|

Combustor

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion chamber is fed high-pressure air by the compression system. The combustor then heats this air at constant pressure as the fuel/air mix burns. As it burns the fuel/air mix heats and rapidly expands. The burned mix is exhausted from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the exhaust is directly fed out through the nozzle. A combustor must contain and maintain stable combustion despite very high air flow rates. To do so combustors are carefully designed to first mix and ignite the air and fuel, and then mix in more air to complete the combustion process. Early gas turbine engines used a single chamber known as a can-type combustor. Today three main configurations exist: can, annular, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cannular Combustor On A Pratt & Whitney JT9D Turbofan

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion chamber is fed high-pressure air by the compression system. The combustor then heats this air at constant pressure as the fuel/air mix burns. As it burns the fuel/air mix heats and rapidly expands. The burned mix is exhausted from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the exhaust is directly fed out through the nozzle. A combustor must contain and maintain stable combustion despite very high air flow rates. To do so combustors are carefully designed to first mix and ignite the air and fuel, and then mix in more air to complete the combustion process. Early gas turbine engines used a single chamber known as a can-type combustor. Today three main configurations exist: can, annular, and c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combustor Diagram Airflow

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion chamber is fed high-pressure air by the compression system. The combustor then heats this air at constant pressure as the fuel/air mix burns. As it burns the fuel/air mix heats and rapidly expands. The burned mix is exhausted from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the exhaust is directly fed out through the nozzle. A combustor must contain and maintain stable combustion despite very high air flow rates. To do so combustors are carefully designed to first mix and ignite the air and fuel, and then mix in more air to complete the combustion process. Early gas turbine engines used a single chamber known as a can-type combustor. Today three main configurations exist: can, annular, and c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combustor Diagram ComponentsPNG

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion chamber is fed high-pressure air by the compression system. The combustor then heats this air at constant pressure as the fuel/air mix burns. As it burns the fuel/air mix heats and rapidly expands. The burned mix is exhausted from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the exhaust is directly fed out through the nozzle. A combustor must contain and maintain stable combustion despite very high air flow rates. To do so combustors are carefully designed to first mix and ignite the air and fuel, and then mix in more air to complete the combustion process. Early gas turbine engines used a single chamber known as a can-type combustor. Today three main configurations exist: can, annular, and c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combustor On Rolls-Royce Nene Turbojet (1)

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion chamber is fed high-pressure air by the compression system. The combustor then heats this air at constant pressure as the fuel/air mix burns. As it burns the fuel/air mix heats and rapidly expands. The burned mix is exhausted from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the exhaust is directly fed out through the nozzle. A combustor must contain and maintain stable combustion despite very high air flow rates. To do so combustors are carefully designed to first mix and ignite the air and fuel, and then mix in more air to complete the combustion process. Early gas turbine engines used a single chamber known as a can-type combustor. Today three main configurations exist: can, annular, and c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ramjet

A ramjet, or athodyd (aero thermodynamic duct), is a form of airbreathing jet engine that uses the forward motion of the engine to produce thrust. Since it produces no thrust when stationary (no ram air) ramjet-powered vehicles require an assisted take-off like a JATO, rocket assist to accelerate it to a speed where it begins to produce thrust. Ramjets work most efficiently at supersonic speeds around and can operate up to speeds of . Ramjets can be particularly useful in applications requiring a small and simple mechanism for high-speed use, such as missiles. The US, Canada, and UK had widespread ramjet powered missile defenses during the 1960s onward, such as the CIM-10 Bomarc and Bloodhound (missile), Bloodhound. Weapon designers are looking to use ramjet technology in artillery shells to give added range; a 120 mm mortar shell, if assisted by a ramjet, is thought to be able to attain a range of . They have also been used successfully, though not efficiently, as tip j ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

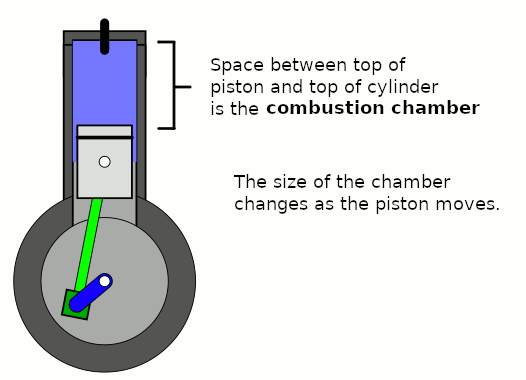

Combustion Chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such that the bottom of combustion chamber is roughly i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scramjet

A scramjet (supersonic combustion ramjet) is a variant of a ramjet airbreathing jet engine in which combustion takes place in supersonic airflow. As in ramjets, a scramjet relies on high vehicle speed to compress the incoming air forcefully before combustion (hence ''ram''jet), but whereas a ramjet decelerates the air to subsonic velocities before combustion using shock cones, a scramjet has no shock cone and slows the airflow using shockwaves produced by its ignition source in place of a shock cone. This allows the scramjet to operate efficiently at extremely high speeds. History Before 2000 The Bell X-1 attained supersonic flight in 1947 and, by the early 1960s, rapid progress toward faster aircraft suggested that operational aircraft would be flying at "hypersonic" speeds within a few years. Except for specialized rocket research vehicles like the North American X-15 and other rocket-powered spacecraft, aircraft top speeds have remained level, generally in the range of M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine Blade

A turbine blade is a radial aerofoil mounted in the rim of a turbine disc and which produces a tangential force which rotates a turbine rotor. Each turbine disc has many blades. As such they are used in gas turbine engines and steam turbines. The blades are responsible for extracting energy from the high temperature, high pressure gas produced by the combustor. The turbine blades are often the limiting component of gas turbines. To survive in this difficult environment, turbine blades often use exotic materials like superalloys and many different methods of cooling that can be categorized as internal and external cooling, and thermal barrier coatings. Blade fatigue is a maj ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller ( turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission ( turboshaft), marine propeller or electrical generator (power turbine). Grea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Unburned Hydrocarbon

Unburned hydrocarbons (UHCs) are the hydrocarbons emitted after petroleum is burned in an engine. When unburned fuel is emitted from a combustor, the emission is caused by fuel "avoiding" the flame zones. For example, in piston engines, some of the fuel-air mixture "hides" from the flame in the crevices provided by the piston ring grooves. Further, some regions of the combustion chamber may have a very weak flame, that is, they have either very fuel-lean or very fuel-rich conditions and consequently they have a low combustion temperature. These regions will cause intermediate species such as formaldehyde and alkenes to be emitted. Sometimes the term "products of incomplete combustion," or PICs, is used to describe such species. Formation The hydrocarbon is an auspicious way to reach low NOx (nitrogen oxide) emissions in diesel engine The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated tem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Barrier Coating

Thermal barrier coatings (TBCs) are advanced materials systems usually applied to metallic surfaces operating at elevated temperatures, such as gas turbine or aero-engine parts, as a form of exhaust heat management. These 100 μm to 2 mm thick coatings of thermally insulating materials serve to insulate components from large and prolonged heat loads and can sustain an appreciable temperature difference between the load-bearing alloys and the coating surface. In doing so, these coatings can allow for higher operating temperatures while limiting the thermal exposure of structural components, extending part life by reducing oxidation and thermal fatigue. In conjunction with active film cooling, TBCs permit working fluid temperatures higher than the melting point of the metal airfoil in some turbine applications. Due to increasing demand for more efficient engines running at higher temperatures with better durability/lifetime and thinner coatings to reduce parasitic mass fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heterogeneous

Homogeneity and heterogeneity are concepts often used in the sciences and statistics relating to the uniformity of a substance or organism. A material or image that is homogeneous is uniform in composition or character (i.e. color, shape, size, weight, height, distribution, texture, language, income, disease, temperature, radioactivity, architectural design, etc.); one that is heterogeneous is distinctly nonuniform in at least one of these qualities. Heterogeneous Mixtures, in chemistry, is where certain elements are unwillingly combined and, when given the option, will separate. Etymology and spelling The words ''homogeneous'' and ''heterogeneous'' come from Medieval Latin ''homogeneus'' and ''heterogeneus'', from Ancient Greek ὁμογενής (''homogenēs'') and ἑτερογενής (''heterogenēs''), from ὁμός (''homos'', “same”) and ἕτερος (''heteros'', “other, another, different”) respectively, followed by γένος (''genos'', “kind”); - ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)