dragline excavator on:

[Wikipedia]

[Google]

[Amazon]

A dragline excavator is a heavy-duty

In a typical cycle of excavation, the bucket is positioned above the material to be excavated. The bucket is then lowered and the dragrope is then drawn so that the bucket is dragged along the surface of the material. The bucket is then lifted by using the hoist rope. A swing operation is then performed to move the bucket to the place where the material is to be dumped. The dragrope is then released causing the bucket to tilt and empty. This is called a dump operation.

On crane-type draglines, the bucket can also be 'thrown' by winding up to the jib and then releasing a

In a typical cycle of excavation, the bucket is positioned above the material to be excavated. The bucket is then lowered and the dragrope is then drawn so that the bucket is dragged along the surface of the material. The bucket is then lifted by using the hoist rope. A swing operation is then performed to move the bucket to the place where the material is to be dumped. The dragrope is then released causing the bucket to tilt and empty. This is called a dump operation.

On crane-type draglines, the bucket can also be 'thrown' by winding up to the jib and then releasing a

The coal mining dragline known as Big Muskie, owned by the Central Ohio Coal Company (a division of American Electric Power), was the world's largest mobile earth-moving machine, weighing 13,500 tons and standing nearly 22 stories tall. It operated in Muskingum County, in the U.S. state of

The coal mining dragline known as Big Muskie, owned by the Central Ohio Coal Company (a division of American Electric Power), was the world's largest mobile earth-moving machine, weighing 13,500 tons and standing nearly 22 stories tall. It operated in Muskingum County, in the U.S. state of

"Dragline Automation"

''Dr Jonathan Roberts CSIRO'' (11 December 2009) accessed 19 December 2011

P&H draglinesBucyrus draglines

{{Authority control Articles containing video clips Engineering vehicles Excavators Mining equipment Draglines

excavator

Excavators are heavy equipment (construction), heavy construction equipment primarily consisting of a backhoe, boom, dipper (or stick), Bucket (machine part), bucket, and cab on a rotating platform known as the "house".

The modern excavator's ...

used in civil engineering

Civil engineering is a regulation and licensure in engineering, professional engineering discipline that deals with the design, construction, and maintenance of the physical and naturally built environment, including public works such as roads ...

and surface mining

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit (the overburden) are removed, in contrast to underground mining, in whic ...

. It was invented in 1904, and presented an immediate challenge to the steam shovel

A steam shovel is a large steam engine, steam-powered excavating machine designed for lifting and moving material such as Rock (geology), rock and soil. It is the earliest type of power shovel or excavator. Steam shovels played a major role in ...

and its diesel and electric powered descendant, the power shovel

A power shovel, also known as a motor shovel, stripping shovel, front shovel, mining shovel or rope shovel, is a bucket-equipped machine usually powered by steam, diesel fuel, gasoline or electricity and used for digging and loading earth or frag ...

. Much more efficient than even the largest of the latter, it enjoyed a heyday in extreme size for most of the 20th century, first becoming challenged by more efficient rotary excavators in the 1950s, then superseded by them on the upper end from the 1970s on.

The largest ever walking dragline was Big Muskie, a Bucyrus-Erie 4250-W put online in 1969 that swung a , 325 ton capacity bucket, had a boom, and weighed 13,500 tons.

The largest walking dragline produced as of 2014 was Joy Global’s digital AC drive control P&H 9020XPC, which has a bucket capacity of and boom lengths ranging from ; working weights vary between 7,539 and 8,002 tons.

Types

Draglines fall into two broad categories: those that are based on standard, lifting cranes, and the heavy units which have to be built on-site. Most crawler cranes, with an added winch drum on the front, can act as a dragline. These units (like other cranes) are designed to be temporarily dismantled and transported over the road on flatbed trailers. Draglines used in mostcivil engineering

Civil engineering is a regulation and licensure in engineering, professional engineering discipline that deals with the design, construction, and maintenance of the physical and naturally built environment, including public works such as roads ...

are of this smaller, crane type. These are used for road construction

A road is a thoroughfare used primarily for movement of traffic. Roads differ from streets, whose primary use is local access. They also differ from stroads, which combine the features of streets and roads. Most modern roads are paved.

The ...

, port construction, pond and canal dredging, and as pile driving rigs. These types are built by crane manufacturers such as Link-Belt and Hyster.

The much larger type which is erected on site is commonly used in strip-mining operations to remove overburden

In mining, overburden (also called waste or spoil) is the material that lies above an area that lends itself to economical exploitation, such as the rock, soil, and ecosystem that lies above a coal seam or ore body. Overburden is distinct from tai ...

above coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other Chemical element, elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal i ...

and more recently for oil sands

Oil sands are a type of unconventional petroleum deposit. They are either loose sands, or partially consolidated sandstone containing a naturally occurring mixture of sand, clay, and water, soaked with bitumen (a dense and extremely viscous ...

mining. The largest heavy draglines are among the largest mobile land machines ever built, weighing up to 13,500 tons, while the smallest and most common of the site-erected type weigh around 8,000 tons.

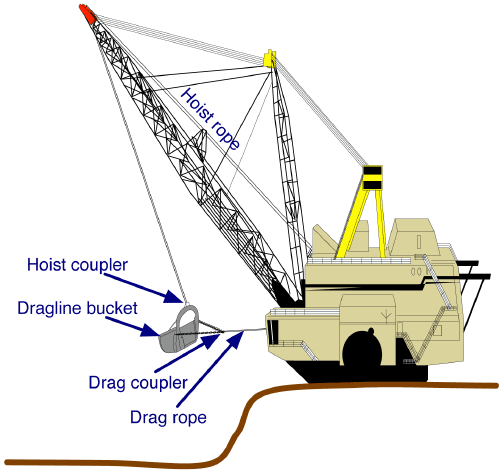

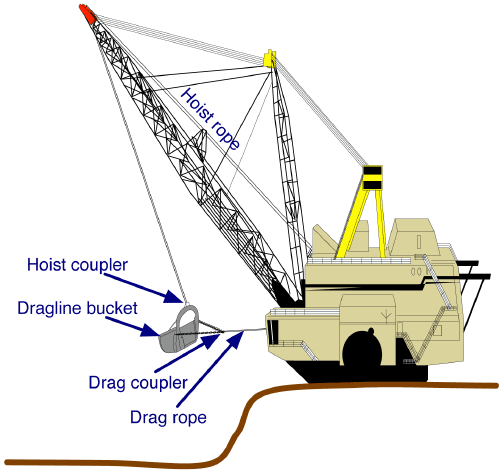

A dragline bucket system consists of a large bucket which is suspended from a large truss

A truss is an assembly of ''members'' such as Beam (structure), beams, connected by ''nodes'', that creates a rigid structure.

In engineering, a truss is a structure that "consists of two-force members only, where the members are organized so ...

-like boom (or mast) with wire rope

Steel wire rope (right hand lang lay)

Wire rope is composed of as few as two solid, metal wires twisted into a helix that forms a composite ''rope'', in a pattern known as ''laid rope''. Larger diameter wire rope consists of multiple strands of ...

s. The bucket is maneuvered by means of a number of ropes and chains. The hoist rope, powered by large diesel or electric motor

An electric motor is a machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a electromagnetic coil, wire winding to gene ...

s, supports the bucket and hoist-coupler assembly from the boom. The dragrope is used to draw the bucket assembly horizontally. By skillful maneuver of the hoist and the dragropes the bucket is controlled for various operations. A schematic of a large dragline bucket system is shown below.

