|

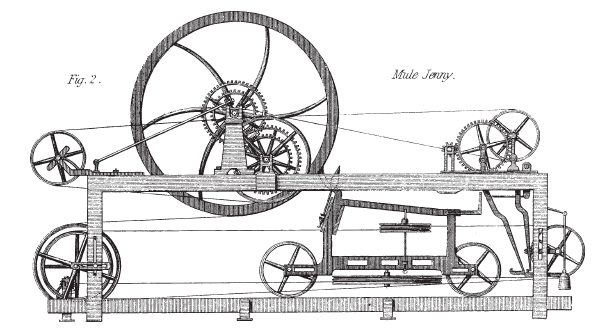

Spinning Mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be long, and would move forward and back a distance of four times a minute. It was invented between 1775 and 1779 by Samuel Crompton. The self-acting (automatic) mule was patented by Richard Roberts in 1825. At its peak there were 50,000,000 mule spindles in Lancashire alone. Modern versions are still in niche production and are used to spin woollen yarns from noble fibres such as cashmere, ultra-fine merino and alpaca for the knitware market. The spinning mule spins textile fibres into yarn by an intermittent process. In the draw stroke, the roving is pulled through rollers and twisted; on the return it is wrapped onto the spin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

A Working Mule Spinning Machine At Quarry Bank Mill

A, or a, is the first letter and the first vowel of the Latin alphabet, used in the modern English alphabet, the alphabets of other western European languages and others worldwide. Its name in English is ''a'' (pronounced ), plural ''aes''. It is similar in shape to the Ancient Greek letter alpha, from which it derives. The uppercase version consists of the two slanting sides of a triangle, crossed in the middle by a horizontal bar. The lowercase version can be written in two forms: the double-storey a and single-storey ɑ. The latter is commonly used in handwriting and fonts based on it, especially fonts intended to be read by children, and is also found in italic type. In English grammar, " a", and its variant " an", are indefinite articles. History The earliest certain ancestor of "A" is aleph (also written 'aleph), the first letter of the Phoenician alphabet, which consisted entirely of consonants (for that reason, it is also called an abjad to distinguish it fr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carding

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing. The word is derived from the Latin meaning thistle or teasel, as dried vegetable teasels were first used to comb the raw wool before technological advances led to the use of machines. Overview These ordered fibres can then be passed on to other processes that are specific to the desired end use of the fibre: Cotton, batting, felt, woollen or worsted yarn, etc. Carding can also be used to create blends of different fibres or different colours. When blending, the cardi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Edmund Cartwright

Edmund Cartwright (24 April 174330 October 1823) was an English inventor. He graduated from Oxford University and went on to invent the power loom. Married to local Elizabeth McMac at 19, he was the brother of Major John Cartwright, a political reformer and radical, and George Cartwright, explorer of Labrador. Early life Cartwright was taught at Queen Elizabeth Grammar School, Wakefield, University College, Oxford, and for an MA degree at Magdalen College, Oxford, (awarded 1766) where he was received a demyship and was elected a Fellow of the College. He became a clergyman of the Church of England. Cartwright began his career as a clergyman, becoming, in 1779, rector of Goadby Marwood, Leicestershire. In 1783, he was elected a prebendary at Lincoln Cathedral. During his time as a clergyman he published the poem ''Armine and Elvira'' in 1770, which was followed by ''The Prince of Peace'' in 1779. Although he became better-known as an inventor he was awarded the degree of D ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Frame

The water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since Ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; this was first used in 1765. The Arkwright water frame was able to spin 96 threads at a time, which was an easier and faster method than ever before. The design was partly based on a spinning machine built for Thomas Highs by clockmaker John Kay, who was hired by Arkwright. Being run on water power, it produced stronger and harder yarn than the then-famous " spinning jenny", and propelled the adoption of the modern factory system. Another water-powered frame for the production of textiles was developed in 1760, in the early industrialized town of Elberfeld, Prussia (now in Wuppertal, Germany), by German bleach plant owner Johann Heinrich Bockmühl. The name ''water frame'' is derived from the use of a water wheel to drive a number of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Warp (weaving)

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft (sometimes woof) is drawn through and inserted over and under the warp. A single thread of the weft crossing the warp is called a ''pick''. Terms vary (for instance, in North America, the weft is sometimes referred to as the ''fill'' or the ''filling yarn'').Barber (1991), p. 79 Each individual warp thread in a fabric is called a ''warp end'' or ''end''.Burnham (1980), pp. 170, 179 Inventions during the 18th century spurred the Industrial Revolution, with the "picking stick" and the " flying shuttle" ( John Kay, 1733) speeding up the production of cloth. The power loom patented by Edmund Cartwright in 1785 allowed sixty picks per minute. Etymology The word ''weft'' derives from the Old English word ''wefan'', to weave. ''Warp'' means "that which is thrown away" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weft

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft (sometimes woof) is drawn through and inserted over and under the warp. A single thread of the weft crossing the warp is called a ''pick''. Terms vary (for instance, in North America, the weft is sometimes referred to as the ''fill'' or the ''filling yarn'').Barber (1991), p. 79 Each individual warp thread in a fabric is called a ''warp end'' or ''end''.Burnham (1980), pp. 170, 179 Inventions during the 18th century spurred the Industrial Revolution, with the "picking stick" and the " flying shuttle" ( John Kay, 1733) speeding up the production of cloth. The power loom patented by Edmund Cartwright in 1785 allowed sixty picks per minute. Etymology The word ''weft'' derives from the Old English word ''wefan'', to weave. ''Warp'' means "that which is thrown awa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

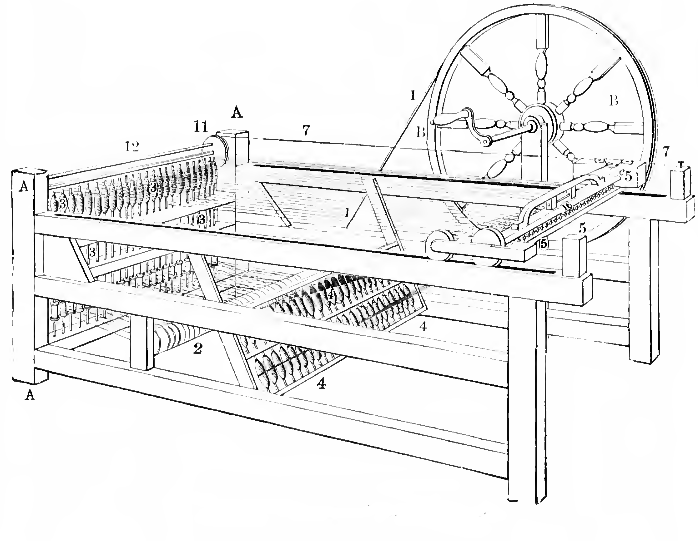

Spinning Jenny

The spinning jenny is a multi- spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England. The device reduced the amount of work needed to produce cloth, with a worker able to work eight or more spools at once. This grew to 120 as technology advanced. The yarn produced by the jenny was not very strong until Richard Arkwright invented the water-powered water frame. The spinning jenny helped to start the factory system of cotton manufacturing. History The spinning jenny was invented by James Hargreaves. He was born in Oswaldtwistle, near Blackburn, around 1720. Blackburn was a town with a population of about 5,000, known for the production of "Blackburn greys," cloths of linen warp and cotton weft initially imported from India. They were usually sent to London to be printed. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Richard Arkwright

Sir Richard Arkwright (23 December 1732 – 3 August 1792) was an English inventor and a leading entrepreneur during the early Industrial Revolution. He is credited as the driving force behind the development of the spinning frame, known as the water frame after it was adapted to use water power; and he patented a rotary carding engine to convert raw cotton to 'cotton lap' prior to spinning. He was the first to develop factories housing both mechanised carding and spinning operations. Arkwright's achievement was to combine power, machinery, semi-skilled labour and the new raw material of cotton to create mass-produced yarn. His organisational skills earned him the accolade "father of the modern industrial factory system," notably through the methods developed in his mill at Cromford, Derbyshire (now preserved as part of the Derwent Valley Mills World Heritage Site). Life and family Richard Arkwright was born in Preston, Lancashire, England on 23 December 1732, the young ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spindle (textiles)

A spindle is a straight spike usually made from wood used for spinning, twisting fibers such as wool, flax, hemp, cotton into yarn. It is often weighted at either the bottom, middle, or top, commonly by a disc or spherical object called a whorl; many spindles, however, are weighted simply by thickening their shape towards the bottom, e.g. Orenburg and French spindles. The spindle may also have a hook, groove, or notch at the top to guide the yarn. Spindles come in many different sizes and weights depending on the thickness of the yarn one desires to spin. History The origin of the first wooden spindle is lost to history because the materials did not survive. Whorl-weighted spindles date back at least to Neolithic times; spindle whorls have been found in archaeological digs around the world. A spindle is also part of traditional spinning wheels where it is horizontal, such as the Indian charkha and the great or walking wheel. In industrial yarn production, spindles are used a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spinning Wheel

A spinning wheel is a device for spinning thread or yarn from fibres. It was fundamental to the cotton textile industry prior to the Industrial Revolution. It laid the foundations for later machinery such as the spinning jenny and spinning frame, which displaced the spinning wheel during the Industrial Revolution. Function The basic spinning of yarn involves taking a clump of fibres and teasing a bit of them out, then twisting it into a basic string shape. The spinner continues pulling and twisting to make it longer and longer, and to control the thickness. Thousands of years ago, people began doing this onto a stick, called a spindle, which was a very lengthy process. The actual wheel part of a spinning wheel does not take the place of the spindle, instead it automates the twisting process, allowing one to "twist" the thread without having to constantly do so manually, and also the size of the wheel lets one more finely control the amount of twist. The thread still ends ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flying Shuttle

The flying shuttle was one of the key developments in the industrialization of weaving during the early Industrial Revolution. It allowed a single weaver to weave much wider fabrics, and it could be mechanized, allowing for automatic machine looms. The flying shuttle, which was patented by John Kay (1704– c. 1779) in 1733, greatly sped up the previous hand process and halved the labour force. Where a broad-cloth loom previously required a weaver on each side, it could now be worked by a single operator. Until this point, the textile industry had required four spinners to service one weaver. Kay's innovation, in wide use by the 1750s, greatly increased this disparity. History The device appears to have been invented in the region of Languedoc of southern France one year before its purported invention in England, but was destroyed by state cloth inspectors of the rent-seeking Ancien Regime. Operation In a typical frame loom, as used previous to the invention of the flying sh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

John Kay (flying Shuttle)

John Kay (17 June 1704 – c. 1779) was an English inventor whose most important creation was the flying shuttle, which was a key contribution to the Industrial Revolution. He is often confused with his namesake, ( John Kay's essay on the two John Kays of the Industrial Revolution). who built the first "spinning frame". Early life John Kay was born on 17 June 1704 in the Lancashire hamlet of Walmersley, just north of Bury. His yeoman farmer father, Robert, owned the "Park" estate in Walmersley, and John was born there. Robert died before John was born, leaving Park House to his eldest son. As Robert's fifth son (out of ten children), John was bequeathed £40 (at age 21) and an education until the age of 14. His mother was responsible for educating him until she remarried. Apprenticeship He apprenticed with a hand-loom reed maker, but is said to have returned home within a month claiming to have mastered the business. He designed a metal substitute for the natural reed t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_and_her_daughter_Mary_Anne%2C_by_Joseph_Wright_of_Derby.jpg)