Cemented carbide on:

[Wikipedia]

[Google]

[Amazon]

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of

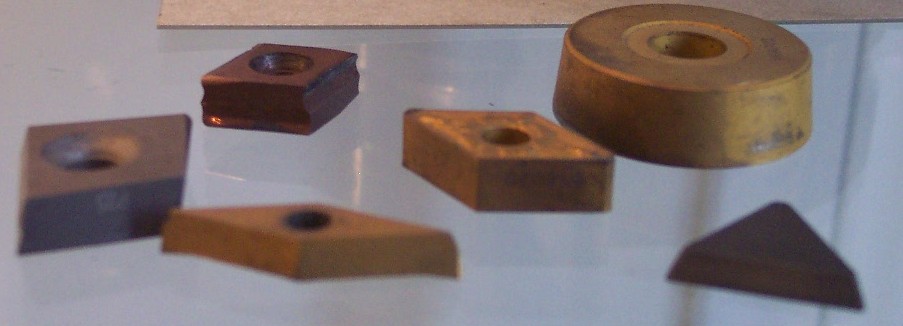

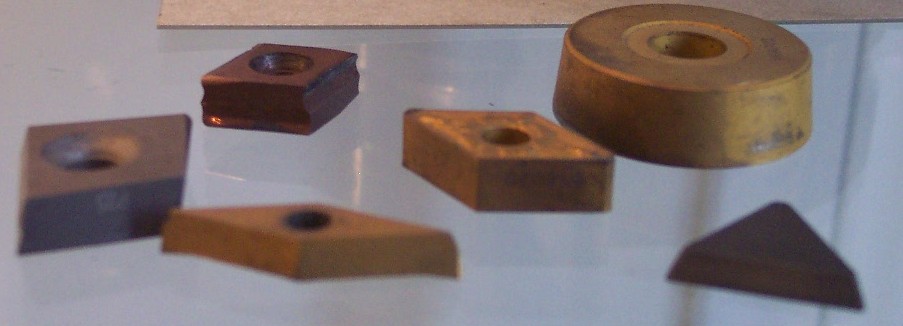

Carbide is more expensive per unit than other typical tool materials, and it is more brittle, making it susceptible to chipping and breaking. To offset these problems, the carbide cutting tip itself is often in the form of a small insert for a larger

Carbide is more expensive per unit than other typical tool materials, and it is more brittle, making it susceptible to chipping and breaking. To offset these problems, the carbide cutting tip itself is often in the form of a small insert for a larger

* Automotive components

* Canning tools for

* Automotive components

* Canning tools for

the free dictionary: pobedit

/ref> Pobedit is usually produced by powder metallurgy in the form of plates of different shapes and sizes. The manufacturing process is as follows: a fine powder of tungsten carbide (or other refractory carbide) and a fine powder of binder material such as cobalt or nickel both get intermixed and then pressed into the appropriate forms. Pressed plates are sintered at a temperature close to the melting point of the binder metal, which yields a very tight and solid substance. The plates of this superhard composite are applied to manufacturing of metal-cutting and drilling tools; they are usually soldered on the cutting tool tips. Heat post-treatment is not required. The pobedit inserts at the tips of drill bits are still very widespread in Russia.

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of t ...

cemented into a composite

Composite or compositing may refer to:

Materials

* Composite material, a material that is made from several different substances

** Metal matrix composite, composed of metal and other parts

** Cermet, a composite of ceramic and metallic materials ...

by a binder metal. Cemented carbides commonly use tungsten carbide (WC), titanium carbide (TiC), or tantalum carbide

Tantalum carbides (TaC) form a family of binary chemical compounds of tantalum and carbon with the empirical formula TaC''x'', where ''x'' usually varies between 0.4 and 1. They are extremely hard, brittle, refractory ceramic materials with metal ...

(TaC) as the aggregate. Mentions of "carbide" or "tungsten carbide" in industrial contexts usually refer to these cemented composites.

Most of the time, carbide cutters will leave a better surface finish on a part and allow for faster machining than high-speed steel or other tool steels. Carbide tools can withstand higher temperatures at the cutter-workpiece interface than standard high-speed steel tools (which is a principal reason enabling the faster machining). Carbide is usually superior for the cutting of tough materials such as carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, coba ...

or stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's r ...

, as well as in situations where other cutting tools would wear away faster, such as high-quantity production runs. In situations where carbide tooling is not required, high-speed steel is preferred for its lower cost.

Composition

Cemented carbides are metal matrix composites where carbide particles act as the aggregate and a metallic binder serves as the matrix (analogous to concrete, where agravel

Gravel is a loose aggregation of rock fragments. Gravel occurs naturally throughout the world as a result of sedimentary and erosive geologic processes; it is also produced in large quantities commercially as crushed stone.

Gravel is classifi ...

aggregate is suspended in a cement matrix). The structure of cemented carbide is conceptually similar to that of a grinding wheel, but the abrasive particles are much smaller; macroscopically, the material of a carbide cutter appears homogeneous.

The process of combining the carbide particles with the binder is referred to as sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

or hot isostatic pressing

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.

The process can be used to p ...

(HIP). During this process, the material is heated until the binder enters a liquid phase while the carbide grains (which have a much higher melting point) remain solid. At this elevated temperature and pressure, the carbide grains rearrange themselves and compact together, forming a porous matrix. The ductility of the metal binder serves to offset the brittleness of the carbide ceramic, resulting in the composite's high overall toughness and durability. By controlling various parameters, including grain size, cobalt content, dotation (e.g., alloy carbides) tantalum carbide

Tantalum carbides (TaC) form a family of binary chemical compounds of tantalum and carbon with the empirical formula TaC''x'', where ''x'' usually varies between 0.4 and 1. They are extremely hard, brittle, refractory ceramic materials with metal ...

, which is tougher than tungsten carbide.

Physical properties

Applications

Inserts for metal cutting

Carbide is more expensive per unit than other typical tool materials, and it is more brittle, making it susceptible to chipping and breaking. To offset these problems, the carbide cutting tip itself is often in the form of a small insert for a larger

Carbide is more expensive per unit than other typical tool materials, and it is more brittle, making it susceptible to chipping and breaking. To offset these problems, the carbide cutting tip itself is often in the form of a small insert for a larger tipped tool

A tipped tool is any cutting tool in which the cutting edge consists of a separate piece of material that is brazed, welded, or clamped onto a body made of another material. In the types in which the cutter portion is an indexable part clamped ...

whose shank is made of another material, usually carbon tool steel. This gives the benefit of using carbide at the cutting interface without the high cost and brittleness of making the entire tool out of carbide. Most modern face mills use carbide inserts, as well as many lathe tools and endmill

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, most m ...

s. In recent decades, though, solid-carbide endmills have also become more commonly used, wherever the application's characteristics make the pros (such as shorter cycle times) outweigh the cons (mentioned above). As well, modern turning (lathe) tooling may use a carbide insert on a carbide tool such as a boring bar, which are more rigid than steel insert holders and therefor less prone to vibration, which is of particular importance with boring or threading bars that may need to reach into a part to a depth many times the tool diameter.

Insert coatings

To increase the life of carbide tools, they are sometimes coated. Five such coatings are TiN ( titanium nitride), TiC ( titanium carbide), Ti(C)N ( titanium carbide-nitride), TiAlN ( titanium aluminium nitride) and AlTiN ( aluminium titanium nitride). (Newer coatings, known as DLC ( diamond-like carbon) are beginning to surface, enabling the cutting power of diamond without the unwanted chemical reaction between real diamond and iron.) Most coatings generally increase a tool's hardness and/or lubricity. A coating allows the cutting edge of a tool to cleanly pass through the material without having the materialgall

Galls (from the Latin , 'oak-apple') or ''cecidia'' (from the Greek , anything gushing out) are a kind of swelling growth on the external tissues of plants, fungi, or animals. Plant galls are abnormal outgrowths of plant tissues, similar to be ...

(stick) to it. The coating also helps to decrease the temperature associated with the cutting process and increase the life of the tool. The coating is usually deposited via thermal chemical vapor deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (subst ...

(CVD) and, for certain applications, with the mechanical physical vapor deposition (PVD) method. However, if the deposition is performed at too high temperature, an ''eta phase'' of a Co6W6C tertiary carbide forms at the interface between the carbide and the cobalt phase, which may lead to adhesion failure of the coating.

Inserts for mining tools

Mining and tunneling cutting tools are most often fitted with cemented carbide tips, the so-called "button bits". Artificial diamond can replace the cemented carbide buttons only when conditions are ideal, but as rock drilling is a tough job cemented carbide button bits remain the most used type throughout the world.Rolls for hot-roll and cold-roll applications

Since the mid-1960s, steel mills around the world have applied cemented carbide to the rolls of their rolling mills for both hot and cold rolling of tubes, bars, and flats.Other industrial applications

This category contains a countless number of applications, but can be split into three main areas: * Engineered components * Wear parts * Tools and tool blanks Some key areas where cemented carbide components are used: * Automotive components

* Canning tools for

* Automotive components

* Canning tools for deep drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "de ...

of two-piece cans

* Rotary cutters for high-speed cutting of artificial fibres

* Metal forming tools for wire drawing and stamping applications

* Rings and bushings typically for bump and seal applications

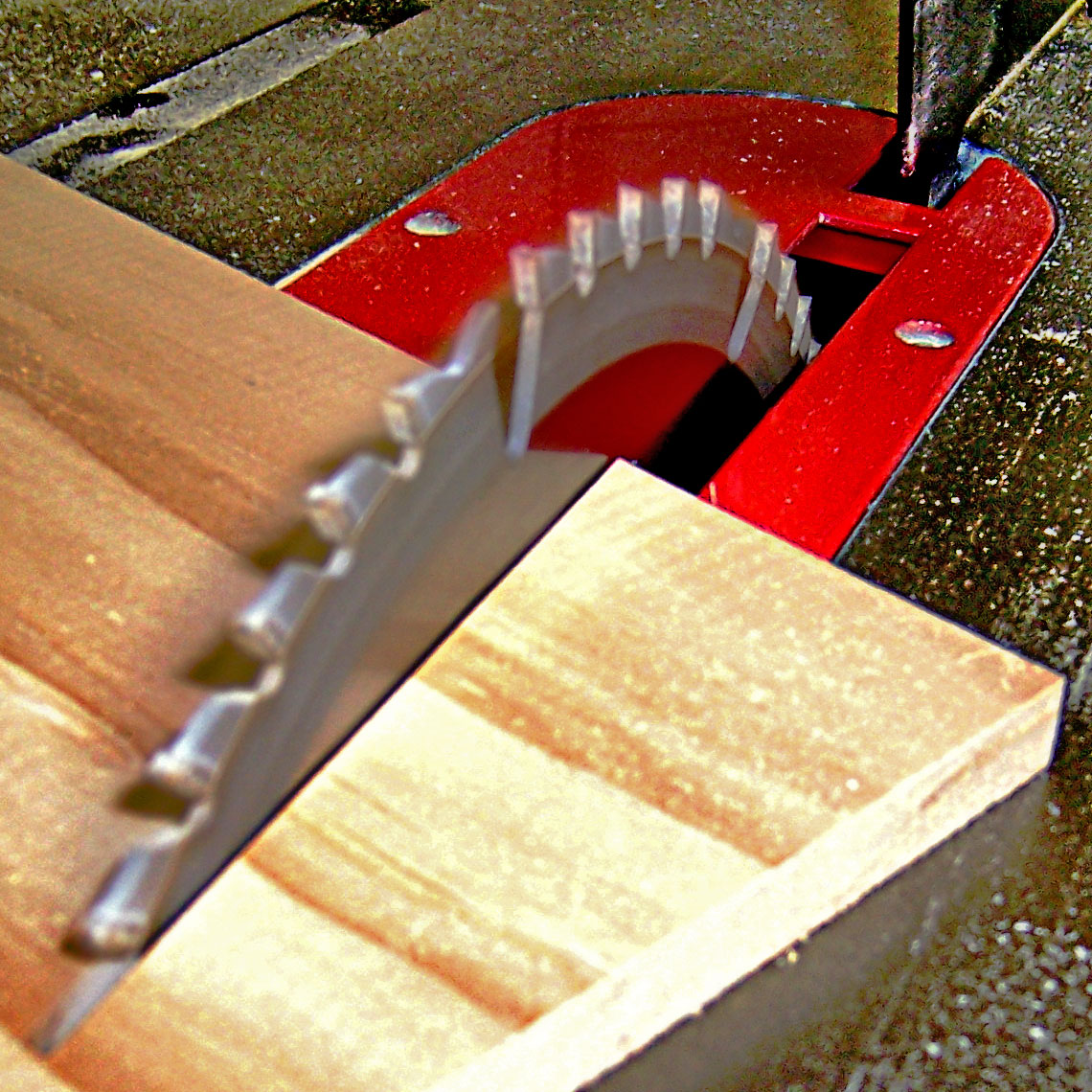

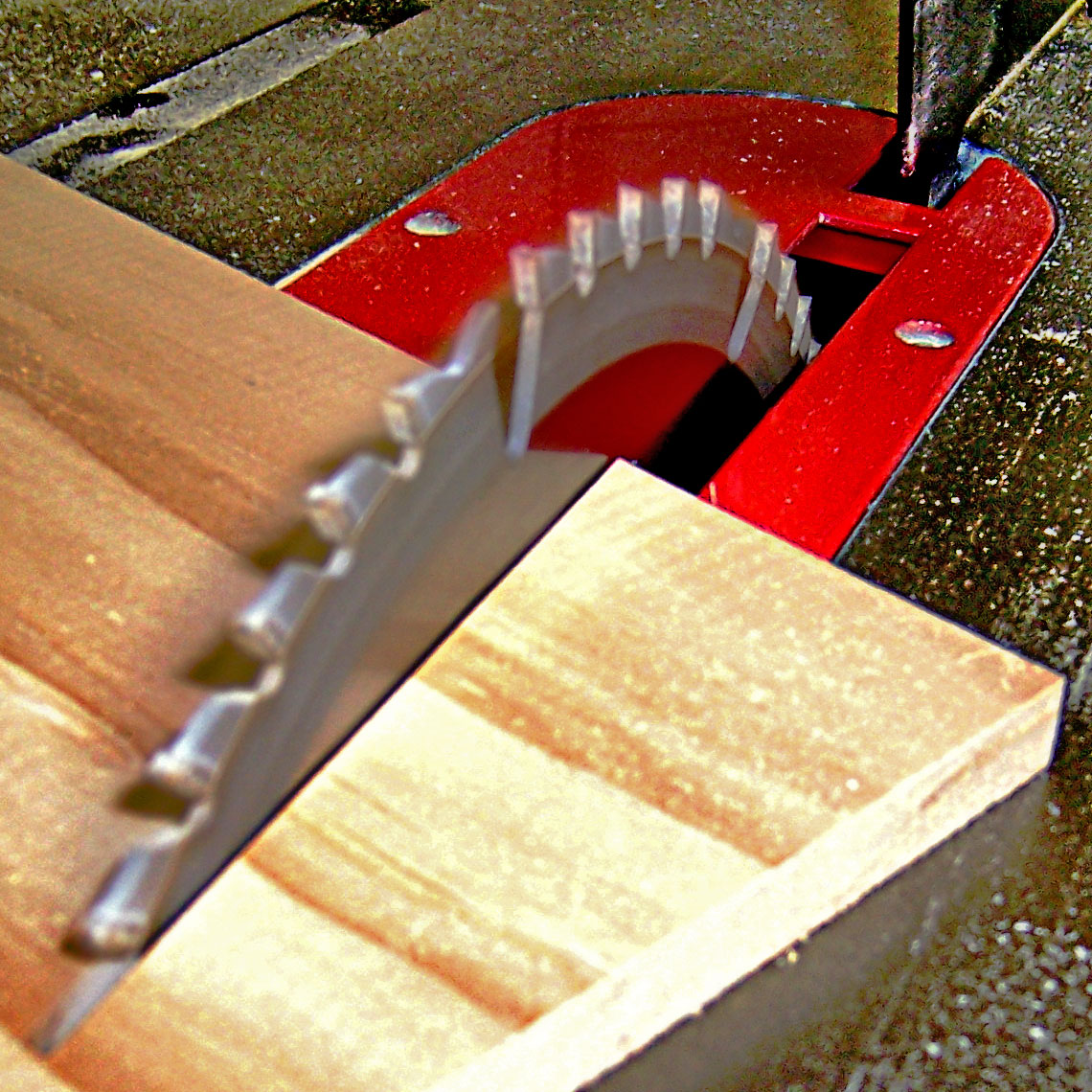

* Woodworking, e.g., for sawing and planing applications

* Pump pistons for high-performance pumps (e.g., in nuclear

Nuclear may refer to:

Physics

Relating to the nucleus of the atom:

*Nuclear engineering

*Nuclear physics

*Nuclear power

*Nuclear reactor

*Nuclear weapon

*Nuclear medicine

*Radiation therapy

*Nuclear warfare

Mathematics

*Nuclear space

*Nuclear ...

installations)

* Nozzles, e.g., high-performance nozzles for oil drilling applications

* Roof and tail tools and components for high wear resistance

* Balls for ball bearing

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this ...

s and ballpoint pen

A ballpoint pen, also known as a biro (British English), ball pen (Hong Kong, Indian and Philippine English), or dot pen (Nepali) is a pen that dispenses ink (usually in paste form) over a metal ball at its point, i.e. over a "ball point". ...

s

Non-industrial uses

Jewellery

Tungsten carbide has become a popular material in the bridal jewellery industry, due to its extreme hardness and high resistance to scratching. Given its brittleness, it is prone to chip, crack, or shatter in jewellery applications. Once fractured, it cannot be repaired.History

The initial development of cemented andsintered

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

carbides occurred in Germany in the 1920s. ThyssenKrupp

ThyssenKrupp AG (, ; stylized as thyssenkrupp) is a German industrial engineering and steel production multinational conglomerate. It is the result of the 1999 merger of Thyssen AG and Krupp and has its operational headquarters in Duisburg a ...

says n_n_historical_present_tense">historical_present.html"_;"title="n_historical_present">n_historical_present_tense_"Sintered__tungsten_carbide_was_developed_by_the_'Osram_study_society_for_electrical_lighting'_to_replace_diamonds_as_a_material_for_machining_metal._Not_having_the_equipment_to_exploit_this_material_on_an_industrial_scale,_Osram_sells_the_license_to_Krupp_at_the_end_of_1925._In_1926_Krupp_brings_sintered_carbide_onto_the_market_under_the_name_WIDIA_(acronym_and_initialism.html" "title="historical_present_tense.html" ;"title="historical_present.html" ;"title="n historical present">n historical present tense">historical_present.html" ;"title="n historical present">n historical present tense "Sintered tungsten carbide was developed by the 'Osram study society for electrical lighting' to replace diamonds as a material for machining metal. Not having the equipment to exploit this material on an industrial scale, Osram sells the license to Krupp at the end of 1925. In 1926 Krupp brings sintered carbide onto the market under the name WIDIA (acronym and initialism">acronym

An acronym is a word or name formed from the initial components of a longer name or phrase. Acronyms are usually formed from the initial letters of words, as in ''NATO'' (''North Atlantic Treaty Organization''), but sometimes use syllables, as ...

for = like diamond)." Machinery's Handbook gives the date of carbide tools' commercial introduction as 1927. Burghardt and Axelrod give the date of their commercial introduction in the United States as 1928. Subsequent development occurred in various countries.

Although the marketing pitch was slightly hyperbolic (carbides being not entirely equal to diamond), carbide tooling offered an improvement in cutting speeds and feeds so remarkable that, like high-speed steel had done two decades earlier, it forced machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. Al ...

designers to rethink every aspect of existing designs, with an eye toward yet more rigidity and yet better spindle bearings.

During World War II there was a tungsten shortage in Germany. It was found that tungsten in carbide cuts metal more efficiently than tungsten in high-speed steel, so to economise on the use of tungsten, carbides were used for metal cutting as much as possible.

The name became a genericized trademark in various countries and languages, including English (widia, ), although the genericized sense was never especially widespread in English ("carbide" is the normal generic term). Since 2009, the name has been revived as a brand name by Kennametal, and the brand subsumes numerous popular brands of cutting tools. For the sake of clear communication, the reviving of the Widia brand may naturally further discourage use of the generic sense.

Uncoated tips brazed to their shanks were the first form. Clamped indexable inserts and today's wide variety of coatings are advances made in the decades since. With every passing decade, the use of carbide has become less "special" and more ubiquitous.

Regarding fine-grained hardmetal, an attempt has been made to follow the scientific and technological steps associated with its production; this task is not easy, though, because of the restrictions placed by commercial, and in some cases research, organisations, in not publicising relevant information until long after the date of the initial work. Thus, placing data in an historical, chronological order is somewhat difficult. However, it has been possible to establish that as far back as 1929, approximately 6 years after the first patent was granted, Krupp/Osram workers had identified the positive aspects of tungsten carbide grain refinement. By 1939, they had also discovered the beneficial effects of adding a small amount of vanadium and tantalum carbide. This effectively controlled discontinuous grain growth.

What was considered 'fine' in one decade was considered not so fine in the next. Thus, a grain size in the range 0.5–3.0 μm was considered fine in the early years, but by the 1990s, the era of the nano-crystalline material had arrived, with a grain size of 20–50 nm.

Pobedit

''Pobedit'' ( rus, победи́т, link=no) is asintered

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

carbide alloy of about 90% tungsten carbide as a hard phase, and about 10% cobalt

Cobalt is a chemical element with the symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, p ...

(Co) as a binder phase, with a small amount of additional carbon. It was developed in the Soviet Union

The Soviet Union,. officially the Union of Soviet Socialist Republics. (USSR),. was a transcontinental country that spanned much of Eurasia from 1922 to 1991. A flagship communist state, it was nominally a federal union of fifteen nationa ...

in 1929, it is described as a material from which cutting tools are made. Later a number of similar alloys based on tungsten and cobalt were developed, and the name of 'pobedit' was retained for them as well./ref> Pobedit is usually produced by powder metallurgy in the form of plates of different shapes and sizes. The manufacturing process is as follows: a fine powder of tungsten carbide (or other refractory carbide) and a fine powder of binder material such as cobalt or nickel both get intermixed and then pressed into the appropriate forms. Pressed plates are sintered at a temperature close to the melting point of the binder metal, which yields a very tight and solid substance. The plates of this superhard composite are applied to manufacturing of metal-cutting and drilling tools; they are usually soldered on the cutting tool tips. Heat post-treatment is not required. The pobedit inserts at the tips of drill bits are still very widespread in Russia.

See also

* Carbide sawReferences

Bibliography

* *Further reading

* *External links

{{Authority control Carbides Superhard materials Tungsten compounds Metalworking tools