|

Mass-production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods. The term ''mass production'' was popularized by a 1926 article in the ''Encyclopædia Britannica'' supplement that was written based on correspondence with Ford Motor Company. ''The New York Times'' used the term in the title of an article that appeared before publication of the ''Britannica'' article. The concepts of mass production are applied to various kinds of products: from fluids and particulates handled in bulk (food, fuel, chemicals and mined minerals), to parts and assemblies of parts (household appliances and automobiles). Some mass production techniques, such as standardized sizes and production lines, predate the Industrial Revolution by many centuries; however, it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

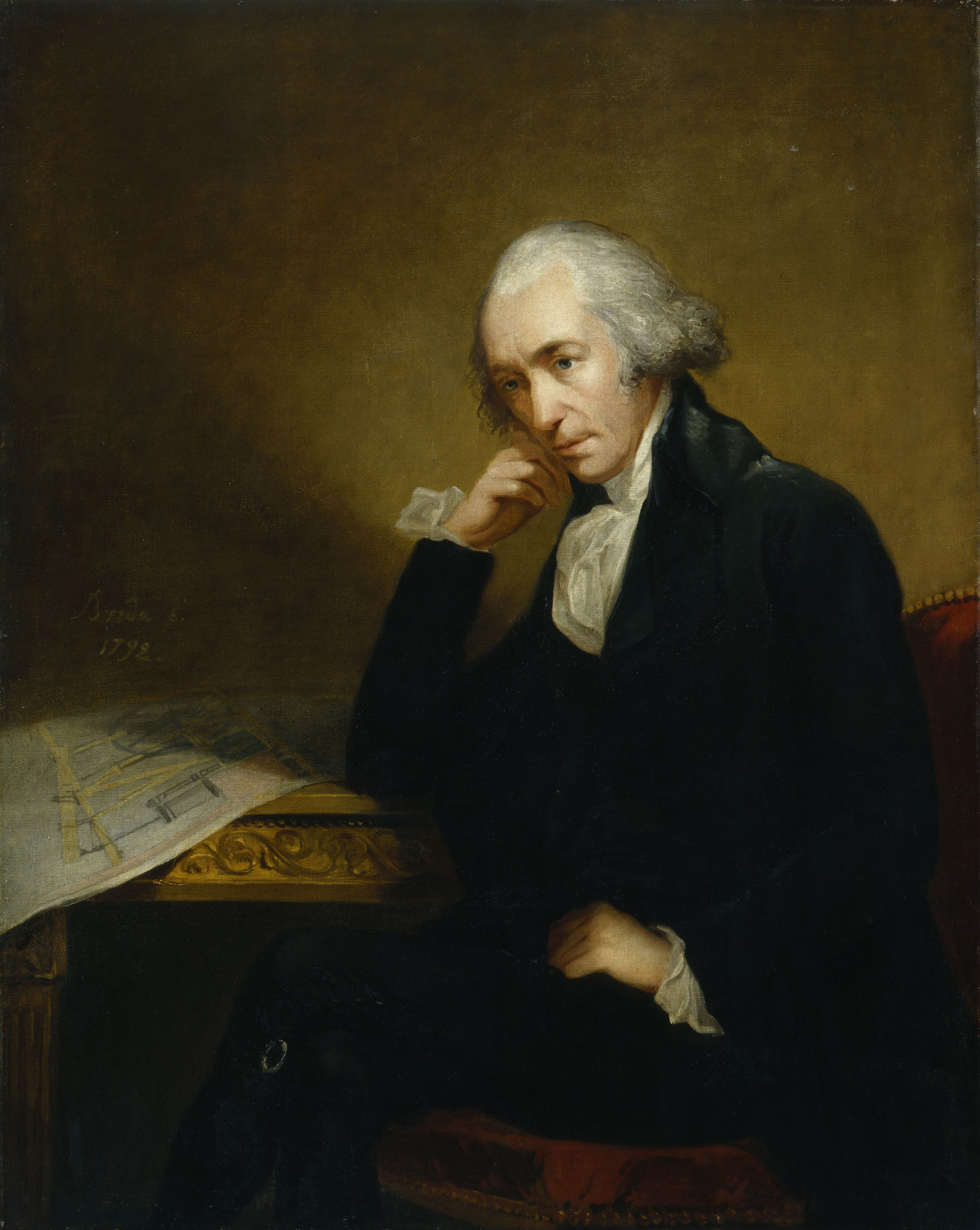

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standardized

Standardization or standardisation is the process of implementing and developing technical standards based on the consensus of different parties that include firms, users, interest groups, standards organizations and governments. Standardization can help maximize compatibility, interoperability, safety, repeatability, or quality. It can also facilitate a normalization of formerly custom processes. In social sciences, including economics, the idea of ''standardization'' is close to the solution for a coordination problem, a situation in which all parties can realize mutual gains, but only by making mutually consistent decisions. History Early examples Standard weights and measures were developed by the Indus Valley civilization.Iwata, Shigeo (2008), "Weights and Measures in the Indus Valley", ''Encyclopaedia of the History of Science, Technology, and Medicine in Non-Western Cultures (2nd edition)'' edited by Helaine Selin, pp. 2254–2255, Springer, . The centralized wei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Batch Production

Batch production is a method of manufacturing where the products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch production is used for many types of manufacturing that may need smaller amounts of production at a time to ensure specific quality standards or changes in the process. This is opposed to large mass production or continuous production methods where the product or process does not need to be checked or changed as frequently or periodically. Characteristics In the manufacturing batch production process, the machines are in chronological order directly related to the manufacturing process. The batch production method is also used so any temporary changes or modifications can be made to the product if necessary during the manufacturing process. For example, if a product needed a sudden change in material or details changed, it can be done in be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Capital Intensity

Capital intensity is the amount of fixed or real capital present in relation to other factors of production, especially labor. At the level of either a production process or the aggregate economy, it may be estimated by the capital to labor ratio, such as from the points along a capital/labor isoquant. Growth The use of tools and machinery makes labor more effective, so rising capital intensity (or "capital deepening") pushes up the productivity of labor. Capital intensive societies tend to have a higher standard of living over the long run. Calculations made by Robert Solow claimed that economic growth was mainly driven by technological progress (productivity growth) rather than inputs of capital and labor. However recent economic research has invalidated that theory, since Solow did not properly consider changes in both investment and labor inputs. Dale Jorgenson, of Harvard University, President of the American Economic Association in 2000, concludes that: 'Griliches and I show ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Conveyor

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a "''flighting''", usually within a tube, to move liquid or granular materials. They are used in many bulk handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others. The first type of screw conveyor was the Archimedes' screw, used since ancient times to pump irrigation water. They usually consist of a trough or tube containing either a spiral blade coiled around a shaft, driven at one end and held at the other, or a "''shaftless spiral''", driven at one end and free at the other. The rate of volume transfer is proportional to the rotation rate of the shaft. In industrial control applications, the device is often used as a variable rate f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bucket Elevator

A bucket elevator, also called a grain leg, is a mechanism for hauling flowable bulk materials (most often grain or fertilizer) vertically. It consists of: # Buckets to contain the material; # A belt to carry the buckets and transmit the pull; # Means to drive the belt; # Accessories for loading the buckets or picking up the material, for receiving the discharged material, for maintaining the belt tension and for enclosing and protecting the elevator. A bucket elevator can elevate a variety of bulk materials from light to heavy and from fine to large lumps. A centrifugal discharge elevator may be vertical or inclined. Vertical elevators depend entirely on centrifugal force to get the material into the discharge chute, and so must be run at a relatively high speed. Inclined elevators with buckets spaced apart or set close together may have the discharge chute set partly under the head pulley. Since they do not depend entirely on centrifugal force to put the material into the chut ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Loader (equipment)

