, which made it ideal for use in ships' powerplant. In a Curtis arrangement, the entire heat drop in the steam takes place in the initial nozzle row and both the subsequent moving blade rows and stationary blade rows merely change the direction of the steam. Use of a small section of a Curtis arrangement, typically one nozzle section and two or three rows of moving blades, is usually termed a Curtis 'Wheel' and in this form, the Curtis found widespread use at sea as a 'governing stage' on many reaction and impulse turbines and turbine sets. This practice is still commonplace today in marine steam plant.

* Pressure compounding in turbines, Pressure compound multi-stage impulse, or "Rateau", after its French inventor, :fr:Auguste Rateau, Auguste Rateau. The Rateau employs simple impulse rotors separated by a nozzle diaphragm. The diaphragm is essentially a partition wall in the turbine with a series of tunnels cut into it, funnel shaped with the broad end facing the previous stage and the narrow the next they are also angled to direct the steam jets onto the impulse rotor.

*Mercury vapour turbines used mercury (element), mercury as the working fluid, to improve the efficiency of fossil-fuelled generating stations. Although a few power plants were built with combined mercury vapour and conventional steam turbines, the toxicity of the metal mercury was quickly apparent.

*Screw turbine is a water turbine which uses the principle of the Archimedean screw to convert the potential energy of water on an upstream level into kinetic energy

In physics, the kinetic energy of an object is the energy that it possesses due to its motion.

It is defined as the work needed to accelerate a body of a given mass from rest to its stated velocity. Having gained this energy during its acc ...

.

Uses

A large proportion of the world's electrical power is generated by turbo generators. Turbines are used ingas turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directio ...

engines on land, sea and air.

Turbochargers are used on piston engines.

Gas turbines have very high power densities (i.e. the ratio of power to mass, or power to volume) because they run at very high speeds. The Space Shuttle main engines used turbopumps (machines consisting of a pump driven by a turbine engine) to feed the propellants (liquid oxygen and liquid hydrogen) into the engine's combustion chamber. The liquid hydrogen turbopump is slightly larger than an automobile engine (weighing approximately 700 lb) with the turbine producing nearly 70,000 horsepower, hp (52.2 megawatt, MW).

Turboexpanders are used for refrigeration in industrial processes.

See also

* Balancing machine * Euler's pump and turbine equation * Helmholtz's theorems * Rotordynamics * Rotor–stator interaction * Secondary flow * Segner wheel * Turbo-alternator * Turbodrill * Turbofan * Turbojet * Turboprop * Turboshaft * Turbine-electric transmissionNotes

Further reading

* Layton, Edwin T. "From Rule of Thumb to Scientific Engineering: James B. Francis and the Invention of the Francis Turbine," NLA Monograph Series. Stony Brook, NY: Research Foundation of the State University of New York, 1992.External links

Turbines

{{Authority control Turbines, Jet engines Power engineering Gas technologies