History

The dragline was invented in 1904 by John W. Page (as a partner of the firm Page & Schnable Contracting) for use in digging the Chicago Canal. By 1912, Page realized that building draglines was more lucrative than contracting, so he created the Page Engineering Company to build draglines. Page built its first crude walking dragline in 1923. These used legs operated by rack and pinion on a separate frame that lifted the crane. The body was then pulled forward by chain on a roller track and then lowered again. Page developed the first diesel engines exclusively for dragline application in 1924. Page also invented the arched dragline bucket, a design still commonly used today by draglines from many other manufacturers, and in the 1960s pioneered an archless bucket design. With its walking mechanism badly behind that of competitor Monighan (see below), Page updated their mechanism to an eccentric drive in 1935. This much improved mechanism gave a proper elliptical motion and was used until 1988. Page modernized its draglines further with the 700 series in 1954. Page's largest dragline was the Model 757 delivered to the Obed Mine near Hinton, Alberta in 1983. It featured a 75-yard bucket on a 298-foot boom and an operating weight of 4,500 tons. In 1988, Harnischfeger Corporation ( P&H Mining Equipment) purchased Page Engineering Company. Harnischfeger Corporation was established as P&H Mining in 1884 by Alonzo Pawling and Henry Harnischfeger. In 1914, P&H introduced the world's first gasoline engine powered dragline. In 1988, Page was acquired by Harnischfeger which makes the P&H line ofshovels

A shovel is a tool used for digging, lifting, and moving bulk materials, such as soil, coal, gravel, snow, sand, or ore. Most shovels are hand tools consisting of a broad blade fixed to a medium-length handle. Shovel blades are usually made of ...

, draglines, and cranes. P&H's largest dragline is the 9030C with a 160-yard bucket and up to a 425-foot boom.

In 1907, Monighan's Machine Works of Chicago became interested in manufacturing draglines when local contractor John W. Page placed an order for hoisting machinery to install one. In 1908, Monighan changed its name to the Monighan Machine Company. In 1913, a Monighan engineer named Oscar Martinson invented the first walking mechanism for a dragline. The device, known as the Martinson Tractor, was installed on a Monighan dragline, creating the first walking dragline. This gave Monighan a significant advantage over other draglines and the company prospered. The cam mechanism was further improved in 1925 by eliminating the drag chains for the shoes and changing to a cam wheel running in an oval track. This gave the shoe a proper elliptical motion. The first dragline using the new mechanism was the 3-W available in 1926. So popular were these machines that the name Monighan became a generic term for dragline. In the early 1930s, Bucyrus-Erie began purchasing shares of Monighan stock with Monighan's approval. Bucyrus purchased a controlling interest and the joint company became known as Bucyrus-Monighan until the formal merger in 1946. The first walking dragline excavator in the United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Northwestern Europe, off the coast of European mainland, the continental mainland. It comprises England, Scotlan ...

was used at the Wellingborough iron quarry in 1940.

Ransomes & Rapier

Ransomes & Rapier was a major United Kingdom, British manufacturer of railway equipment and later cranes, from 1869 to 1987. Originally an offshoot of the major engineering company Ransomes, Sims & Jeffries, Ransome's it was based at Waterside Wo ...

was founded in 1869 by four engineers to build railway equipment and other heavy works. In 1914 they started building two small steam shovels as a result of a customer request. The rope-operated crowd system they built for this was patented and later sold to Bucyrus. After WWI, demand for excavators increased and in 1924 they reached an agreement to build Marion draglines from 1 to 8 cubic yards capacity. In 1927, they built Type-7 1-yard and Type-460 1.5-yard models. The deal to build Marion machines ended in 1936. R&R began building their own designs with the Type-4120 followed by the 4140 of 3.5 cubic yards. In 1958 the Ramsomes & Rapier division was sold to Newton, Chambers & Co. of Sheffield, which was combined with their NCK Crane & Excavator division. This became NCK-Rapier. The walking dragline division of NCK-Rapier was acquired by Bucyrus in 1988.

The Marion Power Shovel Company

Marion Power Shovel Company was an American firm that designed, manufactured and sold steam shovels, power shovels, blast hole drills, excavators, and dragline excavators for use in the construction and mining industries. The company was a majo ...

(established in 1880) built its first walking dragline with a simple single-crank mechanism in 1939. Its largest dragline was the 8950 sold to Amax Coal Company in 1973. It featured a 150-cubic yard bucket on a 310-foot boom and weighed 7,300 tons. Marion was acquired by Bucyrus in 1997.

Bucyrus Foundry and Manufacturing Company entered the dragline market in 1910 with the purchase of manufacturing rights for the Heyworth-Newman dragline excavator. Their "Class 14" dragline was introduced in 1911 as the first crawler mounted dragline. In 1912 Bucyrus helped pioneer the use of electricity as a power source for large stripping shovels and draglines used in mining. An Italian company, Fiorentini, produced dragline excavators from 1919 licensed by Bucyrus. After the merger with Monighan in 1946, Bucyrus began producing much larger machines using the Monighan walking mechanism such as the 800 ton 650-B which used a 15-yard bucket. Bucyrus' largest dragline was Big Muskie built for the Ohio Coal Company in 1969. This machine featured a 220-yard bucket on a 450-foot boom and weighed 14,500 tons. Bucyrus was itself acquired by heavy equipment and diesel engine maker, Caterpillar, in 2011. Caterpillar's largest dragline is the 8750 with a 169-yard bucket, 435-foot boom, and 8,350 ton weight.

The market for draglines began shrinking rapidly after the boom of the 1960s and 1970s which led to more mergers. P&H's acquisition of Page in 1988 along with Bucyrus' acquisition of Ransomes & Rapier in 1988 and Marion in 1997 cut the number of worldwide suppliers of heavy draglines by more than half. Today, P&H and Caterpillar are the only remaining manufacturers of large draglines.

Other manufacturers

Heavy Engineering Corporation Limited was the first Indian company to manufacture a walking dragline of 31-yard bucket capacity. HEC makes up to a 44-yard bucket. For comparison, this would be comparable to Caterpillar's Small Draglines 8000 series with a 42-yard bucket. HEC has supplied fifteen draglines to the Indian mining industry.Operation

In a typical cycle of excavation, the bucket is positioned above the material to be excavated. The bucket is then lowered and the dragrope is then drawn so that the bucket is dragged along the surface of the material. The bucket is then lifted by using the hoist rope. A swing operation is then performed to move the bucket to the place where the material is to be dumped. The dragrope is then released causing the bucket to tilt and empty. This is called a dump operation.

On crane-type draglines, the bucket can also be 'thrown' by winding up to the jib and then releasing a

In a typical cycle of excavation, the bucket is positioned above the material to be excavated. The bucket is then lowered and the dragrope is then drawn so that the bucket is dragged along the surface of the material. The bucket is then lifted by using the hoist rope. A swing operation is then performed to move the bucket to the place where the material is to be dumped. The dragrope is then released causing the bucket to tilt and empty. This is called a dump operation.

On crane-type draglines, the bucket can also be 'thrown' by winding up to the jib and then releasing a clutch

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does th ...

on the drag cable. This would then swing the bucket like a pendulum

A pendulum is a device made of a weight suspended from a pivot so that it can swing freely. When a pendulum is displaced sideways from its resting, equilibrium position, it is subject to a restoring force due to gravity that will accelerate i ...

. Once the bucket had passed the vertical, the hoist cable would be released thus throwing the bucket. On smaller draglines, a skilled operator could make the bucket land about one-half the length of the jib further away than if it had just been dropped. On larger draglines, this is not a common practice.

Draglines in mining

A large dragline system used in the open pit mining industry costs approximatelyUS$

The United States dollar (Currency symbol, symbol: Dollar sign, $; ISO 4217, currency code: USD) is the official currency of the United States and International use of the U.S. dollar, several other countries. The Coinage Act of 1792 introdu ...

50–100 million. A typical bucket has a volume ranging from 40 to 80 cubic yards (30 to 60 cubic metres), though extremely large buckets have ranged up to 220 cubic yards (168 cubic meters). The length of the boom ranges from . In a single cycle, it can move up to 450 tons of material.

Most mining draglines are not diesel-powered like most other mining equipment. Their power consumption on order of several megawatts is so great that they have a direct connection to the high-voltage

High voltage electricity refers to electrical potential large enough to cause injury or damage. In certain industries, ''high voltage'' refers to voltage above a certain threshold. Equipment and conductors that carry high voltage warrant spe ...

grid at voltages of between 6.6 and 22 kV. A typical dragline weighing 4000 to 6000 tons, with a 55-cubic-metre bucket, can use up to 6 megawatts during normal digging operations. Because of this, many (possibly apocryphal

Apocrypha () are biblical or related writings not forming part of the accepted canon of scripture, some of which might be of doubtful authorship or authenticity. In Christianity, the word ''apocryphal'' (ἀπόκρυφος) was first applied to ...

) stories have been told about the blackout-causing effects of mining draglines. For instance, there is a long-lived story that, back in the 1970s, if all seven draglines at Peak Downs Mine (a very large BHP coal mine in central Queensland

Queensland ( , commonly abbreviated as Qld) is a States and territories of Australia, state in northeastern Australia, and is the second-largest and third-most populous state in Australia. It is bordered by the Northern Territory, South Austr ...

, Australia) turned on simultaneously, they would black out all of North Queensland

North Queensland or the Northern Region is the northern part of the Australian state of Queensland that lies just south of Far North Queensland. Queensland is a massive state, larger than many countries, and its Tropical North Queensland, trop ...

. However even in the 2000s if they have been shut down, they are always restarted one at a time due to the immense power requirements of startup.

In all but the smallest of draglines, movement is accomplished by "walking" using feet or pontoons, as caterpillar track

Continuous track or tracked treads are a system of vehicle propulsion used in tracked vehicles, running on a continuous band of treads or track plates driven by two or more wheels. The large surface area of the tracks distributes the w ...

s place too much pressure on the ground, and have great difficulty under the immense weight of the dragline. Maximum speed is only at most a few metres per minute, since the feet must be repositioned for each step. If travelling medium distances (about 30–100 km), a special dragline carrier can be brought in to transport the dragline. Above that distance, disassembly is generally required. But mining draglines due to their reach can work a large area from one position and do not need to constantly move along the face like smaller machines.

Limitations

The primary limitations of draglines are their boom height and boom length, which limits where the dragline can dump the waste material. Another primary limitation is their dig depth, which is limited by the length of rope the dragline can utilize. Inherent with their construction, a dragline is most efficient excavating material below the level of their base. While a dragline can dig above itself, it does so inefficiently and is not suitable to load piled up material (as a rope shovel or wheel loader can). Despite their limitations, and their extremely high capital cost, draglines remain popular with many mines, due to their reliability, and extremely low waste removal cost.Notable examples

Ohio

Ohio ( ) is a U.S. state, state in the Midwestern United States, Midwestern region of the United States. It borders Lake Erie to the north, Pennsylvania to the east, West Virginia to the southeast, Kentucky to the southwest, Indiana to the ...

from 1969 to 1991, and derived power from a 13,800 volt electrical supply. It was dismantled for $700,000 worth of recycled metal in 1999.

The British firm of Ransomes & Rapier

Ransomes & Rapier was a major United Kingdom, British manufacturer of railway equipment and later cranes, from 1869 to 1987. Originally an offshoot of the major engineering company Ransomes, Sims & Jeffries, Ransome's it was based at Waterside Wo ...

produced a few diesel-electric excavators rather over 1/10th its size, the largest in Europe in the 1960s at 1400-1800 tons. One, named '' SUNDEW'', was used in a quarry from 1957 to 1974. After its working life at the first site in Rutland

Rutland is a ceremonial county in the East Midlands of England. It borders Leicestershire to the north and west, Lincolnshire to the north-east, and Northamptonshire to the south-west. Oakham is the largest town and county town.

Rutland has a ...

wrapped it walked in 9 weeks to Corby

Corby is a town and civil parish in the North Northamptonshire district of Northamptonshire, England, northeast of Northampton. In 2021 it had a population of 68,164. From 1974 to 2021, it was the administrative headquarters of the Borough of ...

, where it continued on till being scrapped from January to June 1987.

Smaller draglines were also commonly used before hydraulic excavators came into common use, the smaller draglines are now rarely used other than on river and gravel pit works. The small machines were of a mechanical drive with clutches. Firms such as Ruston and Bucyrus made models such as the RB10 which were popular for small building works and drainage work. Several of these can still be seen in the English Fens of Cambridgeshire

Cambridgeshire (abbreviated Cambs.) is a Ceremonial counties of England, ceremonial county in the East of England and East Anglia. It is bordered by Lincolnshire to the north, Norfolk to the north-east, Suffolk to the east, Essex and Hertfor ...

, Lincolnshire

Lincolnshire (), abbreviated ''Lincs'', is a Ceremonial counties of England, ceremonial county in the East Midlands and Yorkshire and the Humber regions of England. It is bordered by the East Riding of Yorkshire across the Humber estuary to th ...

and parts of Norfolk

Norfolk ( ) is a Ceremonial counties of England, ceremonial county in England, located in East Anglia and officially part of the East of England region. It borders Lincolnshire and The Wash to the north-west, the North Sea to the north and eas ...

. Ruston's are a company also associated with drainage pumping engines. Electric drive systems were only used on the larger mining machines, most modern machines use a diesel-hydraulic drive, as machines are seldom in one location long enough to justify the cost of installing a substation and supply cables.

Technological advances

The basic mechanical technology of draglines, unlike that of most equipment used in earth-moving, has remained relatively unchanged in design and control functions for almost 100 years. Some advances, however, have been made (such as hydraulic, then electro-hydraulic, controls (includingjoystick

A joystick, sometimes called a flight stick, is an input device consisting of a stick that pivots on a base and reports its angle or direction to the device it is controlling. Also known as the control column, it is the principal control devic ...

s) and using simulation software to train new operators), are being pursued (such as improved automation systems), or are arguable as a step forward (as is "universal dig-dump" ( UDD)):

Automation

Researchers atCSIRO

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) is an Australian Government agency that is responsible for scientific research and its commercial and industrial applications.

CSIRO works with leading organisations arou ...

in Australia have a long-term research project into automating draglines. Mining automation teams at QCAT, a CSIRO division; have been developing the automation technology since 1994. Automated systems include cruise control and Digital Terrain Mapping. Working solutions include the proof-of-concept dragline swing cruise control on a Tarong BE1370.''Dr Jonathan Roberts CSIRO'' (11 December 2009) accessed 19 December 2011

Simulation software

Since draglines are typically large, complicated and very expensive, training new operators can be a tricky process. In the same way thatflight simulator

A flight simulator is a device that artificially re-creates aircraft flight and the environment in which it flies, for pilot training, design, or other purposes. It includes replicating the equations that govern how aircraft fly, how they rea ...

s have developed to train pilots, mining simulator software has been developed to assist new operators in learning how to control the machines.

UDD

UDD stands for ''universal dig-dump''. It represents the first fundamental change to draglines for almost a century, since the invention of the 'miracle hitch'. Instead of using two ropes (the hoist rope and the drag rope) to manipulate the bucket, a UDD machine uses four ropes, two hoist and two drag. This allows the dragline operator to have much greater selectivity in when to pick up the bucket, and in how the bucket may be dumped. UDD machines generally have higher productivity than a standard dragline, but often have greater mechanical issues. Within the mining industry, there is still much debate as to whether UDD improvements justify their costs.See also

* Bucket wheel excavator – alternative mining machine *Excavator

Excavators are heavy equipment (construction), heavy construction equipment primarily consisting of a backhoe, boom, dipper (or stick), Bucket (machine part), bucket, and cab on a rotating platform known as the "house".

The modern excavator's ...

– generic class of machine of which draglines are a sub class

*Power shovel

A power shovel, also known as a motor shovel, stripping shovel, front shovel, mining shovel or rope shovel, is a bucket-equipped machine usually powered by steam, diesel fuel, gasoline or electricity and used for digging and loading earth or frag ...

– type of mining machine (also called a front shovel)

*Steam shovel

A steam shovel is a large steam engine, steam-powered excavating machine designed for lifting and moving material such as Rock (geology), rock and soil. It is the earliest type of power shovel or excavator. Steam shovels played a major role in ...

– earliest type of mining excavator

References

*K. Pathak, K. Dasgupta, A. Chattopadhyay, "Determination of the working zone of a dragline bucket – A graphical approach", Doncaster, ''The Institution of mining engineers'', 1992. *Peter Ridley, Peter Corke, "Calculation of Dragline bucket pose under gravity loading", ''Mechanism and machine theory'', Vol. 35, 2000.External links

P&H draglines

{{Authority control Articles containing video clips Engineering vehicles Excavators Mining equipment Draglines