ABWR on:

[Wikipedia]

[Google]

[Amazon]

The advanced boiling water reactor (ABWR) is a Generation III

The advanced boiling water reactor (ABWR) is a Generation III

The ABWR represents an evolutionary route for the BWR family, with numerous changes and improvements to previous BWR designs.

Major areas of improvement include:

* The addition of reactor internal pumps (RIP) mounted on the bottom of the

The ABWR represents an evolutionary route for the BWR family, with numerous changes and improvements to previous BWR designs.

Major areas of improvement include:

* The addition of reactor internal pumps (RIP) mounted on the bottom of the

, four ABWRs were in operation in Japan: Kashiwazaki-Kariwa units 6 and 7, which opened in 1996 and 1997, Hamaoka unit 5, opened 2004 having started construction in 2000, and Shika 2 commenced commercial operations on March 15, 2006. Another two partially constructed reactors are in

, four ABWRs were in operation in Japan: Kashiwazaki-Kariwa units 6 and 7, which opened in 1996 and 1997, Hamaoka unit 5, opened 2004 having started construction in 2000, and Shika 2 commenced commercial operations on March 15, 2006. Another two partially constructed reactors are in

/ref>

For example, in 2010 Kashiwazaki-Kariwa 6 had an operating capacity of 80.9%, and an operating capacity of 93% in 2011. However, in 2008 it did not produce any power as the installation was offline for maintenance, and therefore had an operating capacity of 0% for that year. In contrast other modern nuclear power plants like the Korean

/ref>

IAEA

GE Energy's official page for the ABWREngineered Safety Features in the ABWR

{{DEFAULTSORT:Boiling water reactor (advanced) Nuclear power reactor types Nuclear power in the United States

The advanced boiling water reactor (ABWR) is a Generation III

The advanced boiling water reactor (ABWR) is a Generation III boiling water reactor

A boiling water reactor (BWR) is a type of light water nuclear reactor used for the generation of electrical power. It is a design different from a Soviet graphite-moderated RBMK. It is the second most common type of electricity-generating nu ...

. The ABWR is currently offered by GE Hitachi Nuclear Energy

GE Hitachi Nuclear Energy (GEH) is a provider of advanced reactors and nuclear services. It is headquartered in Wilmington, North Carolina, United States. Established in June 2007, GEH is a nuclear alliance created by General Electric and Hitach ...

(GEH) and Toshiba

, commonly known as Toshiba and stylized as TOSHIBA, is a Japanese multinational conglomerate corporation headquartered in Minato, Tokyo, Japan. Its diversified products and services include power, industrial and social infrastructure system ...

. The ABWR generates electrical power by using steam to power a turbine connected to a generator; the steam is boiled from water using heat generated by fission reactions within nuclear fuel. Kashiwazaki-Kariwa unit 6 is considered the first Generation III reactor in the world.

Boiling water reactors (BWRs) are the second most common form of light water reactor

The light-water reactor (LWR) is a type of thermal-neutron reactor that uses normal water, as opposed to heavy water, as both its coolant and neutron moderator; furthermore a solid form of fissile elements is used as fuel. Thermal-neutron reacto ...

with a direct cycle design that uses fewer large steam supply components than the pressurized water reactor

A pressurized water reactor (PWR) is a type of light-water reactor, light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants (with notable exceptions being the UK, Japan and Canada). In a PWR, the primary ...

(PWR), which employs an indirect cycle. The ABWR is the present state of the art

The state of the art (sometimes cutting edge or leading edge) refers to the highest level of general development, as of a device, technique, or scientific field achieved at a particular time. However, in some contexts it can also refer to a level ...

in boiling water reactors, and is the first Generation III reactor

Generation III reactors, or Gen III reactors, are a class of nuclear reactors designed to succeed Generation II reactors, incorporating evolutionary improvements in design. These include improved fuel technology, higher thermal efficiency, sign ...

design to be fully built, with several reactors complete and operating. The first reactors were built on time and under budget in Japan, with others under construction there and in Taiwan. ABWRs were on order in the United States, including two reactors at the South Texas Project

The South Texas Project Electric Generating Station (also known as STP, STPEGS, South Texas Project), is a nuclear power station southwest of Bay City, Texas, United States. STP occupies a site west of the Colorado River about southwest of Houst ...

site. The projects in both Taiwan and US are reported to be over-budget.

