vulcanised fibre on:

[Wikipedia]

[Google]

[Amazon]

Vulcanized fibre or red fibre is a laminated plastic composed of only

Vulcanized fibre or red fibre is a laminated plastic composed of only

Vulcanized fibre or red fibre is a laminated plastic composed of only

Vulcanized fibre or red fibre is a laminated plastic composed of only cellulose

Cellulose is an organic compound with the formula , a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell w ...

. The material is a tough, resilient, hornlike material that is lighter than aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

, tougher than leather

Leather is a strong, flexible and durable material obtained from the tanning, or chemical treatment, of animal skins and hides to prevent decay. The most common leathers come from cattle, sheep, goats, equine animals, buffalo, pigs and hog ...

, and stiffer than most thermoplastics. The newer wood-laminating grade of vulcanized fibre is used to strengthen wood laminations used in skis

A ski is a narrow strip of semi-rigid material worn underfoot to glide over snow. Substantially longer than wide and characteristically employed in pairs, skis are attached to ski boots with ski bindings, with either a free, lockable, or partial ...

, skateboards

A skateboard is a type of sports equipment used for skateboarding. They are usually made of a specially designed 7-8 ply maple plywood deck and polyurethane wheels attached to the underside by a pair of skateboarding trucks.

The skateboarder ...

, support beams and as a sub-laminate under thin wood veneer

In woodworking, veneer refers to thin slices of wood and sometimes bark, usually thinner than 3 mm (1/8 inch), that typically are glued onto core panels (typically, wood, particle board or medium-density fiberboard) to produce flat panels s ...

s.

A product very similar to vulcanized fibre is leatheroid

Leatheroid is cellulose material very similar to vulcanized fibre in physical properties and uses. It is prepared using unsized cotton rag paper (as is vulcanized fibre) and mineral acid.

Manufacturer

Leatheroid was made by the Leatheroid Manufa ...

. Leatheroid, however, is made using a different chemical process. Since 2004, the scientific community has regained interest in this material due to its renewability and excellent physical properties, giving birth to the field of all-cellulose composites. These composites are all made of a matrix consisting of dissolved or partially dissolved cellulose, and the reinforcement remains cellulose fibres. A variety of solvents other than zinc chloride

Zinc chloride is the name of inorganic chemical compounds with the formula ZnCl2 and its hydrates. Zinc chlorides, of which nine crystalline forms are known, are colorless or white, and are highly soluble in water. This salt is hygroscopic and e ...

has been explored, including sodium hydroxide at low temperatures and ionic liquids

An ionic liquid (IL) is a salt in the liquid state. In some contexts, the term has been restricted to salts whose melting point is below a specific temperature, such as . While ordinary liquids such as water and gasoline are predominantly made of ...

. Whereas the original idea was to use long reinforcing fibres (ramie

Ramie (pronounced: , ; from Malay ) is a flowering plant in the nettle family Urticaceae, native to eastern Asia. It is a herbaceous perennial growing to tall;

, flax, viscose

Rayon is a semi-synthetic fiber, made from natural sources of regenerated cellulose, such as wood and related agricultural products. It has the same molecular structure as cellulose. It is also called viscose. Many types and grades of viscose ...

, ''etc'') in order to confer the composites with anisotropic mechanical properties, the field has also explored the use of nanocellulose.

Applications

Vulcanized fibre has a long history in engineering, from the Victorian period onward. Although there are now many materials, mostly synthetic polymers, with higher performance, fibre has been applied widely and still retains many applications. As it is stronger in thin sections between mechanically rigid components, rather than relying on its own strength, it has mostly been used aswasher

Washer most commonly refers to:

*Washer (hardware), a thin usually disc-shaped plate with a hole in the middle typically used with a bolt or nut

*Washing machine, for cleaning clothes

Washer may also refer to:

*Dishwasher, a machine for cleani ...

s, gasket

Some seals and gaskets

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to c ...

s, and a variety of shims or packing pieces.

Fibre washers are one of the cheapest conformal elastomer gaskets for sealing pipe unions and general plumbing work. They swell slightly with exposure to water, making a good seal. They may also be used with hydrocarbons, provided the temperature is not too high. Unlike rubber, fibre washer seals are considered as a single-use item.

Fibre sheet is easily die-cut to complex shapes and so it is widely used for shaped gaskets. These may be used for sealing, as heat insulators, or as mechanical spacers.

Until the development of modern plastics from the 1930s, fibre was the standard electrical insulating material for many small components. It could be cut to size easily, either in mass production or hand-trimmed to fit. It was particularly common in the assembly of large machines, such as motor winding.

History

The Britishpatent

A patent is a type of intellectual property that gives its owner the legal right to exclude others from making, using, or selling an invention for a limited period of time in exchange for publishing an enabling disclosure of the invention."A ...

for vulcanized fibre was obtained in 1859 by the Englishman Thomas Taylor. He gained the patent after the introduction of celluloid

Celluloids are a class of materials produced by mixing nitrocellulose and camphor, often with added dyes and other agents. Once much more common for its use as photographic film before the advent of safer methods, celluloid's common contemporary ...

in 1856 and before the invention of viscose rayon

Rayon is a semi-synthetic fiber, made from natural sources of regenerated cellulose, such as wood and related agricultural products. It has the same molecular structure as cellulose. It is also called viscose. Many types and grades of viscose f ...

(regenerated cellulose) in 1894. In 1871 Thomas Taylor obtained the United States Patent for vulcanized fibre. The first organized industrial company to make vulcanized fibre was the Vulcanized Fibre Company, incorporated first as a New York Corporation formed June 19, 1873 listed with William Courtenay President and Charles F. Cobby Secretary. The first N.Y. corporation was also found in the 1873 N.Y. City Directory which also listed William Courtenay President and Charles F. Cobby Secretary in 1873. From 1873 until 1878 the Vulcanized Fiber Co. had a New York office address of 17 Dey St., while the factory was located in Wilmington Delaware. This can be seen in the many advertisements that were placed in different publications at this time in history. A special charter was granted by the state of Delaware in 1873 until the Delaware corporation was finally incorporated on February 8, 1875 which now listed William Courtenay President and Clement B. Smyth Secretary.

In 1884 Courtenay & Trull Co. N.Y. was merged into the Vulcanized Fibre Co. which gave the company control over a new invention called by the trade name "Gelatinized Fibre".

On December 4, 1901, during a merger and consolidation the Vulcanized Fibre Co. changed its name to the "American Vulcanized Fiber Co." which was formed for the purpose of consolidating: Kartavert Mfg. Company, Wilmington, Delaware; American Hard Fibre Company, Newark, Delaware; Vulcanized Fibre Company, Wilmington, Delaware. and the Laminar Fibre Company of North Cambridge, Mass.

In 1922 the name was changed again when it was directly purchased by the National Fibre & Insulation Company of Yorklyn Delaware (who was also the owner of the Keystone Fibre Co.). The president of the National Fibre Company at this time was J. Warren Marshall, who took the same office after consolidating into the new company "National Vulcanized Fibre Company.

In 1965 the name was changed again to the NVF Company in order to avoid confusion over the years with a new and changing product line.

The water power of the Piedmont

it, Piemontese

, population_note =

, population_blank1_title =

, population_blank1 =

, demographics_type1 =

, demographics1_footnotes =

, demographics1_title1 =

, demographics1_info1 =

, demographics1_title2 ...

streams in Northern Delaware

Delaware ( ) is a state in the Mid-Atlantic region of the United States, bordering Maryland to its south and west; Pennsylvania to its north; and New Jersey and the Atlantic Ocean to its east. The state takes its name from the adjacent Del ...

led to a proliferation of companies in the vulcanized fibre business. Over the years, these companies reorganized and merged. In 1922 National Vulcanized Fiber

NVF Company, formerly known as National Vulcanized Fiber, was a private company based in Yorklyn, Delaware. One of its original products, a sheet-like material called Forbon, was commonly used on guitar pickups. NVF also made a product called Yor ...

Company emerged as the main competitor to Spaulding Fibre, which had begun developing vulcanized products in Rochester, New Hampshire

Rochester is a city in Strafford County, New Hampshire, United States. The population was 32,492 at the 2020 census. In addition to the downtown area, the city contains the villages of East Rochester, Gonic, and North Rochester. Rochester is ...

and Tonawanda, New York

Tonawanda (formally ''City of Tonawanda'') is a city in Erie County, New York, United States. The population was 15,130 at the 2010 census. It is at the northern edge of Erie County, south across the Erie Canal ( Tonawanda Creek) from North To ...

, nearly a quarter century after the industry began in Delaware.

Some of the companies involved in vulcanized fibre development in the Wilmington region were the Nunsuch Fiber Company, American Hard Fiber Company, American Vulcanized Fibre Company, Continental Fibre Co., Diamond State Fibre Co., and Franklin Fibre Company. In the 1965 Post’s Pulp and Paper Directory, National Vulcanized Fibre Co. was listed as having two mills' producing rag paper for vulcanized fibre. They were at Newark, producing 15 tons a day; and Yorklyn, producing 18 tons a day. This compares with Spaulding Fibre’s Tonawanda plant, then producing 40 tons a day (Post’s directory). The competitors also produced bakelite, but marketed them under different names: Spaulding’s was Spauldite and National’s brand was Phenolite and Iten Industries' Resiten or Itenite.

Process

The process started with paper made from cotton rags. Before the processing of wood pulp and chemical wood pulps in the mid-19th century, the dominant fibre source for paper making was cotton and linen rags. The cotton rag sheet produced for conversion to vulcanized fibre is made like a sheet suitable for saturating. A paper is made for saturating by omitting any sizing additive, either beater added or surface applied. Today most paper sheets made for writing, printing, and coating have internal (beater

Beater may refer to:

Clothes

* Beater (weaving), a tool used to force woven yarn into place

*A shortening of "wifebeater" (shirt), a colloquialism for particular style of sleeveless shirt

Music

*Any of various types of percussion mallets

** A r ...

added) sizing provided by rosin

Rosin (), also called colophony or Greek pitch ( la, links=no, pix graeca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene comp ...

, alkyl succinic anhydride

Succinic anhydride, is an organic compound with the molecular formula (CH2CO)2O. This colorless solid is the acid anhydride of succinic acid.

Preparation

In the laboratory, this material can be prepared by dehydration of succinic acid. Such dehy ...

(ASA), or alkyl ketene dimer (AKD) and surface sizing provided by starch. A sheet made for saturating would have none of those chemical ingredients. The unsized saturating cotton fibre paper prepared for vulcanized fibre would be passed through a vat containing a zinc chloride solution.

Zinc chloride

Zinc chloride

Zinc chloride is the name of inorganic chemical compounds with the formula ZnCl2 and its hydrates. Zinc chlorides, of which nine crystalline forms are known, are colorless or white, and are highly soluble in water. This salt is hygroscopic and e ...

is highly soluble in water. The solution used in saturating the paper was 70 Baumé in density (1.93 specific gravity) and about .James P. Casey, ''Pulp and Paper Chemistry and Chemical Technology''; Vol. II; Second Edition Revised and Enlarged: Interscience Publishers Inc., New York, John Wiley & Sons Inc., New York; 1952, 1960; Library of Congress 60-13120; Third Printing 1967, pp654-655 This is roughly a 70% percent zinc chloride solution. Zinc chloride is a mild Lewis acid with a solution pH of about 4. Zinc chloride can dissolve cellulose, starch, and silk. The zinc chloride used in making vulcanized fibre swelled and gelatinized the cellulose. The fibre swelling explains why paper filters cannot be used to filter zinc chloride solutions. It is also the reason why a number of paper plies were used to build up to the desired vulcanized fibre thickness, rather treating a single paperboard thickness. For instance, the practice was to use 8 paper plies of 0.04 mm thickness each, as opposed to a single paperboard ply of 0.32 mm.

Pressing

Once the paper plies were saturated with the gelatinizing zinc chloride, they were pressed together. The pressing allowed intimate contact of thecellulose fibre

Cellulose fibers () are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and li ...

s, thus promoting bonding between the cellulose chains. Once the bonding was established, the process of leaching out the zinc chloride from the vulcanized fibre could begin. The leaching (removal by diffusion out) of the zinc chloride was accomplished by subjecting the vulcanized fibre to successively less concentrated baths of zinc chloride. The rate at which this could occur was constrained by osmotic forces. If the rate at which the vulcanized fibre was subjected to lower and lower concentrations of zinc chloride solution were too rapid, the osmotic forces could result in ply separations. The final leaching bath concentration was 0.05% zinc chloride. Thicknesses up to 0.093” (=2.4 mm), can be made on continuous lines that stretch up to 1,000 feet (305m) in length.

Vats

For thickness above 0.093” (2.4 mm) and up to 0.375” (9.5 mm), a discrete laminated sheet (similar in size (l x w) to plywood) was produced by the cutdown process. The cutdown sheets were racked and moved from vat to vat by overhead tracked cranes. Each vat was successively less concentrated until the desired 0.05% was reached. The thicker the material, the longer it took to leach the zinc chloride to 0.05%. For the thickest products, times of 18 months to 2 years were needed. The zinc chloride used in these processes was for the most part not consumed in achieving the desired bonding. Indeed any dilution of the zinc chloride resulting from the leaching was dealt with by using evaporators to bring the zinc chloride solution back to the 70 Baume needed for using it again for saturating. In a sense, zinc chloride can be thought of as a catalyst in the making of the vulcanized fibre.Dried and pressed

Once the vulcanized fibre is leached free of the zinc chloride, it is dried to 5 to 6 percent moisture, and pressed or calendered to flatness. The continuous process-made vulcanized fibre could then be sheeted or wound up into rolls. The density of the finished vulcanized fibre is 2 to 3 times greater than the paper from which it starts. The density increase is the result of 10% machine direction shrinkage, 20% cross machine direction shrinkage, and 30% shrinkage in thickness.Properties

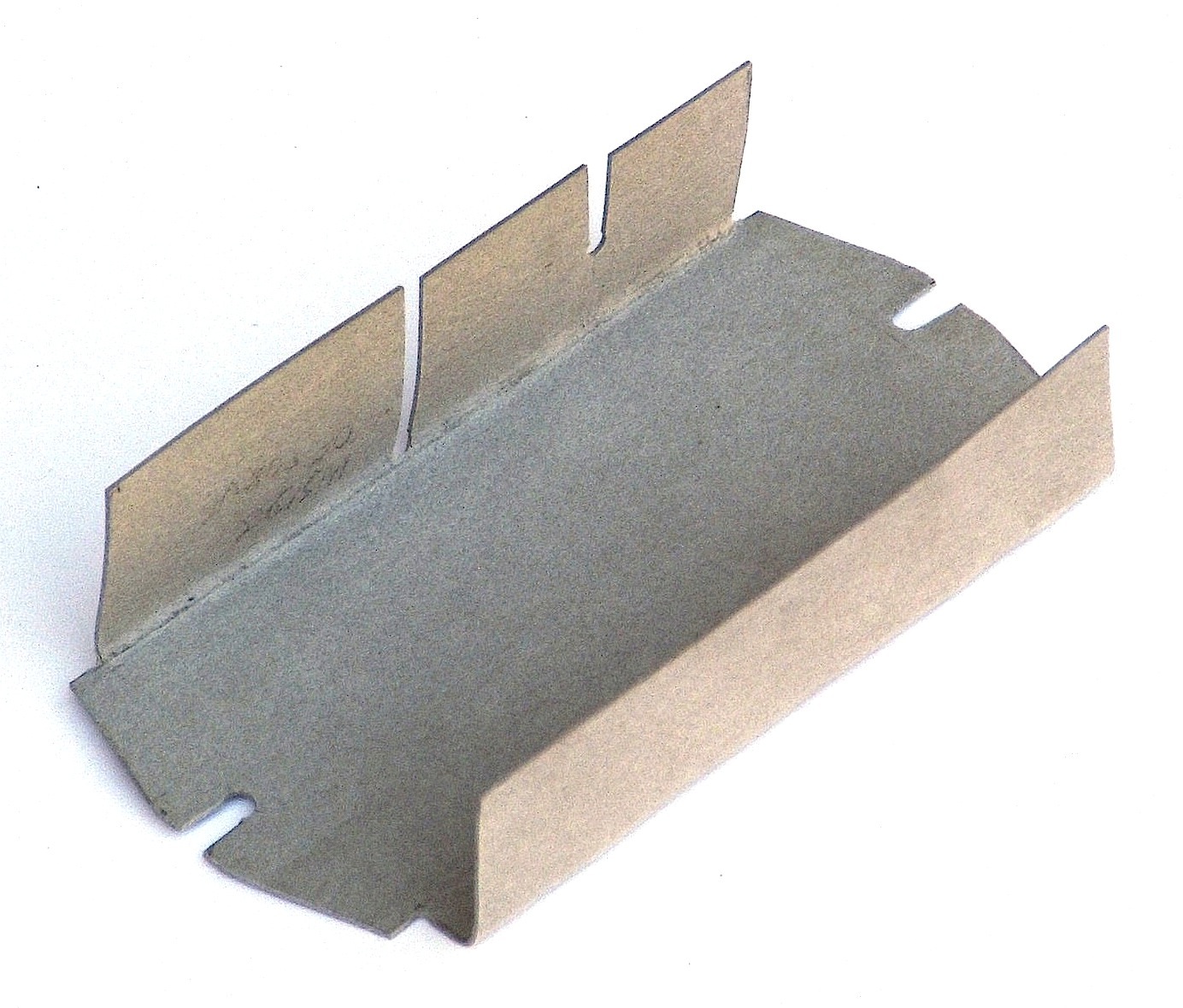

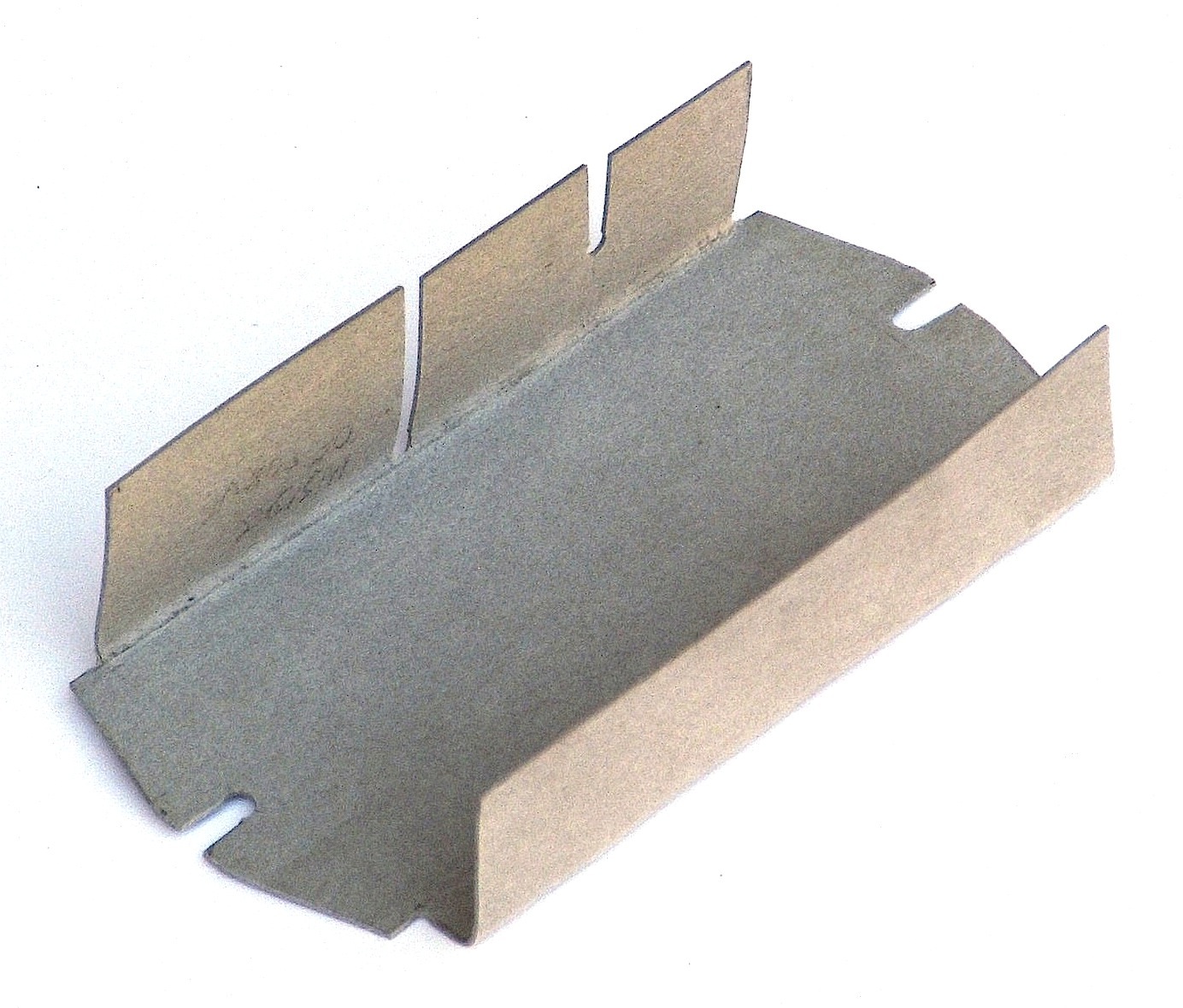

The final product is a homogeneous nearly 100%-cellulose mass free from any artificial glues, resins, or binders. The finished vulcanized fibre has useful mechanical and electrical properties. It offers high tear and tensile strength, while in the thinner thicknesses allowing flexibility to conform to curves and bends. In thicker thicknesses, it can be moulded to shape with steam and pressure. One application for vulcanized fibre that attests to its physical strength is that it is the preferred material for heavy sanding discs. Physical strength is anisotropic, owing to the roller calendering process, with it typically being 50% stronger in the sheet's longitudinal direction, rather than transverse. The electrical properties exhibited by vulcanized fibre are high insulating value, and arc and track resistance with service temperature of up to 110 to 120°C. Fibre was popular as an electrical insulator for a large part of the mid-20th century, not because its resistance as an insulator was particularly good, especially not if moisture levels were high, but it showed far better resistance to tracking and breakdown than early wood flour-filled polymers like Bakelite. Vulcanized fibre shows high resistance to penetration by most organic solvents, oils, and petroleum derivatives.Grades

*Commercial Grade; standard grey, black or red, used for many applications such as washers, gaskets, gears, handles, etc. *Electrical Grade: high dielectric grey, 100% cotton, very flexible, (historically called fishpaper), this grade is suitable for layer and ground insulation and has variations including top-stick grade used for wedges in small motors. *Trunk Fibre: Tough and abrasion resistant; used to surface steamer trunks, drum cases, wear and skid panels. *Bone Fibre: Exceptionally hard and dense, used for tight machining, tubing, pool cue ferrules (tips), cut out fuses. *Wood Laminating: Tough, multi-directional tensile and torsion strength, provides support and strength wherever wood laminations are used, particularly used under thin and exotic veneers as a stabilizer/strengthener.References

{{DEFAULTSORT:Vulcanized Fibre Fibers Paper Cellulose