Polyurethane foam at inniskillin 2.jpg on:

[Wikipedia]

[Google]

[Amazon]

Polyurethane (; often abbreviated PUR and PU) refers to a class of

Polyurethane (; often abbreviated PUR and PU) refers to a class of

Aliphatic and cycloaliphatic isocyanates are used in smaller quantities, most often in coatings and other applications where color and transparency are important since polyurethanes made with aromatic isocyanates tend to darken on exposure to light. The most important aliphatic and cycloaliphatic isocyanates are 1,6-hexamethylene diisocyanate (HDI), 1-isocyanato-3-isocyanatomethyl-3,5,5-trimethyl-cyclohexane (

Aliphatic and cycloaliphatic isocyanates are used in smaller quantities, most often in coatings and other applications where color and transparency are important since polyurethanes made with aromatic isocyanates tend to darken on exposure to light. The most important aliphatic and cycloaliphatic isocyanates are 1,6-hexamethylene diisocyanate (HDI), 1-isocyanato-3-isocyanatomethyl-3,5,5-trimethyl-cyclohexane (

Polyurethanes are combustible. Decomposition from fire can produce significant amounts of carbon monoxide and hydrogen cyanide, in addition to nitrogen oxides, isocyanates, and other toxic products. Because of the flammability of the material, it has to be treated with

Polyurethanes are combustible. Decomposition from fire can produce significant amounts of carbon monoxide and hydrogen cyanide, in addition to nitrogen oxides, isocyanates, and other toxic products. Because of the flammability of the material, it has to be treated with

Image:HighPressureDispenseUnit800x600.png, A high-pressure polyurethane dispense unit, showing control panel, high-pressure pump, integral day tanks, and hydraulic drive unit

Image:HighPressureLHeadFront600x800.png, A high-pressure mix head, showing simple controls (front view)

Image:HighPressureLHeadRear600x800.png, A high-pressure mix head, showing material supply and hydraulic actuator lines (rear view)

The pumps can drive low-pressure (10 to 30 bar, 1 to 3 MPa) or high-pressure (125 to 250 bar, 12.5 to 25.0 MPa) dispense systems. Mix heads can be simple static mix tubes, rotary-element mixers, low-pressure dynamic mixers, or high-pressure hydraulically actuated direct impingement mixers. Control units may have basic on/off and dispense/stop switches, and analogue pressure and temperature gauges, or may be computer-controlled with flow meters to electronically calibrate mix ratio, digital temperature and level sensors, and a full suite of statistical process control software. Add-ons to dispense equipment include nucleation or gas injection units, and third or fourth stream capability for adding pigments or metering in supplemental additive packages.

Image:LowPressureMixHead600x800.png, A low-pressure mix head with calibration chamber installed, showing material supply and air actuator lines

Image:LowPressureMixChamberComponents800x600.png, Low-pressure mix head components, including mix chambers, conical mixers, and mounting plates

Image:LowPressure5GallonDayTanks800x600.png, 5-gallon (20-liter) material day tanks for supplying a low-pressure dispense unit

Center for the Polyurethanes Industry

information for EH&S issues related to polyurethanes developments

Polymer Science Learning Center,

Polyurethane Foam Association

Industry information, educational materials and resources related to flexible polyurethane foam

PU Europe: European PU insulation industry association

(formerly BING): European voice for the national trade associations representing the polyurethane insulation industry

ISOPA: European Diisocyanate & Polyol Producers Association

ISOPA represents the manufacturers in Europe of aromatic diisocyanates and polyols {{Authority control 1937 in Germany 1937 in science Adhesives Building insulation materials Coatings Elastomers Plastics Wood finishing materials German inventions of the Nazi period

Polyurethane (; often abbreviated PUR and PU) refers to a class of

Polyurethane (; often abbreviated PUR and PU) refers to a class of polymer

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

s composed of organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including b ...

and polystyrene, polyurethane is produced from a wide range of starting materials. This chemical variety produces polyurethanes with different chemical structures leading to many different applications. These include rigid and flexible foams, varnishes and coatings, adhesives, electrical potting compounds, and fibers such as spandex

Spandex, Lycra, or elastane is a synthetic fiber known for its exceptional elasticity. It is a polyether-polyurea copolymer that was invented in 1958 by chemist Joseph Shivers at DuPont's Benger Laboratory in Waynesboro, Virginia, US.

The g ...

and PUL. Foams are the largest application accounting for 67% of all polyurethane produced in 2016.

A polyurethane is typically produced by reacting an isocyanate with a polyol

In organic chemistry, a polyol is an organic compound containing multiple hydroxyl groups (). The term "polyol" can have slightly different meanings depending on whether it is used in food science or polymer chemistry. Polyols containing two, thr ...

. Since a polyurethane contains two types of monomers, which polymerize one after the other, they are classed as alternating copolymers. Both the isocyanates and polyols used to make a polyurethane contain two or more functional group

In organic chemistry, a functional group is a substituent or moiety in a molecule that causes the molecule's characteristic chemical reactions. The same functional group will undergo the same or similar chemical reactions regardless of the re ...

s per molecule.

Global production in 2019 was 25 million metric tonnes, accounting for about 6% of all polymers produced in that year. Polyurethane is a commodity plastic.

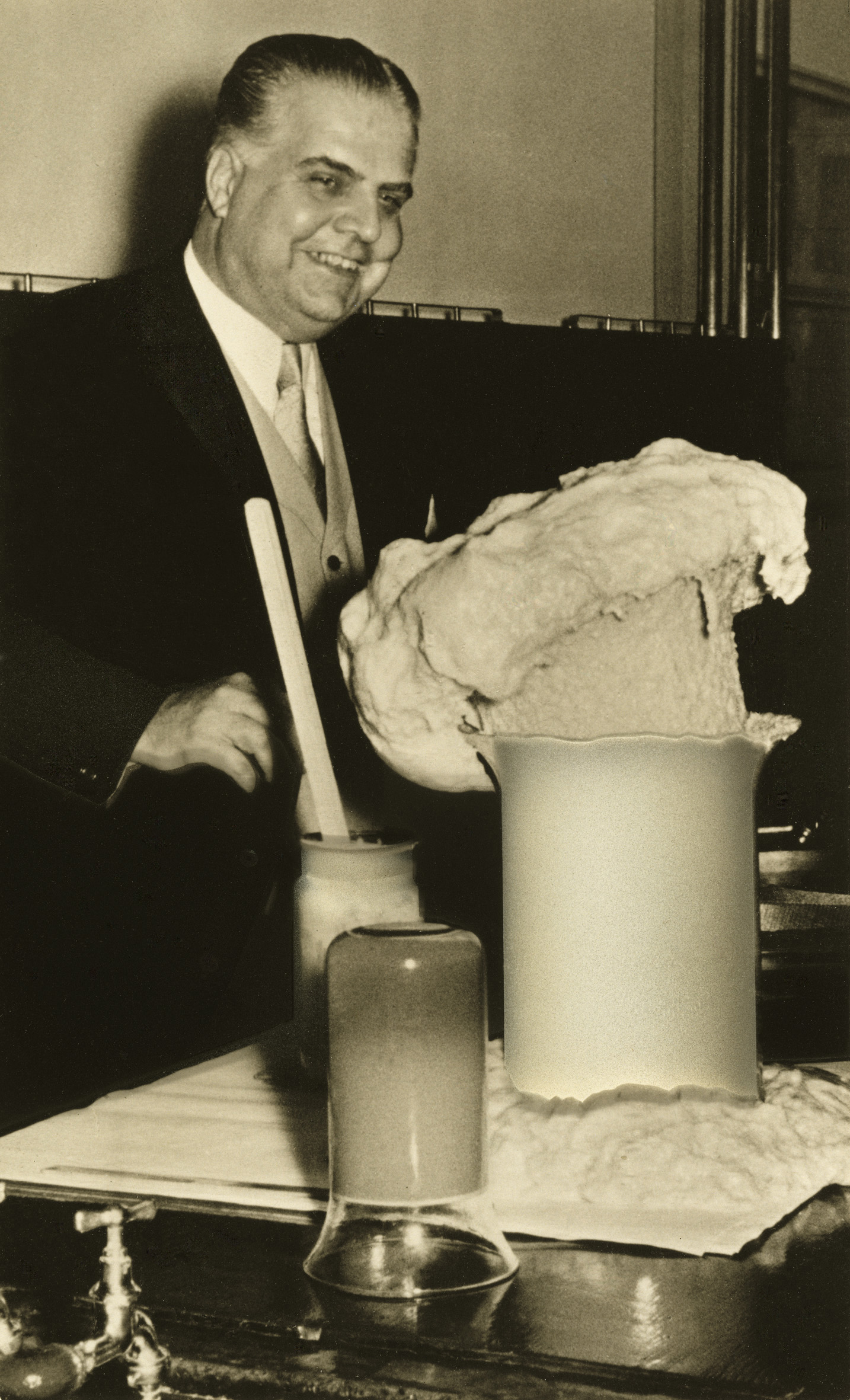

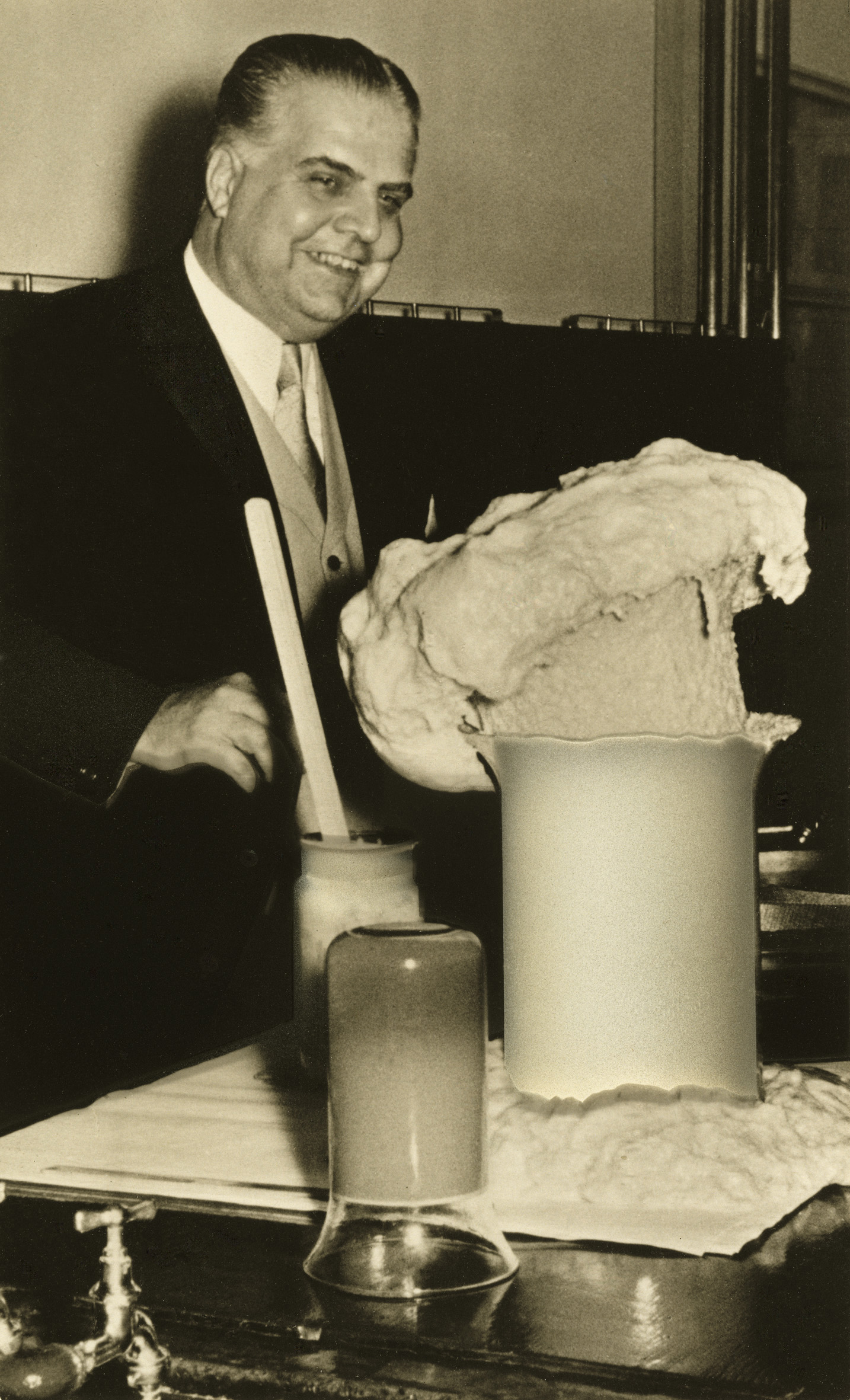

History

Otto Bayer

Otto Bayer (4 November 1902 – 1 August 1982) was a German industrial chemist at IG Farben who was head of the research group that in 1937 discovered the polyaddition for the synthesis of polyurethanes out of poly-isocyanate and polyol.

Ba ...

and his coworkers at IG Farben in Leverkusen, Germany, first made polyurethanes in 1937. The new polymers had some advantages over existing plastics that were made by polymerizing olefins or by polycondensation

In polymer chemistry, condensation polymers are any kind of polymers whose process of polymerization involves a condensation reaction (i.e. a small molecule, such as water or methanol, is produced as a byproduct). Condensation polymers are for ...

, and were not covered by patents obtained by Wallace Carothers

Wallace Hume Carothers (; April 27, 1896 – April 29, 1937) was an American chemist, inventor and the leader of organic chemistry at DuPont, who was credited with the invention of nylon.

Carothers was a group leader at the DuPont Experimen ...

on polyesters. Early work focused on the production of fibers and flexible foams and PUs were applied on a limited scale as aircraft coating during World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposing ...

. Polyisocyanate

In organic chemistry, isocyanate is the functional group with the formula . Organic compounds that contain an isocyanate group are referred to as isocyanates. An organic compound with two isocyanate groups is known as a diisocyanate. Diisocyan ...

s became commercially available in 1952, and production of flexible polyurethane foam began in 1954 by combining toluene diisocyanate

Toluene diisocyanate (TDI) is an organic compound with the formula CH3C6H3(NCO)2. Two of the six possible isomers are commercially important: 2,4-TDI (CAS: 584-84-9) and 2,6-TDI (CAS: 91-08-7). 2,4-TDI is produced in the pure state, but TDI is oft ...

(TDI) and polyester polyols. These materials were also used to produce rigid foams, gum rubber, and elastomers. Linear fibers were produced from hexamethylene diisocyanate

Hexamethylene diisocyanate (HDI) is the organic compound with the formula (CH2)6(NCO)2. It is classified as an diisocyanate. It is a colorless liquid. It has sometimes been called HMDI but this not usually done to avoid confusion with Hydrogenate ...

(HDI) and 1,4-Butanediol

1,4-Butanediol, colloquially known as BD or BDO, is a primary alcohol, and an organic compound, with the formula HOCH2CH2CH2CH2OH. It is a colorless viscous liquid. It is one of four stable isomers of butanediol.

Synthesis

In industrial synthe ...

(BDO).

DuPont introduced polyethers, specifically poly(tetramethylene ether) glycol

Polytetrahydrofuran, also called poly(tetramethylene ether) glycol or poly(tetramethylene oxide), is a chemical compound with formula ()''n''OH2 or HO-(-(CH2)4O-)''n''-H. It can be viewed as a polymer of tetrahydrofuran, or as the polyether deriv ...

, in 1956. BASF

BASF SE () is a German multinational chemical company and the largest chemical producer in the world. Its headquarters is located in Ludwigshafen, Germany.

The BASF Group comprises subsidiaries and joint ventures in more than 80 countries ...

and Dow Chemical introduced polyalkylene glycols in 1957. Polyether polyols were cheaper, easier to handle and more water-resistant than polyester polyols. Union Carbide

Union Carbide Corporation is an American chemical corporation wholly owned subsidiary (since February 6, 2001) by Dow Chemical Company. Union Carbide produces chemicals and polymers that undergo one or more further conversions by customers befo ...

and Mobay, a U.S. Monsanto

The Monsanto Company () was an American agrochemical and agricultural biotechnology corporation founded in 1901 and headquartered in Creve Coeur, Missouri. Monsanto's best known product is Roundup, a glyphosate-based herbicide, developed in ...

/ Bayer joint venture, also began making polyurethane chemicals. In 1960 more than 45,000 metric tons of flexible polyurethane foams were produced. The availability of chlorofluoroalkane

Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) are fully or partly halogenated hydrocarbons that contain carbon (C), hydrogen (H), chlorine (Cl), and fluorine (F), produced as volatile derivatives of methane, ethane, and propa ...

blowing agents, inexpensive polyether polyols, and methylene diphenyl diisocyanate

Methylene diphenyl diisocyanate (MDI) is an aromatic diisocyanate. Three isomers are common, varying by the positions of the isocyanate groups around the rings: 2,2′-MDI, 2,4′-MDI, and 4,4′-MDI. The 4,4′ isomer is most widely used, and i ...

(MDI) allowed polyurethane rigid foams to be used as high-performance insulation materials. In 1967, urethane-modified polyisocyanurate

Polyisocyanurate (), also referred to as PIR, polyiso, or ISO, is a thermoset plastic typically produced as a foam and used as rigid thermal insulation. The starting materials are similar to those used in polyurethane (PUR) except that the propor ...

rigid foams were introduced, offering even better thermal stability and flammability

A combustible material is something that can burn (i.e., ''combust'') in air. A combustible material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable mat ...

resistance. During the 1960s, automotive interior safety components, such as instrument and door panels, were produced by back-filling thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate ...

skins with semi-rigid foam.

In 1969, Bayer exhibited an all-plastic car in Düsseldorf

Düsseldorf ( , , ; often in English sources; Low Franconian and Ripuarian language, Ripuarian: ''Düsseldörp'' ; archaic nl, Dusseldorp ) is the capital city of North Rhine-Westphalia, the most populous state of Germany. It is the second- ...

, Germany. Parts of this car, such as the fascia and body panels, were manufactured using a new process called reaction injection molding

Reaction injection molding (RIM) is similar to injection molding except thermosetting polymers are used, which requires a curing reaction to occur within the mold.

Common items made via RIM include automotive bumpers, air spoilers, and fe ...

(RIM), in which the reactants were mixed and then injected into a mold. The addition of fillers, such as milled glass, mica, and processed mineral fibers, gave rise to reinforced RIM (RRIM), which provided improvements in flexural modulus In mechanics, the flexural modulus or bending modulus is an intensive property that is computed as the ratio of stress to strain in flexural deformation, or the tendency for a material to resist bending. It is determined from the slope of a stres ...

(stiffness), reduction in coefficient of thermal expansion

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions.

Temperature is a monotonic function of the average molecular kinetic ...

and better thermal stability. This technology was used to make the first plastic-body automobile in the United States, the Pontiac Fiero

The Pontiac Fiero is a mid-engine sports car manufactured and marketed by Pontiac for model years 1984-1988. Designed by George Milidrag and Hulki Aldikacti as a sports car, it was the first two-seater Pontiac since the 1926 to 1938 coupes, an ...

, in 1983. Further increases in stiffness were obtained by incorporating pre-placed glass mats into the RIM mold cavity, also known broadly as resin injection molding, or structural RIM.

Starting in the early 1980s, water-blown microcellular flexible foams were used to mold gaskets for automotive panels and air-filter seals, replacing PVC polymers. Polyurethane foams are used in many automotive applications including seating, head and arm rests, and headliners.

Polyurethane foam (including foam rubber) is sometimes made using small amounts of blowing agent

A blowing agent is a substance which is capable of producing a cellular structure via a foaming process in a variety of materials that undergo hardening or phase transition, such as polymers, plastics, and metals. They are typically applied wh ...

s to give less dense foam, better cushioning/energy absorption or thermal insulation. In the early 1990s, because of their impact on ozone depletion, the Montreal Protocol

The Montreal Protocol is an international treaty designed to protect the ozone layer by phasing out the production of numerous substances that are responsible for ozone depletion. It was agreed on 16 September 1987, and entered into force o ...

restricted the use of many chlorine

Chlorine is a chemical element with the symbol Cl and atomic number 17. The second-lightest of the halogens, it appears between fluorine and bromine in the periodic table and its properties are mostly intermediate between them. Chlorine i ...

-containing blowing agents, such as trichlorofluoromethane

Trichlorofluoromethane, also called freon-11, CFC-11, or R-11, is a chlorofluorocarbon (CFC). It is a colorless, faintly ethereal, and sweetish-smelling liquid that boils around room temperature. CFC-11 is a Class 1 ozone-depleting substance ...

(CFC-11). By the late 1990s, blowing agents such as carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is trans ...

, pentane, 1,1,1,2-tetrafluoroethane (HFC-134a) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) were widely used in North America and the EU, although chlorinated blowing agents remained in use in many developing countries. Later, HFC-134a was also banned due to high ODP and GWP readings, and HFC - 141B was introduced in early 2000s as an alternate blowing agent in developing nations.

Chemistry

Polyurethanes are produced by reacting diisocyanate

In organic chemistry, isocyanate is the functional group with the formula . Organic compounds that contain an isocyanate group are referred to as isocyanates. An organic compound with two isocyanate groups is known as a diisocyanate. Diisocyan ...

s with polyol

In organic chemistry, a polyol is an organic compound containing multiple hydroxyl groups (). The term "polyol" can have slightly different meanings depending on whether it is used in food science or polymer chemistry. Polyols containing two, thr ...

s,''n'' ≥ 2 in the presence of a catalyst

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recyc ...

, or upon exposure to ultraviolet light.

Common catalysts include tertiary amine

In chemistry, amines (, ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia (), wherein one or more hydrogen

Hydrogen is the chemical element wi ...

s, such as DABCO

DABCO (1,4-diazabicyclo .2.2ctane), also known as triethylenediamine or TEDA, is a bicyclic organic compound with the formula N2(C2H4)3. This colorless solid is a highly nucleophilic tertiary amine base, which is used as a catalyst and reagen ...

, or metallic soap

A metallic soap is a metallic salt of a fatty acid. Theoretically, soaps can be made of any metal, although not all enjoy practical uses. Varying the metal can strongly affect the properties of the compound, particularly its solubility.

