Rivet on:

[Wikipedia]

[Google]

[Amazon]

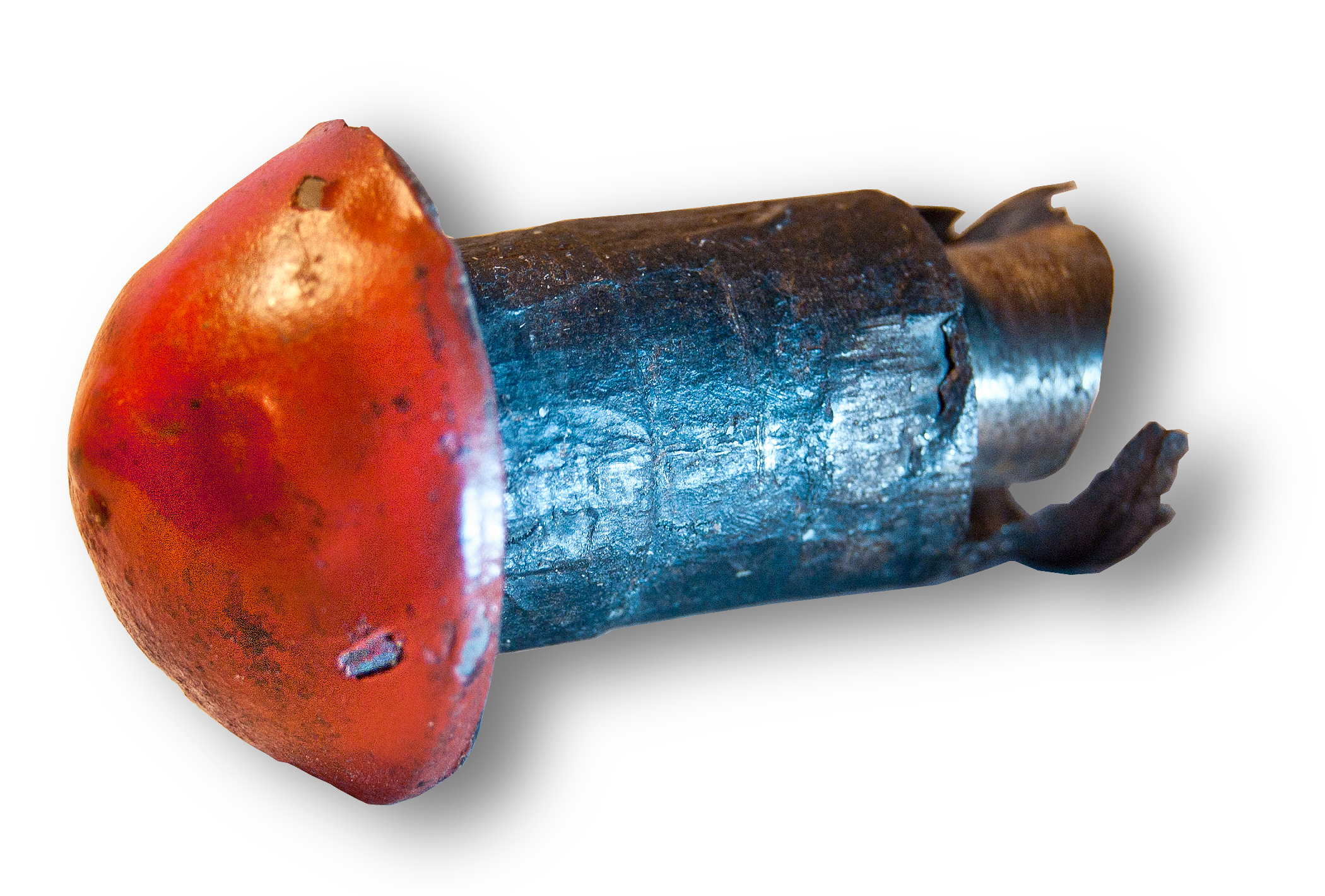

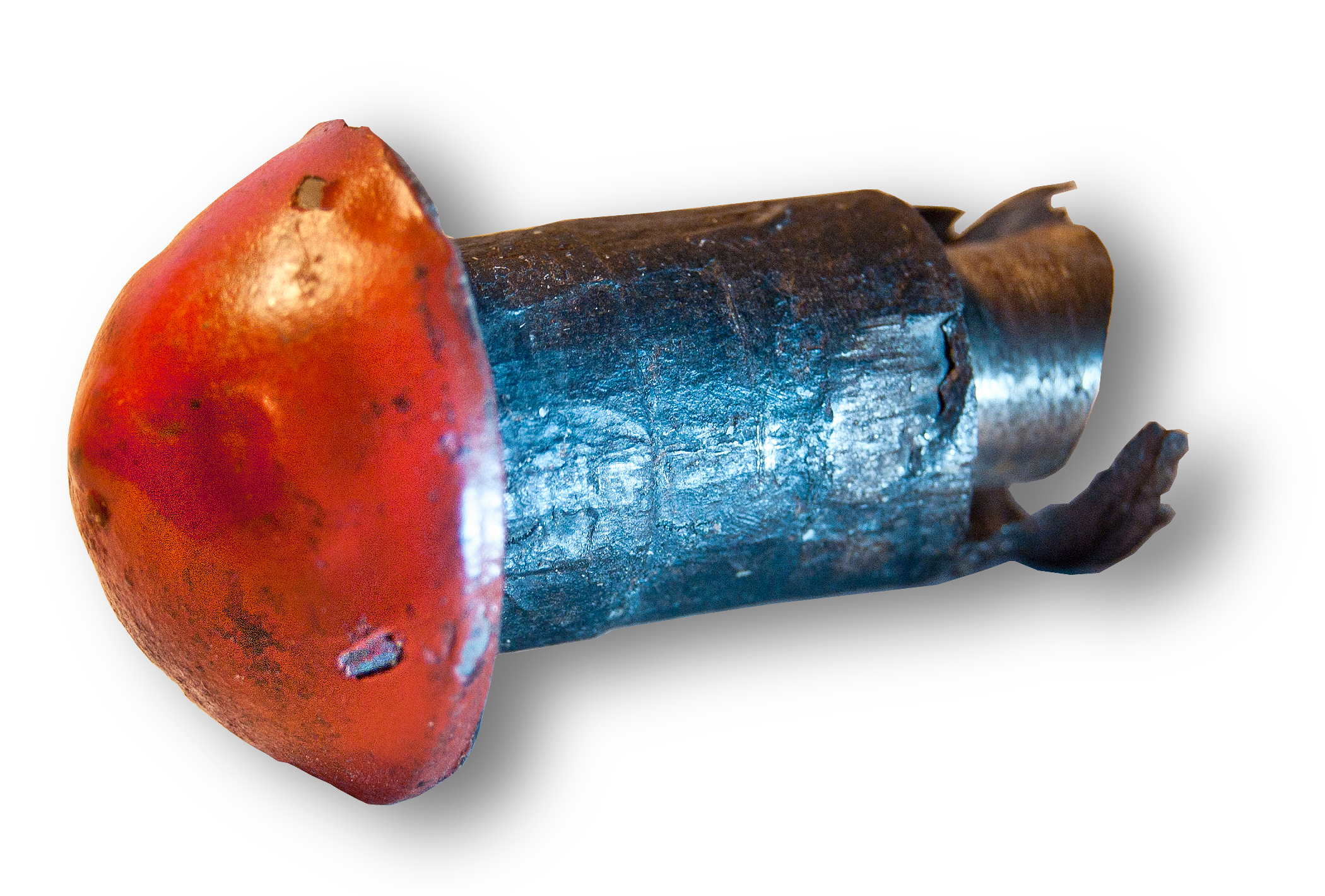

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the ''tail''. On installation, the rivet is placed in a punched or drilled hole, and the tail is ''upset'', or ''bucked'' (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the ''factory head'' and the deformed end is called the ''shop head'' or buck-tail.

Because there is effectively a head on each end of an installed rivet, it can support

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the ''tail''. On installation, the rivet is placed in a punched or drilled hole, and the tail is ''upset'', or ''bucked'' (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the ''factory head'' and the deformed end is called the ''shop head'' or buck-tail.

Because there is effectively a head on each end of an installed rivet, it can support

Solid rivets are one of the oldest and most reliable types of fasteners, having been found in archaeological findings dating back to the

Solid rivets are one of the oldest and most reliable types of fasteners, having been found in archaeological findings dating back to the  Solid rivets are used in applications where reliability and safety count. A typical application for solid rivets can be found within the structural parts of

Solid rivets are used in applications where reliability and safety count. A typical application for solid rivets can be found within the structural parts of

Until relatively recently, structural steel connections were either welded or riveted. High-strength bolts have largely replaced structural steel rivets. Indeed, the latest steel construction specifications published by

Until relatively recently, structural steel connections were either welded or riveted. High-strength bolts have largely replaced structural steel rivets. Indeed, the latest steel construction specifications published by

Semi-tubular rivets (also known as tubular rivets) are similar to solid rivets, except they have a partial hole (opposite the head) at the tip. The purpose of this hole is to reduce the amount of force needed for application by rolling the tubular portion outward. The force needed to apply a semitubular rivet is about 1/4 of the amount needed to apply a solid rivet. Tubular rivets are sometimes preferred for pivot points (a joint where movement is desired) since the swelling of the rivet is only at the tail. The type of equipment used to apply semi-tubular rivets range from prototyping tools to fully automated systems. Typical installation tools (from lowest to highest price) are hand set, manual squeezer, pneumatic squeezer, kick press, impact riveter, and finally PLC-controlled robotics. The most common machine is the impact riveter and the most common use of semitubular rivets is in lighting, brakes, ladders, binders, HVAC duct work, mechanical products, and electronics. They are offered from 1/16-inch (1.6 mm) to 3/8-inch (9.5 mm) in diameter (other sizes are considered highly special) and can be up to 8 inches (203 mm) long. A wide variety of materials and platings are available, most common base metals are steel, brass, copper, stainless, aluminum and most common platings are zinc, nickel, brass, tin. Tubular rivets are normally waxed to facilitate proper assembly. An installed tubular rivet has a head on one side, with a rolled over and exposed shallow blind hole on the other.

Semi-tubular rivets (also known as tubular rivets) are similar to solid rivets, except they have a partial hole (opposite the head) at the tip. The purpose of this hole is to reduce the amount of force needed for application by rolling the tubular portion outward. The force needed to apply a semitubular rivet is about 1/4 of the amount needed to apply a solid rivet. Tubular rivets are sometimes preferred for pivot points (a joint where movement is desired) since the swelling of the rivet is only at the tail. The type of equipment used to apply semi-tubular rivets range from prototyping tools to fully automated systems. Typical installation tools (from lowest to highest price) are hand set, manual squeezer, pneumatic squeezer, kick press, impact riveter, and finally PLC-controlled robotics. The most common machine is the impact riveter and the most common use of semitubular rivets is in lighting, brakes, ladders, binders, HVAC duct work, mechanical products, and electronics. They are offered from 1/16-inch (1.6 mm) to 3/8-inch (9.5 mm) in diameter (other sizes are considered highly special) and can be up to 8 inches (203 mm) long. A wide variety of materials and platings are available, most common base metals are steel, brass, copper, stainless, aluminum and most common platings are zinc, nickel, brass, tin. Tubular rivets are normally waxed to facilitate proper assembly. An installed tubular rivet has a head on one side, with a rolled over and exposed shallow blind hole on the other.

Blind rivets, commonly referred to as "pop" rivets (POP is the brand name of the original manufacturer, now owned by Stanley Engineered Fastening, a division of Stanley Black & Decker) are tubular and are supplied with a nail-like mandrel through the center which has a "necked" or weakened area near the head. The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel through the rivet. The compression force between the head of the mandrel and the tool expands the diameter of the tube throughout its length, locking the sheets being fastened if the hole was the correct size. The head of the mandrel also expands the blind end of the rivet to a diameter greater than that of the drilled hole, compressing the fastened sheets between the head of the rivet and the head of the mandrel. At a predetermined tension, the mandrel breaks at the necked location. With open tubular rivets, the head of the mandrel may or may not remain embedded in the expanded portion of the rivet, and can come loose at a later time. More expensive closed-end tubular rivets are formed around the mandrel so the head of the mandrel is always retained inside the blind end after installation. "Pop" rivets can be fully installed with access to only one side of a part or structure.

Prior to the invention of blind rivets, installation of a rivet typically required access to both sides of the assembly: a rivet hammer on one side and a bucking bar on the other side. In 1916, Royal Navy reservist and engineer Hamilton Neil Wylie filed a patent for an "improved means of closing tubular rivets" (granted May 1917). In 1922 Wylie joined the British aircraft manufacturer

Blind rivets, commonly referred to as "pop" rivets (POP is the brand name of the original manufacturer, now owned by Stanley Engineered Fastening, a division of Stanley Black & Decker) are tubular and are supplied with a nail-like mandrel through the center which has a "necked" or weakened area near the head. The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel through the rivet. The compression force between the head of the mandrel and the tool expands the diameter of the tube throughout its length, locking the sheets being fastened if the hole was the correct size. The head of the mandrel also expands the blind end of the rivet to a diameter greater than that of the drilled hole, compressing the fastened sheets between the head of the rivet and the head of the mandrel. At a predetermined tension, the mandrel breaks at the necked location. With open tubular rivets, the head of the mandrel may or may not remain embedded in the expanded portion of the rivet, and can come loose at a later time. More expensive closed-end tubular rivets are formed around the mandrel so the head of the mandrel is always retained inside the blind end after installation. "Pop" rivets can be fully installed with access to only one side of a part or structure.

Prior to the invention of blind rivets, installation of a rivet typically required access to both sides of the assembly: a rivet hammer on one side and a bucking bar on the other side. In 1916, Royal Navy reservist and engineer Hamilton Neil Wylie filed a patent for an "improved means of closing tubular rivets" (granted May 1917). In 1922 Wylie joined the British aircraft manufacturer

Oscar rivets are similar to blind rivets in appearance and installation, but have splits (typically three) along the hollow shaft. These splits cause the shaft to fold and flare out (similar to the wings on a toggle bolt's nut) as the mandrel is drawn into the rivet. This flare (or flange) provides a wide bearing surface that reduces the chance of rivet pull-out. This design is ideal for high vibration applications where the back surface is inaccessible.

A version of the Oscar rivet is the Olympic rivet which uses an aluminum mandrel that is drawn into the rivet head. After installation, the head and mandrel are shaved off flush resulting in an appearance closely resembling a brazier head driven rivet. They are used in repair of Airstream trailers to replicate the look of the original rivets.

Oscar rivets are similar to blind rivets in appearance and installation, but have splits (typically three) along the hollow shaft. These splits cause the shaft to fold and flare out (similar to the wings on a toggle bolt's nut) as the mandrel is drawn into the rivet. This flare (or flange) provides a wide bearing surface that reduces the chance of rivet pull-out. This design is ideal for high vibration applications where the back surface is inaccessible.

A version of the Oscar rivet is the Olympic rivet which uses an aluminum mandrel that is drawn into the rivet head. After installation, the head and mandrel are shaved off flush resulting in an appearance closely resembling a brazier head driven rivet. They are used in repair of Airstream trailers to replicate the look of the original rivets.

SPR process

The self-pierce rivet fully pierces the top sheet material(s) but only partially pierces the bottom sheet. As the tail end of the rivet does not break through the bottom sheet it provides a water or gas-tight joint. With the influence of the upsetting die, the tail end of the rivet flares and interlocks into the bottom sheet forming a low profile button. Rivets need to be harder than the materials being joined. they are heat treated to various levels of hardness depending on the material's ductility and hardness. Rivets come in a range of diameters and lengths depending on the materials being joined; head styles are either flush countersunk or pan heads. Depending on the rivet setter configuration, i.e. hydraulic, servo, stroke, nose-to-die gap, feed system etc., cycle times can be as quick as one second. Rivets are typically fed to the rivet setter nose from tape and come in cassette or spool form for continuous production. Riveting systems can be manual or automated depending on the application requirements; all systems are very flexible in terms of product design and ease of integration into a manufacturing process. SPR joins a range of dissimilar materials such as steel, aluminum, plastics, composites and pre-coated or pre-painted materials. Benefits include low energy demands, no heat, fumes, sparks or waste and very repeatable quality.

Rivets come in both inch series and metric series:

*

Rivets come in both inch series and metric series:

*

Before

Before

''Popular Science'', November 1941, "Self-Setting Explosive Rivet Speeds Warplane Building"

system used by both the US and Germany in World War Two for aircraft assembly – see bottom half of page

''Four Methods of Flush Riveting''

film made by Disney Studios during World War Two

"Hold Everything", February 1946, ''Popular Science''

new rivet types developed during World War Two

"Blind Rivets they get it all together"

''Popular Science'', October 1975, pp. 126–128.

"RMS ''Titanic'' Remembered"

– The Lads in the Shipyard {{Authority control Articles containing video clips Mechanical fasteners Metalworking Structural steel Textile closures

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the ''tail''. On installation, the rivet is placed in a punched or drilled hole, and the tail is ''upset'', or ''bucked'' (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the ''factory head'' and the deformed end is called the ''shop head'' or buck-tail.

Because there is effectively a head on each end of an installed rivet, it can support

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the ''tail''. On installation, the rivet is placed in a punched or drilled hole, and the tail is ''upset'', or ''bucked'' (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the ''factory head'' and the deformed end is called the ''shop head'' or buck-tail.

Because there is effectively a head on each end of an installed rivet, it can support tension

Tension may refer to:

Science

* Psychological stress

* Tension (physics), a force related to the stretching of an object (the opposite of compression)

* Tension (geology), a stress which stretches rocks in two opposite directions

* Voltage or el ...

loads. However, it is much more capable of supporting shear loads (loads perpendicular to the axis of the shaft).

Fastenings used in traditional wooden boat building

Boat building is the design and construction of boats and their systems. This includes at a minimum a hull, with propulsion, mechanical, navigation, safety and other systems as a craft requires.

Construction materials and methods

Wood

Wo ...

, such as copper nails and clinch bolts, work on the same principle as the rivet but were in use long before the term ''rivet'' was introduced and, where they are remembered, are usually classified among nails and bolts respectively.

History

Rivet holes have been found in Egyptian spearheads dating back to the Naqada culture of between 4400 and 3000 B.C. Archeologists have also uncovered manyBronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second prin ...

swords and daggers with rivet holes where the handles would have been. The rivets themselves were essentially short rods of metal, which metalworkers hammered into a pre-drilled hole on one side and deformed on the other to hold them in place.

Types

There are a number of types of rivets, designed to meet different cost, accessibility, and strength requirements:Solid/round head rivets

Bronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second prin ...

. Solid rivets consist simply of a shaft and head that are deformed with a hammer or rivet gun

A rivet gun, also known as a rivet hammer or a pneumatic hammer, is a type of tool used to drive rivets. The rivet gun is used on rivet's ''factory head'' (the head present before riveting takes place), and a bucking bar is used to support the ...

. A rivet compression or crimping tool can also deform this type of rivet. This tool is mainly used on rivets close to the edge of the fastened material, since the tool is limited by the depth of its frame. A rivet compression tool does not require two people, and is generally the most foolproof way to install solid rivets.

Solid rivets are used in applications where reliability and safety count. A typical application for solid rivets can be found within the structural parts of

Solid rivets are used in applications where reliability and safety count. A typical application for solid rivets can be found within the structural parts of aircraft

An aircraft is a vehicle that is able to fly by gaining support from the air. It counters the force of gravity by using either static lift or by using the dynamic lift of an airfoil, or in a few cases the downward thrust from jet engine ...

. Hundreds of thousands of solid rivets are used to assemble the frame of a modern aircraft. Such rivets come with rounded (universal) or 100° countersunk heads. Typical materials for aircraft rivets are aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

s (2017, 2024, 2117, 7050, 5056, 55000, V-65), titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

, and nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

-based alloys (e.g., Monel

Monel is a group of alloys of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Monel is not a cupronickel alloy because it has less than 60% copper.

Stronger than pure nickel, Monel alloys are res ...

). Some aluminum alloy rivets are too hard to buck and must be softened by solution treating (precipitation hardening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and ...

) prior to being bucked. "Ice box" aluminum alloy rivets harden with age, and must likewise be annealed and then kept at sub-freezing temperatures (hence the name "ice box") to slow the age-hardening process. Steel rivets can be found in static structures such as bridge

A bridge is a structure built to span a physical obstacle (such as a body of water, valley, road, or rail) without blocking the way underneath. It is constructed for the purpose of providing passage over the obstacle, which is usually somethi ...

s, cranes, and building frames.

The setting of these fasteners requires access to both sides of a structure. Solid rivets are driven using a hydraulic

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counte ...

ally, pneumatically, or electromagnetically actuated squeezing tool

A tool is an object that can extend an individual's ability to modify features of the surrounding environment or help them accomplish a particular task. Although many animals use simple tools, only human beings, whose use of stone tools dates ba ...

or even a handheld hammer. Applications where only one side is accessible require "blind" rivets.

Solid rivets are also used by some artisans in the construction of modern reproduction of medieval armour, jewellery and metal couture.

High-strength structural steel rivets

Until relatively recently, structural steel connections were either welded or riveted. High-strength bolts have largely replaced structural steel rivets. Indeed, the latest steel construction specifications published by

Until relatively recently, structural steel connections were either welded or riveted. High-strength bolts have largely replaced structural steel rivets. Indeed, the latest steel construction specifications published by AISC

The American Institute of Steel Construction (AISC) is a not-for-profit technical institute and trade association for the use of structural steel in the construction industry of the United States.

AISC publishes the Steel Construction Manual ...

(the 14th Edition) no longer covers their installation. The reason for the change is primarily due to the expense of skilled workers required to install high strength structural steel rivets. Whereas two relatively unskilled workers can install and tighten high strength bolts, it normally takes four skilled workers to install rivets (warmer, catcher, holder, basher).

At a central location near the areas being riveted, a furnace was set up. Rivets were placed in the furnace and heated to glowing hot (often to white hot) so that they were more malleable and easily deformed. The rivet warmer or ''cook'' used tongs

Tongs are a type of tool used to grip and lift objects instead of holding them directly with hands. There are many forms of tongs adapted to their specific use.

The first pair of tongs belongs to the Egyptians. Tongs likely started off as ...

to remove individual rivets and throw them to a catcher stationed near the joints to be riveted. The ''catcher'' (usually) caught the rivet in a leather or wooden bucket with an ash-lined bottom. The catcher inserted the rivet into the hole to be riveted, then quickly turned to catch the next rivet. The ''holder up'' or ''holder on'' would hold a heavy ''rivet set'' or dolly or another (larger) pneumatic jack against the round head of the rivet, while the riveter (sometimes two riveters) applied a hammer or pneumatic rivet hammer to the unformed head, making it mushroom tightly against the joint in its final domed shape. Alternatively the buck is hammered more or less flush with the structure in a counter sunk hole. Before the use of pneumatic hammers, e.g. in the construction of RMS '' Titanic'', the man who hammered the rivet was known as the "basher". Upon cooling, the rivet contracted and exerted further force, tightening the joint.

The last commonly used high strength structural steel rivets were designated ASTM A502 Grade 1 rivets.

Such riveted structures may be insufficient to resist seismic loading from earthquakes if the structure was not engineered for such forces, a common problem of older steel bridges. This is because a hot rivet cannot be properly heat treated to add strength and hardness. In the seismic retrofit

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with our recent exp ...

of such structures it is common practice to remove critical rivets with an oxygen torch, precision ream the hole, then insert a machined and heat treated bolt.

Semi-tubular rivets

Blind rivets

Blind rivets, commonly referred to as "pop" rivets (POP is the brand name of the original manufacturer, now owned by Stanley Engineered Fastening, a division of Stanley Black & Decker) are tubular and are supplied with a nail-like mandrel through the center which has a "necked" or weakened area near the head. The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel through the rivet. The compression force between the head of the mandrel and the tool expands the diameter of the tube throughout its length, locking the sheets being fastened if the hole was the correct size. The head of the mandrel also expands the blind end of the rivet to a diameter greater than that of the drilled hole, compressing the fastened sheets between the head of the rivet and the head of the mandrel. At a predetermined tension, the mandrel breaks at the necked location. With open tubular rivets, the head of the mandrel may or may not remain embedded in the expanded portion of the rivet, and can come loose at a later time. More expensive closed-end tubular rivets are formed around the mandrel so the head of the mandrel is always retained inside the blind end after installation. "Pop" rivets can be fully installed with access to only one side of a part or structure.

Prior to the invention of blind rivets, installation of a rivet typically required access to both sides of the assembly: a rivet hammer on one side and a bucking bar on the other side. In 1916, Royal Navy reservist and engineer Hamilton Neil Wylie filed a patent for an "improved means of closing tubular rivets" (granted May 1917). In 1922 Wylie joined the British aircraft manufacturer

Blind rivets, commonly referred to as "pop" rivets (POP is the brand name of the original manufacturer, now owned by Stanley Engineered Fastening, a division of Stanley Black & Decker) are tubular and are supplied with a nail-like mandrel through the center which has a "necked" or weakened area near the head. The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel through the rivet. The compression force between the head of the mandrel and the tool expands the diameter of the tube throughout its length, locking the sheets being fastened if the hole was the correct size. The head of the mandrel also expands the blind end of the rivet to a diameter greater than that of the drilled hole, compressing the fastened sheets between the head of the rivet and the head of the mandrel. At a predetermined tension, the mandrel breaks at the necked location. With open tubular rivets, the head of the mandrel may or may not remain embedded in the expanded portion of the rivet, and can come loose at a later time. More expensive closed-end tubular rivets are formed around the mandrel so the head of the mandrel is always retained inside the blind end after installation. "Pop" rivets can be fully installed with access to only one side of a part or structure.

Prior to the invention of blind rivets, installation of a rivet typically required access to both sides of the assembly: a rivet hammer on one side and a bucking bar on the other side. In 1916, Royal Navy reservist and engineer Hamilton Neil Wylie filed a patent for an "improved means of closing tubular rivets" (granted May 1917). In 1922 Wylie joined the British aircraft manufacturer Armstrong-Whitworth

Sir W G Armstrong Whitworth & Co Ltd was a major British manufacturing company of the early years of the 20th century. With headquarters in Elswick, Newcastle upon Tyne, Armstrong Whitworth built armaments, ships, locomotives, automobiles and a ...

Ltd to advise on metal construction techniques; here he continued to develop his rivet design with a further 1927 patent that incorporated the pull-through mandrel, and allowed the rivet to be used ''blind''. By 1928, the George Tucker Eyelet company, of Birmingham, England, produced a "cup" rivet based on the design. It required a separate GKN mandrel and the rivet body to be hand assembled prior to use for the building of the Siskin III aircraft. Together with Armstrong-Whitworth, the Geo. Tucker Co. further modified the rivet design to produce a one-piece unit incorporating mandrel and rivet. This product was later developed in aluminium and trademarked as the "POP" rivet. The United Shoe Machinery Co. produced the design in the U.S. as inventors such as Carl Cherry and Lou Huck experimented with other techniques for expanding solid rivets.

They are available in flat head, countersunk head, and modified flush head with standard diameters of 1/8, 5/32 and 3/16 inch. Blind rivets are made from soft aluminum alloy, steel (including stainless steel), copper, and Monel

Monel is a group of alloys of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Monel is not a cupronickel alloy because it has less than 60% copper.

Stronger than pure nickel, Monel alloys are res ...

.

There are also ', which are designed to take shear and tensile loads.

The rivet body is normally manufactured using one of three methods:

There is a vast array of specialty blind rivets that are suited for high strength or plastic applications. Typical types include:

Internally and externally locked structural blind rivets can be used in aircraft applications because, unlike other types of blind rivets, the locked mandrels cannot fall out and are watertight. Since the mandrel is locked into place, they have the same or greater shear-load-carrying capacity as solid rivets and may be used to replace solid rivets on all but the most critical stressed aircraft structures.

The typical assembly process requires the operator to install the rivet in the nose of the tool by hand and then actuate the tool. However, in recent years automated riveting systems have become popular in an effort to reduce assembly costs and repetitive disorders. The cost of such tools range from US$1,500 for autofeed pneumatics to US$50,000 for fully robotic systems.

While structural blind rivets using a locked mandrel are common, there are also aircraft applications using "non-structural" blind rivets where the reduced, but still predictable, strength of the rivet without the mandrel is used as the design strength. A method popularized by Chris Heintz of Zenith Aircraft

__NOTOC__

Zenith Aircraft Company is in the exclusive business of designing, developing and manufacturing kit aircraft. The independent, privately owned company was formed in 1992 in Mexico, Missouri, centrally located in the United States, and ...

uses a common flat-head (countersunk) rivet which is drawn into a specially machined nosepiece that forms it into a round head rivet, taking up much of the variation inherent in hole size found in amateur aircraft construction. Aircraft designed with these rivets use rivet strength figures measured with the mandrel removed.

Oscar rivets

Oscar rivets are similar to blind rivets in appearance and installation, but have splits (typically three) along the hollow shaft. These splits cause the shaft to fold and flare out (similar to the wings on a toggle bolt's nut) as the mandrel is drawn into the rivet. This flare (or flange) provides a wide bearing surface that reduces the chance of rivet pull-out. This design is ideal for high vibration applications where the back surface is inaccessible.

A version of the Oscar rivet is the Olympic rivet which uses an aluminum mandrel that is drawn into the rivet head. After installation, the head and mandrel are shaved off flush resulting in an appearance closely resembling a brazier head driven rivet. They are used in repair of Airstream trailers to replicate the look of the original rivets.

Oscar rivets are similar to blind rivets in appearance and installation, but have splits (typically three) along the hollow shaft. These splits cause the shaft to fold and flare out (similar to the wings on a toggle bolt's nut) as the mandrel is drawn into the rivet. This flare (or flange) provides a wide bearing surface that reduces the chance of rivet pull-out. This design is ideal for high vibration applications where the back surface is inaccessible.

A version of the Oscar rivet is the Olympic rivet which uses an aluminum mandrel that is drawn into the rivet head. After installation, the head and mandrel are shaved off flush resulting in an appearance closely resembling a brazier head driven rivet. They are used in repair of Airstream trailers to replicate the look of the original rivets.

Drive rivet

A drive rivet is a form of blind rivet that has a short mandrel protruding from the head that is driven in with a hammer to flare out the end inserted in the hole. This is commonly used to rivet wood panels into place since the hole does not need to be drilled all the way through the panel, producing an aesthetically pleasing appearance. They can also be used with plastic, metal, and other materials and require no special setting tool other than a hammer and possibly a backing block (steel or some other dense material) placed behind the location of the rivet while hammering it into place. Drive rivets have less clamping force than most other rivets. Drive screws, possibly another name for drive rivets, are commonly used to hold nameplates into blind holes. They typically have spiral threads that grip the side of the hole.Flush rivet

A flush rivet is used primarily on external metal surfaces where good appearance and the elimination of unnecessary aerodynamic drag are important. A flush rivet takes advantage of a countersink hole; they are also commonly referred to as countersunk rivets. Countersunk or flush rivets are used extensively on the exterior of aircraft for aerodynamic reasons such as reduced drag and turbulence. Additional post-installation machining may be performed to perfect the airflow. Flush riveting was invented in America in the 1930s by Vladimir Pavlecka and his team atDouglas Aircraft

The Douglas Aircraft Company was an American aerospace manufacturer based in Southern California. It was founded in 1921 by Donald Wills Douglas Sr. and later merged with McDonnell Aircraft in 1967 to form McDonnell Douglas; it then operated as ...

. The technology was used by Howard Hughes

Howard Robard Hughes Jr. (December 24, 1905 – April 5, 1976) was an American business magnate, record-setting pilot, engineer, film producer, and philanthropist, known during his lifetime as one of the most influential and richest people in th ...

in the design and production of his H-1 plane, the Hughes H-1 Racer.

Friction-lock rivet

These resemble an expanding bolt except the shaft snaps below the surface when the tension is sufficient. The blind end may be either countersunk ('flush') or dome shaped. One early form of blind rivet that was the first to be widely used for aircraft construction and repair was the Cherry friction-lock rivet. Originally, Cherry friction-locks were available in two styles, hollow shank pull-through and self-plugging types. The pull-through type is no longer common; however, the self-plugging Cherry friction-lock rivet is still used for repairing light aircraft. Cherry friction-lock rivets are available in two head styles, universal and 100 degree countersunk. Furthermore, they are usually supplied in three standard diameters, 1/8, 5/32 and 3/16 inch. A friction-lock rivet cannot replace a solid shank rivet, size for size. When a friction-lock is used to replace a solid shank rivet, it must be at least one size larger in diameter because the friction-lock rivet loses considerable strength if its center stem falls out due to vibrations or damage.Rivet alloys, shear strengths, and driving condition

Self-piercing rivets

Self-pierce riveting (SPR) is a process of joining two or more materials using an engineered rivet. Unlike solid, blind and semi-tubular rivets, self-pierce rivets do not require a drilled or punched hole. SPRs are cold forged to a semi-tubular shape and contain a partial hole to the opposite end of the head. The end geometry of the rivet has a chamfered poke that helps the rivet pierce the materials being joined. A hydraulic or electric servo rivet setter drives the rivet into the material, and an upsetting die provides a cavity for the displaced bottom sheet material to flow. The SPR process is described in herSPR process

The self-pierce rivet fully pierces the top sheet material(s) but only partially pierces the bottom sheet. As the tail end of the rivet does not break through the bottom sheet it provides a water or gas-tight joint. With the influence of the upsetting die, the tail end of the rivet flares and interlocks into the bottom sheet forming a low profile button. Rivets need to be harder than the materials being joined. they are heat treated to various levels of hardness depending on the material's ductility and hardness. Rivets come in a range of diameters and lengths depending on the materials being joined; head styles are either flush countersunk or pan heads. Depending on the rivet setter configuration, i.e. hydraulic, servo, stroke, nose-to-die gap, feed system etc., cycle times can be as quick as one second. Rivets are typically fed to the rivet setter nose from tape and come in cassette or spool form for continuous production. Riveting systems can be manual or automated depending on the application requirements; all systems are very flexible in terms of product design and ease of integration into a manufacturing process. SPR joins a range of dissimilar materials such as steel, aluminum, plastics, composites and pre-coated or pre-painted materials. Benefits include low energy demands, no heat, fumes, sparks or waste and very repeatable quality.

Compression rivets

Compression rivets are commonly used for functional or decorative purposes on clothing, accessories, and other items. They have male and female halves that press together, through a hole in the material. ''Double cap rivets'' have aesthetic caps on both sides. ''Single cap rivets'' have caps on just one side; the other side is low profile with a visible hole. ''Cutlery rivets'' are commonly used to attach handles to knife blades and other utensils.Sizes

Rivets come in both inch series and metric series:

*

Rivets come in both inch series and metric series:

* Imperial units

The imperial system of units, imperial system or imperial units (also known as British Imperial or Exchequer Standards of 1826) is the system of units first defined in the British Weights and Measures Act 1824 and continued to be developed th ...

(fractions of inches) with diameters such as 1/8" or 5/16".

* Système international or SI units with diameters such as 3 mm, 8 mm.

The main official standards relate more to technical parameters such as ultimate tensile strength and surface finishing than physical length and diameter. They are:

Imperial

Rivet diameters are commonly measured in -inch increments and their lengths in -inch increments, expressed as "dash numbers" at the end of the rivet identification number. A "dash 3 dash 4" (XXXXXX-3-4) designation indicates a -inch diameter and -inch (or -inch) length. Some rivets lengths are also available in ''half sizes'', and have a dash number such as –3.5 ( inch) to indicate they are half-size. The letters and digits in a rivet's identification number that precede its dash numbers indicate the specification under which the rivet was manufactured and the head style. On many rivets, a size in 32nds may be stamped on the rivet head. Other makings on the rivet head, such as small raised or depressed dimples or small raised bars indicate the rivet's alloy. To become a proper fastener, a rivet should be placed in hole ideally 4–6 thousandths of an inch larger in diameter. This allows the rivet to be easily and fully inserted, then setting allows the rivet to expand, tightly filling the gap and maximizing strength.Metric

Rivet diameters and lengths are measured in millimeters. Conveniently, the rivet diameter relates to the drill required to make a hole to accept the rivet, rather than the actual diameter of the rivet, which is slightly smaller. This facilitates the use of a simple drill-gauge to check both rivet and drill are compatible. For general use, diameters between 2 mm – 20 mm and lengths from 5 mm – 50 mm are common. The design-type, material and any finish is usually expressed in plain language (often English).Applications

Before

Before welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as bra ...

techniques and bolted joint

A bolted joint is one of the most common elements in construction and machine design. It consists of a male threaded fastener (e. g., a bolt) that captures and joins other parts, secured with a matching female screw thread. There are two main ...

s were developed, metal framed buildings and structures such as the Eiffel Tower, Shukhov Tower

The Shukhov Radio Tower (russian: Шуховская башня), also known as the Shabolovka Tower (), is a broadcasting tower deriving from the Russian avant-garde in Moscow designed by Vladimir Shukhov. The free-standing steel diagrid st ...

and the Sydney Harbour Bridge

The Sydney Harbour Bridge is a steel through arch bridge in Sydney, spanning Port Jackson, Sydney Harbour from the Sydney central business district, central business district (CBD) to the North Shore (Sydney), North Shore. The view of the bridg ...

were generally held together by riveting, as were automobile

A car or automobile is a motor vehicle with wheels. Most definitions of ''cars'' say that they run primarily on roads, seat one to eight people, have four wheels, and mainly transport people instead of goods.

The year 1886 is regarde ...

chassis. Riveting is still widely used in applications where light weight

In science and engineering, the weight of an object is the force acting on the object due to gravity.

Some standard textbooks define weight as a vector quantity, the gravitational force acting on the object. Others define weight as a scalar qua ...

and high strength are critical, such as in an aircraft. Many sheet-metal alloys are preferably not welded as deformation and modification of material properties can occur.

A large number of countries used rivets in the construction of armored tanks during World War II, including the M3 Lee (General Grant) manufactured in the United States. However, many countries soon learned that rivets were a large weakness in tank design, since if a tank was hit by a large projectile it would dislocate the rivets and they would fly around the inside of the tank and injure or kill the crew, even if the projectile did not penetrate the armor. Some countries such as Italy, Japan, and Britain used rivets in some or all of their tank designs throughout the war for various reasons, such as lack of welding equipment or inability to weld very thick plates of armor effectively.

Blind rivets are used almost universally in the construction of plywood road case

A road case, ATA case or flight case is a shipping container specifically built to protect musical instruments, motion picture equipment, audio and lighting production equipment, properties, firearms, or other sensitive equipment when it must be ...

s.

Common but more exotic uses of rivets are to reinforce jeans and to produce the distinctive sound of a sizzle cymbal

A sizzle cymbal is a cymbal to which rivets, chains or other rattles have been added to modify the sound, attached either by means of holes bored in the cymbal or by means of an attachment known as a sizzler.

These rattles have two main effects ...

.

Joint analysis

Thestress

Stress may refer to:

Science and medicine

* Stress (biology), an organism's response to a stressor such as an environmental condition

* Stress (linguistics), relative emphasis or prominence given to a syllable in a word, or to a word in a phrase ...

and shear in a rivet is analyzed like a bolted joint. However, it is not wise to combine rivets with bolts and screws in the same joint. Rivets fill the hole where they are installed to establish a very tight fit (often called interference fit). It is difficult or impossible to obtain such a tight fit with other fasteners. The result is that rivets in the same joint with loose fasteners carry more of the load—they are effectively more stiff. The rivet can then fail before it can redistribute load to the other loose fit fasteners like bolts and screws. This often causes catastrophic failure of the joint when the fasteners ''unzip''. In general, a joint composed of similar fasteners is the most efficient because all fasteners reach capacity simultaneously.

Installation

Solid and semi tubular rivets

There are several methods for installing solid rivets. * Manual with hammer and handset or bucking bar * Pneumatic hammers * Handheld squeezers * Riveting machines * Pin hammer, rivet set Rivets small enough and soft enough are often ''bucked''. In this process the installer places a rivet gun against the factory head and holds a bucking bar against the tail or a hard working surface. The bucking bar is a specially shaped solid block of metal. The rivet gun provides a series of high-impulse forces that upsets and work hardens the tail of the rivet between the work and the inertia of the bucking bar. Rivets that are large or hard may be more easily installed by squeezing instead. In this process a tool in contact with each end of the rivet clinches to deform the rivet. Rivets may also be upset by hand, using a ball-peen hammer. The head is placed in a special hole made to accommodate it, known as a rivet-set. The hammer is applied to the buck-tail of the rivet, rolling an edge so that it is flush against the material.Testing

Solid rivets for construction

A hammer is also used to "ring" an installed rivet, as a non-destructive test for tightness and imperfections. The inspector taps the head (usually the factory head) of the rivet with the hammer while touching the rivet and base plate lightly with the other hand and judges the quality of the audibly returned sound and the feel of the sound traveling through the metal to the operator's fingers. A rivet tightly set in its hole returns a clean and clear ring, while a loose rivet produces a recognizably different sound.Testing of blind rivets

A blind rivet has strength properties that can be measured in terms of shear and tensile strength. Occasionally rivets also undergo performance testing for other critical features, such as pushout force, break load and salt spray resistance. A standardized destructive test according to the Inch Fastener Standards is widely accepted. The shear test involves installing a rivet into two plates at specified hardness and thickness and measuring the force necessary to shear the plates. The tensile test is basically the same, except that it measures the pullout strength. Per the IFI-135 standard, all blind rivets produced must meet this standard. These tests determine the strength of the rivet, and not the strength of the assembly. To determine the strength of the assembly a user must consult an engineering guide or the Machinery's Handbook.Alternatives

* Adhesives *Bolted joint

A bolted joint is one of the most common elements in construction and machine design. It consists of a male threaded fastener (e. g., a bolt) that captures and joins other parts, secured with a matching female screw thread. There are two main ...

s

* Brazing

* Clinching

In metalworking, clinching or press-joining is a bulk sheet metal forming process aimed at joining thin metal sheets without additional components, using special tools to plastically form an interlock between two or more sheets. The process is ...

* Folded joints

* Nails

* Screws

* Soldering

* Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as bra ...

See also

*Boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centr ...

* Cleco

* Clinker (boat building)

* Ring binder

Ring binders (loose leaf binders, looseleaf binders, or sometimes called files in Britain) are large folders that contain file folders or hole punched papers. These binders come in various sizes and can accommodate an array of paper sizes. Th ...

* Rivet nut

* Rosie the Riveter

Rosie the Riveter is an allegorical cultural icon in the United States who represents the women who worked in factories and shipyards during World War II, many of whom produced munitions and war supplies. These women sometimes took entirely new ...

References

Bibliography

*External links

*''Popular Science'', November 1941, "Self-Setting Explosive Rivet Speeds Warplane Building"

system used by both the US and Germany in World War Two for aircraft assembly – see bottom half of page

''Four Methods of Flush Riveting''

film made by Disney Studios during World War Two

"Hold Everything", February 1946, ''Popular Science''

new rivet types developed during World War Two

"Blind Rivets they get it all together"

''Popular Science'', October 1975, pp. 126–128.

"RMS ''Titanic'' Remembered"

– The Lads in the Shipyard {{Authority control Articles containing video clips Mechanical fasteners Metalworking Structural steel Textile closures