opposed-piston engine on:

[Wikipedia]

[Google]

[Amazon]

An opposed-piston engine is a

An opposed-piston engine is a

Compared to contemporary two-stroke engines, which used a conventional design of one piston per cylinder, the advantages of the opposed-piston engine have been recognized as:

* Eliminating the

Compared to contemporary two-stroke engines, which used a conventional design of one piston per cylinder, the advantages of the opposed-piston engine have been recognized as:

* Eliminating the

One of the first opposed-piston engines was the 1882 Atkinson differential engine, which has a power stroke on every rotation of the crankshaft (compared with every second rotation for the contemporary Otto cycle engine), but it was not a commercial success.

In 1898, an Oechelhäuser two-stroke opposed-piston engine producing was installed at the Hoerde ironworks. This design of engine was also produced under licence by manufacturers including Deutsche Kraftgas Gesellschaft in Germany and William Beardmore & Sons in the United Kingdom.

In 1901, the Kansas City Lightning Balanced Gas and Gasoline Engines were gasoline engines producing .

An early opposed-piston car engine was produced by the French company Gobron-Brillié around 1900. In April 1904, a Gobron-Brillié car powered by the opposed-piston engine was the first car ever to exceed 150 km/h with a "World's Record Speed" of . On 17 July 1904, the Gobron-Brillié car became the first to exceed for the flying kilometre. The engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston.

Another early opposed piston car engine was in the Scottish Arrol-Johnston car, which appears to have been first installed in their 10 hp buckboard c1900. The engine was described and illustrated in some detail in the account of their 12-15 hp car exhibited at the 1905 Olympia Motor-Show. The engine was a 4-stroke with two cylinders (with opposed pistons in each) with the crankshaft underneath and the pistons connected by lever arms to the two-throw crankshaft.

The first diesel engine with opposed pistons was a prototype built at Kolomna Locomotive Works in Russia. The designer, Raymond A. Koreyvo, patented the engine in France on 6 November 1907 and displayed the engine at international exhibitions, but it did not reach production. The Kolomna design used a typical layout of two crankshafts connected by gearing.

In 1914, the Simpson's Balanced Two-Stroke motorcycle engine was another opposed-piston engine using a single crankshaft beneath the centre of the cylinders with both pistons connected by levers. This engine was a crankcase compression design, with one piston used to uncover the transfer port, and the other to open the exhaust port. The advantage of this design was to avoid the deflector crowns for pistons used by most two-stroke engines at that time.

Doxford Engine Works in the United Kingdom built large opposed-piston engines for marine use, with the first Doxford engine being installed in a ship in 1921. This diesel engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston. After World War I, these engines were produced in a number of models, such as the P and J series, with outputs as high as . Production of Doxford engines in the UK ceased in 1980.

