Electric Arc Furnace on:

[Wikipedia]

[Google]

[Amazon]

An electric arc furnace (EAF) is a furnace that heats material by means of an

An electric arc furnace (EAF) is a furnace that heats material by means of an

In the 19th century, a number of people had employed an electric arc to melt

In the 19th century, a number of people had employed an electric arc to melt  Initially "electric steel" was a specialty product for such uses as

Initially "electric steel" was a specialty product for such uses as

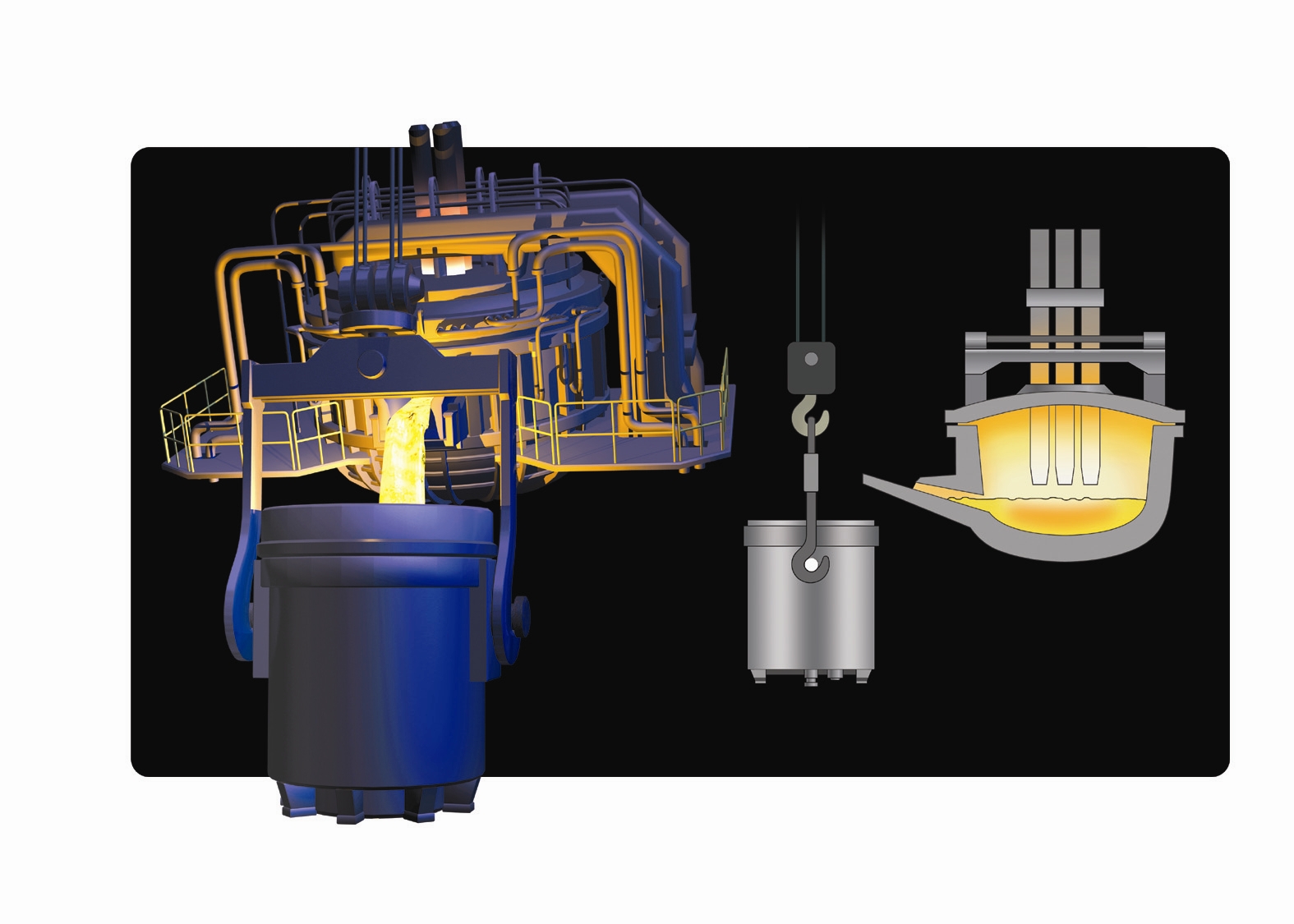

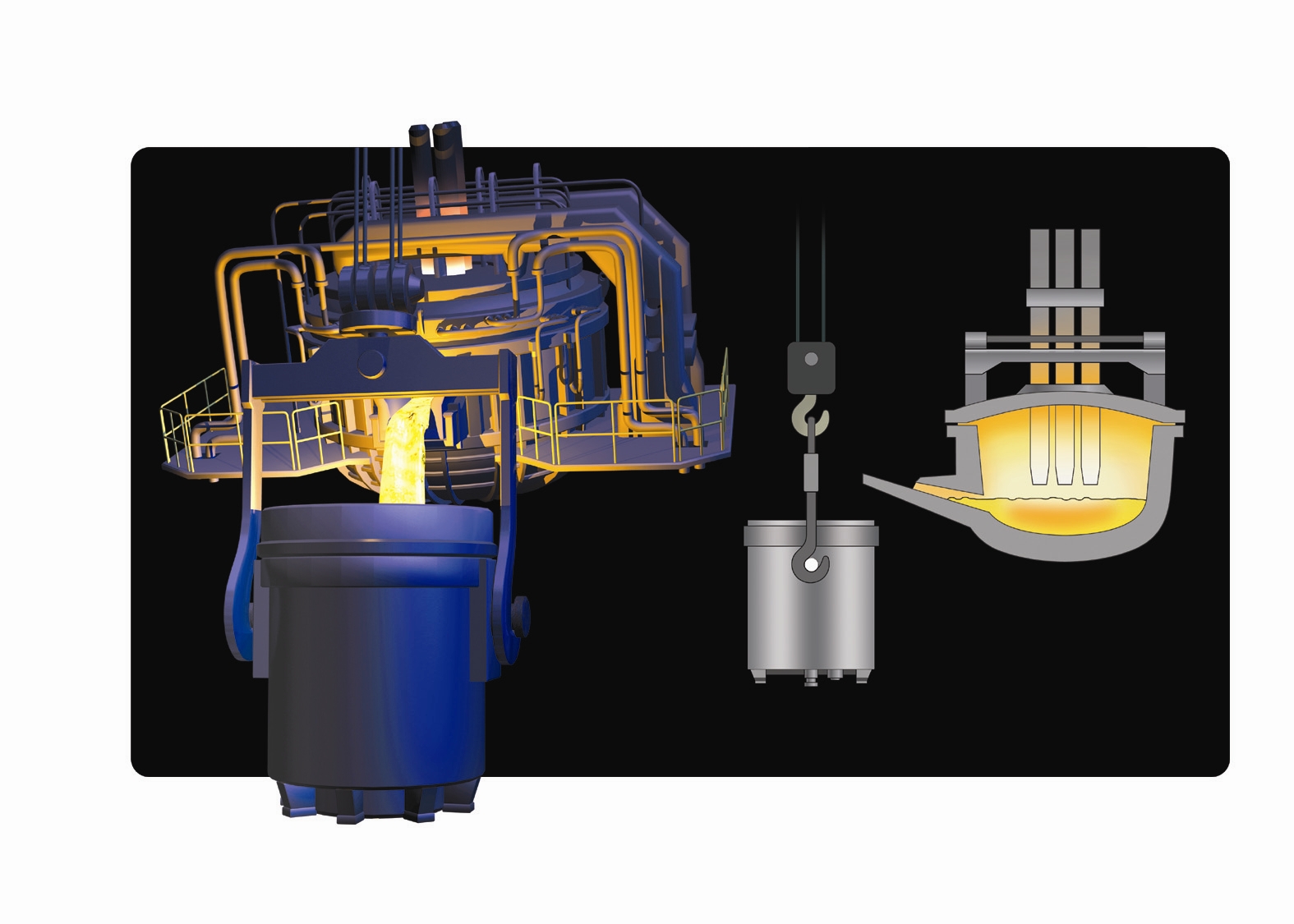

An electric arc furnace used for steelmaking consists of a

An electric arc furnace used for steelmaking consists of a  A typical

A typical

Scrap metal is delivered to a scrap bay, located next to the melt shop. Scrap generally comes in two main grades: shred (

Scrap metal is delivered to a scrap bay, located next to the melt shop. Scrap generally comes in two main grades: shred (

For steelmaking,

For steelmaking,

Smaller arc furnaces may be adequately cooled by circulation of air over structural elements of the shell and roof, but larger installations require intensive forced cooling to maintain the structure within safe operating limits. The furnace shell and roof may be cooled either by water circulated through pipes which form a panel, or by water sprayed on the panel elements. Tubular panels may be replaced when they become cracked or reach their thermal stress life cycle. Spray cooling is the most economical and is the highest efficiency cooling method. A spray cooling piece of equipment can be relined almost endlessly; equipment that lasts 20 years is the norm. However while a tubular leak is immediately noticed in an operating furnace due to the pressure loss alarms on the panels, at this time there exists no immediate way of detecting a very small volume spray cooling leak. These typically hide behind slag coverage and can hydrate the refractory in the hearth leading to a break out of molten metal or in the worst case a steam explosion.