A loader is a Heavy equipment (construction), heavy equipment machine used in construction to move or load materials such as soil, Rock (geology), rock, sand, demolition debris, etc. into or onto another type of machinery (such as a dump truck, conveyor belt, feed-hopper, or railroad car). There are many types of loader, which, depending on design and application, are variously called a bucket loader, front loader, front-end loader, payloader, high lift, scoop, shovel, skip loader, wheel loader, or skid-steer. Description A loader is a type of tractor, usually wheeled, Tracked loader, sometimes on tracks, that has a front-mounted wide Bucket (machine part), bucket connected to the end of two booms (arms) to scoop up loose material from the ground, such as dirt, sand or gravel, and move it from one place to another without pushing the material across the ground. A loader is commonly used to move a stockpiled material from ground level and deposit it into an awaiting dump tru ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Crane

An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of two parallel rails seated on longitudinal I-beams attached to opposite steel columns by means of brackets. The traveling bridge spans the gap. A hoist, the lifting component of a crane, travels along the bridge. If the bridge is rigidly supported on two or more legs running on two fixed rails at ground level, the crane is called a gantry crane (USA, ASME B30 series) or a ''goliath crane'' (UK, BS 466). Unlike mobile or construction cranes, overhead cranes are typically used for either manufacturing or maintenance applications, where efficiency or downtime are critical factors. History In 1876 Sampson Moore in England designed and supplied the first ever electric overhead crane, which was used to hoist guns at the Royal Arsenal in Woolwich, London. Since that time Alliance Machine, now defunct, holds an AISE citation for one of the earliest ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hyundai Car Assembly Line

Hyundai is a Automotive industry in South Korea, South Korean industrial conglomerate ("chaebol"), which was restructured into the following groups: * Hyundai Group, parts of the former conglomerate which have not been divested ** Hyundai Mobis, Korean car parts company ** Hyundai Asan, a real estate construction and civil engineering company * Hyundai Motor Group, the automotive part of the former conglomerate ** Hyundai Motor Company, an automobile manufacturer ** Hyundai N *** Hyundai Motorsport, a racing team *** Hyundai Motor India ** Hyundai Rotem, a manufacturer of railway vehicles, defense systems, and factory equipment ** Hyundai Engineering & Construction, a construction company * Hyundai Heavy Industries Group, the heavy industry part of the former conglomerate ** Hyundai Heavy Industries, the primary company representing the group ** Hyundai Corporation, a trading and industrial investment company ** Hyundai Mipo Dockyard, a shipbuilding company ** Hyundai Oilbank, a petr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, and stabilization of ships, aircraft, and other applications and vehicles with reduced human i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants. There is a wide range of size, type and complexity, but it enables a small number of operators to manage complex processes to a high degree of consistency. The development of large industrial process control systems was instrumental in enabling the design of large high volume and complex processes, which could not be otherwise economically or safely operated. The applications can range from controlling the temperature and level of a single process vessel, to a complete chemical processing plant with several thousand control loops. History Early process control breakthrou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Press

A forming press, commonly shortened to press, is a machine tool that changes the shape of a work-piece by the application of pressure. The operator of a forming press is known as a press-tool setter, often shortened to tool-setter. Presses can be classified according to * their mechanism: hydraulic, mechanical, pneumatic; * their function: forging presses, stamping presses, press brakes, punch press, etc. * their structure, e.g. Knuckle-joint press, screw press * their controllability: conventional vs. servo-presses Shop Press Typically consisting of a simple rectangular frame, often fabricated from C-channel or tubing, containing a bottle jack or hydraulic cylinder to apply pressure via a ram to a work-piece. Often used for general-purpose forming work in the auto mechanic shop, machine shop, garage or basement shops, etc. Typical shop presses are capable of applying between 1 and 30 tons pressure, depending on size and construction. Lighter-duty versions are often c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |