|

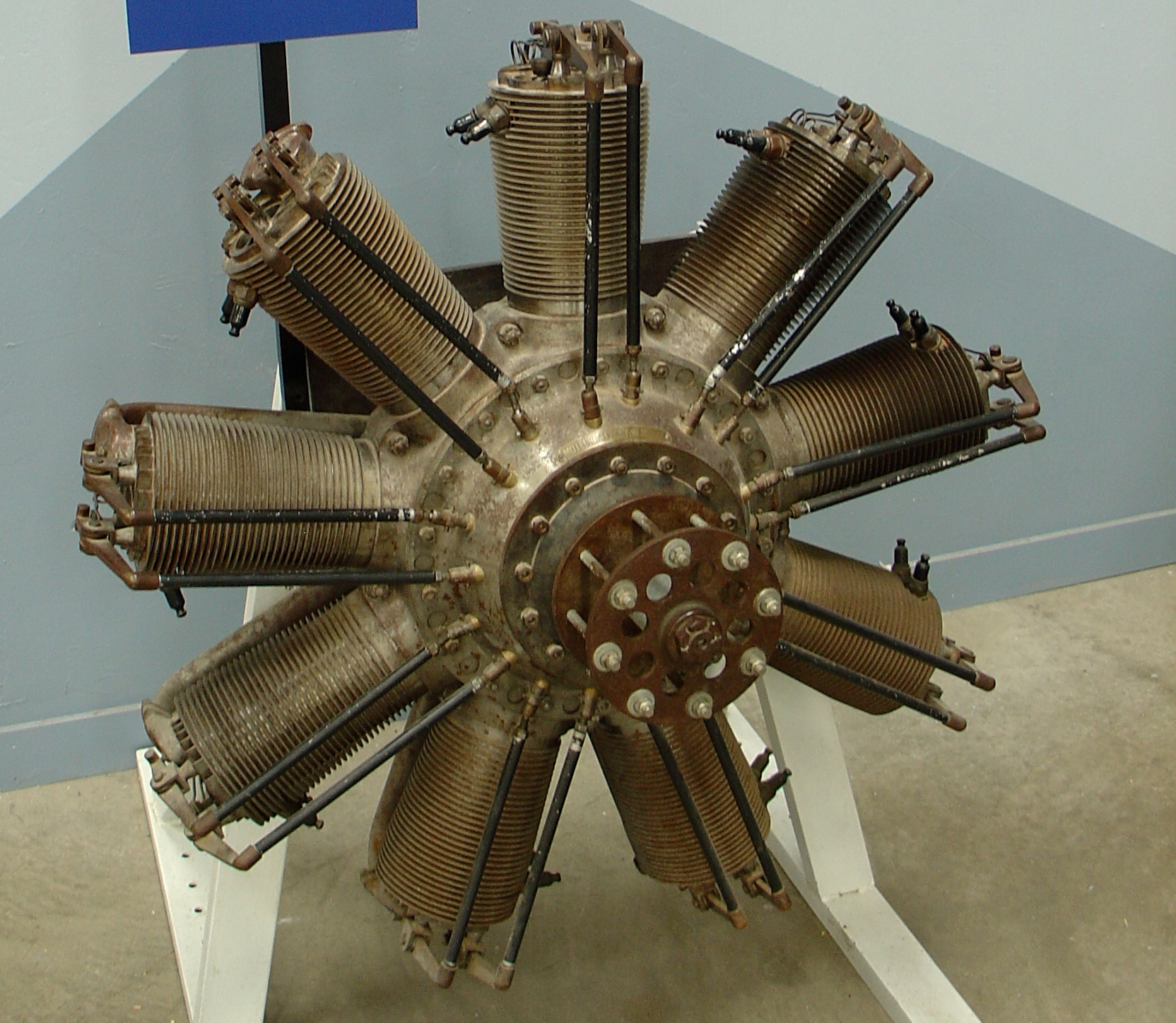

Clerget Aircraft Engines

Clerget was the name given to a series of early rotary aircraft engine types of the World War I era that were designed by Pierre Clerget. Manufactured in France by Clerget-Blin and in Great Britain by Gwynnes Limited they were used on such aircraft as the Sopwith Camel and Vickers Gunbus. In the 1920s Pierre Clerget turned his attention to diesel radial engines and finally produced a H-16 engine before he died in 1943. Rotary engine development (spark ignition) What distinguished the Clerget rotary engine from its rivals (Gnome and Le Rhône) was that the Clerget had normal intake and exhaust valves unlike the Gnome, and the connecting rod arrangement was much simpler than the Le Rhone. A source of failure among the Clerget engines were the special-purpose piston rings, called obturator rings. These were located below the gudgeon or wrist pin, to block heat transfer from the combustion area to the lower part of the cylinder and overcome their subsequent distortion. Thes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clerget 9B

The Clerget 9B was a nine-cylinder rotary aircraft engine of the World War I era designed by Pierre Clerget. Manufactured in both France and Great Britain (Gwynnes Limited), it was used on such aircraft as the Sopwith Camel. The Clerget 9Bf was an increased stroke version.Lumsden 2003, p. 133. Variants ;Clerget 9B (1913) 130 hp (97 kW). 1,300 produced by Ruston Proctor & Co Ltd of Lincoln ;Clerget 9Bf (1915) 140 hp (104 kW). Extended stroke (172 mm (6.75 in)) version, increasing capacity to 17.5 L (1,066.5 cu in). 1,750 produced by Gwynnes Limited and 600 produced by Ruston Proctor. Applications Clerget 9B * Armstrong Whitworth F.K.10 *Avro 504 *Avro 531 *Bristol M.1 * Cierva C.6 * Cierva C.8 * Fairey Hamble Baby *FBA Type C *Nieuport 12 *Nieuport 17bis *Sopwith Baby *Sopwith Camel *Sopwith Scooter *Sopwith Triplane *Sopwith 1½ Strutter Clerget 9Bf *Sopwith Camel Engines on display *A preserved Clerget 9B engine is on public display at t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Ring

A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine. The main functions of piston rings in engines are: # Sealing the combustion chamber so that there is minimal loss of gases to the crank case. # Improving heat transfer from the piston to the cylinder wall. # Maintaining the proper quantity of the oil between the piston and the cylinder wall # Regulating engine oil consumption by scraping oil from the cylinder walls back to the sump. Most piston rings are made from cast iron or steel. Design Piston rings are designed to seal the gap between the piston and the cylinder wall. If this gap were too small, thermal expansion of the piston could mean the piston seizes in the cylinder, causing serious damage to the engine. On the other hand, a large gap would cause insufficient sealing of the piston rings against the cylinder walls, resulting in excessive blow-by (combustion gases entering the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tappet

A tappet is most commonly a component in an internal combustion engine which converts the rotating motion of the camshaft into linear motion of the valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. __TOC__ Beam engines The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets pressed against long levers or 'horns' attached to the engine's valves, working the cycle of steam and injection water valves ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Alloy

An aluminium alloy (or aluminum alloy; see spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.I. J. Polmear, ''Light Alloys'', Arnold, 1995 Alloys ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Four-stroke Engine

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed: #Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing vacuum pressure into the cylinder through its downward motion. The piston is moving down as air is being sucked in by the downward motion against the piston. #Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are clos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tractor Configuration

In aviation, the term tractor configuration refers to an aircraft constructed in the standard configuration with its engine mounted with the propeller in front of it so that the aircraft is "pulled" through the air. Oppositely, the pusher configuration places the airscrew behind and propels the aircraft forward. Through common usage, the word "propeller" has come to mean any airscrew, whether it actually propels or pulls the plane. In the early years of powered aviation both tractor and pusher designs were common. However, by the midpoint of the First World War, interest in pushers declined and the tractor configuration dominated. Today, propeller-driven aircraft are assumed to be tractors unless it is stated otherwise. Origins The first airplane to have a "tractor" configuration was the Goupy No.2 (first flight on 11 March 1909) designed by Mario Calderara and financed by Ambroise Goupy at the French firm Blériot Aéronautique. When it was constructed, it was the fastes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pusher Configuration

In an aircraft with a pusher configuration (as opposed to a tractor configuration), the propeller(s) are mounted behind their respective engine(s). Since a pusher propeller is mounted behind the engine, the drive shaft is in compression in normal operation. Pusher configuration describes this specific ( propeller or ducted fan) thrust device attached to a craft, either aerostat (airship) or aerodyne (aircraft, WIG, paramotor, rotorcraft) or others types such as hovercraft, airboat and propeller-driven snowmobiles. "Pusher configuration" also describes the layout of a fixed-wing aircraft in which the thrust device has a pusher configuration. This kind of aircraft is commonly called a pusher. Pushers have been designed and built in many different layouts, some of them quite radical. History The rubber-powered "Planophore", designed by Alphonse Pénaud in 1871, was an early successful model aircraft with a pusher propeller. Many early aircraft (especially biplan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thrust Bearing

A thrust bearing is a particular type of rotary bearing. Like other bearings they permanently rotate between parts, but they are designed to support a predominantly axial load. Thrust bearings come in several varieties. *''Thrust ball bearings'', composed of bearing balls supported in a ring, can be used in low thrust applications where there is little axial load. *''Cylindrical thrust roller bearing''s consist of small cylindrical rollers arranged flat with their axes pointing to the axis of the bearing. They give very good carrying capacity and are cheap, but tend to wear due to the differences in radial speed and friction which is higher than with ball bearings. *'' Tapered roller thrust bearings'' consist of small tapered rollers arranged so that their axes all converge at a point on the axis of the bearing. The length of the roller and the diameter of the wide and the narrow ends and the angle of rollers need to be carefully calculated to provide the correct taper so that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air-cooled Engine

Air-cooled engines rely on the circulation of air directly over heat dissipation fins or hot areas of the engine to cool them in order to keep the engine within operating temperatures. In all combustion engines, a great percentage of the heat generated (around 44%) escapes through the exhaust, not through the metal fins of an air-cooled engine (12%). About 8% of the heat energy is transferred to the oil, which although primarily meant for lubrication, also plays a role in heat dissipation via a cooler. ''Air-cooled engines'' are used generally in applications which would not suit liquid cooling, as such modern air-cooled engines are used in motorcycles, general aviation aircraft, lawn mowers, generators, outboard motors, pump sets, saw benches and auxiliary power units. Introduction Most modern internal combustion engines are cooled by a closed circuit carrying liquid coolant through channels in the engine block and cylinder head, where the coolant absorbs heat, to a h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bentley BR2

The Bentley B.R.2 was a nine-cylinder British rotary aircraft engine developed during the First World War by the motor car engine designer W. O. Bentley from his earlier Bentley BR.1. Coming as it did near the end of the war, the BR.2 was built in smaller numbers than the earlier BR.1 – its main use being by the Royal Air Force in the early 1920s. Design and development The initial variant of the BR.2 developed , with nine cylinders measuring for a total displacement of 1,522 cubic inches (24.9 L). It weighed , only more than the Bentley B.R.1 (A.R.1). This was the last type of rotary engine to be adopted by the RAF – later air-cooled aircraft engines such as the Cosmos Jupiter and Armstrong Siddeley Jaguar being almost entirely of the fixed radial type. With the BR.2, the rotary engine had reached a point beyond which this type of engine could not be further developed, due to its inherent limitations. Applications The type selected as the standard single-seat fighter o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bentley BR1

The Bentley BR.1 was a British rotary aircraft engine of the First World War. Designed by the motor car engine designer W. O. Bentley, the BR.1 was built in large numbers, being one of the main powerplants of the Sopwith Camel. Design and development The Clerget 9B was an important engine for the British Royal Naval Air Service and Royal Flying Corps, being license-produced in Britain and powering a number of important British aircraft, including the Sopwith Camel. However, at £907 a copy it was expensive, and prone to overheating, so the Admiralty asked Lieutenant W. O. Bentley, an established pre-war engine designer, to produce a modified version to solve these problems. Bentley came up with his idea of an engine - fitted with aluminium cylinders with cast iron liners, and aluminium pistons. Dual ignition was introduced to improve reliability (much as the 160 CV Gnome 9N had already been), and the stroke increased to which allowed power to be increased to . The cost of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throttle

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction. An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' has come to refer, informally, to any mechanism by which the power or speed of an engine is regulated, such as a car's accelerator pedal. What is often termed a ''throttle'' (in an aviation context) is also called a thrust lever, particularly for jet engine powered aircraft. For a steam locomotive, the valve which controls the steam is known as the regulator. Internal combustion engines In an internal combustion engine, the throttle is a means of controlling an engine's power by regulating the amount of fuel or air entering the engine. In a motor vehicle the control used by the driver to regulate power is sometimes called the throttle, accelerator, or gas pedal. For a gasoline engine, the throttle most commonly regulates the amount ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |