cold welding on:

[Wikipedia]

[Google]

[Amazon]

Cold welding or contact welding is a

Cold welding or contact welding is a

Cold welding or contact welding is a

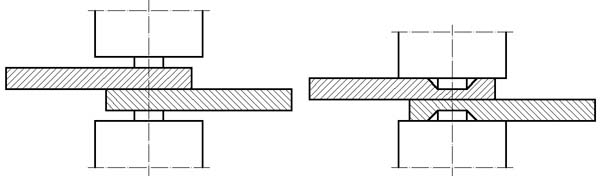

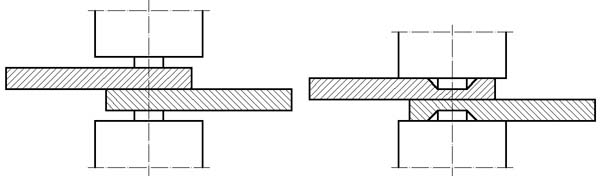

Cold welding or contact welding is a solid

Solid is a state of matter where molecules are closely packed and can not slide past each other. Solids resist compression, expansion, or external forces that would alter its shape, with the degree to which they are resisted dependent upon the ...

-state welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Co ...

process in which joining takes place without fusion or heating at the interface of the two parts to be welded. Unlike in fusion welding, no liquid

Liquid is a state of matter with a definite volume but no fixed shape. Liquids adapt to the shape of their container and are nearly incompressible, maintaining their volume even under pressure. The density of a liquid is usually close to th ...

or molten phase is present in the joint.

Cold welding was first recognized as a general materials phenomenon in the 1940s. It was then discovered that two clean, flat surfaces of similar metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

would strongly adhere if brought into contact while in a vacuum

A vacuum (: vacuums or vacua) is space devoid of matter. The word is derived from the Latin adjective (neuter ) meaning "vacant" or "void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressur ...

. Micro and nano-scale cold welding has shown potential in nanofabrication processes.

Applications include wire stock and electrical connections (such as insulation-displacement connectors and wire wrap connections).

In space

Mechanical problems in earlysatellites

A satellite or an artificial satellite is an object, typically a spacecraft, placed into orbit around a celestial body. They have a variety of uses, including communication relay, weather forecasting, navigation ( GPS), broadcasting, scientif ...

were sometimes attributed to cold welding.

In 2009 the European Space Agency

The European Space Agency (ESA) is a 23-member International organization, international organization devoted to space exploration. With its headquarters in Paris and a staff of around 2,547 people globally as of 2023, ESA was founded in 1975 ...

published a peer reviewed paper detailing why cold welding is a significant issue that spacecraft designers need to carefully consider. The paper also cites a documented example from 1991 with the Galileo spacecraft high-gain antenna.

One source of difficulty is that cold welding does not exclude relative motion between the surfaces that are to be joined. This allows the broadly defined notions of galling, fretting, stiction and adhesion

Adhesion is the tendency of dissimilar particles or interface (matter), surfaces to cling to one another. (Cohesion (chemistry), Cohesion refers to the tendency of similar or identical particles and surfaces to cling to one another.)

The ...

to overlap in some instances. For example, it is possible for a joint to be the result of both cold (or "vacuum") welding and galling (or fretting or impact). Galling and cold welding, therefore, are not mutually exclusive.

Nanoscale

Unlike cold welding process at macro-scale which normally requires large applied pressures, scientists discovered that single-crystalline ultra-thin goldnanowire

file:SnSe@SWCNT.jpg, upright=1.2, Crystalline 2×2-atom tin selenide nanowire grown inside a single-wall carbon nanotube (tube diameter ≈1 nm).

A nanowire is a nanostructure in the form of a wire with the diameter of the order of a nanometre ( ...

s (diameters less than 10 nm) can be cold-welded together within seconds by mechanical contact alone, and under remarkably low applied pressures. High-resolution transmission electron microscopy

Transmission electron microscopy (TEM) is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a g ...

and in-situ measurements reveal that the welds are nearly perfect, with the same crystal orientation, strength and electrical conductivity as the rest of the nanowire. The high quality of the welds is attributed to the nanoscale sample dimensions, oriented-attachment mechanisms and mechanically assisted fast surface diffusion. Nanoscale welds were also demonstrated between gold and silver, and silver and silver, indicating that the phenomenon may be generally applicable and therefore offer an atomistic view of the initial stages of macroscopic cold welding for either bulk metals or metallic thin film.

See also

* * * * * * * *References

Further reading

* *External links

* * {Coldweld Data Base Archived 26 January 2023 at the Wayback Machine. , https://coldweld.aac-research.at/ Welding