|

Microthermoforming

Microthermoforming is the abbreviation for microscopic or microscale thermoforming, or, more precisely, for thermoforming of microproducts or microstructure products. Microstructure products means products that have structures in the micrometre range and have their technical function provided by the shape of the microstructure Thermoforming in turn means shaping of heated and therefore softened semi finished products in the form of thermoplastic polymer films or plates with their edges fixed by three-dimensional stretching. Shaping is carried out mainly by forming the films or plates into female moulds (negative forming) or over male moulds (positive forming). While the other polymer microreplication processes such as micro injection moulding or (vacuum) hot embossing are primary forming processes where forming occurs already in a molten, liquid phase of the heated polymer material, microthermoforming is a secondary forming process where forming occurs in a strongly softened ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature that permits it to be stretched into or onto a mold and cooled to a finished shape. Its simplified version is vacuum forming. In its simplest form, a small tabletop or lab size machine can be used to heat small cut sections of plastic sheet and stretch it over a mold using vacuum. This method is often used for sample and prototype parts. In complex and high-volume applications, very large production machines are utilized to heat and form the plastic sheet and trim the formed parts from the sheet in a continuous high-speed process and can produce many thousands of finished parts per hour depending on the machine and mold size and the size of the parts being formed. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microscopic Scale

The microscopic scale () is the scale of objects and events smaller than those that can easily be seen by the naked eye, requiring a lens or microscope to see them clearly. In physics, the microscopic scale is sometimes regarded as the scale between the macroscopic scale and the quantum scale. Microscopic units and measurements are used to classify and describe very small objects. One common microscopic length scale unit is the micrometre (also called a ''micron'') (symbol: μm), which is one millionth of a metre. History Whilst compound microscopes were first developed in the 1590s, the significance of the microscopic scale was only truly established in the 1600s when Marcello Malphigi and Antonie van Leeuwenhoek microscopically observed frog lungs and microorganisms. As microbiology was established, the significance of making scientific observations at a microscopic level increased. Published in 1665, Robert Hooke’s book Micrographia details his microscopic observatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastics Industry

The plastics industry manufactures polymer materials—commonly called plastics—and offers services in plastics important to a range of industries, including packaging, building and construction, electronics, aerospace, and transportation. It is part of the chemical industry. In addition, as mineral oil is the major constituent of plastics, it therefore forms part of the petrochemical industry. Besides plastics production, plastics engineering is an important part of the industrial sector. The latter field is dominated by engineering plastic as raw material because of its better mechanical and thermal properties than the more widely used commodity plastics. Companies Markets According to PlasticsEurope, the top three markets for plastics are packaging, building and construction, and automotive. Production Plastics production has been growing globally. The numbers include thermoplastics and polyurethanes, as well as thermosets, adhesives, coatings and sealants and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smart Textiles

Electronic textiles or e-textiles are fabrics that enable electronic components such as batteries, lights, sensors, and microcontrollers to be embedded in them. They are not to be confused witsmart textiles which are fabrics that have been developed with new technologies that provide added value. Many smart clothing, wearable technology, and wearable computing projects involve the use of e-textiles. Electronic textiles are distinct from wearable computing because the emphasis is placed on the seamless integration of textiles with electronic elements like microcontrollers, sensors, and actuators. Furthermore, e-textiles need not be wearable. For instance, e-textiles are also found in interior design. The related field of fibretronics explores how electronic and computational functionality can be integrated into textile fibers. A new report from Cientifica Research examines the markets for textile-based wearable technologies, the companies producing them, and the enabling t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

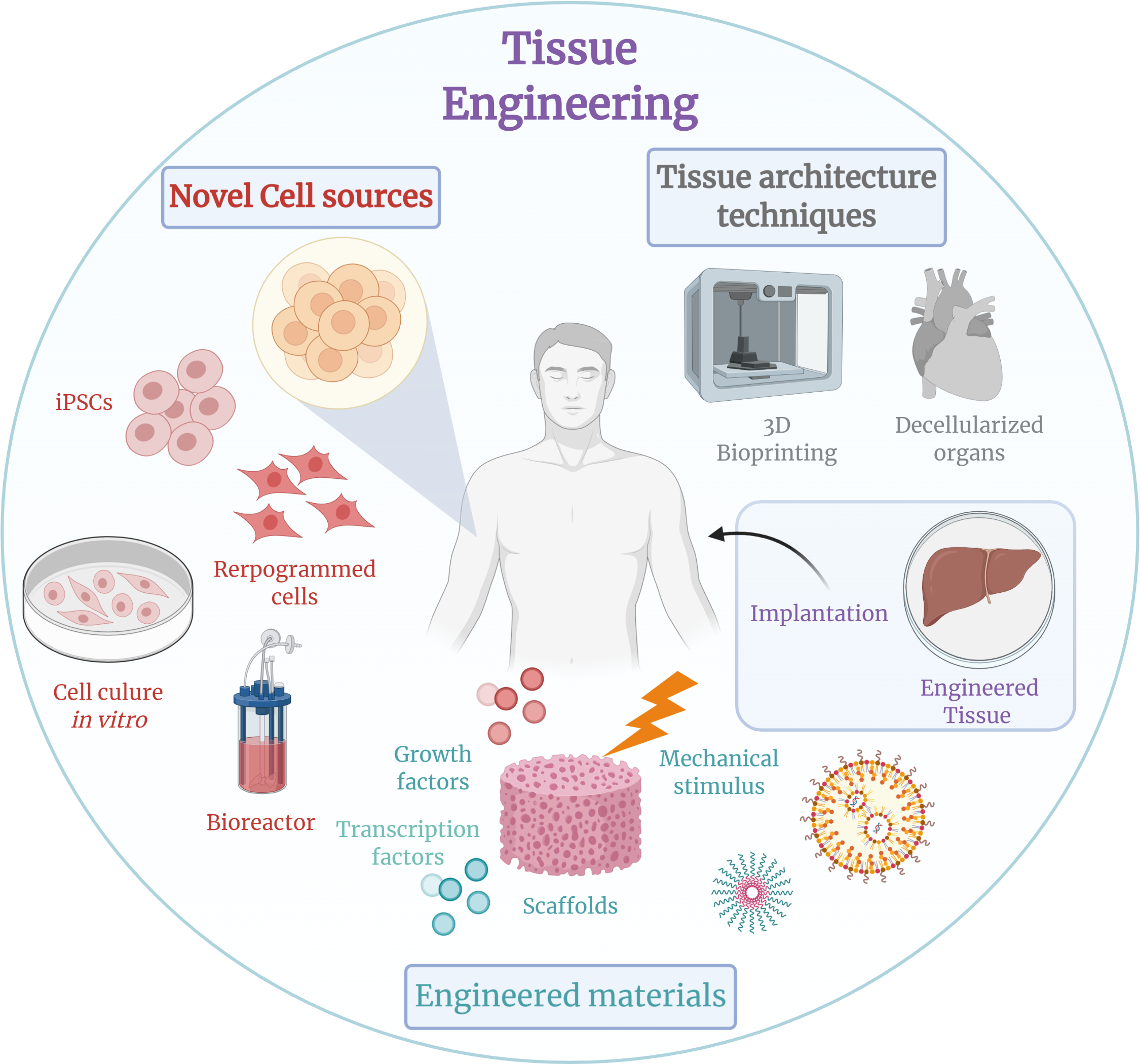

Tissue Engineering

Tissue engineering is a biomedical engineering discipline that uses a combination of Cell (biology), cells, engineering, Materials science, materials methods, and suitable biochemistry, biochemical and physicochemical factors to restore, maintain, improve, or replace different types of biology, biological tissues. Tissue engineering often involves the use of cells placed on tissue scaffolds in the formation of new viable tissue for a medical purpose but is not limited to applications involving cells and tissue scaffolds. While it was once categorized as a sub-field of biomaterials, having grown in scope and importance it can be considered as a field of its own. While most definitions of tissue engineering cover a broad range of applications, in practice the term is closely associated with applications that repair or replace portions of or whole tissues (i.e. bone, Autologous chondrocyte implantation, cartilage, blood vessels, Urinary bladder, bladder, skin, muscle etc.). Often, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

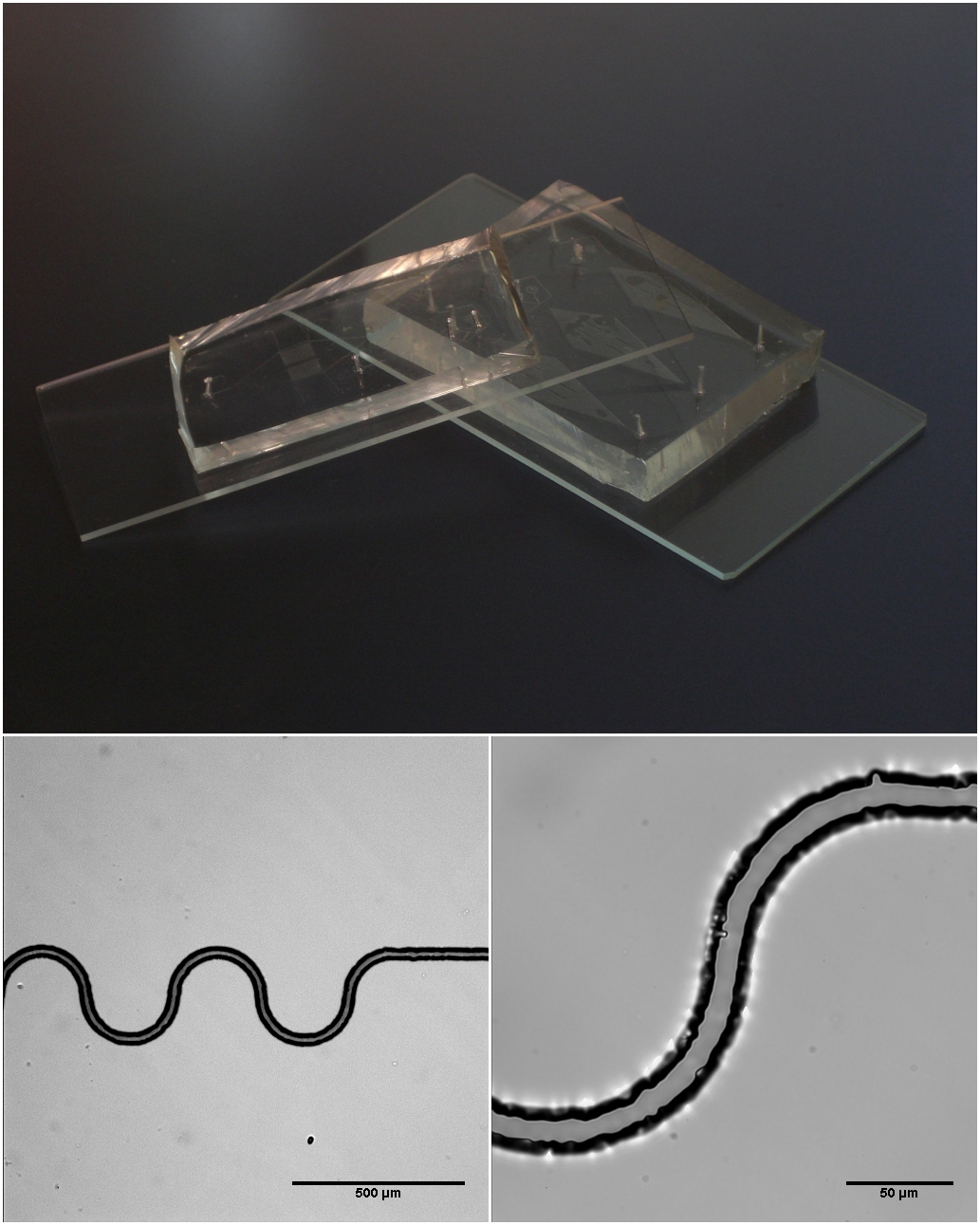

Lab-on-a-chip

A lab-on-a-chip (LOC) is a device that integrates one or several laboratory functions on a single integrated circuit (commonly called a "chip") of only millimeters to a few square centimeters to achieve automation and high-throughput screening. LOCs can handle extremely small fluid volumes down to less than pico-liters. Lab-on-a-chip devices are a subset of microelectromechanical systems (MEMS) devices and sometimes called "micro total analysis systems" (µTAS). LOCs may use microfluidics, the physics, manipulation and study of minute amounts of fluids. However, strictly regarded "lab-on-a-chip" indicates generally the scaling of single or multiple lab processes down to chip-format, whereas "µTAS" is dedicated to the integration of the total sequence of lab processes to perform chemical analysis. The term "lab-on-a-chip" was introduced when it turned out that µTAS technologies were applicable for more than only analysis purposes. History After the invention of microtechnolo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Undercut (manufacturing)

In manufacturing, an undercut is a special type of recessed surface that is inaccessible using a straight tool. In turning, it refers to a recess in a diameter generally on the inside diameter of the part. In milling, it refers to a feature which is not visible when the part is viewed from the spindle. In molding, it refers to a feature that cannot be molded using only a single pull mold. In printed circuit board construction, it refers to the portion of the copper that is etched away under the photoresist. Turning On turned parts an undercut is also known as a ''neck'' or "relief groove". They are often used at the end of the threaded portion of a shaft or screw to provide clearance for the cutting tool. Molding Undercut - Any indentation or protrusion in a shape that will prevent its withdrawal from a one-piece mold. Milling In milling the spindle is where a cutting tool is mounted. In some situations material must be cut from a direction where the feature can not be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfluidic

Microfluidics refers to the behavior, precise control, and manipulation of fluids that are geometrically constrained to a small scale (typically sub-millimeter) at which surface forces dominate volumetric forces. It is a multidisciplinary field that involves engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology. It has practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening. Microfluidics emerged in the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies. Typically, micro means one of the following features: * Small volumes (μL, nL, pL, fL) * Small size * Low energy consumption * Microdomain effects Typically microfluidic systems transport, mix, separate, or otherwise process fluids. Various applications rely on passive fluid control using capillary f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Georgia Institute Of Technology

The Georgia Institute of Technology, commonly referred to as Georgia Tech or, in the state of Georgia, as Tech or The Institute, is a public research university and institute of technology in Atlanta, Georgia. Established in 1885, it is part of the University System of Georgia and has satellite campuses in Savannah, Georgia; Metz, France; Shenzhen, China; and Singapore. The school was founded as the Georgia School of Technology as part of Reconstruction plans to build an industrial economy in the post-Civil War Southern United States. Initially, it offered only a degree in mechanical engineering. By 1901, its curriculum had expanded to include electrical, civil, and chemical engineering. In 1948, the school changed its name to reflect its evolution from a trade school to a larger and more capable technical institute and research university. Today, Georgia Tech is organized into six colleges and contains about 31 departments/units, with emphasis on science and technolo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polycaprolactone

Polycaprolactone (PCL) is a biodegradable polyester with a low melting point of around 60 °C and a glass transition temperature of about −60 °C. The most common use of polycaprolactone is in the production of speciality polyurethanes. Polycaprolactones impart good resistance to water, oil, solvent and chlorine to the polyurethane produced. This polymer is often used as an additive for resins to improve their processing characteristics and their end use properties (e.g., impact resistance). Being compatible with a range of other materials, PCL can be mixed with starch to lower its cost and increase biodegradability or it can be added as a polymeric plasticizer to polyvinyl chloride (PVC). Polycaprolactone is also used for splinting, modeling, and as a feedstock for prototyping systems such as fused filament fabrication 3D printers. Synthesis PCL is prepared by ring opening polymerization of ε-caprolactone using a catalyst such as stannous octoate. A w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastomeric

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of ''elastic polymer'', is often used interchangeably with rubber, although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation is feasible without breaking of covalent bonds. At ambient temperatures, such rubbers are thus relatively compliant ( E ≈ 3 M Pa) and deformable. Their primary uses are for seals, adhesives and molded flexible parts. Application areas for different types of rubber are manifold and cover segments as diverse as tires, soles for shoes, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |