gold plated on:

[Wikipedia]

[Google]

[Amazon]

Gold plating is a method of depositing a thin layer of

Gold plating is a method of depositing a thin layer of

/ref> * ''Soft, pure gold plating'' is used in the

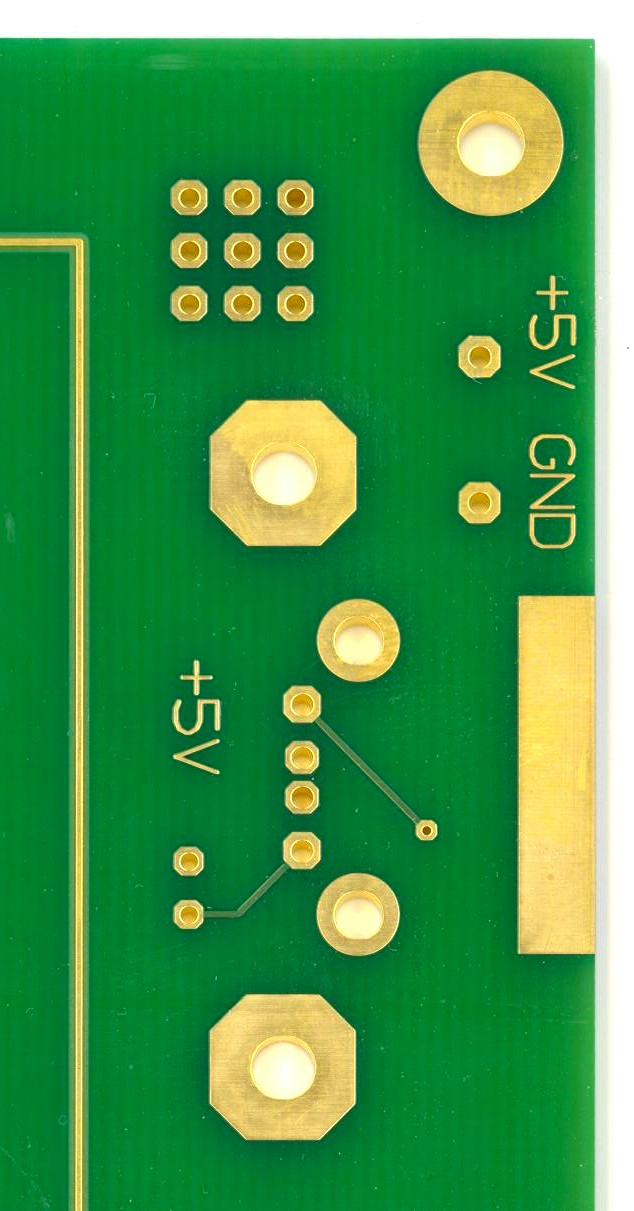

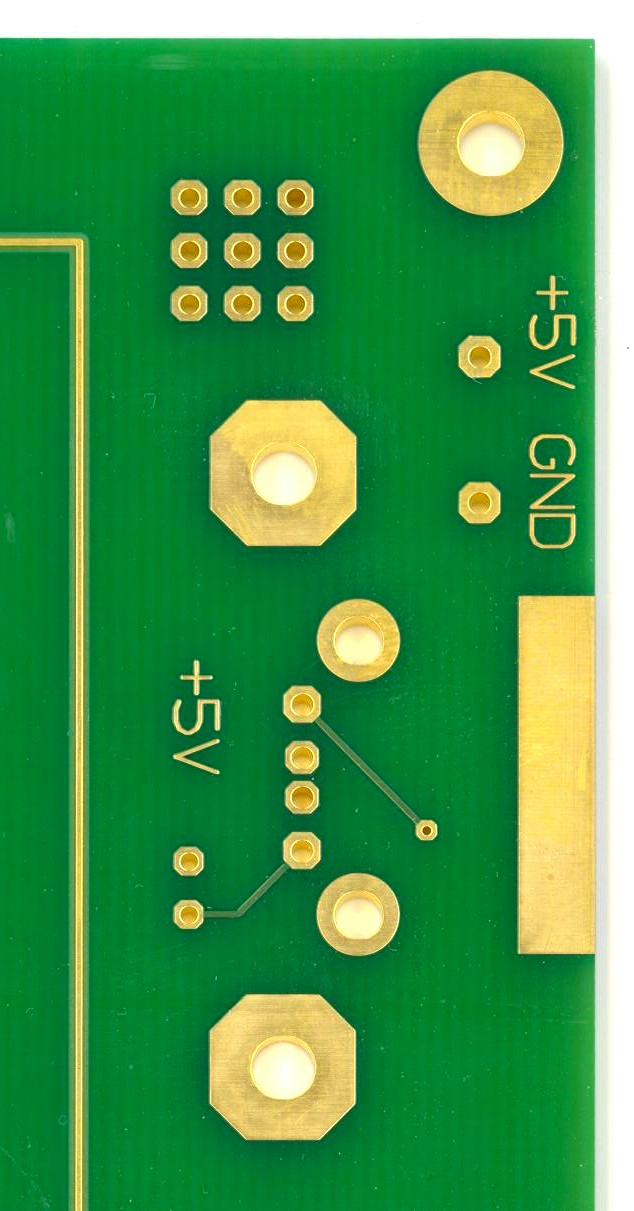

Gold plating is often used in electronics, to provide a

Gold plating is often used in electronics, to provide a

Gold plating is a method of depositing a thin layer of

Gold plating is a method of depositing a thin layer of gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile ...

onto the surface of another metal, most often copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

or silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

(to make silver-gilt

Silver-gilt or gilded/gilt silver, sometimes known in American English by the French term vermeil, is silver (either pure or sterling) which has been gilded with gold. Most large objects made in goldsmithing that appear to be gold are actually ...

), by chemical or electrochemical plating

Plating is a surface covering in which a metal is deposited on a conductive surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to impro ...

. This article covers plating methods used in the modern electronics industry; for more traditional methods, often used for much larger objects, see gilding

Gilding is a decorative technique for applying a very thin coating of gold over solid surfaces such as metal (most common), wood, porcelain, or stone. A gilded object is also described as "gilt". Where metal is gilded, the metal below was tradi ...

.

Types

There are several types of gold plating used in the electronics industry:/ref> * ''Soft, pure gold plating'' is used in the

semiconductor industry

The semiconductor industry is the aggregate of companies engaged in the design and fabrication of semiconductors and semiconductor devices, such as transistors and integrated circuits. It formed around 1960, once the fabrication of semiconduc ...

. The gold layer is easily soldered and wire bonded. Its Knoop hardness

