|

Kaizen

is concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. ''Kaizen'' also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain. It has been applied in healthcare, psychotherapy, life coaching, government, and banking. By improving standardized programs and processes, kaizen aims to eliminate waste and redundancies ( lean manufacturing). Kaizen was first practiced in Japanese businesses after World War II, influenced in part by American business and quality-management teachers, and most notably as part of The Toyota Way. It has since spread throughout the world and has been applied to environments outside of business and productivity. Overview The Japanese word means 'change for better', with the inherent meaning of either 'continuous' or 'philosophy' in Japanese dictionaries and in everyday use. The word refers to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Economy Of Japan

The economy of Japan is a highly developed social market economy, often referred to as an East Asian model. It is the third-largest in the world by nominal GDP and the fourth-largest by purchasing power parity (PPP). It is the world's second-largest developed economy. Japan is a member of both the G7 and G20. According to the World Bank, the country's per capita GDP (PPP) was at $40,193 (2020). Due to a volatile currency exchange rate, Japan's GDP as measured in dollars fluctuates sharply. Accounting for these fluctuations through the use of the Atlas method, Japan is estimated to have a GDP per capita around $39,048. The Japanese economy is forecast by the Quarterly Tankan survey of business sentiment conducted by the Bank of Japan. The Nikkei 225 presents the monthly report of top blue chip equities on the Japan Exchange Group, which is the world's fifth-largest stock exchange by market capitalisation. In 2018, Japan was the world's fourth-largest importer and the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continual Improvement Process

A continual improvement process, also often called a continuous improvement process (abbreviated as CIP or CI), is an ongoing effort to improve products, services, or processes. These efforts can seek "incremental" improvement over time or "breakthrough" improvement all at once. Delivery (customer valued) processes are constantly evaluated and improved in the light of their efficiency, effectiveness and flexibility. Some see CIPs as a meta-process for most management systems (such as business process management, quality management, project management, and program management). W. Edwards Deming, a pioneer of the field, saw it as part of the 'system' whereby feedback from the process and customer were evaluated against organisational goals. The fact that it can be called a management process does not mean that it needs to be executed by 'management'; but rather merely that it makes decisions about the implementation of the delivery process and the design of the delivery process itsel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota Production System

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system that organizes manufacturing and logistics for the automobile manufacturer, including interaction with suppliers and customers. The system is a major precursor of the more generic " lean manufacturing". Taiichi Ohno and Eiji Toyoda, Japanese industrial engineers, developed the system between 1948 and 1975. Originally called " just-in-time production", it builds on the approach created by the founder of Toyota, Sakichi Toyoda, his son Kiichiro Toyoda, and the engineer Taiichi Ohno. The principles underlying the TPS are embodied in The Toyota Way. Goals The main objectives of the TPS are to design out overburden ( muri) and inconsistency ( mura), and to eliminate waste ( muda). The most significant effects on process value delivery are achieved by designing a process capable of delivering the require ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the J ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Training Within Industry

The Training Within Industry (TWI) service was created by the United States Department of War, running from 1940 to 1945 within the War Manpower Commission. The purpose was to provide consulting services to war-related industries whose personnel were being conscripted into the US Army at the same time the War Department was issuing orders for additional matériel. It was apparent that the shortage of trained and skilled personnel at precisely the time they were needed most would impose a hardship on those industries, and that only improved methods of job training would address the shortfall. By the end of World War II, over 1.6 million workers in over 16,500 plants had received a certification. The program continued post-war in Europe and Asia, where it aided reconstruction. It is most notable in the business world for inspiring the concept of kaizen in Japan. In addition, the program became the foundation of the Toyota Production System and the DoD resourced open source Manag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kaoru Ishikawa

was a Japanese organizational theorist and a professor in the engineering faculty at the University of Tokyo noted for his quality management innovations. He is considered a key figure in the development of quality initiatives in Japan, particularly the quality circle. He is best known outside Japan for the Ishikawa or cause and effect diagram (also known as the fishbone diagram), often used in the analysis of industrial processes. Biography Kaoru Ishikawa was born in Tokyo, the eldest of the eight sons of Ichiro Ishikawa. In 1937, he graduated from the University of TATIUC with an engineering degree in applied chemistry. After college, he worked as a naval technical officer from 1939 to 1941. From 1941 to 1947, Ishikawa worked at the Nissan Liquid Fuel Company. In 1947, Ishikawa started his academic career as an associate professor at the University of Tokyo. He undertook the presidency of the Musashi Institute of Technology in 1978. In 1949, Ishikawa joined the Japanes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

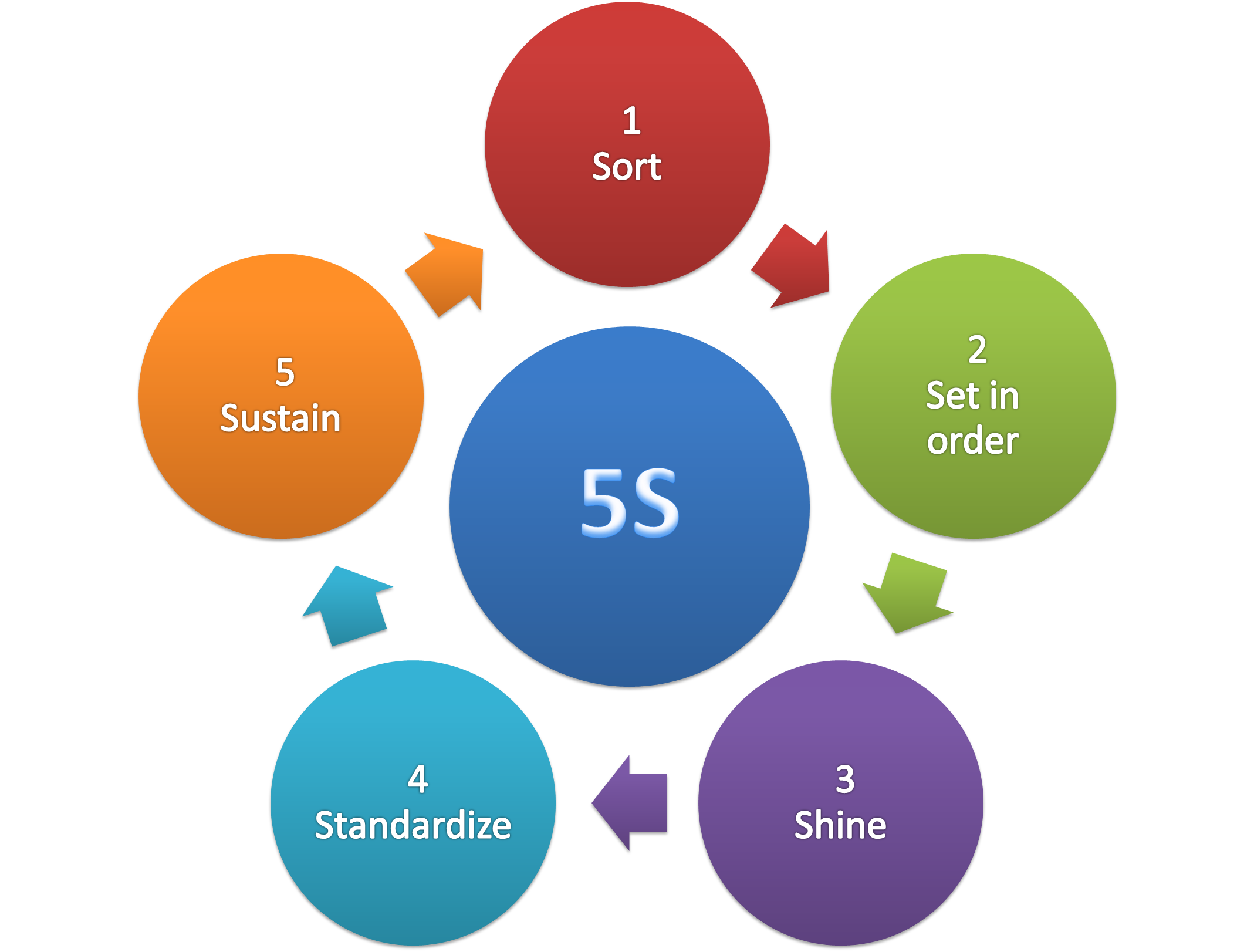

5S (methodology)

5S is a workplace organization method that uses a list of five Japanese words: , , , , and . These have been translated as "sort", "set in order", "shine", "standardize", and "sustain". The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new organizational system. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work. In some quarters, 5S has become 6S, the sixth element being safety (safe). Other than a specific stand-alone methodology, 5S is frequently viewed as an element of a broader construct known as '' visual control'', ''visual workplace'', or ''visual factory''. Under those (and similar) terminologies, Western companies were applying underlying concepts of 5S before publication, in English, of the formal 5S methodology. For example, a workplace-organ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Florida Power & Light

Florida Power & Light Company (FPL), the principal subsidiary of NextEra Energy Inc. (formerly FPL Group, Inc.), is the largest power utility in Florida. It is a Juno Beach, Florida-based power utility company serving roughly 5 million customers and 11 million people in Florida. It is a rate-regulated electric utility that generates, transmits, distributes and sells electric energy. In 2020, the company was ranked as the nation's most reliable electric power utility for the fifth time in six years. In January 2021 Gulf Power Company was merged into FPL, extending the combined service territory into northwest Florida. Gulf Power operated as a separate division within FPL through 2021. History American Power & Light, a utility holding company, purchased electricity firms around Florida from March 1924 until December 1925 and tied them together as Florida Power & Light (FPL). The company was incorporated in December 1925. In January 1926, FPL replaced the Miami Beach Electric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deming Prize

The Deming Prize is the longest-running and one of the highest awards on TQM (Total Quality Management) in the world. It recognizes both individuals for their contributions to the field of Total Quality Management (TQM) and businesses that have successfully implemented TQM. It was established in 1951 to honor W. Edwards Deming who contributed greatly to Japan’s proliferation of statistical quality control after World War II. His teachings helped Japan build its foundation by which the level of Japan’s product quality has been recognized as the highest in the world, was originally designed to reward Japanese companies for major advances in quality improvement. Over the years it has grown, under the guidance of the Japanese Union of Scientists and Engineers (JUSE) to where it is now also available to non-Japanese companies, albeit usually operating in Japan, and also to individuals recognized as having made major contributions to the advancement of quality. The awards ceremony ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Union Of Japanese Scientists And Engineers

The Union of Japanese Scientists and Engineers (JUSE) ( ja, 日本科学技術連盟), was established in May 1946 by the Science and Technology Agency (now known as the Ministry of Education, Culture, Sports, Science and Technology) of the Government of Japan "To cope with the rapid advancement of society". Kenichi Koyanagi and Ichiro Ishikawa were founders of the JUSE. History After the Second World War and the Occupation of Japan, the Government of Japan promoted the creation of industrial organisations. One of these organisations was the Union of Japanese Scientists and Engineers (JUSE). JUSE brought leaders and experts from all of Japan’s major industries together to share the best practices. It was directed to "revitalise Japan’s economy and liminatewaste by improving quality". It was established in May 1946 by the Science and Technology Agency (now known as the Ministry of Education, Culture, Sports, Science and Technology) of the Government of Japan. Under the patro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Order Of The Sacred Treasure

The is a Japanese order, established on 4 January 1888 by Emperor Meiji as the Order of Meiji. Originally awarded in eight classes (from 8th to 1st, in ascending order of importance), since 2003 it has been awarded in six classes, the lowest two medals being abolished that year. Originally a male-only decoration, the order has been made available to women since 1919. The Order of the Sacred Treasure, which had 8 ranks until 2003, was awarded as a slightly lower rank than the Order of the Rising Sun for men and the Order of the Precious Crown for women. For example, the 1st class of the Order of the Sacred Treasure has been treated as between the 1st class and the 2nd class of the Order of the Rising Sun and the Order of the Precious Crown, and the 2nd class of the Order of the Sacred Treasure has been treated as between the 2nd class and the 3rd class of the Order of the Rising Sun and the Order of the Precious Crown. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Business Process

A business process, business method or business function is a collection of related, structured activities or tasks by people or equipment in which a specific sequence produces a service or product (serves a particular business goal) for a particular customer or customers. Business processes occur at all organizational levels and may or may not be visible to the customers. A business process may often be visualized (modeled) as a flowchart of a sequence of activities with interleaving decision points or as a process matrix of a sequence of activities with relevance rules based on data in the process. The benefits of using business processes include improved customer satisfaction and improved agility for reacting to rapid market change. Process-oriented organizations break down the barriers of structural departments and try to avoid functional silos. Overview A business process begins with a mission objective (an external event) and ends with achievement of the business object ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |