Coil spring on:

[Wikipedia]

[Google]

[Amazon]

A selection of conical coil springs

The most common type of

A selection of conical coil springs

The most common type of

Types of coil spring are:

* Tension/extension coil springs, designed to resist stretching. They usually have a hook or eye form at each end for attachment.

* Compression coil springs, designed to resist being compressed. A typical use for compression coil springs is in car suspension systems.

**

Types of coil spring are:

* Tension/extension coil springs, designed to resist stretching. They usually have a hook or eye form at each end for attachment.

* Compression coil springs, designed to resist being compressed. A typical use for compression coil springs is in car suspension systems.

**

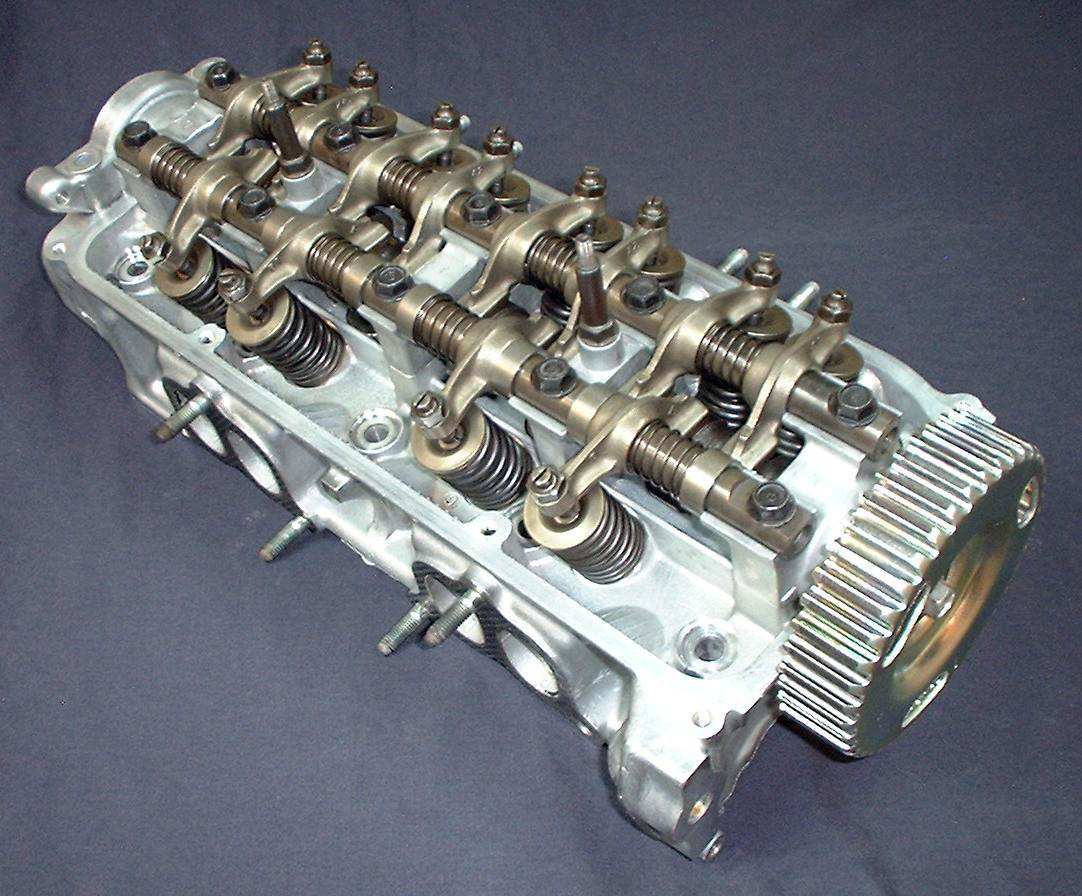

Coil springs used in the engine are compression springs and play an important role in closing the valves that feed air and let exhaust gases out of the combustion chamber. The spring is attached to a rocker that is connected to the valve.

Tension and extension coil springs of a given material, wire diameter and coil diameter exert the same force when fully loaded; increased number of coils merely (linearly) increases free length and compressed/extended length.

Coil springs used in the engine are compression springs and play an important role in closing the valves that feed air and let exhaust gases out of the combustion chamber. The spring is attached to a rocker that is connected to the valve.

Tension and extension coil springs of a given material, wire diameter and coil diameter exert the same force when fully loaded; increased number of coils merely (linearly) increases free length and compressed/extended length.

Helical Spring

' by Sándor Kabai at The Wolfram Demonstrations Project.

Institute of Spring Technology

Cold Coiling Vs Hot Coiling

blog article b

Lesjöfors Heavy Springs

Spring Manufacturers Institute

tutorial by Dave Silberstein.

'' "You Spring From Morning To Night" '', April 1949, Popular Science

article on the basics of steel coil springs manufacturing.

'Springs'

information on each type of spring b

Lesjöfors Heavy Springs

{{design-stub Coil spring Coil spring de:Feder (Technik)#Schraubenfeder

spring

Spring(s) may refer to:

Common uses

* Spring (season), a season of the year

* Spring (device), a mechanical device that stores energy

* Spring (hydrology), a natural source of water

* Spring (mathematics), a geometric surface in the shape of a h ...

is the coil spring, which is made out of a long piece of metal that is wound around itself.

Coil springs were in use in Roman times, evidence of this can be found in bronze Fibulae - the clasps worn by Roman soldiers among others. These are quite commonly found in Roman archeological digs.

Coil springs can be either compression springs, tension springs or torsion springs, depending on how they are wound.

A coil spring is a mechanical device which is typically used to store energy and subsequently release it, to absorb shock, or to maintain a force between contacting surfaces. They are made of an elastic

Elastic is a word often used to describe or identify certain types of elastomer, elastic used in garments or stretchable fabrics.

Elastic may also refer to:

Alternative name

* Rubber band, ring-shaped band of rubber used to hold objects togethe ...

material formed into the shape of a helix

A helix () is a shape like a corkscrew or spiral staircase. It is a type of smooth space curve with tangent lines at a constant angle to a fixed axis. Helices are important in biology, as the DNA molecule is formed as two intertwined helic ...

which returns to its natural length when unloaded.

They are commonly used in mattresses, automotive suspensions, and residential plumbing. Coil springs come in a variety of sizes and shapes and can be used for a variety of applications. Small coil springs are often used in electronic devices, while larger ones are used in automobile suspensions. Coil springs can be made from various materials, including steel, brass, and bronze.

Spring rate

Spring rate is the measurement of how much a coil spring can hold until it compresses . The spring rate is normally specified by the manufacture. If a spring has a rate of 100 then the spring would compress 1 inch with of load.Types

Types of coil spring are:

* Tension/extension coil springs, designed to resist stretching. They usually have a hook or eye form at each end for attachment.

* Compression coil springs, designed to resist being compressed. A typical use for compression coil springs is in car suspension systems.

**

Types of coil spring are:

* Tension/extension coil springs, designed to resist stretching. They usually have a hook or eye form at each end for attachment.

* Compression coil springs, designed to resist being compressed. A typical use for compression coil springs is in car suspension systems.

** Volute spring

A volute spring, also known as a conical spring, is a compression spring in the form of a cone (somewhat like the classical volute decorative architectural ornament). Under compression, the coils slide past each other, thus enabling the spring to ...

s are used as heavy load compression springs. A strip of plate is rolled into the shape of both a helix and a spiral. When compressed, the strip is stiffer edge-on than a wire coil, but the spiral arrangement allows the turns to overlap rather than bottoming out on each other.

** Arc springs (bow springs) are a special form of coil spring which was originally developed for use in the dual-mass flywheel of internal combustion engine drive trains. The force is applied through the ends of the spring. A torque can be transmitted around an axis via the force directed along this helical axis and the lever arm to the system center point .

* Torsion springs, designed to resist twisting actions. Often associated to clothes pegs or up-and-over garage doors.

Heavy duty springs

Heavy-duty springs are designed to withstand high levels of force and tension. They are often used in industrial and commercial applications where heavy loads need to be supported or generated. Heavy-duty springs can be made from various materials, includingsteel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistan ...

, stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's r ...

, and titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion i ...

. They are typically much stiffer and thicker than standard springs (3mm - 65mm thick) and can have a wide range of sizes and shapes because of their strength and durability, heavy-duty springs are often used in automotive and mining applications. They are also commonly used in construction, motorsport, rail and other industries where heavy equipment is used.

Design

Spring design must take into account the desired stiffness of the spring, as well as the amount of space that is available for the spring. In addition, springs must be designed to withstand the forces that will be applied to them, such as the car's weight or the gas pressure. Spring design is an important part of many engineering applications, and it is crucial to ensure that products work correctly and safely.Applications

Coil springs have many applications; notable ones include: *Buckling spring

A buckling spring is a type of keyswitch mechanism, popularized by IBM's keyboards for the PC, PC/AT, 5250/3270 terminals, PS/2, and other systems. It was used by IBM's Model F keyboards (for instance the AT keyboard), and the more common ...

s in computer keyboard

A computer keyboard is a peripheral input device modeled after the typewriter keyboard which uses an arrangement of buttons or keys to act as mechanical levers or electronic switches. Replacing early punched cards and paper tape technolog ...

s

* Mattress coils in innerspring mattresses

* Upholstery coil springs

Upholstery coil springs are an important part of most modern upholstery. The consumer usually never sees the construction features of an upholstered piece. The overall quality of the materials and construction dictate the comfort level of an uphol ...

in upholstery

Upholstery is the work of providing furniture, especially seats, with padding, springs, webbing, and fabric or leather covers. The word also refers to the materials used to upholster something.

''Upholstery'' comes from the Middle English ...

Coil springs are commonly used in vehicle suspension. These springs are compression springs and can differ greatly in strength and in size depending on application. A coil spring suspension can be stiff to soft depending on the vehicle it is used on. Coil spring can be either mounted with a shock absorber or mounted separately. Coil springs in trucks allow them to ride smoothly when unloaded and once loaded the spring compresses and becomes stiff. This allows the vehicle to bounce less when loaded. Coil spring suspension is also used in high performance cars so that the car can absorb bumps and have low body roll. In off-road vehicles they are used because of their range of travel they allow at the wheel.

Manufacture

Metal coil springs are made by winding a wire around a shaped former a cylinder is used to form cylindrical coil springs. Spring manufacture is the process of making springs by coiling, winding, or forming steel wire or other materials. Spring manufacturing includes various processes, including cold coiling and hot coiling. To meet the demands of today's consumers, spring manufacturers must be able to produce springs in a wide range of sizes and shapes. As a result, spring manufacture has become increasingly complex and specialized. They must have a thorough understanding of spring design to produce quality products. In addition, they must be able to operate various machines to produce springs with the desired characteristics. Spring manufacture is a critical part of the economy, and spring makers play an important role in ensuring that products meet the highest quality standards. Coil springs for vehicles are typically made of hardened steel. A machine called an auto-coiler takes spring wire that has been heated so it can easily be shaped. It is then fed onto a lathe that has a metal rod with the desired coil spring size. The machine takes the wire and guides it onto the spinning rod as well as pushing it across the rod to form multiple coils. The spring is then ejected from the machine and an operator will put it in oil to cool off. The spring is then tempered to lose the brittleness from being cooled. The coil size and strength can be controlled by the lathe rod size and material used. Different alloys are used to get certain characteristics out of the spring, such as stiffness, dampening and strengthSee also

*Bogie

A bogie ( ) (in some senses called a truck in North American English) is a chassis or framework that carries a wheelset, attached to a vehicle—a modular subassembly of wheels and axles. Bogies take various forms in various modes of transp ...

* Leaf spring

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. Originally called a ''laminated'' or ''carriage spring'', and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, i ...

* Shock absorber

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most ...

* Slinky

* Timmis system

Timmis was an innovative design of double coiled springs, originally used for railway rolling stock, such as on the Barsi Light Railway c1889, as formulated by Everard Calthrop (1857–1927).

Inventor

The inventor was Illius Augustus Timmis

...

References

External links

*Helical Spring

' by Sándor Kabai at The Wolfram Demonstrations Project.

Institute of Spring Technology

Cold Coiling Vs Hot Coiling

blog article b

Lesjöfors Heavy Springs

Spring Manufacturers Institute

tutorial by Dave Silberstein.

'' "You Spring From Morning To Night" '', April 1949, Popular Science

article on the basics of steel coil springs manufacturing.

'Springs'

information on each type of spring b

Lesjöfors Heavy Springs

{{design-stub Coil spring Coil spring de:Feder (Technik)#Schraubenfeder