Smaller arc furnaces may be adequately cooled by circulation of air over structural elements of the shell and roof, but larger installations require intensive forced cooling to maintain the structure within safe operating limits. The furnace shell and roof may be cooled either by water circulated through pipes which form a panel, or by water sprayed on the panel elements. Tubular panels may be replaced when they become cracked or reach their thermal stress life cycle. Spray cooling is the most economical and is the highest efficiency cooling method. A spray cooling piece of equipment can be relined almost endlessly; equipment that lasts 20 years is the norm. However while a tubular leak is immediately noticed in an operating furnace due to the pressure loss alarms on the panels, at this time there exists no immediate way of detecting a very small volume spray cooling leak. These typically hide behind slag coverage and can hydrate the refractory in the hearth leading to a break out of molten metal or in the worst case a steam explosion.

Recognition of first foundry as historical siteHome made small scale arc furnace using a welder (Caution with experiments!)Electric Arc Furnace module at steeluniversity.org

including a fully interactive simulation

Process models demonstrate the EAF operation and control (MPC)YouTube video of a small EAF in New Zealand

{{DEFAULTSORT:Electric Arc Furnace Electric arcs Industrial furnaces Steelmaking

An electric arc furnace (EAF) is a furnace that heats material by means of an

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc

An electric arc, or arc discharge, is an electrical breakdown of a gas that produces a prolonged electrical discharge. The current through a normally nonconductive medium such as air produces a plasma; the plasma may produce visible light. An ...

.

Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundries

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals pr ...

for producing cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

products) up to about 400-tonne units used for secondary steelmaking

Steelmaking is the process of producing steel from iron ore and carbon/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (the most important impurity) are removed from the sourced iron, and alloy ...