The standard ABWR plant design has a net electrical output of about , generated from about of thermal power.

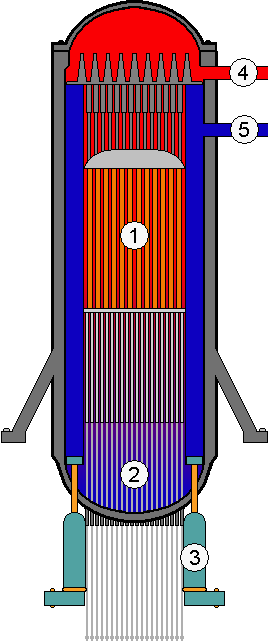

Overview of the design

reactor pressure vessel

A reactor pressure vessel (RPV) in a nuclear power plant is the pressure vessel containing the nuclear reactor coolant, core shroud, and the reactor core.

Classification of nuclear power reactors

Russian Soviet era RBMK reactors have each fuel ...

(RPV) – 10 in total – which achieve improved performance while eliminating large recirculation pumps in containment and associated large-diameter and complex piping interfaces with the RPV (e.g. the recirculation loop found in earlier BWR models). Only the RIP motor is located outside of the RPV in the ABWR. According to the Tier 1 Design Control Document (which is the officially certified Nuclear Regulatory Commission document generally describing the design of the plant), each RIP has a nominal capacity of .

* The control rod

Control rods are used in nuclear reactors to control the rate of fission of the nuclear fuel – uranium or plutonium. Their compositions include chemical elements such as boron, cadmium, silver, hafnium, or indium, that are capable of absorbing ...

adjustment capabilities have been supplemented with the addition of an electro-hydraulic Fine Motion Control Rod Drive (FMCRD), allowing for fine position adjustment using an electrical motor, while not losing the reliability or redundancy of traditional hydraulic systems which are designed to accomplish rapid shutdown in from receipt of an initiating signal, or ARI (alternate rod insertion) in a greater but still insignificant time period. The FMCRD also improves defense-in-depth in the event of primary hydraulic and ARI contingencies.

* A fully digital Reactor Protection System (RPS) (with redundant digital backups as well as redundant manual backups) ensures a high level of reliability and simplification for safety condition detection and response. This system initiates rapid hydraulic insertion of control rods for shutdown (known as SCRAM

A scram or SCRAM is an emergency shutdown of a nuclear reactor effected by immediately terminating the fission reaction. It is also the name that is given to the manually operated kill switch that initiates the shutdown. In commercial reactor ...

by nuclear engineers) when needed. Two-out-of-four per parameter rapid shutdown logic ensures that nuisance rapid shutdowns are not triggered by single instrument failures. RPS can also trigger ARI, FMCRD rod run-in to shut down the nuclear chain reaction. The standby liquid control system (SLCS) actuation is provided as diverse logic in the unlikely event of an Anticipated Transient Without Scram.

* Fully digital reactor controls (with redundant digital backup and redundant manual (analog) backups) allow the control room to easily and rapidly control plant operations and processes. Separate redundant safety and non-safety related digital multiplexing buses allow for reliability and diversity of instrumentation and control.

** In particular, the reactor is automated for startup (i.e., initiate the nuclear chain reaction and ascent to power) and for standard shutdown using automatic systems only. Of course, human operators remain essential to reactor control and supervision, but much of the busy-work of bringing the reactor to power and descending from power can be automated at operator discretion.

* The Emergency Core Cooling System

:''This article covers the technical aspects of active nuclear safety systems in the United States. For a general approach to nuclear safety, see nuclear safety.''

The three primary objectives of nuclear reactor safety systems as defined by the ...

(ECCS) has been improved in many areas, providing a very high level of defense-in-depth against accidents, contingencies, and incidents.

** The overall system has been divided up into 3 divisions; each division is capable – by itself – of reacting to the maximally contingent Limiting Fault/Design Basis Accident (DBA) and terminating the accident prior to core uncovery, even in the event of loss of offsite power and loss of proper feedwater. Previous BWRs had 2 divisions, and uncovery (but no core damage) was predicted to occur for a short time in the event of a severe accident, prior to ECCS response.

