Alnico on:

[Wikipedia]

[Google]

[Amazon]

Alnico is a family of

Alnico is a family of

Alnico magnets are widely used in industrial and consumer applications where strong permanent magnets are needed; examples are

Alnico magnets are widely used in industrial and consumer applications where strong permanent magnets are needed; examples are

MMPA 0100-00

''Standard Specifications for Permanent Magnet Materials'' {{aluminium alloys Ferrous alloys Magnetic alloys Ferromagnetic materials Loudspeakers Nickel alloys

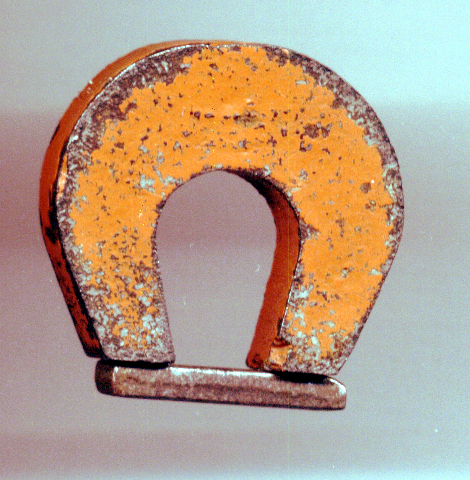

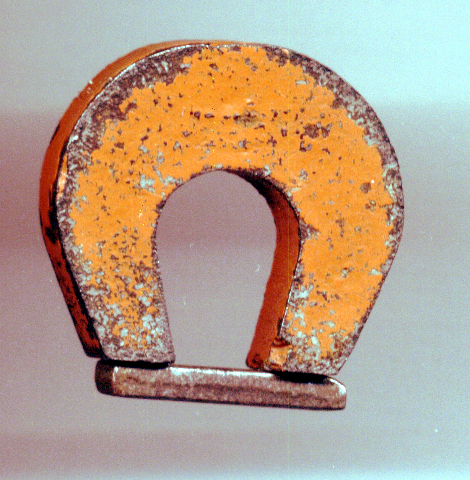

Alnico is a family of

Alnico is a family of iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in ...

alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductili ...

s which in addition to iron are composed primarily of aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

(Al), nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow t ...

(Ni), and cobalt

Cobalt is a chemical element with the symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, p ...

(Co), hence the acronym ''al-ni-co''. They also include copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

, and sometimes titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion i ...

. Alnico alloys are ferromagnetic

Ferromagnetism is a property of certain materials (such as iron) which results in a large observed magnetic permeability, and in many cases a large magnetic coercivity allowing the material to form a permanent magnet. Ferromagnetic materials ...

, and are used to make permanent magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nickel ...

s. Before the development of rare-earth magnet

Rare-earth magnets are strong permanent magnets made from alloys of rare-earth elements. Developed in the 1970s and 1980s, rare-earth magnets are the strongest type of permanent magnets made, producing significantly stronger magnetic fields than ...

s in the 1970s, they were the strongest type of permanent magnet. Other trade names for alloys in this family are: ''Alni, Alcomax, Hycomax, Columax'', and ''Ticonal''.

The composition of alnico alloys is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the rest is Fe. The development of alnico began in 1931, when T. Mishima in Japan discovered that an alloy of iron, nickel, and aluminium had a coercivity

Coercivity, also called the magnetic coercivity, coercive field or coercive force, is a measure of the ability of a ferromagnetic material to withstand an external magnetic field without becoming demagnetized. Coercivity is usually measured in ...

of

, double that of the best magnet steels of the time.

Properties

Alnico alloys can be magnetised to produce strongmagnetic field

A magnetic field is a vector field that describes the magnetic influence on moving electric charges, electric currents, and magnetic materials. A moving charge in a magnetic field experiences a force perpendicular to its own velocity and to ...

s and have a high coercivity (resistance to demagnetization), thus making strong permanent magnets. Of the more commonly available magnets, only rare-earth magnet

Rare-earth magnets are strong permanent magnets made from alloys of rare-earth elements. Developed in the 1970s and 1980s, rare-earth magnets are the strongest type of permanent magnets made, producing significantly stronger magnetic fields than ...

s such as neodymium

Neodymium is a chemical element with the symbol Nd and atomic number 60. It is the fourth member of the lanthanide series and is considered to be one of the rare-earth metals. It is a hard, slightly malleable, silvery metal that quickly tarn ...

and samarium-cobalt are stronger. Alnico magnets produce magnetic field strength at their poles as high as 1500 gauss (0.15 tesla), or about 3000 times the strength of Earth's magnetic field

Earth's magnetic field, also known as the geomagnetic field, is the magnetic field that extends from Earth's interior out into space, where it interacts with the solar wind, a stream of charged particles emanating from the Sun. The magneti ...

. Some brands of alnico are isotropic

Isotropy is uniformity in all orientations; it is derived . Precise definitions depend on the subject area. Exceptions, or inequalities, are frequently indicated by the prefix ' or ', hence '' anisotropy''. ''Anisotropy'' is also used to describ ...

and can be efficiently magnetized in any direction. Other types, such as alnico 5 and alnico 8, are anisotropic

Anisotropy () is the property of a material which allows it to change or assume different properties in different directions, as opposed to isotropy. It can be defined as a difference, when measured along different axes, in a material's physic ...

, with each having a preferred direction of magnetization

In classical electromagnetism, magnetization is the vector field that expresses the density of permanent or induced magnetic dipole moments in a magnetic material. Movement within this field is described by direction and is either Axial or D ...

, or orientation. Anisotropic alloys generally have greater magnetic capacity in a preferred orientation than isotropic types. Alnico's remanence

Remanence or remanent magnetization or residual magnetism is the magnetization left behind in a ferromagnetic material (such as iron) after an external magnetic field is removed. Colloquially, when a magnet is "magnetized", it has remanence. The ...

(Br) may exceed 12,000 G (1.2 T), its coercivity (Hc) can be up to 1000 oersteds (80 kA/m), its maximum energy product ((BH)max) can be up to 5.5 MG·Oe (44 T·A/m). This means that alnico can produce a strong magnetic flux in closed magnetic circuits, but has relatively small resistance against demagnetization. The field strength at the poles of any permanent magnet depends very much on the shape and is usually well below the remanence strength of the material.

Alnico alloys have some of the highest Curie temperatures of any magnetic material, around , although the maximal working temperature is normally limited to around . They are the only magnets that have useful magnetism even when heated red-hot. This property, as well as its brittleness and high melting point, is the result of the strong tendency toward order due to intermetallic

An intermetallic (also called an intermetallic compound, intermetallic alloy, ordered intermetallic alloy, and a long-range-ordered alloy) is a type of metallic alloy that forms an ordered solid-state compound between two or more metallic eleme ...

bonding between aluminium and other constituents. They are also one of the most stable magnets if they are handled properly. Alnico magnets are electrically conductive, unlike ceramic magnets.

As of 2018, Alnico magnets cost about 44 USD/kg (US$20/lb) or US$4.30/BHmax.

Classification

Alnico magnets are traditionally classified using numbers assigned by the Magnetic Materials Producers Association (MMPA), for example, alnico 3 or alnico 5. These classifications indicate chemical composition and magnetic properties. (The classification numbers themselves do not have any direct relation to the properties of the magnet; for instance, a higher number does not necessarily indicate a stronger magnet.) These classification numbers, while still in use, have been deprecated in favor of a new system by the MMPA, which designates Alnico magnets based on maximum energy product in megagauss-oersteds and intrinsic coercive force as kilooersteds, as well as an IEC classification system.Manufacturing process

Alnico magnets are produced bycasting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejecte ...

or sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

processes. Cast alnico is produced by conventional methods using resin bonded sand molds. Sintered alnico magnets are formed using powdered metal manufacturing methods. Sintering alnico is suitable for complex geometries.

Most alnico produced is anisotropic, meaning that the magnetic direction of the grains is oriented in one direction. Anisotropic alnico magnets are oriented by heating above a critical temperature and cooling in the presence of a magnetic field. Both isotropic and anisotropic alnico require proper heat treatment to develop optimal magnetic properties—without it alnico's coercivity is about 10 Oe, comparable to technical iron, which is a soft magnetic material. After the heat treatment alnico becomes a composite material, named "precipitation

In meteorology, precipitation is any product of the condensation of atmospheric water vapor that falls under gravitational pull from clouds. The main forms of precipitation include drizzle, rain, sleet, snow, ice pellets, graupel and hail. ...

material"—it consists of iron- and cobalt-rich precipitates in rich-NiAl matrix. Alnico's anisotropy is oriented along the desired magnetic axis by applying an external magnetic field to it during the precipitate particle nucleation, which occurs when cooling from to , near the Curie point. Without an external field there are local anisotropies of different orientations due to spontaneous magnetization. The precipitate structure is a "barrier" against magnetization changes, as it prefers few magnetization states requiring much energy to get the material into any intermediate state. Also, a weak magnetic field shifts the magnetization of the matrix phase only and is reversible.

Uses

Alnico magnets are widely used in industrial and consumer applications where strong permanent magnets are needed; examples are

Alnico magnets are widely used in industrial and consumer applications where strong permanent magnets are needed; examples are electric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate f ...

s, electric guitar pickups, microphones, sensor

A sensor is a device that produces an output signal for the purpose of sensing a physical phenomenon.

In the broadest definition, a sensor is a device, module, machine, or subsystem that detects events or changes in its environment and sends ...

s, loudspeaker

A loudspeaker (commonly referred to as a speaker or speaker driver) is an electroacoustic transducer that converts an electrical audio signal into a corresponding sound. A ''speaker system'', also often simply referred to as a "speaker" or ...

s, magnetron tubes, and cow magnets. In many applications they are being superseded by rare-earth magnet

Rare-earth magnets are strong permanent magnets made from alloys of rare-earth elements. Developed in the 1970s and 1980s, rare-earth magnets are the strongest type of permanent magnets made, producing significantly stronger magnetic fields than ...

s, whose stronger fields (Br) and larger energy products (B·Hmax) allow smaller-size magnets to be used for a given application.

The high temperature resistance of alnico magnets leads to many uses that cannot be filled by less resistant magnets, such as in magnetic stirring hotplates.

References

Further reading

MMPA 0100-00

''Standard Specifications for Permanent Magnet Materials'' {{aluminium alloys Ferrous alloys Magnetic alloys Ferromagnetic materials Loudspeakers Nickel alloys