. Arc furnaces used in research laboratories and by dentists

A dentist, also known as a dental surgeon, is a health care professional who specializes in dentistry (the diagnosis, prevention, management, and treatment of diseases and conditions of the oral cavity and other aspects of the craniofacial comp ...

may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can reach , while laboratory units can exceed .

In electric arc furnaces, the charged material (the material entered into the furnace for heating, not to be confused with electric charge

Electric charge is the physical property of matter that causes charged matter to experience a force when placed in an electromagnetic field. Electric charge can be ''positive'' or ''negative'' (commonly carried by protons and electrons respe ...

) is directly exposed to an electric arc, and the current from the furnace terminals passes through the charged material.

Arc furnaces differ from induction furnace

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal.

Induction furnace capacities range from less than one kilogram to one hundred tons, and are used to melt iron and steel, copper, aluminum ...

s, in which the charge is heated instead by eddy current

Eddy currents (also called Foucault's currents) are loops of electrical current induced within conductors by a changing magnetic field in the conductor according to Faraday's law of induction or by the relative motion of a conductor in a magnet ...

s.

History

In the 19th century, a number of people had employed an electric arc to melt

In the 19th century, a number of people had employed an electric arc to melt iron

Iron () is a chemical element with Symbol (chemistry), symbol Fe (from la, Wikt:ferrum, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 element, group 8 of the periodic table. It is, Abundanc ...

. Sir Humphry Davy

Sir Humphry Davy, 1st Baronet, (17 December 177829 May 1829) was a British chemist and inventor who invented the Davy lamp and a very early form of arc lamp. He is also remembered for isolating, by using electricity, several elements for t ...

conducted an experimental demonstration in 1810; welding was investigated by Pepys in 1815; Pinchon attempted to create an electrothermic furnace in 1853; and, in 1878–79, Sir William Siemens

Sir Carl Wilhelm Siemens (4 April 1823 – 19 November 1883), anglicised to Charles William Siemens, was a German-British electrical engineer and businessman.

Biography

Siemens was born in the village of Lenthe, today part of Gehrden, near Ha ...

took out patent

A patent is a type of intellectual property that gives its owner the legal right to exclude others from making, using, or selling an invention for a limited period of time in exchange for publishing an enabling disclosure of the invention."A ...

s for electric furnaces of the arc type.

The first successful and operational furnace was invented by James Burgess Readman

Dr James Burgess Readman FRSE FCS FSSA (c.1850–April 1927) was a Scottish chemist who invented an electric furnace for creating phosphorus invented in 1888 and patented in 1889.

Life

He was born in Glasgow the son of George Readman, a bank ...

in Edinburgh

Edinburgh ( ; gd, Dùn Èideann ) is the capital city of Scotland and one of its 32 council areas. Historically part of the county of Midlothian (interchangeably Edinburghshire before 1921), it is located in Lothian on the southern shore of t ...

, Scotland in 1888 and patented in 1889. This was specifically for the creation of phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

.

Further electric arc furnaces were developed by Paul Héroult

Paul (Louis-Toussaint) Héroult (10 April 1863 – 9 May 1914) was a French scientist. He was the inventor of the aluminium electrolysis and developed the first successful commercial electric arc furnace. He lived in Thury-Harcourt, Normandy. ...

, of France

France (), officially the French Republic ( ), is a country primarily located in Western Europe. It also comprises of overseas regions and territories in the Americas and the Atlantic, Pacific and Indian Oceans. Its metropolitan area ...

, with a commercial plant established in the United States

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country primarily located in North America. It consists of 50 states, a federal district, five major unincorporated territori ...

in 1907. The Sanderson brothers formed The Sanderson Brothers Steel Co. in Syracuse, New York, installing the first electric arc furnace in the U.S. This furnace is now on display at Station Square, Pittsburgh, Pennsylvania.

machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All ...

s and spring steel

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon stee ...

. Arc furnaces were also used to prepare calcium carbide

Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C2. Its main use industrially is in the production of acetylene and calcium cyanamide.

The pure material is colorless, while pieces of te ...

for use in carbide lamp

Carbide lamps, or acetylene gas lamps, are simple lamps that produce and burn acetylene (C2H2) which is created by the reaction of calcium carbide (CaC2) with water (H2O).

Acetylene gas lamps were used to illuminate buildings, as lighthouse b ...

s. The '' Stassano electric furnace'' is an arc type furnace that usually rotates to mix the bath. The ''Girod furnace'' is similar to the ''Héroult furnace''.

While EAFs were widely used in World War II for production of alloy steels, it was only later that electric steelmaking began to expand. The low capital cost for a mini-mill—around US$140–200 per ton of annual installed capacity, compared with US$1,000 per ton of annual installed capacity for an integrated steel mill—allowed mills to be quickly established in war-ravaged Europe, and also allowed them to successfully compete with the big United States

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country primarily located in North America. It consists of 50 states, a federal district, five major unincorporated territori ...

steelmakers, such as Bethlehem Steel

The Bethlehem Steel Corporation was an American steelmaking company headquartered in Bethlehem, Pennsylvania. For most of the 20th century, it was one of the world's largest steel producing and shipbuilding companies. At the height of its succe ...

and U.S. Steel, for low-cost, carbon steel "long products" ( structural steel, rod and bar, wire

Overhead power cabling. The conductor consists of seven strands of steel (centre, high tensile strength), surrounded by four outer layers of aluminium (high conductivity). Sample diameter 40 mm

A wire is a flexible strand of metal.