** Eighteen SORVs (safety overpressure relief valves), eight of which are part of the ADS (automatic depressurization system), ensure that RPV overpressure events are quickly mitigated, and that if necessary, that the reactor can be depressurized rapidly to a level where low pressure core flooder (LPCF, the high-capacity mode of the residual heat removal system, which replaces the LPCI and LPCS in previous BWR models) can be used.

** Further, LPCF can inject against much higher RPV pressures, providing an increased level of safety in the event of intermediate-sized breaks, which could be small enough to result in slow natural depressurization but could be large enough to result in high pressure corespray/coolant injection systems' capacities for response being overwhelmed by the size of the break.

** Though the Class 1E (safety-related) power bus is still powered by 3 highly-reliable emergency diesel generators that are safety related, an additional Plant Investment Protection power bus using a combustion gas turbine is located on-site to generate electricity to provide defense-in-depth against station blackout contingencies as well as to power important but non-safety critical systems in the event of a loss of offsite power.

** Though one division of the ECCS does not have high pressure flood (HPCF) capacities, there exists a steam-driven, safety-rated reactor core isolation cooling (RCIC) turbopump that is high-pressure rated and has extensive battery backup for its instrumentation and control systems, ensuring cooling is maintained even in the event of a full station blackout with failure of all 3 emergency diesel generators, the combustion gas turbine, primary battery backup, and the diesel firewater pumps.

** There exists an extremely thick basaltic

Basalt (; ) is an aphanitic (fine-grained) extrusive igneous rock formed from the rapid cooling of low-viscosity lava rich in magnesium and iron (mafic lava) exposed at or very near the surface of a rocky planet or moon. More than 90% of a ...

reinforced concrete

Reinforced concrete (RC), also called reinforced cement concrete (RCC) and ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having hig ...

pad under the RPV that will both catch and hold any heated core melt that might fall on that pad in extraordinarily contingent situations. In addition, there are several fusible links within the wall separating the wetwell from the lower drywell that flood the pad using the wetwell's water supply, ensuring cooling of that area even with the failure of standard mitigation systems.

* The containment has been significantly improved over the conventional Mark I type. Like the conventional Mark I type, it is of the pressure suppression type, designed to handle evolved steam in the event of a transient, incident, or accident by routing the steam using pipes that go into a pool of water enclosed in the wetwell (or torus in the case of the Mark I), the low temperature of which will condense the steam back into liquid water. This will keep containment pressure low. Notably, the typical ABWR containment has numerous hardened layers between the interior of the primary containment and the outer shield wall, and is cubical in shape. One major enhancement is that the reactor has a standard safe shutdown earthquake acceleration of .3G; further, it is designed to withstand a tornado with >320 mph wind speed. Seismic hardening is possible in earthquake-prone areas and has been done at the Lungmen facility in Taiwan which has been hardened up 0.4 g in any direction.

* The ABWR is designed for a lifetime of at least 60 years. The comparatively simple design of the ABWR also means that no expensive steam generators need to be replaced either, decreasing total cost of operation.

* According to GEH's Probabilistic Risk Assessment

Probabilistic risk assessment (PRA) is a systematic and comprehensive methodology to evaluate risks associated with a complex engineered technological entity (such as an airliner or a nuclear power plant) or the effects of stressors on the environm ...

, a core damage event would occur no more often than once in six million years as the core damage frequency

Core damage frequency (CDF) is a term used in probabilistic risk assessment (PRA) that indicates the likelihood of an accident that would cause severe damage to a nuclear fuel in a nuclear reactor core.

Core damage accidents are considered extrem ...

(CDF) of the ABWR is , second in lowest CDF probability to the ESBWR.

The RPV and Nuclear Steam Supply System (NSSS) have significant improvements, such as the substitution of RIPs, eliminating conventional external recirculation piping loops and pumps in the containment that in turn drive jet pumps producing forced flow in the RPV. RIPs provide significant improvements related to reliability, performance and maintenance, including a reduction in occupational radiation exposure related to containment activities during maintenance outages. These pumps are powered by wet-rotor motors with the housings connected to the bottom of the RPV and eliminating large diameter external recirculation pipes that are possible leakage paths. The 10 internal recirculation pumps are located at the bottom of the annulus downcomer region (i.e., between the core shroud and the inside surface of the RPV). Consequently, internal recirculation pumps eliminate all of the jet pumps in the RPV, all of the large external recirculation loop pumps and piping, the isolation valves and the large diameter nozzles that penetrated the RPV and needed to suction water from and return it to the RPV. This design therefore reduces the worst leak below the core region to effectively equivalent to a leak. The conventional BWR3-BWR6 product line has an analogous potential leak of 24 or more inches in diameter. A major benefit of this design is that it greatly reduces the flow capacity required of the ECCS.

The first reactors to use internal recirculation pumps were designed by ASEA-Atom

''Allmänna Svenska Elektriska Aktiebolaget'' (English translation: General Swedish Electrical Limited Company; Swedish abbreviation: ASEA) was a Swedish industrial company.

History

ASEA was founded in 1883 by Ludvig Fredholm in Västerås a ...

(now Westinghouse Electric Company

Westinghouse Electric Company LLC is an American nuclear power company formed in 1999 from the nuclear power division of the original Westinghouse Electric Corporation. It offers nuclear products and services to utilities internationally, includi ...

by way of mergers and buyouts, which was owned by Toshiba

, commonly known as Toshiba and stylized as TOSHIBA, is a Japanese multinational conglomerate corporation headquartered in Minato, Tokyo, Japan. Its diversified products and services include power, industrial and social infrastructure system ...

) and built in Sweden

Sweden, formally the Kingdom of Sweden,The United Nations Group of Experts on Geographical Names states that the country's formal name is the Kingdom of SwedenUNGEGN World Geographical Names, Sweden./ref> is a Nordic country located on ...

. These plants have operated very successfully for many years.

The internal pumps reduce the required pumping power for the same flow to about half that required with the jet pump system with external recirculation loops. Thus, in addition to the safety and cost improvements due to eliminating the piping, the overall plant thermal efficiency is increased. Eliminating the external recirculation piping also reduces occupational radiation exposure to personnel during maintenance.

An operational feature in the ABWR design is electric fine motion control rod

Control rods are used in nuclear reactors to control the rate of fission of the nuclear fuel – uranium or plutonium. Their compositions include chemical elements such as boron, cadmium, silver, hafnium, or indium, that are capable of absorbing ...

drives, first used in the BWRs of AEG (later Kraftwerk Union AG, now AREVA

Areva S.A. is a French multinational group specializing in nuclear power headquartered in Courbevoie, France. Before its 2016 corporate restructuring, Areva was majority-owned by the French state through the French Alternative Energies and Atom ...

). Older BWRs use a hydraulic locking piston system to move the control rods in six-inch increments. The electric fine motion control rod design greatly enhances positive actual control rod position and similarly reduces the risk of a control rod drive accident to the point that no velocity limiter is required at the base of the cruciform control rod blades.

Certifications and approvals

Slightly different versions of the ABWR are offered by GE-Hitachi, Hitachi-GE, and Toshiba. In 1997 the GE-Hitachi U.S. ABWR design was certified as a final design in final form by the U.S. Nuclear Regulatory Commission, meaning that its performance, efficiency, output, and safety have already been verified, making it bureaucratically easier to build it rather than a non-certified design. In 2013, following its purchase ofHorizon Nuclear Power

Horizon Nuclear Power is a British Energy industry, energy company that was expected to build new nuclear power stations in the United Kingdom. It was established in 2009, with its head office in Gloucester, and is now owned by Hitachi.

On 17 Ja ...

, Hitachi

() is a Japanese multinational corporation, multinational Conglomerate (company), conglomerate corporation headquartered in Chiyoda, Tokyo, Japan. It is the parent company of the Hitachi Group (''Hitachi Gurūpu'') and had formed part of the Ni ...

began the process of generic design assessment of the Hitachi-GE ABWR with the UK Office for Nuclear Regulation

The Office for Nuclear Regulation (ONR) is the regulator for the nuclear industry in the United Kingdom.< ...

. This was completed in December 2017.

In July 2016 Toshiba withdrew the U.S. design certification renewal for the ABWR because "it has become increasingly clear that energy price declines in the US prevent Toshiba from expecting additional opportunities for ABWR construction projects".

Locations

The ABWR is licensed to operate in Japan, the United States and Taiwan, although most of the construction projects have been halted or shelved.Japan and Taiwan

, four ABWRs were in operation in Japan: Kashiwazaki-Kariwa units 6 and 7, which opened in 1996 and 1997, Hamaoka unit 5, opened 2004 having started construction in 2000, and Shika 2 commenced commercial operations on March 15, 2006. Another two partially constructed reactors are in

, four ABWRs were in operation in Japan: Kashiwazaki-Kariwa units 6 and 7, which opened in 1996 and 1997, Hamaoka unit 5, opened 2004 having started construction in 2000, and Shika 2 commenced commercial operations on March 15, 2006. Another two partially constructed reactors are in Lungmen

The Lungmen Nuclear Power Plant (), formerly known as Gongliao and commonly as the Fourth Nuclear Power Plant (), is an unfinished nuclear power plant in New Taipei City, Taiwan. It consists of two ABWRs each of 1,300 Megawatt, MWe net. It i ...

in Taiwan

Taiwan, officially the Republic of China (ROC), is a country in East Asia, at the junction of the East and South China Seas in the northwestern Pacific Ocean, with the People's Republic of China (PRC) to the northwest, Japan to the nort ...

, and one more (Shimane Nuclear Power Plant

The is a nuclear power plant located in the town of Kashima-chou in the city of Matsue in the Shimane Prefecture. It is owned and operated by the Chūgoku Electric Power Company.

This plant was once said to be the closest nuclear power plant to ...

3) in Japan. Work on Lungmen halted in 2014. Work on Shimane halted after the 2011 earthquake

United States

On June 19, 2006NRG Energy

NRG Energy, Inc. is an American energy company, headquartered in Houston, Texas. It was formerly the wholesale arm of Northern States Power Company (NSP), which became Xcel Energy, but became independent in 2000. NRG Energy is involved in ener ...

filed a Letter Of Intent with the Nuclear Regulatory Commission

The Nuclear Regulatory Commission (NRC) is an independent agency of the United States government tasked with protecting public health and safety related to nuclear energy. Established by the Energy Reorganization Act of 1974, the NRC began operat ...

to build two 1358 MWe ABWRs at the South Texas Project

The South Texas Project Electric Generating Station (also known as STP, STPEGS, South Texas Project), is a nuclear power station southwest of Bay City, Texas, United States. STP occupies a site west of the Colorado River about southwest of Houst ...

site. On September 25, 2007, NRG Energy

NRG Energy, Inc. is an American energy company, headquartered in Houston, Texas. It was formerly the wholesale arm of Northern States Power Company (NSP), which became Xcel Energy, but became independent in 2000. NRG Energy is involved in ener ...

and CPS Energy submitted a Construction and Operations License

The Combined Construction and Operating License (Regulatory Guide 1.206, COL) replaced the previous Draft Regulatory Guide 1145 as the licensing process for new nuclear power plants in the United States. It is a part of a newer "streamlined" proce ...

(COL) request for these plants with the NRC. NRG Energy is a merchant generator and CPS Energy is the nation's largest municipally owned utility. The COL was approved by the NRC on February 9, 2016. Due to market conditions, these two planned units may never be built and do not have a planned construction date.

United Kingdom

Horizon Nuclear Power

Horizon Nuclear Power is a British Energy industry, energy company that was expected to build new nuclear power stations in the United Kingdom. It was established in 2009, with its head office in Gloucester, and is now owned by Hitachi.

On 17 Ja ...

had plans to build Hitachi-GE ABWRs at Wylfa

Wylfa nuclear power station ( cy, Atomfa'r Wylfa) is a Magnox nuclear power station undergoing decommissioning. Wylfa is situated west of Cemaes Bay on the island of Anglesey, off the northwestern coast of Wales. Construction of the two 490MW n ...

in Wales and Oldbury in England. Both projects were paused in March 2012 by the shareholders at the time (RWE

RWE AG is a German multinational energy company headquartered in Essen. It generates and trades electricity in Asia-Pacific, Europe and the United States. The company is Europe's most climate threatening Company, the world's number two in offsh ...

and E-ON) to put Horizon up for sale, with Hitachi

() is a Japanese multinational corporation, multinational Conglomerate (company), conglomerate corporation headquartered in Chiyoda, Tokyo, Japan. It is the parent company of the Hitachi Group (''Hitachi Gurūpu'') and had formed part of the Ni ...

becoming the new owner. The 'Development Consent Order' for Wylfa was accepted in June 2018 and in August Bechtel were appointed as project managers. The first reactor was expected online in the mid-2020s with construction at Oldbury expected to start a few years after this. However, on January 17, 2019, Horizon Nuclear Power

Horizon Nuclear Power is a British Energy industry, energy company that was expected to build new nuclear power stations in the United Kingdom. It was established in 2009, with its head office in Gloucester, and is now owned by Hitachi.

