Mud logging on:

[Wikipedia]

[Google]

[Amazon]

Mud logging is the creation of a detailed record (

Mud logging is the creation of a detailed record (

Mud logging includes observation and microscopic examination of

Mud logging includes observation and microscopic examination of

Example1Example2

Other real-time drilling parameters that may be compiled include, but are not limited to; rate of penetration ( ROP) of the bit (sometimes called the drill rate), pump rate (quantity of fluid being pumped), pump pressure, weight on bit, Mud logging is often written as a single word "mudlogging". The finished product can be called a "mud log" or "mudlog". The occupational description is "mud logger" or "mudlogger". In most cases, the two word usage seems to be more common. The mud log provides a reliable ''time log'' of drilled formations.P.W. Purcell "Chapter 16 Mud Logging" pp. 347-354 in L.W. Leroy, D.O. Leroy, and J.W. Raese, editors, 1977, Subsurface Geology, Colorado School of Mines, Golden, 941 pp.

Mud logging is often written as a single word "mudlogging". The finished product can be called a "mud log" or "mudlog". The occupational description is "mud logger" or "mudlogger". In most cases, the two word usage seems to be more common. The mud log provides a reliable ''time log'' of drilled formations.P.W. Purcell "Chapter 16 Mud Logging" pp. 347-354 in L.W. Leroy, D.O. Leroy, and J.W. Raese, editors, 1977, Subsurface Geology, Colorado School of Mines, Golden, 941 pp.

mud logs

it is measured in minutes per foot. *The '' porosity'' in (Figure 1) is represented by the blue line farthest to the left of the log. It indicates the pore space within the rock structure. An analogy would be the holes in a sponge. The oil and gas resides within this pore space. Notice how far to the left the porosity goes where all the sand (in yellow) is. This indicates that the sand has good porosity. Porosity is not a direct or physical measurement of the pore space but rather an extrapolation from other drilling parameters and therefore not always reliable. *The ''

*The ''

units

as the quantity of total gas, but does not represent the actual quantity of oil or gas the reservoir contains. In (Figure 1) the squared-off dash-dot lines just to the right of the sand (in yellow) and left of the gas (in green) represents the heavier hydrocarbons detected. Cyan = C2 ( ethane), purple = C3 ( propane) and blue = C4 (

Articles and books on mud logging

Geoservices definition of Mud Logging

Maverick Energy LexiconMud Logging Gas Detectors

Well logging Petroleum geology

Mud logging is the creation of a detailed record (

Mud logging is the creation of a detailed record (well log

Well logging, also known as borehole logging is the practice of making a detailed record (a ''well log'') of the geologic formations penetrated by a borehole. The log may be based either on visual inspection of samples brought to the surface (' ...

) of a borehole by examining the cuttings of rock brought to the surface by the circulating drilling medium (most commonly drilling mud

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also u ...

). Mud logging is usually performed by a third-party mud logging company. This provides well owners and producers with information about the lithology

The lithology of a rock unit is a description of its physical characteristics visible at outcrop, in hand or core samples, or with low magnification microscopy. Physical characteristics include colour, texture, grain size, and composition. Lit ...

and fluid content of the borehole while drilling. Historically it is the earliest type of well log. Under some circumstances compressed air is employed as a circulating fluid, rather than mud. Although most commonly used in petroleum exploration, mud logging is also sometimes used when drilling water wells and in other mineral exploration, where drilling fluid is the circulating medium used to lift cuttings out of the hole. In hydrocarbon exploration

Hydrocarbon exploration (or oil and gas exploration) is the search by petroleum geologists and geophysicists for deposits of hydrocarbons, particularly petroleum and natural gas, in the Earth using petroleum geology.

Exploration methods

Visi ...

, hydrocarbon surface gas detectors record the level of natural gas brought up in the mud. A mobile laboratory is situated by the mud logging company near the drilling rig or on deck of an offshore drilling rig, or on a drill ship.

The service provided

Mud logging technicians in an oil field drilling operation determine positions of hydrocarbons with respect to depth, identify downholelithology

The lithology of a rock unit is a description of its physical characteristics visible at outcrop, in hand or core samples, or with low magnification microscopy. Physical characteristics include colour, texture, grain size, and composition. Lit ...

, monitor natural gas entering the drilling mud stream, and draw well logs for use by oil company geologist

A geologist is a scientist who studies the solid, liquid, and gaseous matter that constitutes Earth and other terrestrial planets, as well as the processes that shape them. Geologists usually study geology, earth science, or geophysics, alth ...

. Rock cuttings circulated to the surface in drilling mud are sampled and discussed.

The mud logging company is normally contracted by the oil company (or operator). They then organize this information in the form of a graphic log, showing the data charted on a representation of the wellbore.

Well-site geologist mudlogging

The oil company representative (Company Man or "CoMan") together with the tool pusher

A tool pusher (sometimes toolpusher or just pusher or even, when spoken of in the third person, The Push) is an occupation within the oil drilling industry.

On a land drilling rig the tool pusher may be rig manager and responsible for all operat ...

, and well-site geologist (WSG) provides mud loggers their instruction. The mud logging company is contracted specifically as to when to start well-logging activity and what services to provide. Mud logging may begin on the first day of drilling, known as the "spud in" date but is more likely at some later time (and depth) determined by the oil industry geologist's research. The mud logger may also possess logs from wells drilled in the surrounding area. This information (known as "offset data") can provide valuable clues as to the characteristics of the particular geo-strata that the rig crew is about to drill through.

Mud loggers connect various sensors to the drilling apparatus and install specialized equipment to monitor or "log" drill activity. This can be physically and mentally challenging, especially when having to be done during drilling activity. Much of the equipment will require precise calibration or alignment by the mud logger to provide accurate readings.

Mud logging technicians observe and interpret the indicators in the mud returns during the drilling process, and at regular intervals log properties such as drilling rate, mud weight, flowline temperature, oil indicators, pump pressure, pump rate, lithology (rock type) of the drilled cuttings, and other data. Mud logging requires a good deal of diligence and attention. Sampling the drilled cuttings must be performed at predetermined intervals, and can be difficult during rapid drilling.

Another important task of the mud logger is to monitor gas levels (and types) and notify other personnel on the rig when gas levels may be reaching dangerous levels, so appropriate steps can be taken to avoid a dangerous well blowout condition.

Because of the lag time between drilling and the time required for the mud and cuttings to return to the surface, a modern augmentation has come into use: Measurement while drilling. The MWD technician, often a separate service company employee, logs data in a similar manner but the data is different in source and content. Most of the data logged by an MWD technician comes from expensive and complex, sometimes electronic, tools that are downhole installed at or near the drill bit.

Scope

Mud logging includes observation and microscopic examination of

Mud logging includes observation and microscopic examination of drill cuttings

Drill cuttings are broken bits of solid material removed from a borehole drilled by rotary, percussion, or auger methods and brought to the surface in the drilling mud. Boreholes drilled in this way include oil or gas wells, water wells, an ...

(formation rock chips), and evaluation of gas hydrocarbon and its constituents, basic chemical and mechanical parameters of drilling fluid

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also ...

or drilling mud

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also u ...

(such as chloride

The chloride ion is the anion (negatively charged ion) Cl−. It is formed when the element chlorine (a halogen) gains an electron or when a compound such as hydrogen chloride is dissolved in water or other polar solvents. Chloride salts ...

s and temperature), as well as compiling other information about the drilling parameters. Then data is plotted on a graphic log called a mud log

A MUD (; originally multi-user dungeon, with later variants multi-user dimension and multi-user domain) is a multiplayer real-time virtual world, usually text-based or storyboarded. MUDs combine elements of role-playing games, hack and sla ...

.Example1

Other real-time drilling parameters that may be compiled include, but are not limited to; rate of penetration ( ROP) of the bit (sometimes called the drill rate), pump rate (quantity of fluid being pumped), pump pressure, weight on bit,

drill string

A drill string on a drilling rig is a column, or string, of drill pipe that transmits drilling fluid (via the mud pumps) and torque (via the kelly drive or top drive) to the drill bit. The term is loosely applied to the assembled collection ...

weight, rotary speed, rotary torque, RPM (Revolutions Per Minute), SPM (Strokes Per Minute) mud volumes, mud weight

Introduction

In the oil industry, mud weight is the density of the drilling fluid and is normally measured in pounds per gallon (lb/gal) (ppg) or pound cubic feet (pcf) . In the field it is measured using a mud scale or mud balance. Mud can w ...

and mud viscosity. This information is usually obtained by attaching ''monitoring devices'' to the drilling rig's equipment with a few exceptions such as the mud weight and mud viscosity which are measured by the derrickhand

A derrickhand or derrickman is the person who sits atop the derrick on a drilling rig. Though the exact duties vary from rig to rig, they almost always report directly to the driller. Their job is to guide the stands of the drill pipe into the fi ...

or the mud engineer

A mud engineer (correctly called a drilling fluids engineer, but most often referred to as the "mud man") works on an oil well or gas well drilling rig, and is responsible for ensuring the properties of the drilling fluid, also known as drilling mu ...

.

Rate of drilling is affected by the pressure of the column of mud in the borehole and its relative counterbalance to the internal pore pressures of the encountered rock. A rock pressure greater than the mud fluid will tend to cause rock fragments to spall as it is cut and can increase the drilling rate. "D-exponents" are mathematical trend lines which estimate this internal pressure. Thus both visual evidence of spalling and mathematical plotting assist in formulating recommendations for optimum drilling mud densities for both safety (blowout prevention) and economics. (Faster drilling is generally preferred.)

Mud logging is often written as a single word "mudlogging". The finished product can be called a "mud log" or "mudlog". The occupational description is "mud logger" or "mudlogger". In most cases, the two word usage seems to be more common. The mud log provides a reliable ''time log'' of drilled formations.P.W. Purcell "Chapter 16 Mud Logging" pp. 347-354 in L.W. Leroy, D.O. Leroy, and J.W. Raese, editors, 1977, Subsurface Geology, Colorado School of Mines, Golden, 941 pp.

Mud logging is often written as a single word "mudlogging". The finished product can be called a "mud log" or "mudlog". The occupational description is "mud logger" or "mudlogger". In most cases, the two word usage seems to be more common. The mud log provides a reliable ''time log'' of drilled formations.P.W. Purcell "Chapter 16 Mud Logging" pp. 347-354 in L.W. Leroy, D.O. Leroy, and J.W. Raese, editors, 1977, Subsurface Geology, Colorado School of Mines, Golden, 941 pp.

Details of the mud log

*The ''rate of penetration

In the drilling industry, the rate of penetration (ROP), also known as penetration rate or drill rate, is the speed at which a drill bit breaks the rock under it to deepen the borehole. It is normally measured in feet per minute or meters per hou ...

'' in (Figure 1 & 2) is represented by the black line on the left side of the log. The farther to the left that the line goes, the faster the rate of penetration. On this mud log, ROP is measured in feet per hour but on some older, hand drawmud logs

it is measured in minutes per foot. *The '' porosity'' in (Figure 1) is represented by the blue line farthest to the left of the log. It indicates the pore space within the rock structure. An analogy would be the holes in a sponge. The oil and gas resides within this pore space. Notice how far to the left the porosity goes where all the sand (in yellow) is. This indicates that the sand has good porosity. Porosity is not a direct or physical measurement of the pore space but rather an extrapolation from other drilling parameters and therefore not always reliable.

*The ''

*The ''lithology

The lithology of a rock unit is a description of its physical characteristics visible at outcrop, in hand or core samples, or with low magnification microscopy. Physical characteristics include colour, texture, grain size, and composition. Lit ...

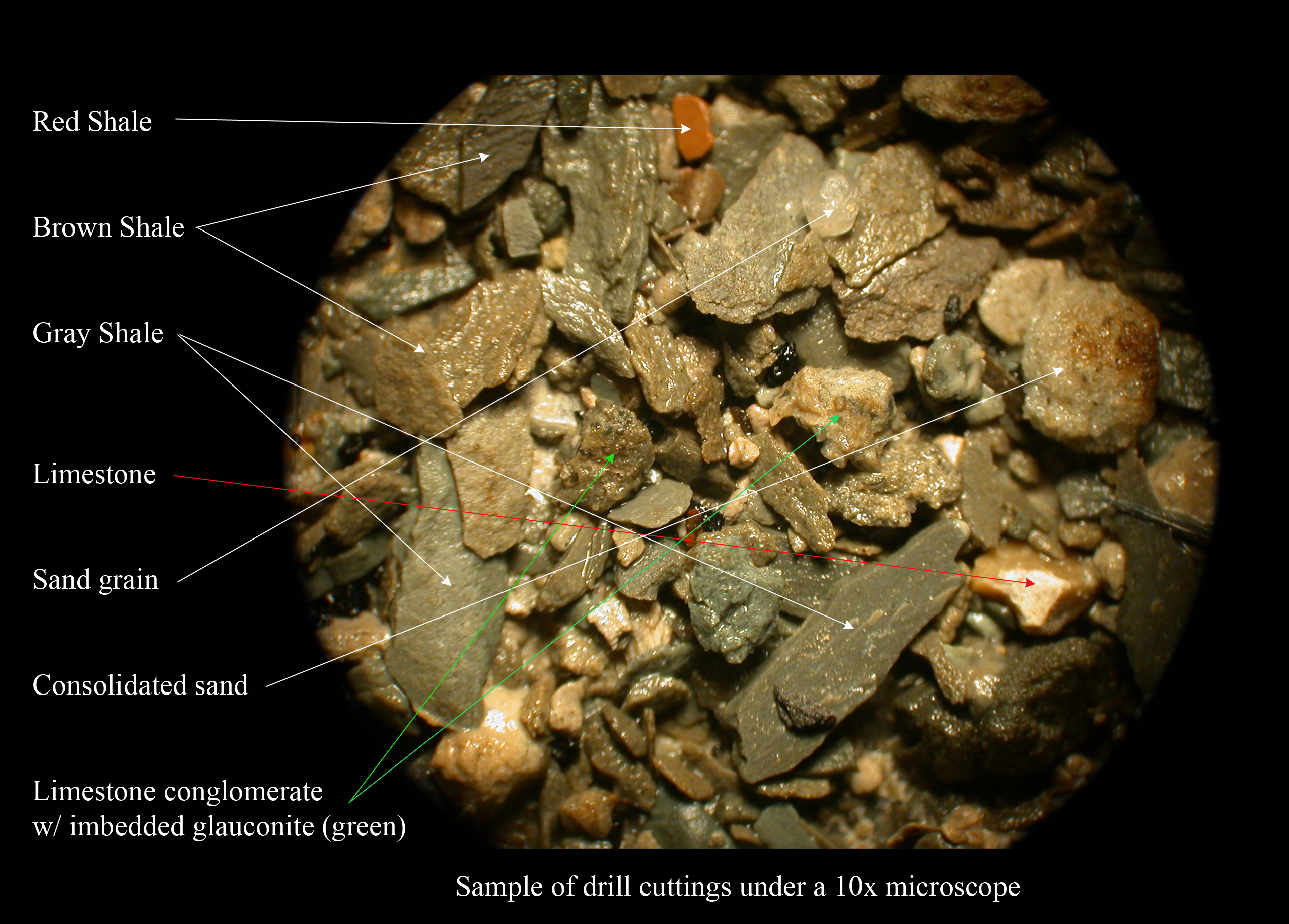

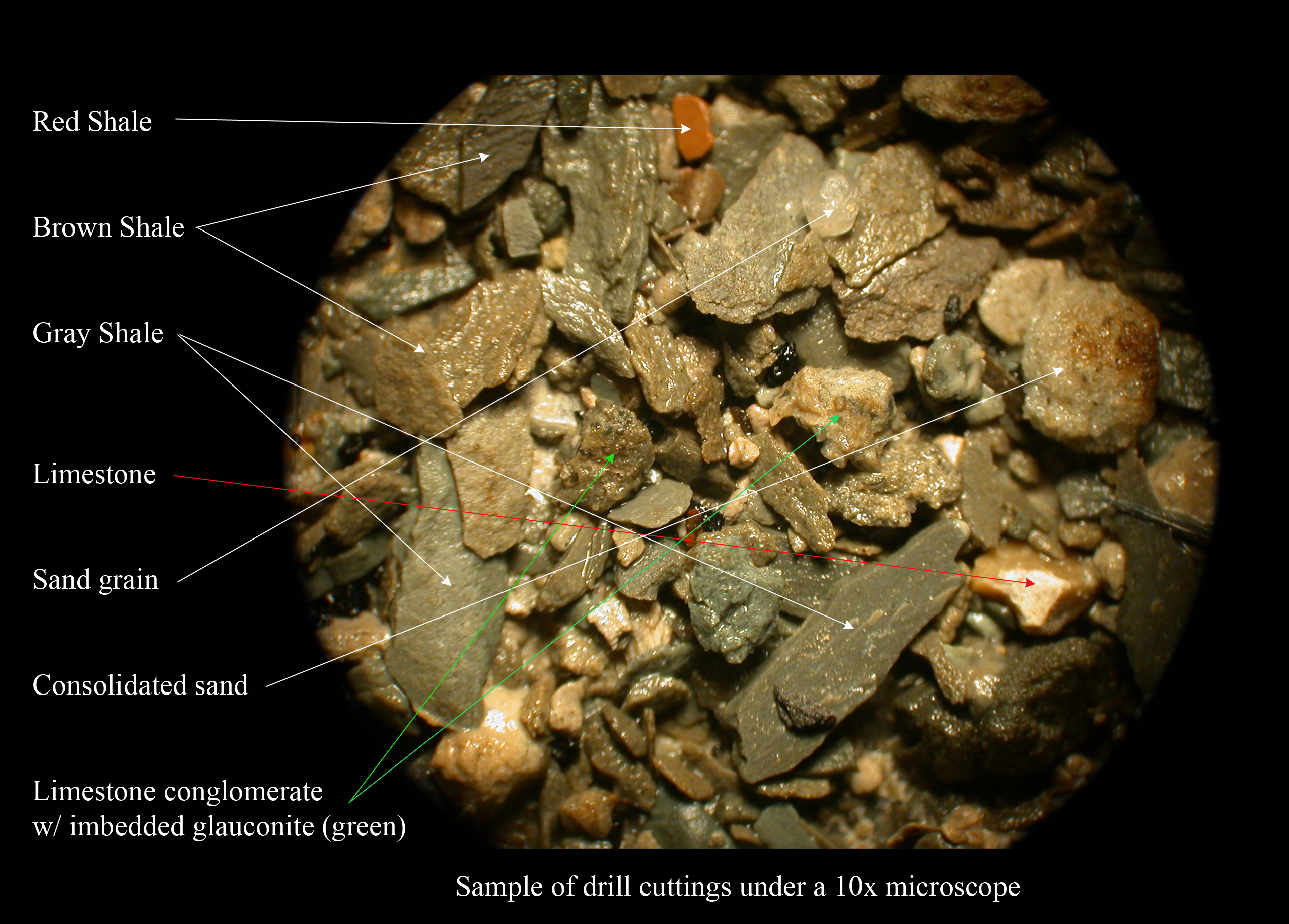

'' in (Figure 1 & 2) is represented by the cyan, gray/black and yellow blocks of color. Cyan = lime, gray/black = shale and yellow = sand. More yellow represents more sand identified at that depth. The lithology is measured as percentage of the total sample, as visually inspected under a microscope, normally at 10x magnification (Figure 3). These are but a fraction of the different types of formation

Formation may refer to:

Linguistics

* Back-formation, the process of creating a new lexeme by removing or affixes

* Word formation, the creation of a new word by adding affixes

Mathematics and science

* Cave formation or speleothem, a secondar ...

s that might be encountered. (Color coding is not necessarily standardized among different mud logging companies, though the symbol representation for each are very similar.) In (Figure 3) you can see a sample of cuttings under a microscope at 10x magnification after they have been washed off. Some of the larger shale and lime fragments are separated from this sample by running it through sieves and must be considered when estimating percentages. Also, this image view is only a fragment of the total sample and some of the sand at the bottom of the tray can not be seen and must also be considered in the total estimation. With that in mind this sample would be considered to be about 90% shale, 5% sand and 5% lime (In 5% increments).

*The ''gas

Gas is one of the four fundamental states of matter (the others being solid, liquid, and plasma).

A pure gas may be made up of individual atoms (e.g. a noble gas like neon), elemental molecules made from one type of atom (e.g. oxygen), or ...

'' in (Figure 1 & 2) is represented by the green line and is measured iunits

as the quantity of total gas, but does not represent the actual quantity of oil or gas the reservoir contains. In (Figure 1) the squared-off dash-dot lines just to the right of the sand (in yellow) and left of the gas (in green) represents the heavier hydrocarbons detected. Cyan = C2 ( ethane), purple = C3 ( propane) and blue = C4 (

butane

Butane () or ''n''-butane is an alkane with the formula C4H10. Butane is a gas at room temperature and atmospheric pressure. Butane is a highly flammable, colorless, easily liquefied gas that quickly vaporizes at room temperature. The name bu ...

). Detecting and analyzing these heavy gases help to determine the type of oil or gas the formation contains.

See also

*Directional drilling

Directional drilling (or slant drilling) is the practice of drilling non-vertical bores. It can be broken down into four main groups: oilfield directional drilling, utility installation directional drilling, directional boring (horizontal dire ...

*Drilling fluid

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also ...

(mud)

*Geosteering Geosteering is the optimal placement of a wellbore based on the results of realtime downhole geological and geophysical logging measurements rather than three-dimensional targets in space. The objective is usually to keep a directional wellbore with ...

* LWD (Logging While Drilling)

* MWD (Measurement While Drilling)

*Well logging

Well logging, also known as borehole logging is the practice of making a detailed record (a ''well log'') of the geologic formations penetrated by a borehole. The log may be based either on visual inspection of samples brought to the surface (' ...

References

Further reading

* Chambre Syndicale de la recherche et de la production du petrole et du gaz naturel, 1982, Geological and mud logging in drilling control: catalogue of typical cases, Houston, TX: Gulf Publishing Company and Paris: Editions technip, 81 p. * Exlog, 1979, Field geologist's training guide: an introduction to oilfield geology, mud logging and formation evaluation, Sacramento, CA: Exploration Logging, Inc., 301 p. Privately published with no ISBN * Whittaker, Alun, 1991, Mud logging handbook, Englewood Cliffs, NJ: Prentice Hall, 531 p. {{ISBN, 0-13-155268-6External links

Articles and books on mud logging

Geoservices definition of Mud Logging

Maverick Energy Lexicon

Well logging Petroleum geology