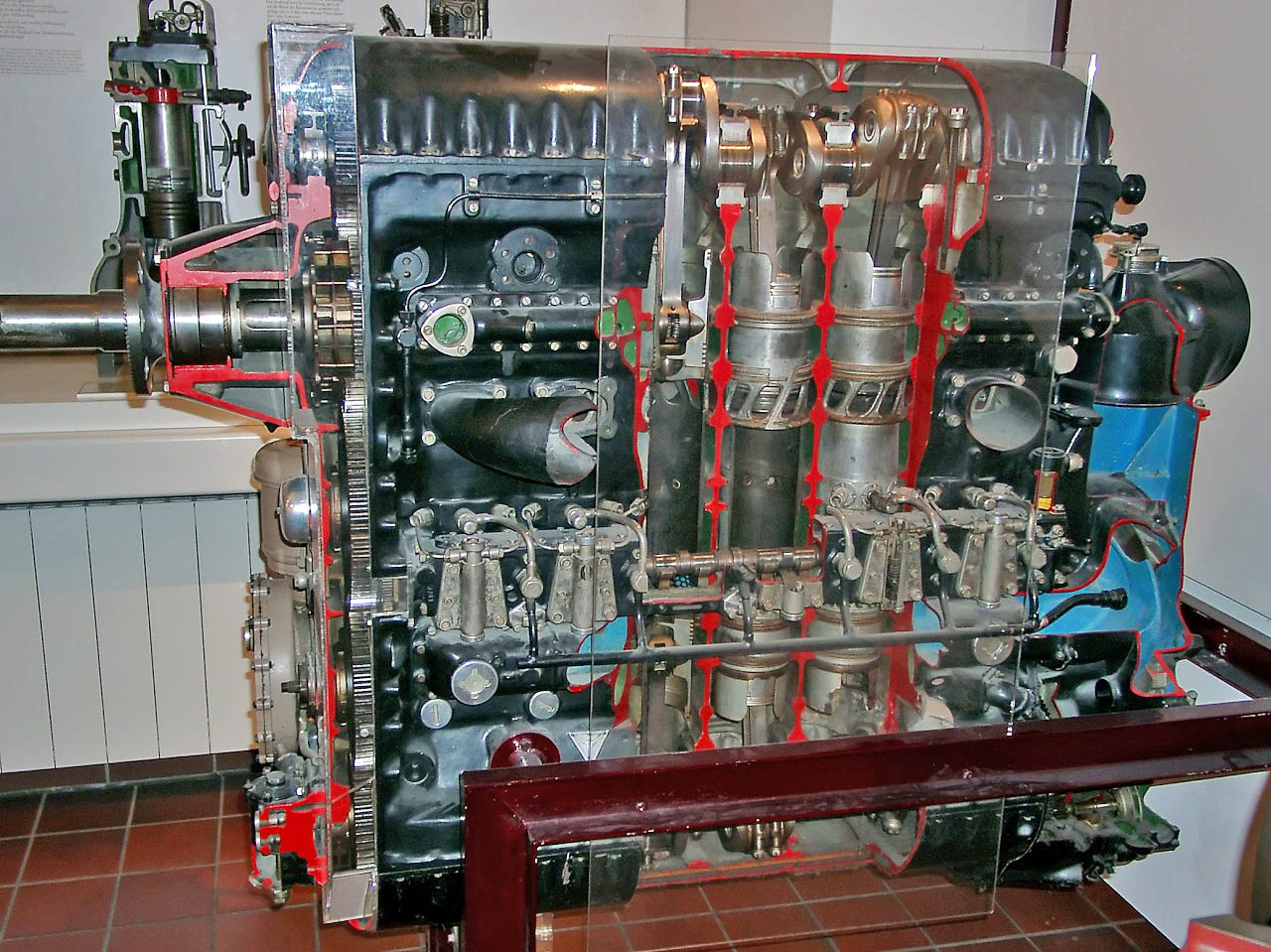

Later opposed-piston diesel engines include the 1932 Junkers Jumo 205 aircraft engine built in Germany, which had two crankshafts, not using a design similar to the 1900–1922 Gobron-Brillié engines.

One of the first opposed-piston engines was the 1882 Atkinson differential engine, which has a power stroke on every rotation of the crankshaft (compared with every second rotation for the contemporary Otto cycle engine), but it was not a commercial success.

In 1898, an Oechelhäuser two-stroke opposed-piston engine producing was installed at the Hoerde ironworks. This design of engine was also produced under licence by manufacturers including Deutsche Kraftgas Gesellschaft in Germany and William Beardmore & Sons in the United Kingdom.

In 1901, the Kansas City Lightning Balanced Gas and Gasoline Engines were gasoline engines producing .

An early opposed-piston car engine was produced by the French company Gobron-Brillié around 1900. In April 1904, a Gobron-Brillié car powered by the opposed-piston engine was the first car ever to exceed 150 km/h with a "World's Record Speed" of . On 17 July 1904, the Gobron-Brillié car became the first to exceed for the flying kilometre. The engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston.

Another early opposed piston car engine was in the Scottish Arrol-Johnston car, which appears to have been first installed in their 10 hp buckboard c1900. The engine was described and illustrated in some detail in the account of their 12-15 hp car exhibited at the 1905 Olympia Motor-Show. The engine was a 4-stroke with two cylinders (with opposed pistons in each) with the crankshaft underneath and the pistons connected by lever arms to the two-throw crankshaft.

The first diesel engine with opposed pistons was a prototype built at Kolomna Locomotive Works in Russia. The designer, Raymond A. Koreyvo, patented the engine in France on 6 November 1907 and displayed the engine at international exhibitions, but it did not reach production. The Kolomna design used a typical layout of two crankshafts connected by gearing.

In 1914, the Simpson's Balanced Two-Stroke motorcycle engine was another opposed-piston engine using a single crankshaft beneath the centre of the cylinders with both pistons connected by levers. This engine was a crankcase compression design, with one piston used to uncover the transfer port, and the other to open the exhaust port. The advantage of this design was to avoid the deflector crowns for pistons used by most two-stroke engines at that time.

Doxford Engine Works in the United Kingdom built large opposed-piston engines for marine use, with the first Doxford engine being installed in a ship in 1921. This diesel engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston. After World War I, these engines were produced in a number of models, such as the P and J series, with outputs as high as . Production of Doxford engines in the UK ceased in 1980.

Later opposed-piston diesel engines include the 1932 Junkers Jumo 205 aircraft engine built in Germany, which had two crankshafts, not using a design similar to the 1900–1922 Gobron-Brillié engines.

File:OechelhäuserEngine.jpg, 1898 Oechelhäuser gas engine

File:Gobron engine (Autocar Handbook, Ninth edition).jpg, 1900 Gobron-Brillié opposed-piston engine with overhung yoke

File:Opposed piston engine 1.jpg, Fairbanks Morse 38 8-1/8 diesel engine on the submarine

File:The Tank Museum (2383).jpg,

5TDF

An opposed-piston engine is a

An opposed-piston engine is a piston engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common feat ...

in which each cylinder

A cylinder (from ) has traditionally been a three-dimensional solid, one of the most basic of curvilinear geometric shapes. In elementary geometry, it is considered a prism with a circle as its base.

A cylinder may also be defined as an ...

has a piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-t ...

at both ends, and no cylinder head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber.

In sidevalve engines, the head is a simple sheet of metal; whereas in more modern o ...

. Petrol and diesel opposed-piston engines have been used mostly in large-scale applications such as ships, military tanks, and factories. Current manufacturers of opposed-piston engines include Fairbanks-Morse, Cummins

Cummins Inc. is an American multinational corporation that designs, manufactures, and distributes engines, filtration, and power generation products. Cummins also services engines and related equipment, including fuel systems, controls, air ...

and Achates Power.

Design

Compared to contemporary two-stroke engines, which used a conventional design of one piston per cylinder, the advantages of the opposed-piston engine have been recognized as:

* Eliminating the

Compared to contemporary two-stroke engines, which used a conventional design of one piston per cylinder, the advantages of the opposed-piston engine have been recognized as:

* Eliminating the cylinder head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber.

In sidevalve engines, the head is a simple sheet of metal; whereas in more modern o ...

and valvetrain, which reduces weight, complexity, cost, heat loss, and friction loss of the engine.

* Creating a uniflow-scavenged movement of gas through the combustion chamber, which avoided the drawbacks associated with the contemporary crossflow-scavenged designs (however later advancements have provided methods for achieving uniflow scavenging in conventional piston engine designs).

* A reduced height of the engine

The main drawback was that the power from the two opposing pistons have to be geared together. This added weight and complexity when compared to conventional piston engines, which use a single crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecti ...

as the power output.

The most common layout was two crankshafts, with the crankshafts geared together (in either the same direction or opposing directions). The Koreyvo, Jumo, and Napier Deltic engines used one piston per cylinder to expose an intake port, and the other to expose an exhaust port. Each piston is referred to as either an intake piston or an exhaust piston, depending on its function in this regard. This layout gives superior scavenging, as gas flow through the cylinder is axial rather than radial, and simplifies design of the piston crowns. In the Jumo 205 and its variants, the upper crankshaft serves the exhaust pistons, and the lower crankshaft the intake pistons. In designs using multiple cylinder banks, each big end bearing serves one inlet and one exhaust piston, using a forked connecting rod for the exhaust piston.

History

1880s to 1930s

One of the first opposed-piston engines was the 1882 Atkinson differential engine, which has a power stroke on every rotation of the crankshaft (compared with every second rotation for the contemporary Otto cycle engine), but it was not a commercial success.

In 1898, an Oechelhäuser two-stroke opposed-piston engine producing was installed at the Hoerde ironworks. This design of engine was also produced under licence by manufacturers including Deutsche Kraftgas Gesellschaft in Germany and William Beardmore & Sons in the United Kingdom.

In 1901, the Kansas City Lightning Balanced Gas and Gasoline Engines were gasoline engines producing .

An early opposed-piston car engine was produced by the French company Gobron-Brillié around 1900. In April 1904, a Gobron-Brillié car powered by the opposed-piston engine was the first car ever to exceed 150 km/h with a "World's Record Speed" of . On 17 July 1904, the Gobron-Brillié car became the first to exceed for the flying kilometre. The engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston.

Another early opposed piston car engine was in the Scottish Arrol-Johnston car, which appears to have been first installed in their 10 hp buckboard c1900. The engine was described and illustrated in some detail in the account of their 12-15 hp car exhibited at the 1905 Olympia Motor-Show. The engine was a 4-stroke with two cylinders (with opposed pistons in each) with the crankshaft underneath and the pistons connected by lever arms to the two-throw crankshaft.

The first diesel engine with opposed pistons was a prototype built at Kolomna Locomotive Works in Russia. The designer, Raymond A. Koreyvo, patented the engine in France on 6 November 1907 and displayed the engine at international exhibitions, but it did not reach production. The Kolomna design used a typical layout of two crankshafts connected by gearing.

In 1914, the Simpson's Balanced Two-Stroke motorcycle engine was another opposed-piston engine using a single crankshaft beneath the centre of the cylinders with both pistons connected by levers. This engine was a crankcase compression design, with one piston used to uncover the transfer port, and the other to open the exhaust port. The advantage of this design was to avoid the deflector crowns for pistons used by most two-stroke engines at that time.

Doxford Engine Works in the United Kingdom built large opposed-piston engines for marine use, with the first Doxford engine being installed in a ship in 1921. This diesel engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston. After World War I, these engines were produced in a number of models, such as the P and J series, with outputs as high as . Production of Doxford engines in the UK ceased in 1980.

Later opposed-piston diesel engines include the 1932 Junkers Jumo 205 aircraft engine built in Germany, which had two crankshafts, not using a design similar to the 1900–1922 Gobron-Brillié engines.

One of the first opposed-piston engines was the 1882 Atkinson differential engine, which has a power stroke on every rotation of the crankshaft (compared with every second rotation for the contemporary Otto cycle engine), but it was not a commercial success.

In 1898, an Oechelhäuser two-stroke opposed-piston engine producing was installed at the Hoerde ironworks. This design of engine was also produced under licence by manufacturers including Deutsche Kraftgas Gesellschaft in Germany and William Beardmore & Sons in the United Kingdom.

In 1901, the Kansas City Lightning Balanced Gas and Gasoline Engines were gasoline engines producing .

An early opposed-piston car engine was produced by the French company Gobron-Brillié around 1900. In April 1904, a Gobron-Brillié car powered by the opposed-piston engine was the first car ever to exceed 150 km/h with a "World's Record Speed" of . On 17 July 1904, the Gobron-Brillié car became the first to exceed for the flying kilometre. The engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston.

Another early opposed piston car engine was in the Scottish Arrol-Johnston car, which appears to have been first installed in their 10 hp buckboard c1900. The engine was described and illustrated in some detail in the account of their 12-15 hp car exhibited at the 1905 Olympia Motor-Show. The engine was a 4-stroke with two cylinders (with opposed pistons in each) with the crankshaft underneath and the pistons connected by lever arms to the two-throw crankshaft.

The first diesel engine with opposed pistons was a prototype built at Kolomna Locomotive Works in Russia. The designer, Raymond A. Koreyvo, patented the engine in France on 6 November 1907 and displayed the engine at international exhibitions, but it did not reach production. The Kolomna design used a typical layout of two crankshafts connected by gearing.

In 1914, the Simpson's Balanced Two-Stroke motorcycle engine was another opposed-piston engine using a single crankshaft beneath the centre of the cylinders with both pistons connected by levers. This engine was a crankcase compression design, with one piston used to uncover the transfer port, and the other to open the exhaust port. The advantage of this design was to avoid the deflector crowns for pistons used by most two-stroke engines at that time.

Doxford Engine Works in the United Kingdom built large opposed-piston engines for marine use, with the first Doxford engine being installed in a ship in 1921. This diesel engine used a single crankshaft at one end of the cylinders and a crosshead for the opposing piston. After World War I, these engines were produced in a number of models, such as the P and J series, with outputs as high as . Production of Doxford engines in the UK ceased in 1980.

Later opposed-piston diesel engines include the 1932 Junkers Jumo 205 aircraft engine built in Germany, which had two crankshafts, not using a design similar to the 1900–1922 Gobron-Brillié engines.

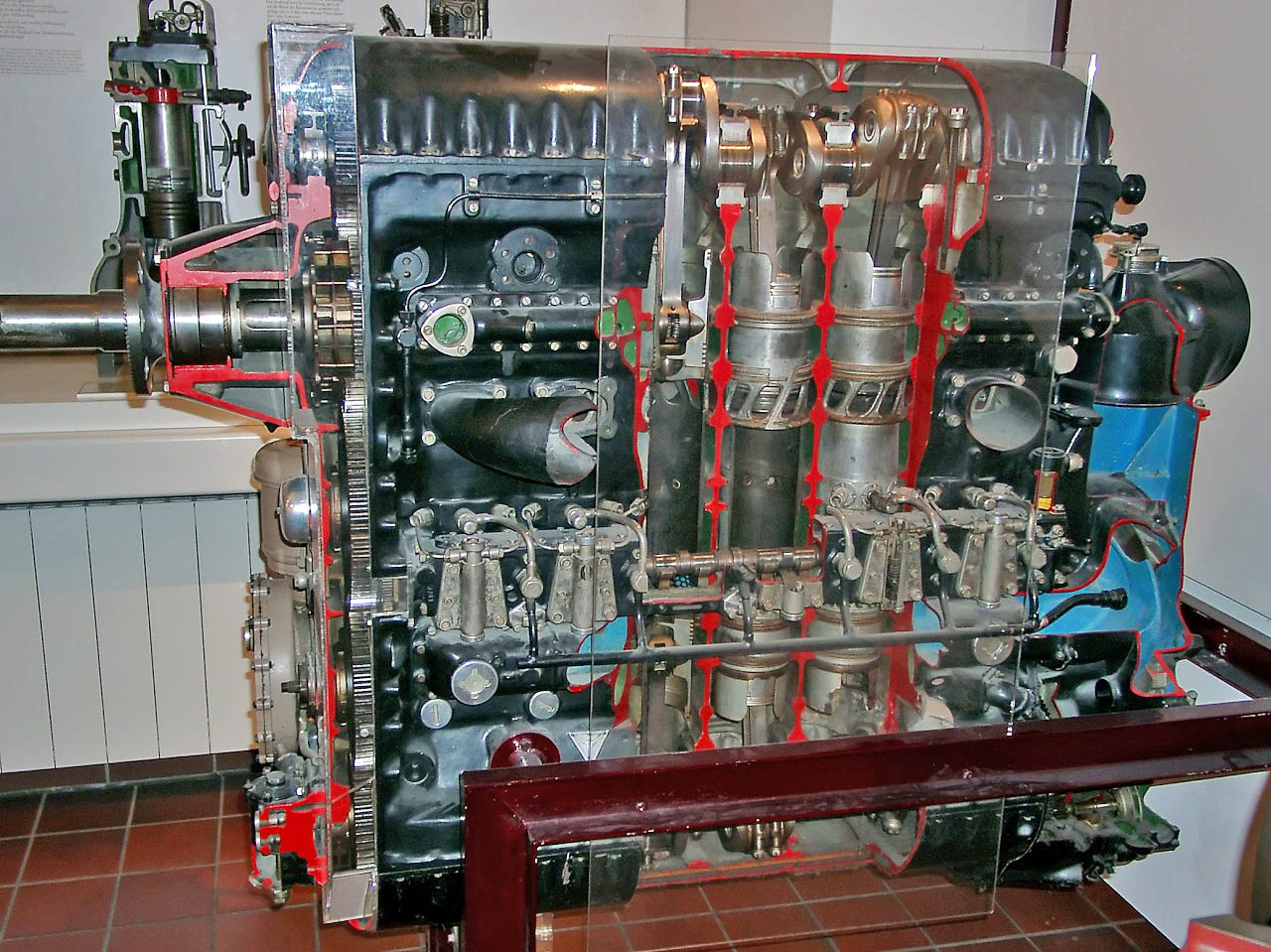

Leyland L60

The Leyland L60 was a British vertical six-cylinder opposed-piston two-stroke multi-fuel diesel engine designed by Leyland Motors in the late 1950s/early 1960s for the Chieftain main battle tank (MBT). The engine was also used in the Vic ...

as used in the Chieftain tank

1940s to present

The Fairbanks Morse 38 8-1/8 diesel engine, originally designed in Germany in the 1930s, was used in U.S. submarines in the 1940s and 1950s, and in boats from the 1930s-present. It was also used in locomotives from 1944. The latest (November 2021) version of the Fairbanks-Morse 38 8-1/8 is known as the FM 38D 8-1/8 Diesel and Dual Fuel. This two-stroke opposed-piston engine retains the same extra-heavy-duty design and has a rated in-service lifespan of more than 40 years, but now the optional capability of burning dual fuels (gaseous and liquid fuels, with automatic switchover to full diesel if the gas supply runs out) is available. TheCommer TS3

The Commer TS3 was a diesel engine fitted in Commer trucks built by the Rootes Group in the 1950s and 1960s. It was the first diesel engine used by the company.

Development

Rootes' intention for the engine was for it to fit under the QX "cab forwa ...

three-cylinder diesel truck engines, released in 1954, have a single crankshaft beneath the centre of the cylinders with both pistons connected by levers.

Also released in 1954 was the Napier Deltic engine for military boats. It uses three crankshafts, one at each corner, to form the three banks of double-ended cylinders arranged in an equilateral triangle. The Deltic engine was used in British Rail Class 55 and British Rail Class 23 locomotives and to power fast patrol boats and Royal Navy

The Royal Navy (RN) is the United Kingdom's naval warfare force. Although warships were used by English and Scottish kings from the early medieval period, the first major maritime engagements were fought in the Hundred Years' War against Fr ...

mine sweepers. Beginning in 1962, Gibbs invited Mack Trucks to take part in designing FDNY’s super pumper and its companion tender. DeLaval Turbine was commissioned to design a multistage centrifugal pump with a Napier-Deltic T18-37C diesel to power the pumps.

In 1959, the Leyland L60

The Leyland L60 was a British vertical six-cylinder opposed-piston two-stroke multi-fuel diesel engine designed by Leyland Motors in the late 1950s/early 1960s for the Chieftain main battle tank (MBT). The engine was also used in the Vic ...

six-cylinder diesel engine was introduced. The L60 was produced in the United Kingdom for use in the Chieftain tank. The Soviet T-64 tank, produced from 1963-1987, also used an opposed-piston diesel engin5TDF

Volvo

The Volvo Group ( sv, Volvokoncernen; legally Aktiebolaget Volvo, shortened to AB Volvo, stylized as VOLVO) is a Swedish multinational manufacturing corporation headquartered in Gothenburg. While its core activity is the production, distributio ...

filed for a patent in 2017.

The Diesel Air Dair 100 is a two-cylinder diesel

Diesel may refer to:

* Diesel engine, an internal combustion engine where ignition is caused by compression

* Diesel fuel, a liquid fuel used in diesel engines

* Diesel locomotive, a railway locomotive in which the prime mover is a diesel engi ...

aircraft engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years ma ...

, designed and produced by Diesel Air Ltd of Olney, Buckinghamshire for use in airship

An airship or dirigible balloon is a type of aerostat or lighter-than-air aircraft that can navigate through the air under its own power. Aerostats gain their lift from a lifting gas that is less dense than the surrounding air.

In early ...

s, home-built kitplanes, and light aircraft.

In July 2021, Cummins

Cummins Inc. is an American multinational corporation that designs, manufactures, and distributes engines, filtration, and power generation products. Cummins also services engines and related equipment, including fuel systems, controls, air ...

was awarded an $87M contract by the United States Army

The United States Army (USA) is the land service branch of the United States Armed Forces. It is one of the eight U.S. uniformed services, and is designated as the Army of the United States in the U.S. Constitution.Article II, section 2, ...

to complete development of the Advanced Combat Engine (ACE), a modular and scalable diesel engine solution that uses opposed-piston technology.

Free-piston engine

A variation of the opposed-piston design is the free-piston engine, which was first patented in 1934. Free piston engines have no crankshaft, and the pistons are returned after each firing stroke by compression and expansion of air in a separate cylinder. Early applications were for use as an air compressor or as a gas generator for a gas turbine.See also

* Junk head * Michel engine * Split-single engineReferences

{{Authority control Locomotive parts Two-stroke diesel engines Opposed piston engines Piston ported engines Piston engine configurations