Wire is c ...

, and fastener

A fastener (US English) or fastening (UK English) is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or disman ...

s) in the U.S. market.

When Nucor

Nucor Corporation is an American producer of steel and related products based in Charlotte, North Carolina. It is the largest steel producer in the United States, the largest "mini-mill" steelmaker (i.e. it uses electric arc furnaces to melt s ...

—now one of the largest steel producers in the US—decided to enter the market for long steel products in 1969, they chose to start up a mini-mill, with an EAF as its steelmaking furnace, soon followed by other manufacturers. Whilst Nucor expanded rapidly in the Eastern U.S., the companies that followed them into mini-mill operations concentrated on local markets for long products, where the use of an EAF allowed the plants to vary production according to local demand. This pattern was also followed globally, with EAF steel production primarily used for long products, while integrated mills, using blast furnaces and basic oxygen furnace

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing ...

s, cornered the markets for "flat products"— sheet steel and heavier steel plate. In 1987, Nucor made the decision to expand into the flat products market, still using the EAF production method.

Construction

refractory

In materials science, a refractory material or refractory is a material that is resistant to decomposition by heat, pressure, or chemical attack, and retains strength and form at high temperatures. Refractories are polycrystalline, polyphase, ...

-lined vessel, usually water-cooled in larger sizes, covered with a retractable roof, and through which one or more graphite electrodes enter the furnace.H. W. Beaty (ed.), ''Standard Handbook for Electrical Engineers, 11th Ed.'', McGraw Hill, New York 1978, pages 21.171-21.176

The furnace is primarily split into three sections:

* the ''shell'', which consists of the sidewalls and lower steel "bowl";

* the ''hearth'', which consists of the refractory that lines the lower bowl;

* the ''roof'', which may be refractory-lined or water-cooled, and can be shaped as a section of a sphere

A sphere () is a geometrical object that is a three-dimensional analogue to a two-dimensional circle. A sphere is the set of points that are all at the same distance from a given point in three-dimensional space.. That given point is th ...

, or as a frustum

In geometry, a (from the Latin for "morsel"; plural: ''frusta'' or ''frustums'') is the portion of a solid (normally a pyramid or a cone) that lies between two parallel planes cutting this solid. In the case of a pyramid, the base faces are ...

(conical section). The roof also supports the refractory delta in its centre, through which one or more graphite

Graphite () is a crystalline form of the element carbon. It consists of stacked layers of graphene. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on lar ...

electrodes enter.

The hearth may be hemispherical in shape, or in an eccentric bottom tapping furnace (see below), the hearth has the shape of a halved egg. In modern meltshops, the furnace is often raised off the ground floor, so that ladles and slag pots can easily be maneuvered under either end of the furnace. Separate from the furnace structure is the electrode support and electrical system, and the tilting platform on which the furnace rests. Two configurations are possible: the electrode supports and the roof tilt with the furnace, or are fixed to the raised platform.

A typical

A typical alternating current

Alternating current (AC) is an electric current which periodically reverses direction and changes its magnitude continuously with time in contrast to direct current (DC) which flows only in one direction. Alternating current is the form in whic ...

furnace is powered by a three-phase electrical supply and therefore has three electrodes. Electrodes are round in section, and typically in segments with threaded couplings, so that as the electrodes wear, new segments can be added. The arc forms between the charged material and the electrode; the charge is heated both by current passing through the charge and by the radiant energy

Radiant may refer to:

Computers, software, and video games

* Radiant (software), a content management system

* GtkRadiant, a level editor created by id Software for their games

* Radiant AI, a technology developed by Bethesda Softworks for '' ...

evolved by the arc. The electric arc temperature reaches around , thus causing the lower sections of the electrodes to glow incandescently when in operation. The electrodes are automatically raised and lowered by a positioning system, which may use either electric winch

A winch is a mechanical device that is used to pull in (wind up) or let out (wind out) or otherwise adjust the tension of a rope or wire rope (also called "cable" or "wire cable").

In its simplest form, it consists of a spool (or drum) attach ...

hoists or hydraulic cylinder

A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment ( engineering vehicles ...

s. The regulating system maintains approximately constant current and power input during the melting of the charge, even though scrap may move under the electrodes as it melts. The mast arms holding the electrodes can either carry heavy busbars (which may be hollow water-cooled copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

pipes carrying current to the electrode clamps) or be "hot arms", where the whole arm carries the current, increasing efficiency. Hot arms can be made from copper-clad steel or aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

. Large water-cooled cables connect the bus tubes or arms with the transformer

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer' ...

located adjacent to the furnace. The transformer is installed in a vault and is cooled by pump-circulated transformer oil, with the oil being cooled by water via heat exchangers.

The furnace is built on a tilting platform so that the liquid steel can be poured into another vessel for transport. The operation of tilting the furnace to pour molten steel is called "tapping". Originally, all steelmaking furnaces had a tapping spout closed with refractory that washed out when the furnace was tilted, but often modern furnaces have an eccentric bottom tap-hole (EBT) to reduce inclusion of nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

and slag in the liquid steel. These furnaces have a taphole that passes vertically through the hearth and shell, and is set off-centre in the narrow "nose" of the egg-shaped hearth. It is filled with refractory sand, such as olivine

The mineral olivine () is a magnesium iron silicate with the chemical formula . It is a type of nesosilicate or orthosilicate. The primary component of the Earth's upper mantle, it is a common mineral in Earth's subsurface, but weathers quickl ...

, when it is closed off. Modern plants may have two shells with a single set of electrodes that can be transferred between the two; one shell preheats scrap while the other shell is utilised for meltdown. Other DC-based furnaces have a similar arrangement, but have electrodes for each shell and one set of electronics.

AC furnaces usually exhibit a pattern of hot and cold-spots around the hearth perimeter, with the cold-spots located between the electrodes. Modern furnaces mount oxygen-fuel burners in the sidewall and use them to provide chemical energy to the cold-spots, making the heating of the steel more uniform. Additional chemical energy is provided by injecting oxygen and carbon into the furnace; historically this was done through lances (hollow mild-steel tubes) in the slag door, but now this is mainly done through wall-mounted injection units that combine the oxygen-fuel burners and the oxygen or carbon injection systems into one unit.

A mid-sized modern steelmaking furnace would have a transformer

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer' ...

rated about 60,000,000 volt-amperes (60 MVA), with a secondary voltage between 400 and 900 volts and a secondary current in excess of 44,000 amperes. In a modern shop such a furnace would be expected to produce a quantity of 80 tonnes of liquid steel in approximately 50 minutes from charging with cold scrap to tapping the furnace. In comparison, basic oxygen furnace

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing ...

s can have a capacity of 150–300 tonnes per batch, or "heat", and can produce a heat in 30–40 minutes. Enormous variations exist in furnace design details and operation, depending on the end product and local conditions, as well as ongoing research to improve furnace efficiency. The largest scrap-only furnace (in terms of tapping weight and transformer rating) is a DC furnace operated by Tokyo Steel in Japan, with a tap weight of 420 tonnes and fed by eight 32 MVA transformers for 256 MVA total power.

Energy density

To produce a ton of steel in an electric arc furnace requires approximately 400 kilowatt-hours (1.44 gigajoules) per short ton or about 440 kWh (1.6 GJ) pertonne

The tonne ( or ; symbol: t) is a unit of mass equal to 1000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton to distinguish it from the non-metric units of the short ton ( United State ...

; the theoretical minimum amount of energy required to melt a tonne of scrap steel is 300 kWh (1.09 GJ) (melting point ). Therefore, a 300-tonne, 300 MVA EAF will require approximately 132 MWh of energy to melt the steel, and a "power-on time" (the time that steel is being melted with an arc) of approximately 37 minutes. Electric arc steelmaking is only economical where there is plentiful, reliable electricity, with a well-developed electrical grid. In many locations, mills operate during off-peak hours when utilities have surplus power generating capacity and the price of electricity is less.

This compares very favourably with energy consumption of global steel production by all methods estimated at some 20 GJ per tonne (1 gigajoule is equal to approximately 270 kWh).

Operation

Scrap metal is delivered to a scrap bay, located next to the melt shop. Scrap generally comes in two main grades: shred (

Scrap metal is delivered to a scrap bay, located next to the melt shop. Scrap generally comes in two main grades: shred (whitegoods

A major appliance, also known as a large domestic appliance or large electric appliance or simply a large appliance, large domestic, or large electric, is a non-portable or semi-portable machine used for routine housekeeping tasks such as cookin ...

, cars and other objects made of similar light-gauge steel) and heavy melt (large slabs and beams), along with some direct reduced iron

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) into iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suit ...

(DRI) or pig iron for chemical balance. Some furnaces melt almost 100% DRI.

The scrap is loaded into large buckets called baskets, with "clamshell" doors for a base. Care is taken to layer the scrap in the basket to ensure good furnace operation; heavy melt is placed on top of a light layer of protective shred, on top of which is placed more shred. These layers should be present in the furnace after charging. After loading, the basket may pass to a scrap pre-heater, which uses hot furnace off-gases to heat the scrap and recover energy, increasing plant efficiency.

The scrap basket is then taken to the melt shop, the roof is swung off the furnace, and the furnace is charged with scrap from the basket. Charging is one of the more dangerous operations for the EAF operators. A lot of potential energy is released by the tonnes of falling metal; any liquid metal in the furnace is often displaced upwards and outwards by the solid scrap, and the grease and dust on the scrap is ignited if the furnace is hot, resulting in a fireball erupting. In some twin-shell furnaces, the scrap is charged into the second shell while the first is being melted down, and pre-heated with off-gas from the active shell. Other operations are continuous charging—pre-heating scrap on a conveyor belt, which then discharges the scrap into the furnace proper, or charging the scrap from a shaft set above the furnace, with off-gases directed through the shaft. Other furnaces can be charged with hot (molten) metal from other operations.

After charging, the roof is swung back over the furnace and meltdown commences. The electrodes are lowered onto the scrap, an arc is struck and the electrodes are then set to bore into the layer of shred at the top of the furnace. Lower voltages are selected for this first part of the operation to protect the roof and walls from excessive heat and damage from the arcs. Once the electrodes have reached the heavy melt at the base of the furnace and the arcs are shielded by the scrap, the voltage can be increased and the electrodes raised slightly, lengthening the arcs and increasing power to the melt. This enables a molten pool to form more rapidly, reducing tap-to-tap times. Oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

is blown into the scrap, combusting or cutting the steel, and extra chemical heat is provided by wall-mounted oxygen-fuel burners. Both processes accelerate scrap meltdown. Supersonic nozzles enable oxygen jets to penetrate foaming slag and reach the liquid bath.

An important part of steelmaking is the formation of slag, which floats on the surface of the molten steel. Slag usually consists of metal oxides, and acts as a destination for oxidised impurities, as a thermal blanket (stopping excessive heat loss) and helping to reduce erosion of the refractory

In materials science, a refractory material or refractory is a material that is resistant to decomposition by heat, pressure, or chemical attack, and retains strength and form at high temperatures. Refractories are polycrystalline, polyphase, ...

lining. For a furnace with basic refractories, which includes most carbon steel-producing furnaces, the usual slag formers are calcium oxide

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term "''lime''" connotes calcium-containing inorganic ...

(CaO, in the form of burnt lime

Lime commonly refers to:

* Lime (fruit), a green citrus fruit

* Lime (material), inorganic materials containing calcium, usually calcium oxide or calcium hydroxide

* Lime (color), a color between yellow and green

Lime may also refer to:

Botany ...

) and magnesium oxide (MgO, in the form of dolomite and magnesite). These slag formers are either charged with the scrap, or blown into the furnace during meltdown. Another major component of EAF slag is iron oxide from steel combusting with the injected oxygen. Later in the heat, carbon (in the form of coke or coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

) is injected into this slag layer, reacting with the iron oxide to form metallic iron and carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

gas, which then causes the slag to foam

Foams are materials formed by trapping pockets of gas in a liquid or solid.

A bath sponge and the head on a glass of beer are examples of foams. In most foams, the volume of gas is large, with thin films of liquid or solid separating the ...

, allowing greater thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For a ...

, and better arc stability and electrical efficiency

The efficiency of a system in electronics and electrical engineering is defined as useful power output divided by the total electrical power consumed (a vulgar fraction, fractional Expression (mathematics), expression), typically denoted by the Gr ...

. The slag blanket also covers the arcs, preventing damage to the furnace roof and sidewalls from radiant heat.

Once the initial scrap charge has been melted down, another bucket of scrap can be charged into the furnace, although EAF development is moving towards single-charge designs. The scrap-charging and meltdown process can be repeated as many times as necessary to reach the required heat weight - the number of charges is dependent on the density of scrap; lower-density scrap means more charges. After all scrap charges have completely melted, refining operations take place to check and correct the steel chemistry and superheat the melt above its freezing temperature in preparation for tapping. More slag formers are introduced and more oxygen is blown into the bath, burning out impurities such as silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ta ...

, sulfur, phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

, aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

, manganese

Manganese is a chemical element with the symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese is a transition metal with a multifaceted array of industrial alloy use ...

, and calcium

Calcium is a chemical element with the symbol Ca and atomic number 20. As an alkaline earth metal, calcium is a reactive metal that forms a dark oxide-nitride layer when exposed to air. Its physical and chemical properties are most similar t ...

, and removing their oxides to the slag. Removal of carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon mak ...

takes place after these elements have burnt out first, as they have a greater affinity for oxygen. Metals that have a poorer affinity for oxygen than iron, such as nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

and copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

, cannot be removed through oxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a ...

and must be controlled through scrap chemistry alone, such as introducing the direct reduced iron and pig iron mentioned earlier. A foaming slag is maintained throughout, and often overflows the furnace to pour out of the slag door into the slag pit. Temperature sampling and chemical sampling take place via automatic lances. Oxygen and carbon can be automatically measured via special probes that dip into the steel, but for all other elements, a "chill" sample — a small, solidified sample of the steel — is analysed on an arc-emission spectrometer

A spectrometer () is a scientific instrument used to separate and measure spectral components of a physical phenomenon. Spectrometer is a broad term often used to describe instruments that measure a continuous variable of a phenomenon where the ...

.

Once the temperature and chemistry are correct, the steel is tapped out into a preheated ladle through tilting the furnace. For plain-carbon steel furnaces, as soon as slag is detected during tapping the furnace is rapidly tilted back towards the deslagging side, minimising slag carryover into the ladle. For some special steel grades, including stainless steel, the slag is poured into the ladle as well, to be treated at the ladle furnace to recover valuable alloying elements. During tapping some alloy additions are introduced into the metal stream, and more fluxes such as lime are added on top of the ladle to begin building a new slag layer. Often, a few tonnes of liquid steel and slag is left in the furnace in order to form a "hot heel", which helps preheat the next charge of scrap and accelerate its meltdown. During and after tapping, the furnace is "turned around": the slag door is cleaned of solidified slag, the visible refractories are inspected and water-cooled components checked for leaks, and electrodes are inspected for damage or lengthened through the addition of new segments; the taphole is filled with sand at the completion of tapping. For a 90-tonne, medium-power furnace, the whole process will usually take about 60–70 minutes from the tapping of one heat to the tapping of the next (the tap-to-tap time).

The furnace is completely emptied of steel and slag on a regular basis so that an inspection of the refractories can be made and larger repairs made if necessary. As the refractories are often made from calcined

Calcination refers to thermal treatment of a solid chemical compound (e.g. mixed carbonate ores) whereby the compound is raised to high temperature without melting under restricted supply of ambient oxygen (i.e. gaseous O2 fraction of air), gener ...

carbonate

A carbonate is a salt of carbonic acid (H2CO3), characterized by the presence of the carbonate ion, a polyatomic ion with the formula . The word ''carbonate'' may also refer to a carbonate ester, an organic compound containing the carbonate ...

s, they are extremely susceptible to hydration from water, so any suspected leaks from water-cooled components are treated extremely seriously, beyond the immediate concern of potential steam explosion

A steam explosion is an explosion caused by violent boiling or flashing of water or ice into steam, occurring when water or ice is either superheated, rapidly heated by fine hot debris produced within it, or heated by the interaction of molten m ...

s. Excessive refractory wear can lead to breakouts, where the liquid metal and slag penetrate the refractory and furnace shell and escape into the surrounding areas.

Advantages for steelmaking

The use of EAFs allows steel to be made from a 100% scrap metal feedstock. This greatly reduces the energy required to make steel when compared with primary steelmaking from ores. Another benefit is flexibility: while blast furnaces cannot vary their production by much and can remain in operation for years at a time, EAFs can be rapidly started and stopped, allowing the steel mill to vary production according to demand. Although steelmaking arc furnaces generally use scrap steel as their primary feedstock, if hot metal from a blast furnace or direct-reduced iron is available economically, these can also be used as furnace feed. As EAFs require large amounts of electrical power, many companies schedule their operations to take advantage of off-peakelectricity pricing

Electricity pricing (also referred to as electricity tariffs or the price of electricity) can vary widely by country or by locality within a country. Electricity prices are dependent on many factors, such as the price of power generation, gover ...

.

A typical steelmaking arc furnace is the source of steel for a mini-mill, which may make bars or strip product. Mini-mills can be sited relatively near the markets for steel products, so the transport requirements are less than for an integrated mill, which would commonly be sited near a harbor for better access to shipping.

Electric arc furnace steelmaking results in lower carbon dioxide emissions of around 0.6 ton CO2 per ton of steel produced, which is significantly lower than the conventional production route via blast furnaces and the basic oxygen furnace.

In theory, electric arc furnaces can be powered used only renewable energy sources such as wind and photovoltaic solar power. This would even further reduce the emissions and embodied energy associated with steelmaking, or any of the many other materials requiring furnaces, including glass. This makes EAF's an attractive option for green industry.

Issues

Although the modern electric arc furnace is a highly efficient recycler of steel scrap, operation of an arc furnace shop can have adverse environmental effects. Much of the capital cost of a new installation will be devoted to systems intended to reduce these effects, which include: * Enclosures to reduce high sound levels *Dust collector

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists ...

for furnace off-gas

* Slag production

* Cooling water demand

* Heavy truck traffic for scrap, materials handling, and product

* Environmental effects of electricity generation

Because of the very dynamic quality of the arc furnace load, power systems may require technical measures to maintain the quality of power for other customers; flicker and harmonic distortion are common power system side-effects of arc furnace operation.

Other electric arc furnaces

For steelmaking,

For steelmaking, direct current

Direct current (DC) is one-directional flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor such as a wire, but can also flow through semiconductors, insulators, or eve ...

(DC) arc furnaces are used, with a single electrode in the roof and the current return through a conductive bottom lining or conductive pins in the base. The advantage of DC is lower electrode consumption per ton of steel produced, since only one electrode is used, as well as less electrical harmonics and other similar problems. The size of DC arc furnaces is limited by the current carrying capacity of available electrodes, and the maximum allowable voltage. Maintenance of the conductive furnace hearth is a bottleneck in extended operation of a DC arc furnace.

In a steel plant, a ladle furnace (LF) is used to maintain the temperature of liquid steel during processing after tapping from EAF or to change the alloy composition. The ladle is used for the first purpose when there is a delay later in the steelmaking process. The ladle furnace consists of a refractory roof, a heating system, and, when applicable, a provision for injecting argon gas into the bottom of the melt for stirring. Unlike a scrap melting furnace, a ladle furnace does not have a tilting or scrap-charging mechanism.

Electric arc furnaces are also used for production of calcium carbide

Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C2. Its main use industrially is in the production of acetylene and calcium cyanamide.

The pure material is colorless, while pieces of te ...

, ferroalloys, and other non-ferrous alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

s, and for production of phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

. Furnaces for these services are physically different from steel-making furnaces and may operate on a continuous, rather than batch, basis. Continuous-process furnaces may also use paste-type, Søderberg electrodes to prevent interruptions from electrode changes. Such a furnace is known as a submerged arc furnace, because the electrode tips are buried in the slag/charge, and arcing occurs through the slag, between the matte

Matte may refer to:

Art

* paint with a non-glossy finish. See diffuse reflection.

* a framing element surrounding a painting or watercolor within the outer frame

Film

* Matte (filmmaking), filmmaking and video production technology

* Matte p ...

and the electrode. A steelmaking arc furnace, by comparison, arcs in the open. The key is the electrical resistance

The electrical resistance of an object is a measure of its opposition to the flow of electric current. Its reciprocal quantity is , measuring the ease with which an electric current passes. Electrical resistance shares some conceptual paralle ...

, which is what generates the heat required: the resistance in a steelmaking furnace is the atmosphere, while in a submerged-arc furnace, the slag (or charge) supplies the resistance. The liquid metal formed in either furnace is too conductive to form an effective heat-generating resistance.

Amateurs have constructed a variety of arc furnaces, often based on electric arc welding kits contained by silica blocks or flower pots. Though crude, these simple furnaces can melt a wide range of materials, create calcium carbide

Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C2. Its main use industrially is in the production of acetylene and calcium cyanamide.

The pure material is colorless, while pieces of te ...

, and more.

Cooling methods

Smaller arc furnaces may be adequately cooled by circulation of air over structural elements of the shell and roof, but larger installations require intensive forced cooling to maintain the structure within safe operating limits. The furnace shell and roof may be cooled either by water circulated through pipes which form a panel, or by water sprayed on the panel elements. Tubular panels may be replaced when they become cracked or reach their thermal stress life cycle. Spray cooling is the most economical and is the highest efficiency cooling method. A spray cooling piece of equipment can be relined almost endlessly; equipment that lasts 20 years is the norm. However while a tubular leak is immediately noticed in an operating furnace due to the pressure loss alarms on the panels, at this time there exists no immediate way of detecting a very small volume spray cooling leak. These typically hide behind slag coverage and can hydrate the refractory in the hearth leading to a break out of molten metal or in the worst case a steam explosion.

Smaller arc furnaces may be adequately cooled by circulation of air over structural elements of the shell and roof, but larger installations require intensive forced cooling to maintain the structure within safe operating limits. The furnace shell and roof may be cooled either by water circulated through pipes which form a panel, or by water sprayed on the panel elements. Tubular panels may be replaced when they become cracked or reach their thermal stress life cycle. Spray cooling is the most economical and is the highest efficiency cooling method. A spray cooling piece of equipment can be relined almost endlessly; equipment that lasts 20 years is the norm. However while a tubular leak is immediately noticed in an operating furnace due to the pressure loss alarms on the panels, at this time there exists no immediate way of detecting a very small volume spray cooling leak. These typically hide behind slag coverage and can hydrate the refractory in the hearth leading to a break out of molten metal or in the worst case a steam explosion.

Plasma arc furnace

A plasma arc furnace (PAF) uses plasma torches instead of graphite electrodes. Each of these torches has a casing with a nozzle and axial tubing for feeding a plasma-forming gas (either nitrogen or argon) and a burnable cylindrical graphite electrode within the tubing. Such furnaces can be called "PAM" (Plasma Arc Melt) furnaces; they are used extensively in the titanium-melting industry and similar specialty metal industries.Vacuum arc remelting

Vacuum arc remelting (VAR) is a secondary remelting process for vacuum refining and manufacturing of ingots with improved chemical and mechanical homogeneity. In critical military and commercial aerospace applications, material engineers commonly specify VIM-VAR steels. VIM means Vacuum Induction Melted and VAR means Vacuum Arc Remelted. VIM-VAR steels become bearings for jet engines, rotor shafts for military helicopters, flap actuators for fighter jets, gears in jet or helicopter transmissions, mounts or fasteners for jet engines, jet tail hooks and other demanding applications. Most grades of steel are melted once and are then cast or teemed into a solid form prior to extensive forging or rolling to a metallurgically-sound form. In contrast, VIM-VAR steels go through two more highly purifying melts under vacuum. After melting in an electric arc furnace and alloying in an argon oxygen decarburization vessel, steels destined for vacuum remelting are cast into ingot molds. The solidified ingots then head for a vacuum induction melting furnace. This vacuum remelting process rids the steel of inclusions and unwanted gases while optimizing the chemical composition. The VIM operation returns these solid ingots to the molten state in the contaminant-free void of a vacuum. This tightly controlled melt often requires up to 24 hours. Still enveloped by the vacuum, the hot metal flows from the VIM furnace crucible into giant electrode molds. A typical electrode is about 15 feet (5 m) tall and will be in various diameters. The electrodes solidify under vacuum. For VIM-VAR steels, the surface of the cooled electrodes must be ground to remove surface irregularities and impurities before the next vacuum remelt. Then the ground electrode is placed in a VAR furnace. In a VAR furnace, the steel gradually melts drop-by-drop in the vacuum-sealed chamber. Vacuum arc remelting further removes lingering inclusions to provide superior steel cleanliness and remove gases like oxygen, nitrogen and hydrogen. Controlling the rate at which these droplets form and solidify ensures a consistency of chemistry and microstructure throughout the entire VIM-VAR ingot, making the steel more resistant to fracture or fatigue. This refinement process is essential to meet the performance characteristics of parts like a helicopter rotor shaft, a flap actuator on a military jet, or a bearing in a jet engine. For some commercial or military applications, steel alloys may go through only one vacuum remelt, namely the VAR. For example, steels for solid rocket cases, landing gears, or torsion bars for fighting vehicles typically involve one vacuum remelt. Vacuum arc remelting is also used in production oftitanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

and other metals which are reactive or in which high purity is required.

See also

* Flodin process *Vacuum arc remelting Vacuum arc remelting (VAR) is a secondary melting process for production of metal ingots with elevated chemical and mechanical homogeneity for highly demanding applications. The VAR process has revolutionized the specialty traditional metallurgica ...

References

Further reading

*J.A.T. Jones, B. Bowman, P.A. Lefrank, "Electric Furnace Steelmaking", in ''The Making, Shaping and Treating of Steel'', R.J. Fruehan, Editor. 1998, The AISE Steel Foundation: Pittsburgh. p. 525–660. *Thomas Commerford Martin

Thomas Commerford Martin (July 22, 1856 – May 17, 1924) was an American electrical engineer and editor.

Martin was born in Limehouse, England. His father worked with Lord Kelvin and other pioneers of submarine telegraph cables, and Martin worke ...

and Stephen Leidy Coles, ''The Story of Electricity'', New York 1919, no ISBN, Chapter 13 "The Electric Furnace", available on the Internet Archive

The Internet Archive is an American digital library with the stated mission of "universal access to all knowledge". It provides free public access to collections of digitized materials, including websites, software applications/games, music, ...

External links

Recognition of first foundry as historical site

including a fully interactive simulation

Process models demonstrate the EAF operation and control (MPC)

{{DEFAULTSORT:Electric Arc Furnace Electric arcs Industrial furnaces Steelmaking