Alkali, a ...

s, such as dibutyltin dilaurate

Dibutyltin dilaurate (abbreviated DBTDL), also called dibutyltindilaurate or butynorate, is an organotin compound that is used as a catalyst. It is a colourless oily liquid. In terms of its structure, the molecule consists of two laurate groups ...

. The stoichiometry of the starting materials must be carefully controlled as excess isocyanate can trimerise, leading to the formation of rigid polyisocyanurate

Polyisocyanurate (), also referred to as PIR, polyiso, or ISO, is a thermoset plastic typically produced as a foam and used as rigid thermal insulation. The starting materials are similar to those used in polyurethane (PUR) except that the propor ...

s. The polymer usually has a highly crosslink

In chemistry and biology a cross-link is a bond or a short sequence of bonds that links one polymer chain to another. These links may take the form of covalent bonds or ionic bonds and the polymers can be either synthetic polymers or natural ...

ed molecular structure, resulting in a thermosetting

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

material which does not melt on heating; although some thermoplastic polyurethane

Thermoplastic polyurethane (TPU) is any of a class of polyurethane plastics with many properties, including elasticity, transparency, and resistance to oil, grease, and abrasion. Technically, they are thermoplastic elastomers consisting of linea ...

s are also produced.

The most common application of polyurethane is as solid foam

Foams are materials formed by trapping pockets of gas in a liquid or solid.

A bath sponge and the head on a glass of beer are examples of foams. In most foams, the volume of gas is large, with thin films of liquid or solid separating the ...

s, which requires the presence of a gas, or blowing agent

A blowing agent is a substance which is capable of producing a cellular structure via a foaming process in a variety of materials that undergo hardening or phase transition, such as polymers, plastics, and metals. They are typically applied wh ...

, during the polymerization step. This is commonly achieved by adding small amounts of water, which reacts with isocyanates to form CO2 gas and an amine

In chemistry, amines (, ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia (), wherein one or more hydrogen

Hydrogen is the chemical element wi ...

, via an unstable carbamic acid

Carbamic acid, which might also be called aminoformic acid or aminocarboxylic acid, is the chemical compound with the formula . It can be obtained by the reaction of ammonia and carbon dioxide at very low temperatures, which also yields an equ ...

group. The amine produced can also react with isocyanates to form urea

Urea, also known as carbamide, is an organic compound with chemical formula . This amide has two amino groups (–) joined by a carbonyl functional group (–C(=O)–). It is thus the simplest amide of carbamic acid.

Urea serves an important ...

groups, and as such the polymer will contain both these and urethane linkers. The urea is not very soluble in the reaction mixture and tends to form separate "hard segment" phases consisting mostly of polyurea

Polyurea is a type of elastomer that is derived from the reaction product of an isocyanate component and a synthetic resin blend component through step-growth polymerization. The isocyanate can be aromatic or aliphatic in nature. It can be mon ...

. The concentration and organization of these polyurea phases can have a significant impact on the properties of the foam.

The type of foam produced can be controlled by regulating the amount of blowing agent and also by the addition of various surfactants which change the rheology

Rheology (; ) is the study of the flow of matter, primarily in a fluid (liquid or gas) state, but also as "soft solids" or solids under conditions in which they respond with Plasticity (physics), plastic flow rather than deforming Elasticity (phy ...

of the polymerising mixture. Foams can be either "closed-cell", where most of the original bubbles or cells remain intact, or "open-cell", where the bubbles have broken but the edges of the bubbles are stiff enough to retain their shape, in extreme cases reticulated foam

Reticulated foam is a very porous, low density solid foam. 'Reticulated' means like a net. Reticulated foams are extremely open foams i.e. there are few, if any, intact bubbles or cell windows. In contrast, the foam formed by soap bubbles is compo ...

s can be formed. Open-cell foams feel soft and allow air to flow through, so they are comfortable when used in seat cushions or mattresses

A mattress is a large, usually rectangular pad for supporting a lying person. It is designed to be used as a bed, or on a bed frame as part of a bed. Mattresses may consist of a quilted or similarly fastened case, usually of heavy cloth, contain ...

. Closed-cell foams are used as rigid thermal insulation

Thermal insulation is the reduction of heat transfer (i.e., the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with ...

. High-density microcellular foams can be formed without the addition of blowing agents by mechanically frothing the polyol prior to use. These are tough elastomeric materials used in covering car steering wheels or shoe sole

A shoe is an item of footwear intended to protect and comfort the human foot. They are often worn with a sock. Shoes are also used as an item of decoration and fashion. The design of shoes has varied enormously through time and from culture to ...

s.

The properties of a polyurethane are greatly influenced by the types of isocyanates and polyols used to make it. Long, flexible segments, contributed by the polyol, give soft, elastic

Elastic is a word often used to describe or identify certain types of elastomer, elastic used in garments or stretchable fabrics.

Elastic may also refer to:

Alternative name

* Rubber band, ring-shaped band of rubber used to hold objects togeth ...

polymer. High amounts of crosslinking give tough or rigid polymers. Long chains and low crosslinking give a polymer that is very stretchy, short chains with many crosslinks produce a hard polymer while long chains and intermediate crosslinking give a polymer useful for making foam. The choices available for the isocyanates and polyols, in addition to other additives and processing conditions allow polyurethanes to have the very wide range of properties that make them such widely used polymers.

Raw materials

The main ingredients to make a polyurethane are di- and tri-isocyanates

In organic chemistry, isocyanate is the functional group with the formula . Organic compounds that contain an isocyanate group are referred to as isocyanates. An organic compound with two isocyanate groups is known as a diisocyanate. Diisocyan ...

and polyols

In organic chemistry, a polyol is an organic compound containing multiple hydroxyl groups (). The term "polyol" can have slightly different meanings depending on whether it is used in food science or polymer chemistry. Polyols containing two, thr ...

. Other materials are added to aid processing the polymer or to modify the properties of the polymer.

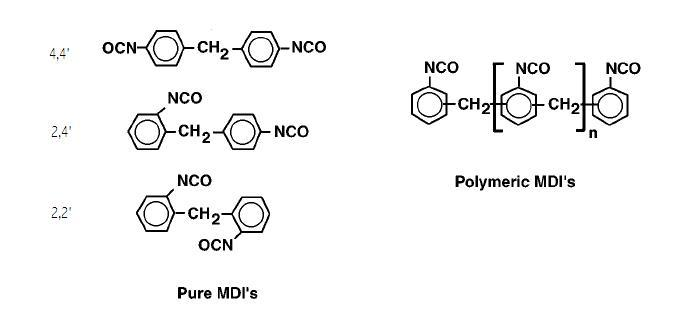

Isocyanates

Isocyanates used to make polyurethane have two or more isocyanate groups on each molecule. The most commonly used isocyanates are thearomatic

In chemistry, aromaticity is a chemical property of cyclic ( ring-shaped), ''typically'' planar (flat) molecular structures with pi bonds in resonance (those containing delocalized electrons) that gives increased stability compared to satur ...

diisocyanates, toluene diisocyanate

Toluene diisocyanate (TDI) is an organic compound with the formula CH3C6H3(NCO)2. Two of the six possible isomers are commercially important: 2,4-TDI (CAS: 584-84-9) and 2,6-TDI (CAS: 91-08-7). 2,4-TDI is produced in the pure state, but TDI is oft ...

(TDI) and methylene diphenyl diisocyanate

Methylene diphenyl diisocyanate (MDI) is an aromatic diisocyanate. Three isomers are common, varying by the positions of the isocyanate groups around the rings: 2,2′-MDI, 2,4′-MDI, and 4,4′-MDI. The 4,4′ isomer is most widely used, and i ...

, (MDI). These aromatic isocyanates are more reactive than aliphatic

In organic chemistry, hydrocarbons ( compounds composed solely of carbon and hydrogen) are divided into two classes: aromatic compounds and aliphatic compounds (; G. ''aleiphar'', fat, oil). Aliphatic compounds can be saturated, like hexane, ...

isocyanates.

TDI and MDI are generally less expensive and more reactive than other isocyanates. Industrial grade TDI and MDI are mixtures of isomers and MDI often contains polymeric materials. They are used to make flexible foam (for example slabstock foam for mattresses or molded foams for car seats), rigid foam (for example insulating foam in refrigerators) elastomers (shoe soles, for example), and so on. The isocyanates may be modified by partially reacting them with polyols or introducing some other materials to reduce volatility (and hence toxicity) of the isocyanates, decrease their freezing points to make handling easier or to improve the properties of the final polymers.

isophorone diisocyanate

Isophorone diisocyanate (IPDI) is an organic compound in the class known as isocyanates. More specifically, it is an aliphatic diisocyanate. It is produced in relatively small quantities, accounting for (with hexamethylene diisocyanate) only 3.4% ...

, IPDI), and 4,4′-diisocyanato dicyclohexylmethane (H12MDI or hydrogenated MDI).

Polyols

Polyols

In organic chemistry, a polyol is an organic compound containing multiple hydroxyl groups (). The term "polyol" can have slightly different meanings depending on whether it is used in food science or polymer chemistry. Polyols containing two, thr ...

are polymers in their own right and have on average two or more hydroxyl groups per molecule. They can be converted to polyether polyols co-polymerizing ethylene oxide

Ethylene oxide is an organic compound with the formula . It is a cyclic ether and the simplest epoxide: a three-membered ring consisting of one oxygen atom and two carbon atoms. Ethylene oxide is a colorless and flammable gas with a faintly sw ...

and propylene oxide

Propylene oxide is an acutely toxic and carcinogenic organic compound with the molecular formula CH3CHCH2O. This colourless volatile liquid with an odour similar to ether, is produced on a large scale industrially. Its major application is its us ...

with a suitable polyol precursor. Polyester polyols are made by the polycondensation of multifunctional carboxylic acids and polyhydroxyl compounds. They can be further classified according to their end use. Higher molecular weight polyols (molecular weights from 2,000 to 10,000) are used to make more flexible polyurethanes while lower molecular weight polyols make more rigid products.

Polyols for flexible applications use low functionality initiators such as dipropylene glycol

Dipropylene glycol is a mixture of three isomeric chemical compounds, 4-oxa-2,6-heptandiol, 2-(2-hydroxy-propoxy)-propan-1-ol, and 2-(2-hydroxy-1-methyl-ethoxy)-propan-1-ol. It is a colorless, nearly odorless liquid with a high boiling point and ...

(''f'' = 2), glycerine

Glycerol (), also called glycerine in British English and glycerin in American English, is a simple triol compound. It is a colorless, odorless, viscous liquid that is sweet-tasting and non-toxic. The glycerol backbone is found in lipids known ...

(''f'' = 3), or a sorbitol/water solution (''f'' = 2.75). Polyols for rigid applications use high functionality initiators such as sucrose (''f'' = 8), sorbitol (''f'' = 6), toluenediamine Toluenediamine may refer to these isomeric organic compounds with the formula C6H3(NH2)2(CH3):

*2,4-Diaminotoluene, precursor to toluene diisocyanate and azo dye

Azo dyes are organic compounds bearing the functional group R−N=N−R� ...

(''f'' = 4), and Mannich bases (''f'' = 4). Propylene oxide

Propylene oxide is an acutely toxic and carcinogenic organic compound with the molecular formula CH3CHCH2O. This colourless volatile liquid with an odour similar to ether, is produced on a large scale industrially. Its major application is its us ...

and/or ethylene oxide

Ethylene oxide is an organic compound with the formula . It is a cyclic ether and the simplest epoxide: a three-membered ring consisting of one oxygen atom and two carbon atoms. Ethylene oxide is a colorless and flammable gas with a faintly sw ...

is added to the initiators until the desired molecular weight is achieved. The order of addition and the amounts of each oxide affect many polyol properties, such as compatibility, water-solubility, and reactivity. Polyols made with only propylene oxide are terminated with secondary hydroxyl groups and are less reactive than polyols capped with ethylene oxide, which contain primary hydroxyl groups. Incorporating carbon dioxide into the polyol structure is being researched by multiple companies.

Graft polyols (also called filled polyols or polymer polyols) contain finely dispersed styrene–acrylonitrile, acrylonitrile

Acrylonitrile is an organic compound with the formula and the structure . It is a colorless, volatile liquid although commercial samples can be yellow due to impurities. It has a pungent odor of garlic or onions. In terms of its molecula ...

, or polyurea (PHD) polymer solids chemically grafted to a high molecular weight polyether backbone. They are used to increase the load-bearing properties of low-density high-resiliency (HR) foam, as well as add toughness to microcellular foams and cast elastomers. Initiators such as ethylenediamine and triethanolamine

Triethanolamine, or TEA is a viscous organic compound that is both a tertiary amine and a triol. A triol is a molecule with three alcohol groups. Approximately 150,000 tonnes were produced in 1999. It is a colourless compound although samples m ...

are used to make low molecular weight rigid foam polyols that have built-in catalytic activity due to the presence of nitrogen atoms in the backbone. A special class of polyether polyols, poly(tetramethylene ether) glycol

Polytetrahydrofuran, also called poly(tetramethylene ether) glycol or poly(tetramethylene oxide), is a chemical compound with formula ()''n''OH2 or HO-(-(CH2)4O-)''n''-H. It can be viewed as a polymer of tetrahydrofuran, or as the polyether deriv ...

s, which are made by polymerizing tetrahydrofuran

Tetrahydrofuran (THF), or oxolane, is an organic compound with the formula (CH2)4O. The compound is classified as heterocyclic compound, specifically a cyclic ether. It is a colorless, water- miscible organic liquid with low viscosity. It is ...

, are used in high performance coating, wetting and elastomer applications.

Conventional polyester polyols are based on virgin raw materials and are manufactured by the direct polyesterification of high-purity diacids and glycols, such as adipic acid and 1,4-butanediol. Polyester polyols are usually more expensive and more viscous than polyether polyols, but they make polyurethanes with better solvent, abrasion, and cut resistance. Other polyester polyols are based on reclaimed raw materials. They are manufactured by transesterification ( glycolysis) of recycled poly(ethyleneterephthalate) (PET) or dimethylterephthalate (DMT) distillation bottoms with glycols such as diethylene glycol. These low molecular weight, aromatic polyester polyols are used in rigid foam, and bring low cost and excellent flammability characteristics to polyisocyanurate

Polyisocyanurate (), also referred to as PIR, polyiso, or ISO, is a thermoset plastic typically produced as a foam and used as rigid thermal insulation. The starting materials are similar to those used in polyurethane (PUR) except that the propor ...

(PIR) boardstock and polyurethane spray foam insulation.

Specialty polyols include polycarbonate polyols, polycaprolactone

Polycaprolactone (PCL) is a biodegradable polyester with a low melting point of around 60 °C and a glass transition temperature of about −60 °C. The most common use of polycaprolactone is in the production of speciality polyureth ...

polyols, polybutadiene polyols, and polysulfide

Polysulfides are a class of chemical compounds containing chains of sulfur atoms. There are two main classes of polysulfides: inorganic and organic. Among the inorganic polysulfides, there are ones which contain anions, which have the general formu ...

polyols. The materials are used in elastomer, sealant, and adhesive applications that require superior weatherability, and resistance to chemical and environmental attack. Natural oil polyols derived from castor oil

Castor oil is a vegetable oil pressed from castor beans.

It is a colourless or pale yellow liquid with a distinct taste and odor. Its boiling point is and its density is 0.961 g/cm3. It includes a mixture of triglycerides in which about ...

and other vegetable oils

Vegetable oils, or vegetable fats, are oils extracted from seeds or from other parts of fruits. Like animal fats, vegetable fats are ''mixtures'' of triglycerides. Soybean oil, grape seed oil, and cocoa butter are examples of seed oils, or f ...

are used to make elastomers, flexible bunstock, and flexible molded foam.

Co-polymerizing chlorotrifluoroethylene

Chlorotrifluoroethylene (CTFE) is a chlorofluorocarbon with chemical formula CFCl=CF2. It is commonly used as a refrigerant in cryogenic applications. CTFE has a carbon-carbon double bond and so can be polymerized to form polychlorotrifluoroethy ...

or tetrafluoroethylene

Tetrafluoroethylene (TFE) is a fluorocarbon with the chemical formula C2 F4. It is the simplest perfluorinated alkene. This gaseous species is used primarily in the industrial preparation of fluoropolymers.

Properties

Tetrafluoroethylene is a ...

with vinyl ethers containing hydroxyalkyl vinyl ether produces fluorinated (FEVE) polyols. Two-component fluorinated polyurethanes prepared by reacting FEVE fluorinated polyols with polyisocyanate have been used to make ambient cure paints and coatings. Since fluorinated polyurethanes contain a high percentage of fluorine–carbon bonds, which are the strongest bonds among all chemical bonds, fluorinated polyurethanes exhibit resistance to UV, acids, alkali, salts, chemicals, solvents, weathering, corrosion, fungi and microbial attack. These have been used for high performance coatings and paints.

Phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

-containing polyols are available that become chemically bonded to the polyurethane matrix for the use as flame retardants

The term flame retardants subsumes a diverse group of chemicals that are added to manufactured materials, such as plastics and textiles, and surface finishes and coatings. Flame retardants are activated by the presence of an ignition source and ...

. This covalent linkage prevents migration and leaching of the organophosphorus compound.

Bio-derived materials

Interest in sustainable "green" products raised interest in polyols derived fromvegetable oil

Vegetable oils, or vegetable fats, are oils extracted from seeds or from other parts of fruits. Like animal fats, vegetable fats are ''mixtures'' of triglycerides. Soybean oil, grape seed oil, and cocoa butter are examples of seed oils, or f ...

s.

Various oils used in the preparation polyols for polyurethanes include soybean, cotton seed, neem seed, and castor. Vegetable oils are functionalized by various ways and modified to polyetheramide, polyethers, alkyds, etc. Renewable sources used to prepare polyols may be dimer fatty acids or fatty acids. Some biobased and isocyanate-free polyurethanes exploit the reaction between polyamines and cyclic carbonates to produce polyhydroxurethanes.

Chain extenders and cross linkers

Chain extenders (''f'' = 2) and cross linkers (''f'' ≥ 3) are low molecular weight hydroxyl and amine terminated compounds that play an important role in the polymer morphology of polyurethane fibers, elastomers, adhesives, and certain integral skin and microcellular foams. The elastomeric properties of these materials are derived from the phase separation of the hard and soft copolymer segments of the polymer, such that the urethane hard segment domains serve as cross-links between the amorphous polyether (or polyester) soft segment domains. This phase separation occurs because the mainly nonpolar, low melting soft segments are incompatible with the polar, high melting hard segments. The soft segments, which are formed from high molecular weight polyols, are mobile and are normally present in coiled formation, while the hard segments, which are formed from the isocyanate and chain extenders, are stiff and immobile. Because the hard segments are covalently coupled to the soft segments, they inhibit plastic flow of the polymer chains, thus creating elastomeric resiliency. Upon mechanical deformation, a portion of the soft segments are stressed by uncoiling, and the hard segments become aligned in the stress direction. This reorientation of the hard segments and consequent powerful hydrogen bonding contributes to high tensile strength, elongation, and tear resistance values. The choice of chain extender also determines flexural, heat, and chemical resistance properties. The most important chain extenders areethylene glycol

Ethylene glycol (IUPAC name: ethane-1,2-diol) is an organic compound (a vicinal diol) with the formula . It is mainly used for two purposes, as a raw material in the manufacture of polyester fibers and for antifreeze formulations. It is an odo ...

, 1,4-butanediol

1,4-Butanediol, colloquially known as BD or BDO, is a primary alcohol, and an organic compound, with the formula HOCH2CH2CH2CH2OH. It is a colorless viscous liquid. It is one of four stable isomers of butanediol.

Synthesis

In industrial synthe ...

(1,4-BDO or BDO), 1,6-hexanediol

1,6-Hexanediol is an organic compound with the formula (CH2CH2CH2OH)2. It is a colorless water-soluble solid.

Production

1,6-Hexanediol is prepared by the hydrogenation of adipic acid or its esters. Laboratory preparation could be achieved by r ...

, cyclohexane dimethanol

Cyclohexanedimethanol (CHDM) is a mixture of isomeric organic compounds with formula C6H10(CH2OH)2. It is a colorless low-melting solid used in the production of polyester resins. Commercial samples consist of a mixture of cis and trans isomers. ...

and hydroquinone bis(2-hydroxyethyl) ether (HQEE). All of these glycols form polyurethanes that phase separate well and form well defined hard segment domains, and are melt processable. They are all suitable for thermoplastic polyurethanes

Thermoplastic polyurethane (TPU) is any of a class of polyurethane plastics with many properties, including elasticity, transparency, and resistance to oil, grease, and abrasion. Technically, they are thermoplastic elastomers consisting of line ...

with the exception of ethylene glycol, since its derived bis-phenyl urethane undergoes unfavorable degradation at high hard segment levels. Diethanolamine and triethanolamine are used in flex molded foams to build firmness and add catalytic activity. Diethyltoluenediamine is used extensively in RIM, and in polyurethane and polyurea elastomer formulations.

Catalysts

Polyurethanecatalyst

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recyc ...

s can be classified into two broad categories, basic and acidic amine

In chemistry, amines (, ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia (), wherein one or more hydrogen

Hydrogen is the chemical element wi ...

. Tertiary amine

In chemistry, amines (, ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia (), wherein one or more hydrogen atoms have been replaced by a substituent such ...

catalysts function by enhancing the nucleophilicity of the diol component. Alkyl tin carboxylates, oxides and mercaptides oxides function as mild Lewis acids in accelerating the formation of polyurethane. As bases, traditional amine catalysts include triethylenediamine (TEDA, also called DABCO

DABCO (1,4-diazabicyclo .2.2ctane), also known as triethylenediamine or TEDA, is a bicyclic organic compound with the formula N2(C2H4)3. This colorless solid is a highly nucleophilic tertiary amine base, which is used as a catalyst and reagen ...

, 1,4-diazabicyclo .2.2ctane), dimethylcyclohexylamine (DMCHA), dimethylethanolamine

Dimethylethanolamine (DMAE or DMEA) is an organic compound with the formula (CH3)2NCH2CH2OH. It is bifunctional, containing both a tertiary amine and primary alcohol functional groups. It is a colorless viscous liquid. It is used in skin care prod ...

(DMEA), and bis-(2-dimethylaminoethyl)ether, a blowing catalyst also called A-99. A typical Lewis acidic catalyst is dibutyltin dilaurate

Dibutyltin dilaurate (abbreviated DBTDL), also called dibutyltindilaurate or butynorate, is an organotin compound that is used as a catalyst. It is a colourless oily liquid. In terms of its structure, the molecule consists of two laurate groups ...

. The process is highly sensitive to the nature of the catalyst and is also known to be autocatalytic

A single chemical reaction is said to be autocatalytic if one of the reaction products is also a catalyst for the same or a coupled reaction.Steinfeld J.I., Francisco J.S. and Hase W.L. ''Chemical Kinetics and Dynamics'' (2nd ed., Prentice-Hall 199 ...

.

Factors affecting catalyst selection include balancing three reactions: urethane (polyol+isocyanate, or gel) formation, the urea (water+isocyanate, or "blow") formation, or the isocyanate trimerization reaction (e.g., using potassium acetate, to form isocyanurate rings). A variety of specialized catalysts have been developed.

Surfactants

Surfactants

Surfactants are chemical compounds that decrease the surface tension between two liquids, between a gas and a liquid, or interfacial tension between a liquid and a solid. Surfactants may act as detergents, wetting agents, emulsifiers, foaming ...

are used to modify the characteristics of both foam and non-foam polyurethane polymers. They take the form of polydimethylsiloxane-polyoxyalkylene block copolymers, silicone oils, nonylphenol

Nonylphenols are a family of closely related organic compounds composed of phenol bearing a 9 carbon-tail. Nonylphenols can come in numerous structures, all of which may be considered alkylphenols. They are used in manufacturing antioxidants, lubr ...

ethoxylates, and other organic compounds. In foams, they are used to emulsify the liquid components, regulate cell size, and stabilize the cell structure to prevent collapse and sub-surface voids. In non-foam applications they are used as air release and antifoaming agents, as wetting agents, and are used to eliminate surface defects such as pin holes, orange peel, and sink marks.

Production

Polyurethanes are produced by mixing two or more liquid streams. The polyol stream contains catalysts, surfactants,blowing agent

A blowing agent is a substance which is capable of producing a cellular structure via a foaming process in a variety of materials that undergo hardening or phase transition, such as polymers, plastics, and metals. They are typically applied wh ...

s (when making polyurethane foam insulation) and so on. The two components are referred to as a polyurethane system, or simply a system. The isocyanate is commonly referred to in North America as the 'A-side' or just the 'iso'. The blend of polyols and other additives is commonly referred to as the 'B-side' or as the 'poly'. This mixture might also be called a 'resin' or 'resin blend'. In Europe the meanings for 'A-side' and 'B-side' are reversed. Resin blend additives may include chain extenders, cross linkers, surfactants, flame retardant

The term flame retardants subsumes a diverse group of chemicals that are added to manufactured materials, such as plastics and textiles, and surface finishes and coatings. Flame retardants are activated by the presence of an ignition source and ...

s, blowing agent

A blowing agent is a substance which is capable of producing a cellular structure via a foaming process in a variety of materials that undergo hardening or phase transition, such as polymers, plastics, and metals. They are typically applied wh ...

s, pigment

A pigment is a colored material that is completely or nearly insoluble in water. In contrast, dyes are typically soluble, at least at some stage in their use. Generally dyes are often organic compounds whereas pigments are often inorganic compou ...

s, and fillers

In processed animal foods, a filler is an ingredient added to provide dietary fiber, bulk or some other non-nutritive purpose.

Products like corncobs, feathers, soy, cottonseed hulls, peanut hulls, citrus pulp, screening, weeds, straw, and cere ...

. Polyurethane can be made in a variety of densities and hardnesses by varying the isocyanate, polyol or additives.

Health and safety

Fully reacted polyurethane polymer is chemically inert. No exposure limits have been established in the U.S. by OSHA (Occupational Safety and Health Administration

The Occupational Safety and Health Administration'' (OSHA ) is a large regulatory agency of the United States Department of Labor that originally had federal visitorial powers to inspect and examine workplaces. Congress established the agenc ...

) or ACGIH (American Conference of Governmental Industrial Hygienists

The American Conference of Governmental Industrial Hygienists (ACGIH) is a professional association of industrial hygienists and practitioners of related professions, with headquarters in Cincinnati, Ohio. One of its goals is to advance worker pr ...

). It is not regulated by OSHA for carcinogenicity.

Polyurethanes are combustible. Decomposition from fire can produce significant amounts of carbon monoxide and hydrogen cyanide, in addition to nitrogen oxides, isocyanates, and other toxic products. Because of the flammability of the material, it has to be treated with

Polyurethanes are combustible. Decomposition from fire can produce significant amounts of carbon monoxide and hydrogen cyanide, in addition to nitrogen oxides, isocyanates, and other toxic products. Because of the flammability of the material, it has to be treated with flame retardant

The term flame retardants subsumes a diverse group of chemicals that are added to manufactured materials, such as plastics and textiles, and surface finishes and coatings. Flame retardants are activated by the presence of an ignition source and ...

s (at least in case of furniture), almost all of which are considered harmful. California later issued Technical Bulletin 117 2013 which allowed most polyurethane foam to pass flammability tests without the use of flame retardants. Green Science Policy Institute states: "Although the new standard can be met without flame retardants, it does NOT ban their

use. Consumers who wish to reduce household exposure to flame retardants can look for a TB117-2013 tag on furniture, and verify with retailers that products do not contain flame retardants."

Liquid resin blends and isocyanate

In organic chemistry, isocyanate is the functional group with the formula . Organic compounds that contain an isocyanate group are referred to as isocyanates. An organic compound with two isocyanate groups is known as a diisocyanate. Diisocyan ...

s may contain hazardous or regulated components. Isocyanates are known skin and respiratory sensitizers. Additionally, amines, glycols, and phosphate present in spray polyurethane foams present risks.

Exposure to chemicals that may be emitted during or after application of polyurethane spray foam (such as isocyanates) are harmful to human health and therefore special precautions are required during and after this process.

In the United States, additional health and safety information can be found through organizations such as the Polyurethane Manufacturers Association (PMA) and the Center for the Polyurethanes Industry (CPI), as well as from polyurethane system and raw material manufacturers. Regulatory information can be found in the Code of Federal Regulations Title 21 (Food and Drugs) and Title 40 (Protection of the Environment). In Europe, health and safety information is available from ISOPA, the European Diisocyanate and Polyol Producers Association.

Manufacturing

The methods of manufacturing polyurethane finished goods range from small, hand pour piece-part operations to large, high-volume bunstock and boardstock production lines. Regardless of the end-product, the manufacturing principle is the same: to meter the liquid isocyanate and resin blend at a specified stoichiometric ratio, mix them together until a homogeneous blend is obtained, dispense the reacting liquid into a mold or on to a surface, wait until it cures, then demold the finished part.Dispensing equipment

Although the capital outlay can be high, it is desirable to use a meter-mix or dispense unit for even low-volume production operations that require a steady output of finished parts. Dispense equipment consists of material holding (day) tanks, metering pumps, a mix head, and a control unit. Often, a conditioning or heater–chiller unit is added to control material temperature in order to improve mix efficiency, cure rate, and to reduce process variability. Choice of dispense equipment components depends on shot size, throughput, material characteristics such asviscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

and filler content, and process control. Material day tanks may be single to hundreds of gallons in size and may be supplied directly from drums, IBCs (intermediate bulk container

Intermediate bulk containers (also known as IBC tank, IBC tote, IBC, or pallet tank) are industrial-grade containers engineered for the mass handling, transport, and storage of liquids, semi-solids, pastes, or solids. The two main categories of I ...

s, such as totes), or bulk storage tanks. They may incorporate level sensors, conditioning jackets, and mixers. Pumps can be sized to meter in single grams per second up to hundreds of pounds per minute. They can be rotary, gear, or piston pumps, or can be specially hardened lance pumps to meter liquids containing highly abrasive fillers such as chopped or hammer-milled glass fiber

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass.

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the inventio ...

and wollastonite

Wollastonite is a calcium inosilicate mineral ( Ca Si O3) that may contain small amounts of iron, magnesium, and manganese substituting for calcium. It is usually white. It forms when impure limestone or dolomite is subjected to high temperature ...

.

Tooling

Distinct from pour-in-place, bun and boardstock, and coating applications, the production of piece parts requires tooling to contain and form the reacting liquid. The choice of mold-making material is dependent on the expected number of uses to end-of-life (EOL), molding pressure, flexibility, and heat transfer characteristics. RTV silicone is used for tooling that has an EOL in the thousands of parts. It is typically used for molding rigid foam parts, where the ability to stretch and peel the mold around undercuts is needed. The heat transfer characteristic of RTV silicone tooling is poor. High-performance, flexible polyurethane elastomers are also used in this way. Epoxy, metal-filled epoxy, and metal-coated epoxy is used for tooling that has an EOL in the tens of thousands of parts. It is typically used for molding flexible foam cushions and seating, integral skin and microcellular foam padding, and shallow-draft RIM bezels and fascia. The heat transfer characteristic of epoxy tooling is fair; the heat transfer characteristic of metal-filled and metal-coated epoxy is good. Copper tubing can be incorporated into the body of the tool, allowing hot water to circulate and heat the mold surface. Aluminum is used for tooling that has an EOL in the hundreds of thousands of parts. It is typically used for molding microcellular foam gasketing and cast elastomer parts, and is milled or extruded into shape. Mirror-finish stainless steel is used for tooling that imparts a glossy appearance to the finished part. The heat transfer characteristic of metal tooling is excellent. Finally, molded or milledpolypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

Polypropylene

belongs to the group of polyolefins a ...

is used to create low-volume tooling for molded gasket applications. Instead of many expensive metal molds, low-cost plastic tooling can be formed from a single metal master, which also allows greater design flexibility. The heat transfer characteristic of polypropylene tooling is poor, which must be taken into consideration during the formulation process.

Applications

In 2007, the global consumption of polyurethane raw materials was above 12 million metric tons, and the average annual growth rate was about 5%. Revenues generated with PUR on the global market are expected to rise to approximately US$75 billion by 2022.Degradation and environmental fate

Effects of visible light

Polyurethanes, especially those made usingaromatic

In chemistry, aromaticity is a chemical property of cyclic ( ring-shaped), ''typically'' planar (flat) molecular structures with pi bonds in resonance (those containing delocalized electrons) that gives increased stability compared to satur ...

isocyanates, contain chromophores

A chromophore is the part of a molecule responsible for its color.

The color that is seen by our eyes is the one not absorbed by the reflecting object within a certain wavelength spectrum of visible light. The chromophore is a region in the mo ...

that interact with light. This is of particular interest in the area of polyurethane coatings, where light

Light or visible light is electromagnetic radiation that can be perceived by the human eye. Visible light is usually defined as having wavelengths in the range of 400–700 nanometres (nm), corresponding to frequencies of 750–420 te ...

stability is a critical factor and is the main reason that aliphatic

In organic chemistry, hydrocarbons ( compounds composed solely of carbon and hydrogen) are divided into two classes: aromatic compounds and aliphatic compounds (; G. ''aleiphar'', fat, oil). Aliphatic compounds can be saturated, like hexane, ...

isocyanates are used in making polyurethane coatings. When PU foam, which is made using aromatic isocyanates, is exposed to visible light, it discolors, turning from off-white to yellow to reddish brown. It has been generally accepted that apart from yellowing, visible light has little effect on foam properties. This is especially the case if the yellowing happens on the outer portions of a large foam, as the deterioration of properties in the outer portion has little effect on the overall bulk properties of the foam itself.

It has been reported that exposure to visible light can affect the variability of some physical property test results.

Higher-energy UV radiation promotes chemical reactions in foam, some of which are detrimental to the foam structure.

Hydrolysis and biodegradation

Polyurethanes may crumble due to hydrolysis. This is a common problem with shoes left in a closet, and reacting with moisture in the air. Microbial degradation of polyurethane is believed to be due to the action ofesterase

An esterase is a hydrolase enzyme that splits esters into an acid and an alcohol in a chemical reaction with water called hydrolysis.

A wide range of different esterases exist that differ in their substrate specificity, their protein structure ...

, urethanase, hydrolase

Hydrolase is a class of enzyme that commonly perform as biochemical catalysts that use water to break a chemical bond, which typically results in dividing a larger molecule into smaller molecules. Some common examples of hydrolase enzymes are este ...

and protease

A protease (also called a peptidase, proteinase, or proteolytic enzyme) is an enzyme that catalyzes (increases reaction rate or "speeds up") proteolysis, breaking down proteins into smaller polypeptides or single amino acids, and spurring the ...

enzymes. The process is slow as most microbes have difficulty moving beyond the surface of the polymer. Susceptibility to fungi is better due to their release of extracellular enzymes,

which are more able to permeate the polymer matrix. Two species of the Ecuadorian fungus '' Pestalotiopsis'' are capable of biodegrading polyurethane in aerobic and anaerobic conditions such as found at the bottom of landfills. Degradation of polyurethane items at museums has been reported. Polyester-type polyurethanes are more easily biodegraded by fungus than polyether-type.

See also

*Passive fire protection

Passive fire protection (PFP) is components or systems of a building or structure that slows or impedes the spread of the effects of fire or smoke without system activation, and usually without movement. Examples of passive systems include floo ...

* Penetrant (mechanical, electrical, or structural)

Penetrants, or penetrating items, are the mechanical, electrical or structural items that pass through an opening in a wall or floor, such as pipes, electrical conduits, ducting, electrical cables and cable trays, or structural steel beams and ...

* Polyaspartic

* Thermoplastic polyurethanes

Thermoplastic polyurethane (TPU) is any of a class of polyurethane plastics with many properties, including elasticity, transparency, and resistance to oil, grease, and abrasion. Technically, they are thermoplastic elastomers consisting of line ...

* Thermoset polymer matrix

References

External links

Center for the Polyurethanes Industry

information for EH&S issues related to polyurethanes developments

Polymer Science Learning Center,

University of Southern Mississippi

The University of Southern Mississippi (Southern Miss or USM) is a public research university with its main campus located in Hattiesburg, Mississippi. It is accredited by the Southern Association of Colleges and Schools to award bachelor's, ma ...

Polyurethane Foam Association

Industry information, educational materials and resources related to flexible polyurethane foam

PU Europe: European PU insulation industry association

(formerly BING): European voice for the national trade associations representing the polyurethane insulation industry

ISOPA: European Diisocyanate & Polyol Producers Association

ISOPA represents the manufacturers in Europe of aromatic diisocyanates and polyols {{Authority control 1937 in Germany 1937 in science Adhesives Building insulation materials Coatings Elastomers Plastics Wood finishing materials German inventions of the Nazi period