The Knoop hardness test is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed ...

ranges between 60 and 85. The plating baths have to be kept free of contamination.

* ''Soft, pure gold'' is deposited from special electrolytes

An electrolyte is a medium containing ions that is electrically conducting through the movement of those ions, but not conducting electrons. This includes most soluble salts, acids, and bases dissolved in a polar solvent, such as water. Upon di ...

. Entire printed circuit boards

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich struc ...

can be plated. This technology can be used for depositing layers suitable for wire bonding.

* ''Bright hard gold on contacts'', with Knoop hardness between 120–300 and purity of 99.7–99.9% gold. Often contains a small amount of nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow t ...

and/or cobalt

Cobalt is a chemical element with the symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, p ...

; these elements interfere with die bonding, therefore the plating baths cannot be used for semiconductors.

* ''Bright hard gold on printed circuit board

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich str ...

tabs'' is deposited using lower concentration of gold in the baths. Usually contains nickel and/or cobalt as well. Edge connector

An edge connector is the portion of a printed circuit board (PCB) consisting of traces leading to the edge of the board that are intended to plug into a matching socket. The edge connector is a money-saving device because it only requires a si ...

s are often made by controlled-depth immersion of only the edge of the boards.

Gold plating chemistry

There are five recognized classes of gold plating chemistry: # Alkaline goldcyanide

Cyanide is a naturally occurring, rapidly acting, toxic chemical that can exist in many different forms.

In chemistry, a cyanide () is a chemical compound that contains a functional group. This group, known as the cyano group, consists of ...

, for gold and gold alloy plating

# Neutral gold cyanide, for high-purity plating

# Acid gold plating for bright hard gold and gold alloy plating

# Non-cyanide, generally sulphite or chloride-based for gold and gold alloy plating

# Miscellaneous

Jewelry

Gold plating of silver is used in the manufacture ofjewelry

Jewellery ( UK) or jewelry ( U.S.) consists of decorative items worn for personal adornment, such as brooches, rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the clothes. From a w ...

. The thickness of gold plating on jewellery is noted in microns (or micro-meters). The microns of thickness determines how long the gold plating lasts with usage. The jewellery industry denotes different qualities of gold plating in the following terminology

# Gold flashed / Gold washed - gold layer thickness less than 0.5 micron

# Gold plated - gold layer thickness greater than or equal to 0.5 micron

# Heavy gold plated / Vermeil - gold layer thickness greater than or equal to 2.5 micron

Gold plated silver jewellery can still tarnish as the silver atoms diffuse into the gold layer, causing slow gradual fading of its color and eventually causing tarnishing

Tarnish is a thin layer of corrosion that forms over copper, brass, aluminum, magnesium, neodymium and other similar metals as their outermost layer undergoes a chemical reaction. Tarnish does not always result from the sole effects of oxygen in ...

of the surface. This process may take months and even years, depending on the thickness of the gold layer. A barrier metal A diffusion barrier is a thin layer (usually micrometres thick) of metal usually placed between two other metals. It is done to act as a barrier to protect either one of the metals from corrupting the other..

Adhesion of a plated metal layer to it ...

layer is used to counter this effect - these can be nickel or rhodium. Copper, which also migrates into gold, does so more slowly than silver. The copper is usually further plated with nickel. A gold-plated silver article is usually a silver substrate with layers of copper, nickel, and gold deposited on top of it.

Infrared reflectivity

Gold, applied by evaporated methods or electroplating, has been specified by NASA to thermally control spacecraft instruments, due to its 99% reflectivity in infrared wavelengths.Electronics

Gold plating is often used in electronics, to provide a

Gold plating is often used in electronics, to provide a corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

-resistant electrically conductive layer on copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

, typically in electrical connector

Components of an electrical circuit are electrically connected if an electric current can run between them through an electrical conductor. An electrical connector is an electromechanical device used to create an electrical connection betwee ...

s and printed circuit board

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich str ...

s.

With direct gold-on-copper plating, the copper atom

Every atom is composed of a nucleus and one or more electrons bound to the nucleus. The nucleus is made of one or more protons and a number of neutrons. Only the most common variety of hydrogen has no neutrons.

Every solid, liquid, gas, a ...

s tend to diffuse through the gold layer, causing tarnish

Tarnish is a thin layer of corrosion that forms over copper, brass, aluminum, magnesium, neodymium and other similar metals as their outermost layer undergoes a chemical reaction. Tarnish does not always result from the sole effects of oxygen in ...

ing of its surface and formation of an oxide

An oxide () is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O2– (molecular) ion. with oxygen in the oxidation state of −2. Most of the E ...

and/or sulphide

Sulfide (British English also sulphide) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to chemical compounds lar ...

layer.

A layer of a suitable barrier metal A diffusion barrier is a thin layer (usually micrometres thick) of metal usually placed between two other metals. It is done to act as a barrier to protect either one of the metals from corrupting the other..

Adhesion of a plated metal layer to it ...

, usually nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow t ...

, is often deposited on the copper substrate before the gold plating. The layer of nickel provides mechanical backing for the gold layer, improving its wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in ...

resistance. It also reduces the impact of pores present in the gold layer.

Both the nickel and gold layers can be plated by electrolytic or electroless processes. There are many factors to consider in selection of either electrolytic or electroless plating methods. These include what the deposit will be used for, configuration of the part, materials compatibility and cost of processing. In different applications, electrolytic or electroless plating can have cost advantages.

At higher frequencies, the skin effect

Skin effect is the tendency of an alternating electric current (AC) to become distributed within a conductor such that the current density is largest near the surface of the conductor and decreases exponentially with greater depths in the co ...

may cause higher losses due to higher electrical resistance of nickel; a nickel-plated trace can have its useful length shortened three times in the 1 GHz band in comparison with the non-plated one. Selective plating is used, depositing the nickel and gold layers only on areas where it is required and does not cause the detrimental side effects.

Gold plating may lead to formation of gold whiskers

Vibrissae (; singular: vibrissa; ), more generally called Whiskers, are a type of stiff, functional hair used by mammals to sense their environment. These hairs are finely specialised for this purpose, whereas other types of hair are coarse ...

.

Wire bonding between gold plated contacts and aluminium wires or between aluminium contacts and gold wires under certain conditions develops a brittle layer of gold-aluminium intermetallics, known as purple plague

Purple is any of a variety of colors with hue between red and blue. In the RGB color model used in computer and television screens, purples are produced by mixing red and blue light. In the RYB color model historically used by painters, p ...

.

Soldering issues

Soldering

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal ( solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not inv ...

gold-plated parts can be problematic as gold is soluble in solder

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable ...

. Solder which contains more than 4–5% gold can become brittle. The joint surface is dull-looking.

Gold reacts with both tin and lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cut, ...

in their liquid state, forming brittle intermetallics

An intermetallic (also called an intermetallic compound, intermetallic alloy, ordered intermetallic alloy, and a long-range-ordered alloy) is a type of metallic alloy that forms an ordered solid-state compound between two or more metallic eleme ...

. When eutectic 63% tin – 37% lead solder is used, no lead-gold compounds are formed, because gold preferentially reacts with tin, forming the compound. Particles of disperse in the solder matrix, forming preferential cleavage planes, significantly lowering the mechanical strength and therefore reliability of the resulting solder joints.

If the gold layer does not completely dissolve into the solder, then slow intermetallic reactions can proceed in the solid state as the tin and gold atoms cross-migrate. Intermetallics have poor electrical conductivity and low strength. The ongoing intermetallic reactions also cause Kirkendall effect, leading to mechanical failure of the joint, similar to the degradation of gold-aluminium bonds known as purple plague

Purple is any of a variety of colors with hue between red and blue. In the RGB color model used in computer and television screens, purples are produced by mixing red and blue light. In the RYB color model historically used by painters, p ...

.

A 2–3 µm layer of gold dissolves completely within one second during typical wave soldering conditions. Layers of gold thinner than 0.5 µm (0.02 thou

The word ''thou'' is a second-person singular pronoun in English. It is now largely archaic, having been replaced in most contexts by the word '' you'', although it remains in use in parts of Northern England and in Scots (). ''Thou'' is the ...

) also dissolve completely into the solder, exposing the underlying metal (usually nickel) to the solder. Impurities in the nickel layer can prevent the solder from bonding to it. Electroless nickel plating

Electroless nickel-phosphorus plating is a chemical process that deposits an even layer of nickel-phosphorus alloy on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containi ...

contains phosphorus. Nickel with more than 8% phosphorus is not solderable. Electrodeposited nickel may contain nickel hydroxide

Nickel(II) hydroxide is the inorganic compound with the formula Ni(OH)2. It is an apple-green solid that dissolves with decomposition in ammonia and amines and is attacked by acids. It is electroactive, being converted to the Ni(III) oxy-hydroxi ...

. An acid bath is required to remove the passivation layer before applying the gold layer; improper cleaning leads to a nickel surface difficult to solder. A stronger flux

Flux describes any effect that appears to pass or travel (whether it actually moves or not) through a surface or substance. Flux is a concept in applied mathematics and vector calculus which has many applications to physics. For transport ...

can help, as it aids dissolving the oxide deposits. Carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

is another nickel contaminant that hinders solderability.

See also

* Daniel Davis Jr. - inventor who was first to do gold plating as a business *Gold filled jewelry

Gold-filled jewelry is jewelry composed of a solid layer of gold (typically constituting at least 5% of the item's total weight) mechanically bonded to a base of either sterling silver or some base metal. The related terms "rolled gold plate" an ...

References

External links

* {{DEFAULTSORT:Gold Plating Electronics manufacturing Coatings Jewellery Metal plating de:Vergolden#Galvanische Verfahren