On 17 Ja ...

announced the suspension of both these projects for financial reasons.

Reliability

In comparison with comparable designs, the four ABWRs in operation are often shut down due to technical problems. The International Atomic Energy Agency documents this with the 'operating factor' (the time with electricity feed-in relative to the total time since commercial operation start). The first two plants in Kashiwazaki-Kariwa (block 6 & 7) reach total life operating factors of 70%, meaning that about 30% of the time, since commissioning, they were not producing electricity./ref>

For example, in 2010 Kashiwazaki-Kariwa 6 had an operating capacity of 80.9%, and an operating capacity of 93% in 2011. However, in 2008 it did not produce any power as the installation was offline for maintenance, and therefore had an operating capacity of 0% for that year. In contrast other modern nuclear power plants like the Korean

OPR-1000 __NOTOC__

The OPR-1000 is a South Korean designed two-loop 1000 MWe PWR Generation II nuclear reactor, developed by KHNP and KEPCO. The OPR-1000 was originally designated as the Korean Standard Nuclear Power Plant (KSNP), and was re-designated as ...

or the German Konvoi show operating factors of about 90%.IAEA – Nuclear Power Reactors in the World – 2010 Edition – Vienna 2010

The output power of the two new ABWRs at the Hamaoka and Shika power plant had to be lowered because of technical problems in the power plants steam turbine

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam turbin ...

section. After throttling both power plants down, they still have a heightened downtime and show a lifetime operating factor under 50%./ref>

IAEA

Deployments

ABWR-II design

A number of design variants have been considered, with power outputs varying from 600 to 1800 MWe. The most developed design variant is the ABWR-II, started in 1991, an enlarged 1718 MWe ABWR, intended to make nuclear power generation more competitive in the late 2010s. None of these designs have been deployed. The new designs hoped to achieve 20% reductions in operating costs, 30% reduction in capital costs, and tight planned construction schedule of 30 months. The design would allow for more flexibility in choices of nuclear fuels.See also

*Nuclear power

Nuclear power is the use of nuclear reactions to produce electricity. Nuclear power can be obtained from nuclear fission, nuclear decay and nuclear fusion reactions. Presently, the vast majority of electricity from nuclear power is produced b ...

*Nuclear safety in the U.S.

Nuclear safety in the United States is governed by federal regulations issued by the Nuclear Regulatory Commission (NRC). The NRC regulates all nuclear plants and materials in the United States except for nuclear plants and materials controlled by ...

*Economics of new nuclear power plants

Nuclear power construction costs have varied significantly across the world and in time. Large and rapid increases in cost occurred during the 1970s, especially in the United States. Recent cost trends in countries such as Japan and Korea have ...

*Pressurized water reactor

A pressurized water reactor (PWR) is a type of light-water reactor, light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants (with notable exceptions being the UK, Japan and Canada). In a PWR, the primary ...

*Reduced moderation water reactor

The Reduced-Moderation Water Reactor (RMWR), also referred to as the Resource-renewable BWR, is a proposed type of light water reactor, light water moderated nuclear power reactor, featuring some characteristics of a fast neutron reactor, thereby c ...

*Advanced Heavy Water Reactor

The advanced heavy-water reactor (AHWR) or AHWR-300 is the latest Indian design for a next-generation nuclear reactor that burns thorium in its fuel core. It is slated to form the third stage in India's three-stage fuel-cycle plan. This phase ...

Other Gen III+ designs

* EPR *AP1000

The AP1000 is a nuclear power plant designed and sold by Westinghouse Electric Company. The plant is a pressurized water reactor with improved use of passive nuclear safety and many design features intended to lower its capital cost and improve ...

* ESBWR

* US-APWR

*VVER-TOI

The VVER-TOI or WWER-TOI (russian: text=Водо-водяной энергетический реактор типовой оптимизированный информатизированный, translit=Vodo-Vodyanoi Energetichesky Reactor Tipov ...

* ACR

* Framatom Kerena

References

External links

GE Energy's official page for the ABWR

{{DEFAULTSORT:Boiling water reactor (advanced) Nuclear power reactor types Nuclear power in the United States