|

Peening

In metallurgy, peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening), or focusing light ( laser peening). Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal. Residual stress Plastic deformation from peening induces a residual compressive stress in a peened surface, along with tensile stress in the interior. This stress state resembles the one seen in toughened glass, and is useful for similar reasons. Surface compressive stresses confer resistance to metal fatigue and to some forms of corrosion, since cracks will not grow in a compressive environment. The benefit comes at the expense of higher tensile stresses deeper in t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Peening

Laser peening (LP), or laser shock peening (LSP), is a surface engineering process used to impart beneficial residual stresses in materials. The deep, high-magnitude compressive residual stresses induced by laser peening increase the resistance of materials to surface-related failures, such as fatigue, fretting fatigue and stress corrosion cracking. Laser shock peening can also be used to strengthen thin sections, harden surfaces, shape or straighten parts (known as laser peen forming), break up hard materials, compact powdered metals and for other applications where high pressure, short duration shock waves offer desirable processing results. History Discovery and development (1960s) Initial scientific discoveries towards modern day laser peening began in the early 1960s as pulsed laser technology began to proliferate across the globe. In an early investigation of the laser interaction with materials by Gurgen Askaryan and E.M. Moroz, they documented pressure measurements on a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shot Peening

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with force sufficient to create plastic deformation."Shot Peening," ''Tool and Manufacturing Engineers Handbook'' (TMEH), Volume 3, Society of Manufacturing Engineers, 1985 In machining, shot peening is used to strengthen and relieve stress in components like steel automobile crankshafts and connecting rods. In architecture it provides a muted finish to metal. Shot peening is similar mechanically to sandblasting, though its purpose is not to remove material, but rather it employs the mechanism of plasticity to achieve its goal, with each particle functioning as a ball-peen hammer. Details Peening a surface spreads it plastically, causing changes in the mechanical properties of the surface. Its main application is to avoid the propagation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Peening Jig Anvil

In metallurgy, peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening), or focusing light (laser peening). Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal. Residual stress Plastic deformation from peening induces a residual compressive stress in a peened surface, along with tensile stress in the interior. This stress state resembles the one seen in toughened glass, and is useful for similar reasons. Surface compressive stresses confer resistance to metal fatigue and to some forms of corrosion, since cracks will not grow in a compressive environment. The benefit comes at the expense of higher tensile stresses deeper in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

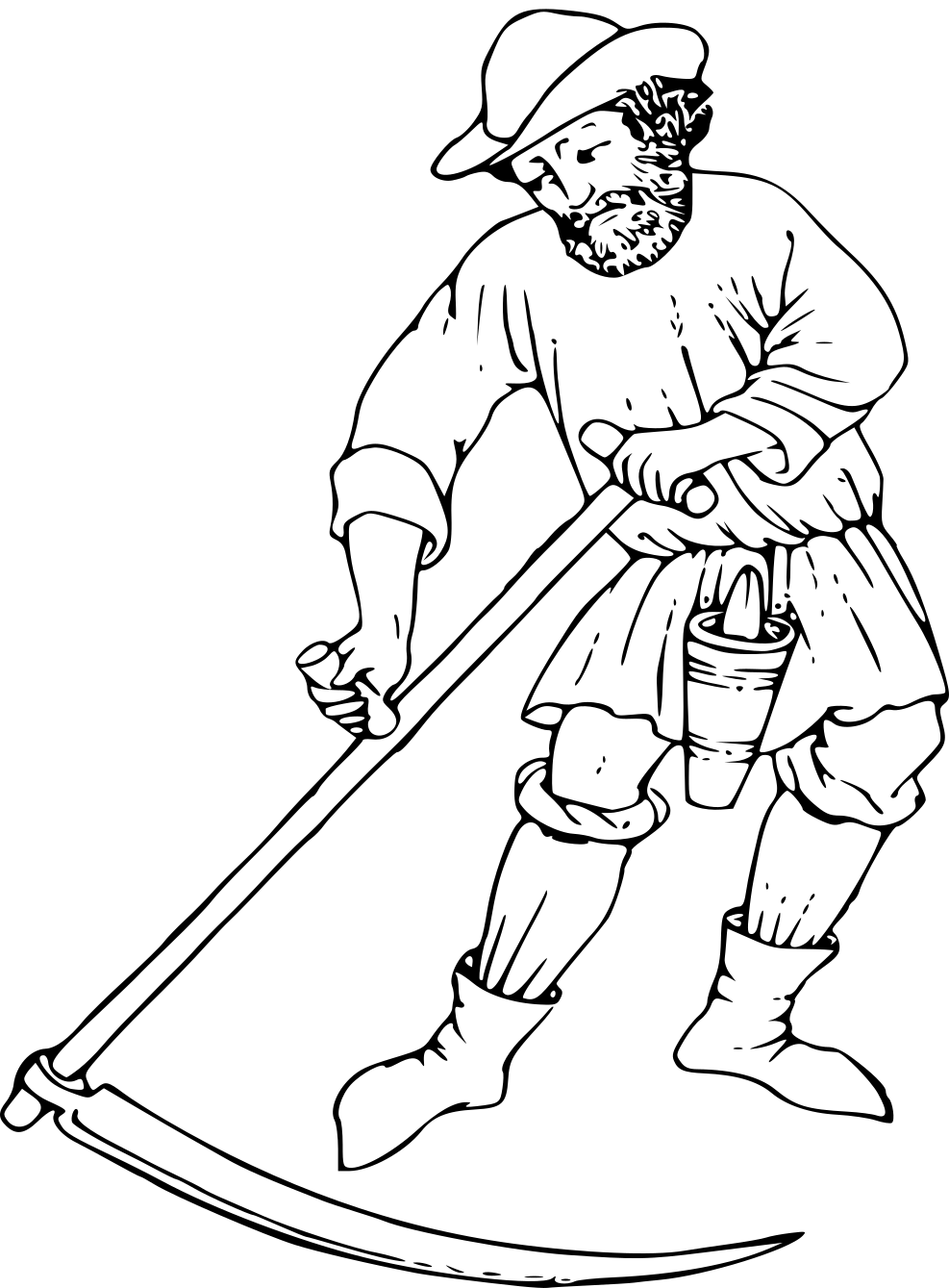

Peening Blade2

In metallurgy, peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening), or focusing light (laser peening). Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal. Residual stress Plastic deformation from peening induces a residual compressive stress in a peened surface, along with tensile stress in the interior. This stress state resembles the one seen in toughened glass, and is useful for similar reasons. Surface compressive stresses confer resistance to metal fatigue and to some forms of corrosion, since cracks will not grow in a compressive environment. The benefit comes at the expense of higher tensile stresses deeper in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shot Peening Of Steel Belts

Shot peening Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with ... can be used to recondition distorted steel conveyor belts. The shot peening process is quick and cost-effective compared with other methods and does not interrupt daily production. A deformed steel belt has the following disadvantages: *Exerts uneven pressure on the product, *Can cause steel belt tracking problems in the press, *The steel belt is exposed to unnecessary high stress, *Increases the risk of accidental damage to the edge of the belt, *Overall reduces the life span of the steel belt. The shot peening process Shot peening is a maintenance process for flattening a deformed steel belt in which the surface of the belt is impacted by small spherical stainless steel or carbon steel balls called peening shot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scythe

A scythe ( ) is an agricultural hand tool for mowing grass or harvesting crops. It is historically used to cut down or reap edible grains, before the process of threshing. The scythe has been largely replaced by horse-drawn and then tractor machinery, but is still used in some areas of Europe and Asia. Reapers are bladed machines that automate the cutting of the scythe, and sometimes subsequent steps in preparing the grain or the straw or hay. The word "scythe" derives from Old English ''siðe''. In Middle English and later, it was usually spelt ''sithe'' or ''sythe''. However, in the 15th century some writers began to use the ''sc-'' spelling as they thought (wrongly) the word was related to the Latin ''scindere'' (meaning "to cut"). Nevertheless, the ''sithe'' spelling lingered and notably appears in Noah Webster's dictionaries. A scythe consists of a shaft about long called a ''snaith'', ''snath'', ''snathe'' or ''sned'', traditionally made of wood but now sometimes met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residual Stress

In materials science and solid mechanics, residual stresses are stresses that remain in a solid material after the original cause of the stresses has been removed. Residual stress may be desirable or undesirable. For example, laser peening imparts deep beneficial compressive residual stresses into metal components such as turbine engine fan blades, and it is used in toughened glass to allow for large, thin, crack- and scratch-resistant glass displays on smartphones. However, unintended residual stress in a designed structure may cause it to fail prematurely. Residual stresses can result from a variety of mechanisms including inelastic (plastic) deformations, temperature gradients (during thermal cycle) or structural changes ( phase transformation). Heat from welding may cause localized expansion, which is taken up during welding by either the molten metal or the placement of parts being welded. When the finished weldment cools, some areas cool and contract more than othe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals; that is, the way in which science is applied to the production of metals, and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist. The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Frequency Impact Treatment

The high-frequency impact treatment or HiFIT – Method is the treatment of welded steel constructions at the weld transition to increase the fatigue strength. Features The durability and life of dynamically loaded, welded steel structures is determined in many cases by the welds, in particular the weld transitions. Through selective treatment of the transitions ( grinding (abrasive cutting), abrasive blasting, hammering, etc.), the durability of many designs increase significantly. Hammering methods have proven to be particularly effective treatment methods and were within the joint project REFRESH extensively studied and developed. The HiFIT (High-Frequency Impact Treatment (also called HFMI (High Frequency Mechanical Impact))) process is such a hammering method that is universally applicable, requires only a low tech equipment and still offers high reproducibility and the possibility for quality control. Operation The HiFIT hammer operates with a hardened pin with a ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tensile Stress

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elongation which is also known as deformation, like the stretching of an elastic band, it is called tensile stress. But, when the forces result in the compression of an object, it is called compressive stress. It results when forces like tension or compression act on a body. The greater this force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Therefore, stress is measured in newton per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material. For example, when a solid vertical bar is supporting an overhead weight, each particle in the bar pushe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |