|

RepRap

The RepRap project started in England in 2005 as a University of Bath initiative to develop a low-cost 3D printer that can print most of its own components, but it is now made up of hundreds of collaborators worldwide. RepRap is short for rep''licating'' rap''id prototyper''. As an open design, all of the designs produced by the project are released under a free software license, the GNU General Public License. Due to the ability of the machine to make some of its own parts, authors envisioned the possibility of cheap RepRap units, enabling the manufacture of complex products without the need for extensive industrial infrastructure.J.M. Pearce, ''Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs'', Elsevier, 2014. They intended for the RepRap to demonstrate evolution in this process as well as for it to increase in number exponentially. A preliminary study claimed that using RepRaps to print common products results in economic savings. History RepRap wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RepRap Mendel

The RepRap project started in England in 2005 as a University of Bath initiative to develop a low-cost 3D printer that can print most of its own components, but it is now made up of hundreds of collaborators worldwide. RepRap is short for rep''licating'' rap''id prototyper''. As an open design, all of the designs produced by the project are released under a free software license, the GNU General Public License. Due to the ability of the machine to make some of its own parts, authors envisioned the possibility of cheap RepRap units, enabling the manufacture of complex products without the need for extensive industrial infrastructure.J.M. Pearce, ''Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs'', Elsevier, 2014. They intended for the RepRap to demonstrate evolution in this process as well as for it to increase in number exponentially. A preliminary study claimed that using RepRaps to print common products results in economic savings. History RepRap wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

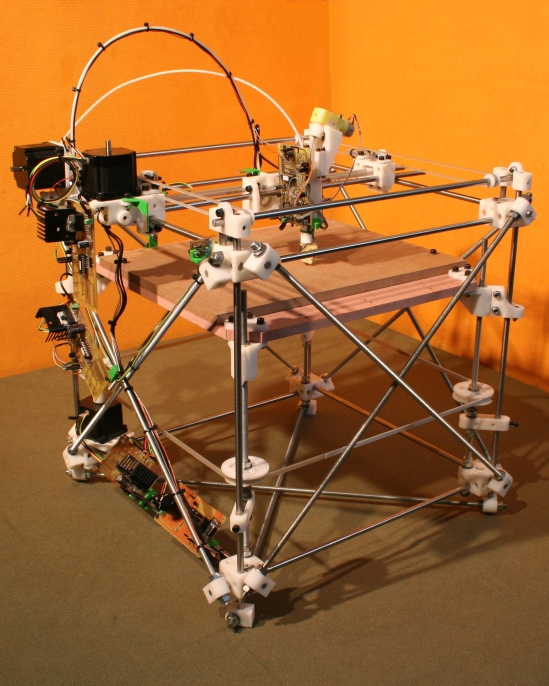

RepRap Darwin

The RepRap project started in England in 2005 as a University of Bath initiative to develop a low-cost 3D printer that can print most of its own components, but it is now made up of hundreds of collaborators worldwide. RepRap is short for rep''licating'' rap''id prototyper''. As an open design, all of the designs produced by the project are released under a free software license, the GNU General Public License. Due to the ability of the machine to make some of its own parts, authors envisioned the possibility of cheap RepRap units, enabling the manufacture of complex products without the need for extensive industrial infrastructure.J.M. Pearce, ''Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs'', Elsevier, 2014. They intended for the RepRap to demonstrate evolution in this process as well as for it to increase in number exponentially. A preliminary study claimed that using RepRaps to print common products results in economic savings. History RepRap wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RepRap Morgan

The RepRap Morgan is an open-source fused deposition modeling 3D printer. The Morgan is part of the RepRap project and has an unusual SCARA arm design. The first Morgan printer was designed by Quentin Harley, a South African engineer (working for Siemens at the time) at the House4Hack Makerspace in Centurion. The SCARA arm design was developed due to the lack of access to components of existing 3D printer designs in South Africa and their relatively high cost. In 2013 the Morgan won the HumanityPlus Uplift Personal Manufacturing Prize and third place in the Gauteng Accelerator Program. The Morgan name comes from the RepRap convention of naming printers after famous deceased biologists. The Morgan printers was named after Thomas Hunt Morgan Thomas Hunt Morgan (September 25, 1866 – December 4, 1945) was an American evolutionary biologist, geneticist, embryologist, and science author who won the Nobel Prize in Physiology or Medicine in 1933 for discoveries elucidating the r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RepRap Fisher

The RepRap Fisher is an open-source fused deposition modeling 3D printer and is part of the RepRap project. The RepRap Fisher is named after the English statistician and biologist Ronald Fisher Sir Ronald Aylmer Fisher (17 February 1890 – 29 July 1962) was a British polymath who was active as a mathematician, statistician, biologist, geneticist, and academic. For his work in statistics, he has been described as "a genius who ..., it was designed by RepRapPro. The RepRap Fisher has a 150mm diameter by 180mm height build volume, uses a Bowden extruder and has a print resolution of 12.5 um in all directions, it also has a micro SD card and USB and Ethernet connections allowing it to be connected to a network. The printer was praised for its ease of construction and low price and is only available in kit form. See also * RepRap Ormerod * Prusa i3 References {{reflist External links RepRap Ltd Fisher kitseMaker RepRap Fisher kitsRepRap Fisher page on RepRa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RepRap Snappy

The RepRap Snappy is an open-source fused deposition modeling 3D printer, part of the RepRap project The RepRap project started in England in 2005 as a University of Bath initiative to develop a low-cost 3D printer that can print most of its own components, but it is now made up of hundreds of collaborators worldwide. RepRap is short for rep''li ..., it is the most self replicating 3D printer in the world. The RepRap Snappy is designed to address the core goal of the RepRap project of creating a general-purpose self-replicating manufacturing machine'''. The RepRap Snappy is able to create 73% of its own parts by volume with a design that eliminates as many of the non 3D printed parts as possible including belts and bearings which are replaced with a rack and pinion system. The name Snappy comes from the use of snap fit connectors used on the small printed parts to construct larger pieces, this both cuts down on the use of non 3D printed parts and means a smaller build volum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RepRap Ormerod

The RepRap Ormerod is an open-source fused deposition modeling 3D printer and is part of the RepRap project. The RepRap Ormerod is named after the English entomologist Eleanor Anne Ormerod, it was designed by RepRapPro. There have been two versions of the Ormerod, the Ormerod 1 was released in December 2013 and the Ormerod 2 released in December 2014. The RepRap Ormerod has a 200 mm × 200 mm × 200 mm build volume, uses a Bowden extruder, it also has a micro SD card and USB and Ethernet connections allowing it to be connected to a network. The printer was praised for the simplicity of construction and its low cost. See also * RepRap Fisher * Prusa i3 The Prusa i3 series consists of open-source fused deposition modeling 3D printers, manufactured by Czech company Prusa Research under the trademarked name Original Prusa i3. Part of the RepRap project, Prusa i3 printers were named the most used ... References {{reflist External links ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prusa I3

The Prusa i3 series consists of open-source fused deposition modeling 3D printers, manufactured by Czech company Prusa Research under the trademarked name Original Prusa i3. Part of the RepRap project, Prusa i3 printers were named the most used 3D printer in the world. The first Prusa i3 was designed by Josef Průša in 2012, and was released as a commercial kit product in 2015. The latest model (MK3S+, as of November 2020) is available in both kit and factory assembled versions. The Prusa i3's comparable low cost and ease of construction and modification has made it popular in education and with hobbyists and professionals. Since the i3 series is open source, there have been many variants produced by companies and individuals worldwide. Models File:Assembled Prusa Mendel.jpg, Prusa Mendel File:Prusa Mendel (iteration 2).jpg, Prusa Mendel (iteration 2) File:Prusa i3 metal frame.jpg, Prusa i3 File:Prusa i3 MK2.jpg, Prusa i3 MK2 RepRap Mendel First conceived in 2009, RepRap M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printer

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would be otherwise impossible to construct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hangprinter

Hangprinter is an Open-source model, open-source fused deposition modeling delta 3D printer notable for its unique frameless design. It was created by Torbjørn Ludvigsen. The Hangprinter uses relatively low cost parts and can be constructed for around US$250. The printer is part of the RepRap project, meaning many of the parts of the printer are able to be produced on the printer itself (partially self replicating). The design files for the printer are available on GitHub for download, modification and redistribution. Versions Version 0 The Hangprinter v0, also called the Slideprinter, is a 2D plotter. It was designed solely to test if a 3D version could realistically be created. File:Hangprinter version 0.jpg, Hangprinter v0 Version 1 The Hangprinter v1 uses counter weights to stay elevated. File:Hangprinter v1 first print.jpg, Hangprinter v1. Counterweights tied in at its center cylinder. Version 2 All parts of the Hangprinter Version 2 are contained within a single un ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adrian Bowyer

Adrian Bowyer is an English engineer and mathematician, formerly an academic at the University of Bath. Born in 1952 in London, Bowyer is the older child of the late Rosemary and John Bowyer; the latter was a writer, painter and one of the founders of Zisman, Bowyer and Partners, consulting engineers. Bowyer was educated at Woodroffe School, Lyme Regis and Imperial College London. In 1977 he joined the Mathematics Department at the University of Bath. Shortly after that he received a doctorate from Imperial College London for research in friction-induced vibration. Whilst working in the Mathematics Department he invented (at the same time as David Watson) the algorithm for computing Voronoi diagrams that bears their names (the Bowyer–Watson algorithm). He then spent twenty-two years as a lecturer then senior lecturer in the Mechanical Engineering Department at the University of Bath. He retired from academic life in 2012, though he is still a director of the company Rep ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Open Design

The open-design movement involves the development of physical products, machines and systems through use of publicly shared design information. This includes the making of both free and open-source software (FOSS) as well as open-source hardware. The process is generally facilitated by the Internet and often performed without monetary compensation. The goals and philosophy of the movement are identical to that of the open-source movement, but are implemented for the development of physical products rather than software. Open design is a form of co-creation, where the final product is designed by the users, rather than an external stakeholder such as a private company. Origin Sharing of manufacturing information can be traced back to the 18th and 19th century. Aggressive patenting put an end to that period of extensive knowledge sharing. More recently, principles of open design have been related to the free and open-source software movements.Vallance, Kiani and Nayfeh, Open D ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Open Source

Open source is source code that is made freely available for possible modification and redistribution. Products include permission to use the source code, design documents, or content of the product. The open-source model is a decentralized software development model that encourages open collaboration. A main principle of open-source software development is peer production, with products such as source code, blueprints, and documentation freely available to the public. The open-source movement in software began as a response to the limitations of proprietary code. The model is used for projects such as in open-source appropriate technology, and open-source drug discovery. Open source promotes universal access via an open-source or free license to a product's design or blueprint, and universal redistribution of that design or blueprint. Before the phrase ''open source'' became widely adopted, developers and producers have used a variety of other terms. ''Open source'' ga ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |