Blacksmith on:

[Wikipedia]

[Google]

[Amazon]

A blacksmith is a metalsmith who creates objects primarily from

Blacksmiths work by heating pieces of wrought iron or steel until the metal becomes soft enough for shaping with hand tools, such as a hammer, an anvil and a chisel. Heating generally takes place in a forge fueled by propane, natural gas, coal, charcoal, coke, or oil.

Some modern blacksmiths may also employ an

Blacksmiths work by heating pieces of wrought iron or steel until the metal becomes soft enough for shaping with hand tools, such as a hammer, an anvil and a chisel. Heating generally takes place in a forge fueled by propane, natural gas, coal, charcoal, coke, or oil.

Some modern blacksmiths may also employ an

Drawing lengthens the metal by reducing one or both of the other two dimensions. As the depth is reduced, or the width narrowed, the piece is lengthened or "drawn out."

As an example of drawing, a smith making a chisel might flatten a square bar of steel, lengthening the metal, reducing its depth but keeping its width consistent.

Drawing does not have to be uniform. A taper can result as in making a wedge or a woodworking chisel blade. If tapered in two dimensions, a point results.

Drawing can be accomplished with a variety of tools and methods. Two typical methods using only hammer and anvil would be hammering on the anvil horn, and hammering on the anvil face using the cross peen of a hammer.

Another method for drawing is to use a tool called a fuller, or the peen of the hammer, to hasten the drawing out of a thick piece of metal. (The technique is called fullering from the tool.) Fullering consists of hammering a series of indentations with corresponding ridges, perpendicular to the long section of the piece being drawn. The resulting effect looks somewhat like waves along the top of the piece. Then the smith turns the hammer over to use the flat face to hammer the tops of the ridges down level with the bottoms of the indentations. This forces the metal to grow in length (and width if left unchecked) much faster than just hammering with the flat face of the hammer.

Drawing lengthens the metal by reducing one or both of the other two dimensions. As the depth is reduced, or the width narrowed, the piece is lengthened or "drawn out."

As an example of drawing, a smith making a chisel might flatten a square bar of steel, lengthening the metal, reducing its depth but keeping its width consistent.

Drawing does not have to be uniform. A taper can result as in making a wedge or a woodworking chisel blade. If tapered in two dimensions, a point results.

Drawing can be accomplished with a variety of tools and methods. Two typical methods using only hammer and anvil would be hammering on the anvil horn, and hammering on the anvil face using the cross peen of a hammer.

Another method for drawing is to use a tool called a fuller, or the peen of the hammer, to hasten the drawing out of a thick piece of metal. (The technique is called fullering from the tool.) Fullering consists of hammering a series of indentations with corresponding ridges, perpendicular to the long section of the piece being drawn. The resulting effect looks somewhat like waves along the top of the piece. Then the smith turns the hammer over to use the flat face to hammer the tops of the ridges down level with the bottoms of the indentations. This forces the metal to grow in length (and width if left unchecked) much faster than just hammering with the flat face of the hammer.

Heating iron to a "forging heat" allows bending as if it were a soft,

Heating iron to a "forging heat" allows bending as if it were a soft,

A modern blacksmith has a range of options and tools to accomplish this. The basic types of welding commonly employed in a modern workshop include traditional

A modern blacksmith has a range of options and tools to accomplish this. The basic types of welding commonly employed in a modern workshop include traditional  The dressed metal goes back in the fire, is brought near to welding heat, removed from the fire, and brushed. Flux is sometimes applied, which prevents oxygen from reaching and burning the metal during forging, and it is returned to the fire. The smith now watches carefully to avoid overheating the metal. There is some challenge to this because, to see the color of the metal, the smith must remove it from the fire—exposing it to air, which can rapidly oxidize it. So the smith might probe into the fire with a bit of steel wire, prodding lightly at the mating faces. When the end of the wire sticks on to the metal, it is at the right temperature (a small weld forms where the wire touches the mating face, so it sticks). The smith commonly places the metal in the fire so he can see it without letting surrounding air contact the surface. (Note that smiths don't always use flux, especially in the UK.)

Now the smith moves with rapid purpose, quickly taking the metal from the fire to the anvil and bringing the mating faces together. A few light hammer taps bring the mating faces into complete contact and squeeze out the flux—and finally, the smith returns the work to the fire. The weld begins with the taps, but often the joint is weak and incomplete, so the smith reheats the joint to welding temperature and works the weld with light blows to "set" the weld and finally to dress it to the shape.

The dressed metal goes back in the fire, is brought near to welding heat, removed from the fire, and brushed. Flux is sometimes applied, which prevents oxygen from reaching and burning the metal during forging, and it is returned to the fire. The smith now watches carefully to avoid overheating the metal. There is some challenge to this because, to see the color of the metal, the smith must remove it from the fire—exposing it to air, which can rapidly oxidize it. So the smith might probe into the fire with a bit of steel wire, prodding lightly at the mating faces. When the end of the wire sticks on to the metal, it is at the right temperature (a small weld forms where the wire touches the mating face, so it sticks). The smith commonly places the metal in the fire so he can see it without letting surrounding air contact the surface. (Note that smiths don't always use flux, especially in the UK.)

Now the smith moves with rapid purpose, quickly taking the metal from the fire to the anvil and bringing the mating faces together. A few light hammer taps bring the mating faces into complete contact and squeeze out the flux—and finally, the smith returns the work to the fire. The weld begins with the taps, but often the joint is weak and incomplete, so the smith reheats the joint to welding temperature and works the weld with light blows to "set" the weld and finally to dress it to the shape.

Depending on the intended use of the piece, a blacksmith may finish it in a number of ways:

* A simple jig (a tool) that the smith might only use a few times in the shop may get the minimum of finishing—a rap on the anvil to break off scale and a brushing with a wire brush.

* Files bring a piece to final shape, removing burrs and sharp edges, and smoothing the surface.

*

Depending on the intended use of the piece, a blacksmith may finish it in a number of ways:

* A simple jig (a tool) that the smith might only use a few times in the shop may get the minimum of finishing—a rap on the anvil to break off scale and a brushing with a wire brush.

* Files bring a piece to final shape, removing burrs and sharp edges, and smoothing the surface.

*

A blacksmith's striker is an assistant (frequently an apprentice) whose job is to swing a large sledgehammer in heavy forging operations, as directed by the blacksmith. In practice, the blacksmith holds the hot iron at the anvil (with tongs) in one hand, and indicates where to strike the iron by tapping it with a small hammer in the other hand. The striker then delivers a heavy blow to the indicated spot with a sledgehammer. During the 20th century and into the 21st century, this role has become increasingly unnecessary and automated through the use of

A blacksmith's striker is an assistant (frequently an apprentice) whose job is to swing a large sledgehammer in heavy forging operations, as directed by the blacksmith. In practice, the blacksmith holds the hot iron at the anvil (with tongs) in one hand, and indicates where to strike the iron by tapping it with a small hammer in the other hand. The striker then delivers a heavy blow to the indicated spot with a sledgehammer. During the 20th century and into the 21st century, this role has become increasingly unnecessary and automated through the use of

*

*

In Hindu mythology,

In Hindu mythology,  The Anglo-Saxon Wayland Smith, known in

The Anglo-Saxon Wayland Smith, known in  Seppo Ilmarinen, the Eternal Hammerer, blacksmith and inventor in the ''

Seppo Ilmarinen, the Eternal Hammerer, blacksmith and inventor in the ''

When historical records resume after the 1200 BC upheavals and the ensuing

When historical records resume after the 1200 BC upheavals and the ensuing

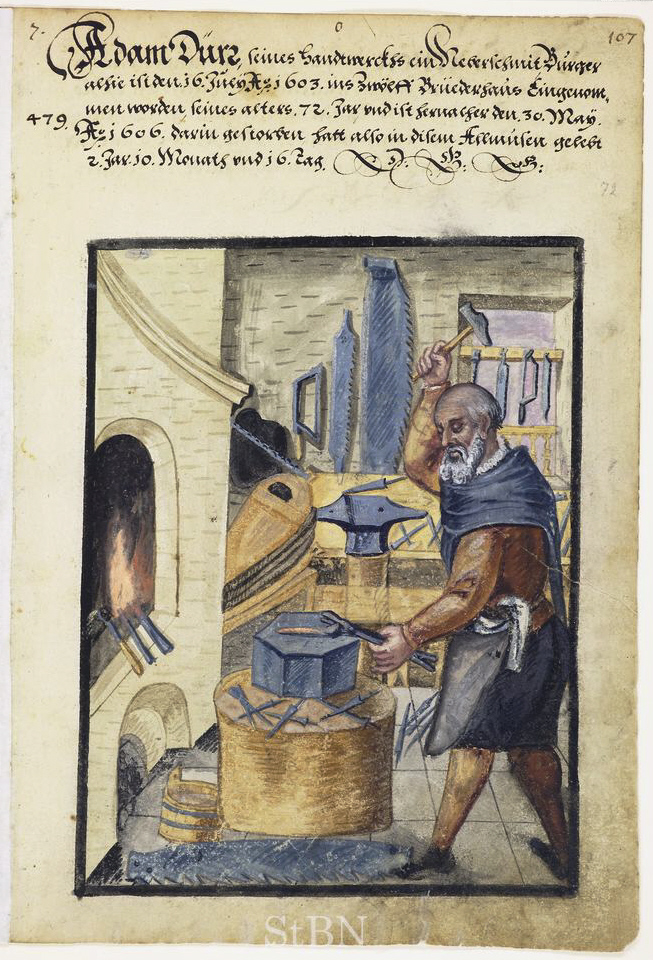

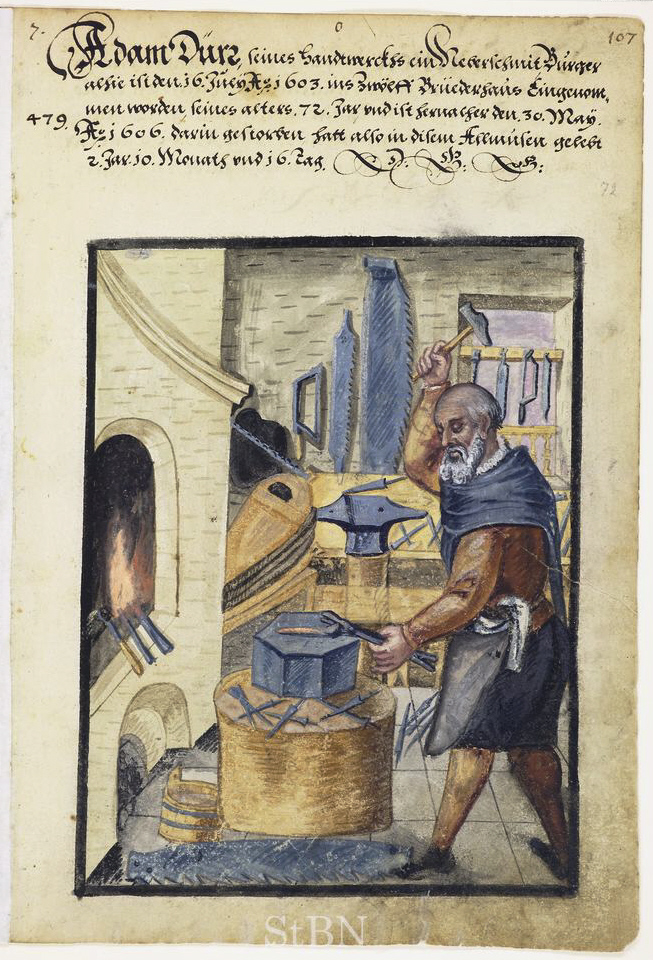

In the medieval period, blacksmithing was considered part of the set of '' seven mechanical arts''.

Prior to the

In the medieval period, blacksmithing was considered part of the set of '' seven mechanical arts''.

Prior to the

During the first half of the nineteenth century, the US government included in their treaties with many Native American tribes, that the US would employ blacksmiths and strikers at

During the first half of the nineteenth century, the US government included in their treaties with many Native American tribes, that the US would employ blacksmiths and strikers at

A renewed interest in blacksmithing occurred as part of the trend in "do-it-yourself" and "self-sufficiency" that occurred during the 1970s. Currently there are many books, organizations and individuals working to help educate the public about blacksmithing, including local groups of smiths who have formed clubs, with some of those smiths demonstrating at historical sites and living history events. Some modern blacksmiths who produce decorative metalwork refer to themselves as artist-blacksmiths. In 1973 the Artists Blacksmiths’ Association of North America was formed with 27 members. By 2013 it had almost 4000 members. Likewise the British Artist Blacksmiths Association was created in 1978, with 30 charter members and had about 600 members in 2013 and publish for members a quarterly magazine.

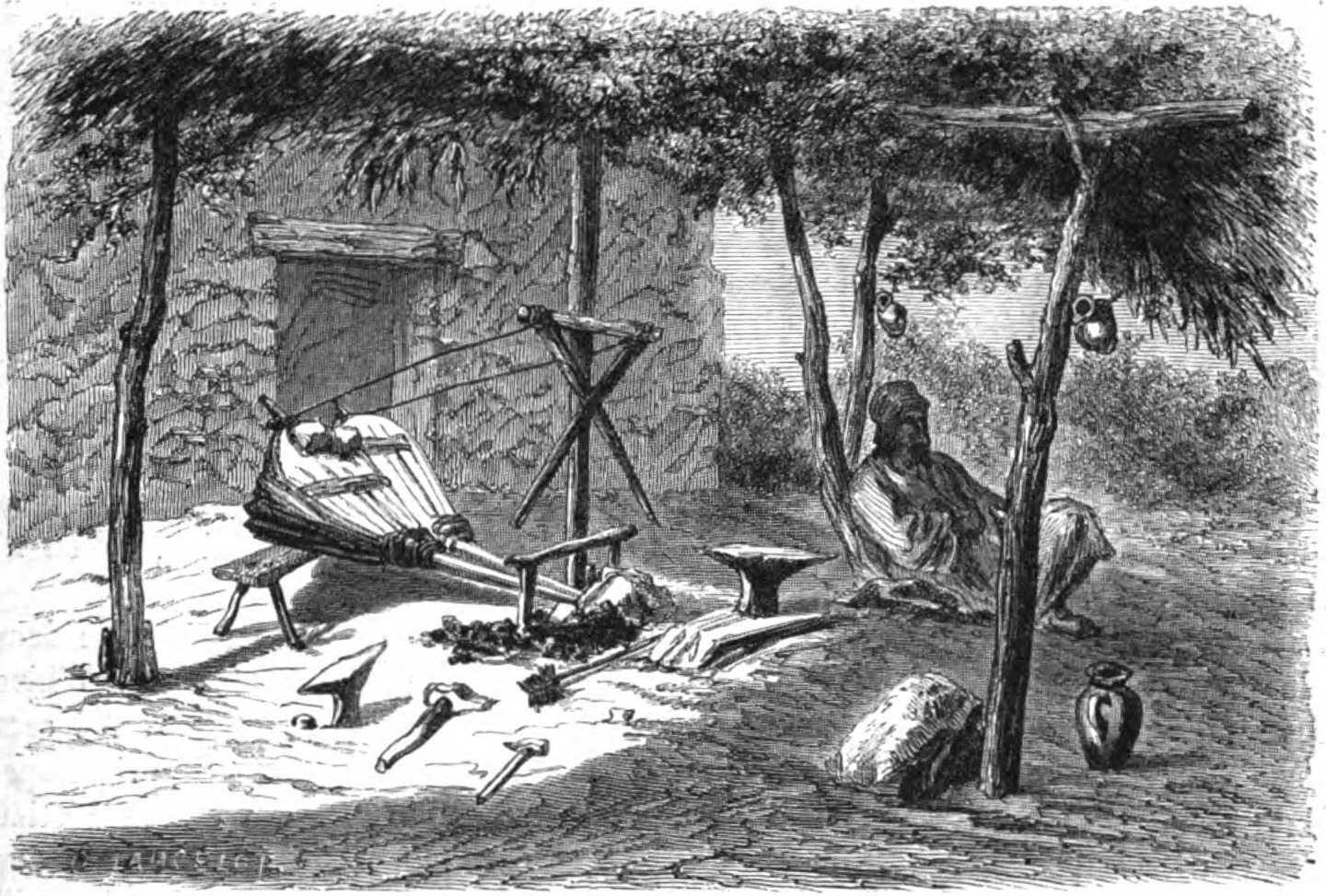

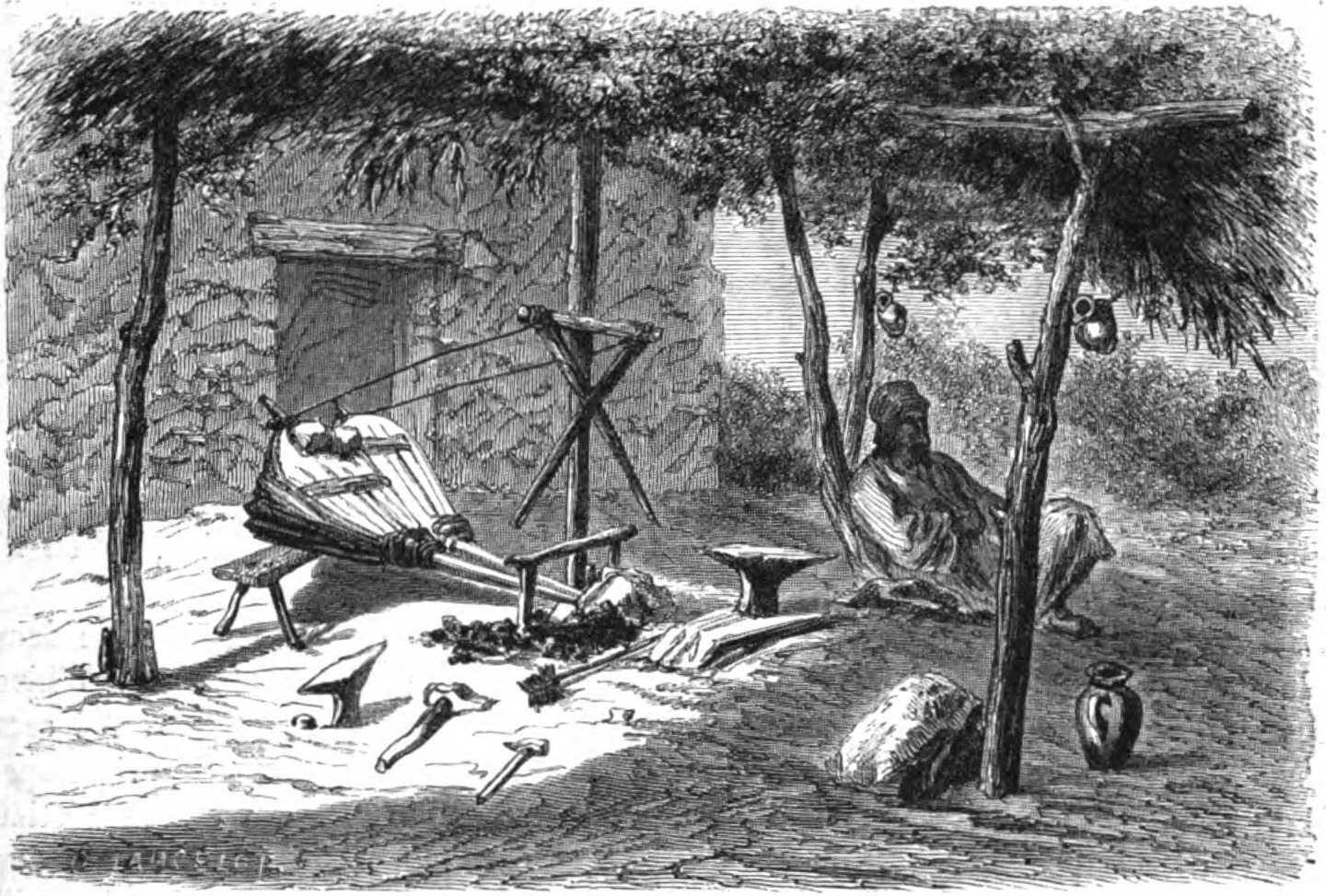

While developed nations saw a decline and re-awakening of interest in blacksmithing, in many developing nations blacksmiths continued doing what blacksmiths have been doing for 3500 years: making and repairing iron and steel tools and hardware for people in their local area.

A renewed interest in blacksmithing occurred as part of the trend in "do-it-yourself" and "self-sufficiency" that occurred during the 1970s. Currently there are many books, organizations and individuals working to help educate the public about blacksmithing, including local groups of smiths who have formed clubs, with some of those smiths demonstrating at historical sites and living history events. Some modern blacksmiths who produce decorative metalwork refer to themselves as artist-blacksmiths. In 1973 the Artists Blacksmiths’ Association of North America was formed with 27 members. By 2013 it had almost 4000 members. Likewise the British Artist Blacksmiths Association was created in 1978, with 30 charter members and had about 600 members in 2013 and publish for members a quarterly magazine.

While developed nations saw a decline and re-awakening of interest in blacksmithing, in many developing nations blacksmiths continued doing what blacksmiths have been doing for 3500 years: making and repairing iron and steel tools and hardware for people in their local area.

* Blacksmiths festival, an annual festival that takes place in Ivano-Frankivsk

* Blacksmith Scene (also, known as Blacksmith Scene #1 and Blacksmithing Scene)

* Bladesmith

* Hefaiston, one of the most important annual meetings of artist blacksmiths in the world (Czech Republic)

*

* Blacksmiths festival, an annual festival that takes place in Ivano-Frankivsk

* Blacksmith Scene (also, known as Blacksmith Scene #1 and Blacksmithing Scene)

* Bladesmith

* Hefaiston, one of the most important annual meetings of artist blacksmiths in the world (Czech Republic)

*

Royal Naval Museum – Sea Your History – Blacksmiths

Find Blacksmiths In the UK with The National Directory Of Blacksmiths

'' "Be Your Own Blacksmith" '', Popular Science, January 1949

basics of being a blacksmith

(ABANA) The Artist Blacksmith's Association of North America, Inc.

Family of English blacksmiths dating back to c1550.

Blacksmith Scene (1893) (video)

Forging of Chain by Two Blacksmiths (video)

{{Authority control Metalworking occupations Articles containing video clips

wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

or steel, but sometimes from other metals

The metallic elements in the periodic table located between the transition metals and the chemically weak nonmetallic metalloids have received many names in the literature, such as ''post-transition metals'', ''poor metals'', ''other metals'', ...

, by forging the metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typicall ...

, using tools to hammer, bend, and cut (cf. tinsmith

A tinsmith is a person who makes and repairs things made of tin or other light metals. The profession may sometimes also be known as a tinner, tinker, tinman, or tinplate worker; whitesmith may also refer to this profession, though the same w ...

). Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was an historical distinction between the heavy work of the blacksmith and the more delicate operation of a whitesmith, who usually worked in gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile me ...

, silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

, pewter

Pewter () is a malleable metal alloy consisting of tin (85–99%), antimony (approximately 5–10%), copper (2%), bismuth, and sometimes silver. Copper and antimony (and in antiquity lead) act as hardeners, but lead may be used in lower grades ...

, or the finishing steps of fine steel. The place where a blacksmith works is called variously a smithy, a forge or a blacksmith's shop.

While there are many people who work with metal such as farrier

A farrier is a specialist in equine hoof care, including the trimming and balancing of horses' hooves and the placing of shoes on their hooves, if necessary. A farrier combines some blacksmith's skills (fabricating, adapting, and adj ...

s, wheelwright

A wheelwright is a craftsman who builds or repairs wooden wheels. The word is the combination of "wheel" and the word "wright", (which comes from the Old English word "''wryhta''", meaning a worker or shaper of wood) as in shipwright and arkwr ...

s, and armorers, in former times the blacksmith had a general knowledge of how to make and repair many things, from the most complex of weapons and armor to simple things like nails or lengths of chain.

Etymology

The "black" in "blacksmith" refers to the black firescale, a layer of oxides that forms on the surface of the metal during heating. The origin of smith is theOld English

Old English (, ), or Anglo-Saxon, is the earliest recorded form of the English language, spoken in England and southern and eastern Scotland in the early Middle Ages. It was brought to Great Britain by Anglo-Saxon settlers in the mid-5th c ...

word ''smið'' meaning "blacksmith", originating from the Proto-Germanic

Proto-Germanic (abbreviated PGmc; also called Common Germanic) is the reconstructed proto-language of the Germanic branch of the Indo-European languages.

Proto-Germanic eventually developed from pre-Proto-Germanic into three Germanic bran ...

''*smithaz'' meaning "skilled worker."

Smithing process

Blacksmiths work by heating pieces of wrought iron or steel until the metal becomes soft enough for shaping with hand tools, such as a hammer, an anvil and a chisel. Heating generally takes place in a forge fueled by propane, natural gas, coal, charcoal, coke, or oil.

Some modern blacksmiths may also employ an

Blacksmiths work by heating pieces of wrought iron or steel until the metal becomes soft enough for shaping with hand tools, such as a hammer, an anvil and a chisel. Heating generally takes place in a forge fueled by propane, natural gas, coal, charcoal, coke, or oil.

Some modern blacksmiths may also employ an oxyacetylene

Principle of burn cutting

Oxy-fuel welding (commonly called oxyacetylene welding, oxy welding, or gas welding in the United States) and oxy-fuel cutting are processes that use fuel gases (or liquid fuels such as gasoline or petrol, diesel, ...

or similar blowtorch

A blowtorch, also referred to as a blowlamp, is an ambient air fuel-burning gas lamp used for applying flame and heat to various applications, usually metalworking.

Early blowtorches used liquid fuel, carried in a refillable reservoir attach ...

for more localized heating. Induction heating

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an induction coil that creates an electromagnetic field within th ...

methods are gaining popularity among modern blacksmiths.

Color is important for indicating the temperature and workability of the metal. As iron heats to higher temperatures, it first glows red, then orange, yellow, and finally white. The ideal heat for most forging is the bright yellow-orange color that indicates ''forging heat''. Because they must be able to see the glowing color of the metal, some blacksmiths work in dim, low-light conditions, but most work in well-lit conditions. The key is to have consistent lighting, but not too bright. Direct sunlight obscures the colors.

The techniques of smithing

A metalsmith or simply smith is a craftsperson fashioning useful items (for example, tools, kitchenware, tableware, jewelry, armor and weapons) out of various metals. Smithing is one of the oldest metalworking occupations. Shaping metal with a h ...

can be roughly divided into forging (sometimes called "sculpting"), welding, heat-treating, and finishing.

Forging

Forging—the process smiths use to shape metal by hammering—differs from machining in that forging does not remove material. Instead, the smith hammers the iron into shape. Even punching and cutting operations (except when trimming waste) by smiths usually re-arrange metal around the hole, rather than drilling it out as swarf. Forging uses seven basic operations or techniques: * Drawing down * Shrinking (a type of upsetting) * Bending * Upsetting *Swaging

Swaging () is a forging process in which the dimensions of an item are altered using dies into which the item is forced. Swaging is usually a cold working process, but also may be hot worked.

The term swage may apply to the process (verb) or ...

* Punching

* Forge welding

These operations generally require at least a hammer and anvil, but smiths also use other tools and techniques to accommodate odd-sized or repetitive jobs.

Drawing

Bending

Heating iron to a "forging heat" allows bending as if it were a soft,

Heating iron to a "forging heat" allows bending as if it were a soft, ductile

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stres ...

metal, like copper or silver.

Bending can be done with the hammer over the horn or edge of the anvil or by inserting a bending fork into the hardy hole (the square hole in the top of the anvil), placing the work piece between the tines of the fork, and bending the material to the desired angle. Bends can be dressed and tightened, or widened, by hammering them over the appropriately shaped part of the anvil.

Some metals are "hot short", meaning they lose their tensile strength when heated. They become like Plasticine

Plasticine is a putty-like modelling material made from calcium salts, petroleum jelly and aliphatic acids. Though originally a brand name for the British version of the product, it is now applied generically in English as a product category ...

: although they may still be manipulated by squeezing, an attempt to stretch them, even by bending or twisting, is likely to have them crack and break apart. This is a problem for some blade-making steels, which must be worked carefully to avoid developing hidden cracks that would cause failure in the future. Though rarely hand-worked, titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

is notably hot short. Even such common smithing processes as decoratively twisting a bar are impossible with it.

Upsetting

Upsetting is the process of making metal thicker in one dimension through shortening in the other. One form is to heat the end of a rod and then hammer on it as one would drive a nail: the rod gets shorter, and the hot part widens. An alternative to hammering on the hot end is to place the hot end on the anvil and hammer on the cold end.Punching

Punching may be done to create a decorative pattern, or to make a hole. For example, in preparation for making a hammerhead, a smith would punch a hole in a heavy bar or rod for the hammer handle. Punching is not limited to depressions and holes. It also includes cutting, slitting, and drifting—all done with a chisel.Combining processes

The five basic forging processes are often combined to produce and refine the shapes necessary for finished products. For example, to fashion a cross-peen hammer head, a smith would start with a bar roughly the diameter of the hammer face: the handle hole would be punched and drifted (widened by inserting or passing a larger tool through it), the head would be cut (punched, but with a wedge), the peen would be drawn to a wedge, and the face would be dressed by upsetting. As with making a chisel, since it is lengthened by drawing it would also tend to spread in width. A smith would therefore frequently turn the chisel-to-be on its side and hammer it back down—upsetting it—to check the spread and keep the metal at the correct width. Or, if a smith needed to put a 90-degree bend in a bar and wanted a sharp corner on the outside of the bend, they would begin by hammering an unsupported end to make the curved bend. Then, to "fatten up" the outside radius of the bend, one or both arms of the bend would need to be pushed back to fill the outer radius of the curve. So they would hammer the ends of the stock down into the bend, 'upsetting' it at the point of the bend. They would then dress the bend by drawing the sides of the bend to keep the correct thickness. The hammering would continue—upsetting and then drawing—until the curve had been properly shaped. In the primary operation was the bend, but the drawing and upsetting are done to refine the shape.Welding

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as bra ...

is the joining of the same or similar kind of metal.

A modern blacksmith has a range of options and tools to accomplish this. The basic types of welding commonly employed in a modern workshop include traditional

A modern blacksmith has a range of options and tools to accomplish this. The basic types of welding commonly employed in a modern workshop include traditional forge welding

Forge welding (FOW), also called fire welding, is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together ...

as well as modern methods, including oxyacetylene and arc welding

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals. It is a type of welding that uses a welding powe ...

.

In forge welding, the pieces to join are heated to what is generally referred to as ''welding heat''. For mild steel most smiths judge this temperature by color: the metal glows an intense yellow or white. At this temperature the steel is near molten.

Any foreign material in the weld, such as the oxides or "scale" that typically form in the fire, can weaken it and cause it to fail. Thus the mating surfaces to be joined must be kept clean. To this end a smith makes sure the fire is a reducing fire: a fire where, at the heart, there is a great deal of heat and very little oxygen. The smith also carefully shapes mating faces so that as they come together foreign material squeezes out as the metal is joined. To clean the faces, protect them from oxidation, and provide a medium to carry foreign material out of the weld, the smith sometimes uses flux—typically powdered borax, silica sand, or both.

The smith first cleans parts to be joined with a wire brush, then puts them in the fire to heat. With a mix of drawing and upsetting the smith shapes the faces so that when finally brought together, the center of the weld connects first and the connection spreads outward under the hammer blows, pushing out the flux (if used) and foreign material.

Finishing

Depending on the intended use of the piece, a blacksmith may finish it in a number of ways:

* A simple jig (a tool) that the smith might only use a few times in the shop may get the minimum of finishing—a rap on the anvil to break off scale and a brushing with a wire brush.

* Files bring a piece to final shape, removing burrs and sharp edges, and smoothing the surface.

*

Depending on the intended use of the piece, a blacksmith may finish it in a number of ways:

* A simple jig (a tool) that the smith might only use a few times in the shop may get the minimum of finishing—a rap on the anvil to break off scale and a brushing with a wire brush.

* Files bring a piece to final shape, removing burrs and sharp edges, and smoothing the surface.

* Heat treatment

Heat treating (or heat treatment) is a group of industrial process, industrial, thermal and metalworking, metalworking processes used to alter the physical property, physical, and sometimes chemical property, chemical, properties of a material. ...

and case-hardening

Case-hardening or surface hardening is the process of hardening the surface of a metal object while allowing the metal deeper underneath to remain soft, thus forming a thin layer of harder metal at the surface. For iron or steel with low carbon ...

achieve the desired hardness.

* The wire brush—as a hand tool or power tool—can further smooth, brighten, and polish surfaces.

* Grinding stones, abrasive paper, and emery wheels can further shape, smooth, and polish the surface.

A range of treatments and finishes can inhibit oxidation and enhance or change the appearance of the piece. An experienced smith selects the finish based on the metal and on the intended use of the item. Finishes include (among others): paint, varnish, bluing, browning, oil, and wax.

Blacksmith's striker

A blacksmith's striker is an assistant (frequently an apprentice) whose job is to swing a large sledgehammer in heavy forging operations, as directed by the blacksmith. In practice, the blacksmith holds the hot iron at the anvil (with tongs) in one hand, and indicates where to strike the iron by tapping it with a small hammer in the other hand. The striker then delivers a heavy blow to the indicated spot with a sledgehammer. During the 20th century and into the 21st century, this role has become increasingly unnecessary and automated through the use of

A blacksmith's striker is an assistant (frequently an apprentice) whose job is to swing a large sledgehammer in heavy forging operations, as directed by the blacksmith. In practice, the blacksmith holds the hot iron at the anvil (with tongs) in one hand, and indicates where to strike the iron by tapping it with a small hammer in the other hand. The striker then delivers a heavy blow to the indicated spot with a sledgehammer. During the 20th century and into the 21st century, this role has become increasingly unnecessary and automated through the use of trip hammer

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, wikt:decorticate, decorticating and polishing of grain in agriculture. In mining, trip hammers were used f ...

s or reciprocating power hammers.

Blacksmith's materials

When ironore

Ore is natural rock or sediment that contains one or more valuable minerals, typically containing metals, that can be mined, treated and sold at a profit.Encyclopædia Britannica. "Ore". Encyclopædia Britannica Online. Retrieved 7 Apr ...

is smelted into usable metal, a certain amount of carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon mak ...

is usually alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

ed with the iron. (Charcoal is almost pure carbon.) The amount of carbon significantly affects the properties of the metal. If the carbon content is over 2%, the metal is called cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

, because it has a relatively low melting point and is easily cast. It is quite brittle, however, and cannot be forged so therefore not used for blacksmithing. If the carbon content is between 0.25% and 2%, the resulting metal is tool steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive har ...

, which can be heat treated as discussed above. When the carbon content is below 0.25%, the metal is either "wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

(wrought iron is not smelted and cannot come from this process) " or "mild steel." The terms are never interchangeable. In preindustrial times, the material of choice for blacksmiths was wrought iron. This iron had a very low carbon content, and also included up to 5% of glassy iron silicate slag in the form of numerous very fine stringers. This slag content made the iron very tough, gave it considerable resistance to rusting, and allowed it to be more easily "forge welded," a process in which the blacksmith permanently joins two pieces of iron, or a piece of iron and a piece of steel, by heating them nearly to a white heat and hammering them together. Forge welding is more difficult with modern mild steel, because it welds in a narrower temperature band. The fibrous nature of wrought iron required knowledge and skill to properly form any tool which would be subject to stress. Modern steel is produced using either the blast furnace or arc furnaces. Wrought iron was produced by a labor-intensive process called ''puddling'', so this material is now a difficult-to-find specialty product. Modern blacksmiths generally substitute mild steel for making objects traditionally of wrought iron. Sometimes they use electrolytic-process pure iron.

Other metals

Many blacksmiths also incorporate materials such as bronze,copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

, or brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other wit ...

in artistic products. Aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

and titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

may also be forged by the blacksmith's process. Bronze is an alloy of copper and tin, while brass is an alloy of copper and zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodi ...

. Each material responds differently under the hammer and must be separately studied by the blacksmith.

Terminology

*

* Iron

Iron () is a chemical element with Symbol (chemistry), symbol Fe (from la, Wikt:ferrum, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 element, group 8 of the periodic table. It is, Abundanc ...

is a naturally occurring metallic element. It is almost never found in its native form (pure iron) in nature. It is usually found as an oxide or sulfide, with many other impurity elements mixed in.

* Wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

is the purest form of iron generally encountered or produced in quantity. It may contain as little as 0.04% carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon mak ...

(by weight). From its traditional method of manufacture, wrought iron has a fibrous internal texture. Quality wrought-iron blacksmithing takes the direction of these fibers into account during forging, since the strength of the material is stronger in line with the grain than across the grain. Most of the remaining impurities from the initial smelting become concentrated in silicate slag trapped between the iron fibers. This slag produces a lucky side effect during forge-welding. When the silicate melts, it makes wrought iron self-fluxing. The slag becomes a liquid glass that covers the exposed surfaces of the wrought iron, preventing oxidation which would otherwise interfere with the successful welding process.

* Steel is an alloy of iron and between 0.3% and 1.7% carbon by weight. The presence of carbon allows steel to assume one of several different crystalline configurations. Macroscopically, this is seen as the ability to "turn the hardness of a piece of steel on and off" through various processes of heat-treatment. If the concentration of carbon is held constant, this is a reversible process. Steel with a higher carbon percentage may be brought to a higher state of maximum hardness.

* Cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

is iron that contains between 2.0% to 6% carbon by weight. There is so much carbon present that the hardness cannot be switched off. Hence, cast iron is a brittle metal, which can break like glass. Cast iron cannot be forged without special heat treatment to convert it to malleable iron.

Steel with less than 0.6% carbon content cannot be hardened enough by simple heat-treatment to make useful hardened-steel tools. Hence, in what follows, wrought-iron, low-carbon-steel, and other soft unhardenable iron varieties are referred to indiscriminately as just ''iron''.

History, prehistory, religion, and mythology

Mythology

In Hindu mythology,

In Hindu mythology, Tvastar

Tvashtr ( sa, त्वष्टृ, Tvaṣṭṛ) is a Vedic artisan god or fashioner. He is also mentioned in later literature of Hinduism like the ''Harivamsa''. Sometimes, Tvashtr is identified with another deity named Vishvakarma. In Hindu ...

also known as Vishvakarma is the blacksmith of the devas. The earliest references of Tvastar

Tvashtr ( sa, त्वष्टृ, Tvaṣṭṛ) is a Vedic artisan god or fashioner. He is also mentioned in later literature of Hinduism like the ''Harivamsa''. Sometimes, Tvashtr is identified with another deity named Vishvakarma. In Hindu ...

can be found in the Rigveda

The ''Rigveda'' or ''Rig Veda'' ( ', from ' "praise" and ' "knowledge") is an ancient Indian collection of Vedic Sanskrit hymns (''sūktas''). It is one of the four sacred canonical Hindu texts ('' śruti'') known as the Vedas. Only one ...

.

Hephaestus

Hephaestus (; eight spellings; grc-gre, Ἥφαιστος, Hḗphaistos) is the Greek god of blacksmiths, metalworking, carpenters, craftsmen, artisans, sculptors, metallurgy, fire (compare, however, with Hestia), and volcanoes.Walter B ...

(Latin: Vulcan

Vulcan may refer to:

Mythology

* Vulcan (mythology), the god of fire, volcanoes, metalworking, and the forge in Roman mythology

Arts, entertainment and media Film and television

* Vulcan (''Star Trek''), name of a fictional race and their home p ...

) was the blacksmith of the gods

A deity or god is a supernatural being who is considered divine or sacred. The ''Oxford Dictionary of English'' defines deity as a god or goddess, or anything revered as divine. C. Scott Littleton defines a deity as "a being with powers greater ...

in Greek

Greek may refer to:

Greece

Anything of, from, or related to Greece, a country in Southern Europe:

*Greeks, an ethnic group.

*Greek language, a branch of the Indo-European language family.

**Proto-Greek language, the assumed last common ancestor ...

and Roman mythology

Roman mythology is the body of myths of ancient Rome as represented in the literature and visual arts of the Romans. One of a wide variety of genres of Roman folklore, ''Roman mythology'' may also refer to the modern study of these representa ...

. A supremely skilled artisan whose forge was a volcano, he constructed most of the weapons of the gods, as well as beautiful assistants for his smithy and a metal fishing-net of astonishing intricacy. He was the god of metalworking, fire, and craftsmen.

In Celtic mythology, the role of Smith is held by eponymous (their names do mean 'smith') characters : Goibhniu

In Irish mythology, Goibniu (pronounced , modern spelling: Gaibhne) was the metalsmith of the Tuatha Dé Danann. He is believed to have been a smithing god and is also associated with hospitality. His name is related to the Welsh Gofannon and the ...

(Irish myths of the Tuatha Dé Danann cycle) or Gofannon

Gofannon () is a Middle Welsh reflex of Gobannus, one of the deities worshipped by the ancient Celts. He features in Middle Welsh literature as a great metal worker and as the son of Dôn. His name can be compared with the Old Irish ''gobae'' ( ...

(Welsh myths/ the Mabinogion). Brigid

Brigid ( , ; meaning 'exalted one' from Old Irish),Campbell, MikBehind the Name.See also Xavier Delamarre, ''brigantion / brigant-'', in ''Dictionnaire de la langue gauloise'' (Éditions Errance, 2003) pp. 87–88: "Le nom de la sainte irlandais ...

or Brigit, an Irish goddess, is sometimes described as the patroness of blacksmiths.

In the Nart mythology of the Caucasus

The Caucasus () or Caucasia (), is a region between the Black Sea and the Caspian Sea, mainly comprising Armenia, Azerbaijan, Georgia (country), Georgia, and parts of Southern Russia. The Caucasus Mountains, including the Greater Caucasus range ...

the hero known to the Ossetians as Kurdalægon and the Circassians

The Circassians (also referred to as Cherkess or Adyghe; Adyghe and Kabardian: Адыгэхэр, romanized: ''Adıgəxər'') are an indigenous Northwest Caucasian ethnic group and nation native to the historical country-region of Circassia ...

as Tlepsh Tlepsh ( Adyghe Лъэпш ) is a mythological figure who appears (as a blacksmith and also a powerful leader) in some cycles of the Nart sagas of the Caucasus, in which his Ossetian counterpart is the smith Kurdalægon. Tlepsh's name is a borrowi ...

is a blacksmith and skilled craftsman whose exploits exhibit shaman

Shamanism is a religious practice that involves a practitioner (shaman) interacting with what they believe to be a spirit world through altered states of consciousness, such as trance. The goal of this is usually to direct spirits or spir ...

ic features, sometimes bearing comparison to those of the Scandinavian deity Odin. One of his greatest feats is acting as a type of male midwife

A midwife is a health professional who cares for mothers and newborns around childbirth, a specialization known as midwifery.

The education and training for a midwife concentrates extensively on the care of women throughout their lifespan; co ...

to the hero Xamyc, who has been made the carrier of the embryo of his son Batraz by his dying wife the water-sprite Lady Isp, who spits it between his shoulder blades, where it forms a womb-like cyst. Kurdalaegon prepares a type of tower or scaffold above a quenching bath for Xamyc, and, when the time is right, lances the cyst to liberate the infant hero Batraz as a newborn babe of white-hot steel, whom Kurdalægon then quenches like a newly forged sword.

The Anglo-Saxon Wayland Smith, known in

The Anglo-Saxon Wayland Smith, known in Old Norse

Old Norse, Old Nordic, or Old Scandinavian, is a stage of development of North Germanic dialects before their final divergence into separate Nordic languages. Old Norse was spoken by inhabitants of Scandinavia and their overseas settlemen ...

as Völundr, is a heroic blacksmith in Germanic mythology. The Poetic Edda

The ''Poetic Edda'' is the modern name for an untitled collection of Old Norse anonymous narrative poems, which is distinct from the ''Prose Edda'' written by Snorri Sturluson. Several versions exist, all primarily of text from the Icelandic med ...

states that he forged beautiful gold rings set with wonderful gems. He was captured by king Níðuðr, who cruelly hamstrung him and imprisoned him on an island. Völundr eventually had his revenge by killing Níðuðr's sons and fashioning goblets

A chalice (from Latin 'mug', borrowed from Ancient Greek () 'cup') or goblet is a footed cup intended to hold a drink. In religious practice, a chalice is often used for drinking during a ceremony or may carry a certain symbolic meaning.

R ...

from their skulls, jewels from their eyes and a brooch

A brooch (, also ) is a decorative jewelry item designed to be attached to garments, often to fasten them together. It is usually made of metal, often silver or gold or some other material. Brooches are frequently decorated with enamel or with g ...

from their teeth. He then rape

Rape is a type of sexual assault usually involving sexual intercourse or other forms of sexual penetration carried out against a person without their consent. The act may be carried out by physical force, coercion, abuse of authority, or ...

d the king's daughter, after drugging her with strong beer, and escaped, laughing, on wings of his own making, boasting that he had fathered a child upon her.

Seppo Ilmarinen, the Eternal Hammerer, blacksmith and inventor in the ''

Seppo Ilmarinen, the Eternal Hammerer, blacksmith and inventor in the ''Kalevala

The ''Kalevala'' ( fi, Kalevala, ) is a 19th-century work of epic poetry compiled by Elias Lönnrot from Karelian and Finnish oral folklore and mythology, telling an epic story about the Creation of the Earth, describing the controversies and ...

'', is an archetypal artificer from Finnish

Finnish may refer to:

* Something or someone from, or related to Finland

* Culture of Finland

* Finnish people or Finns, the primary ethnic group in Finland

* Finnish language, the national language of the Finnish people

* Finnish cuisine

See also ...

mythology.

Tubal-Cain

Tubal-cain or Tubalcain ( he, תּוּבַל קַיִן – ''Tūḇal Qayīn'') is a person mentioned in the Bible, in , known for being the first blacksmith. He is stated as the "forger of all instruments of bronze and iron". A descendant of C ...

is mentioned in the book of Genesis

The Book of Genesis (from Greek ; Hebrew: בְּרֵאשִׁית ''Bəreʾšīt'', "In hebeginning") is the first book of the Hebrew Bible and the Christian Old Testament. Its Hebrew name is the same as its first word, ( "In the beginning" ...

of the Torah

The Torah (; hbo, ''Tōrā'', "Instruction", "Teaching" or "Law") is the compilation of the first five books of the Hebrew Bible, namely the books of Genesis, Exodus, Leviticus, Numbers and Deuteronomy. In that sense, Torah means the ...

as the original smith.

Ogun

Ogun or Ogoun (Yoruba: Ògún, Portuguese: Ogum, Gu; also spelled Oggun or Ogou; known as Ogún or Ogum in Latin America) is a spirit that appears in several African religions. He attempted to seize the throne after the demise of Obatala, who ...

, the god of blacksmiths, warriors, hunters and others who work with iron is one of the pantheon of Orisha traditionally worshipped by the Yoruba people

The Yoruba people (, , ) are a West African ethnic group that mainly inhabit parts of Nigeria, Benin, and Togo. The areas of these countries primarily inhabited by Yoruba are often collectively referred to as Yorubaland. The Yoruba constitut ...

of Nigeria

Nigeria ( ), , ig, Naìjíríyà, yo, Nàìjíríà, pcm, Naijá , ff, Naajeeriya, kcg, Naijeriya officially the Federal Republic of Nigeria, is a country in West Africa. It is situated between the Sahel to the north and the Gulf o ...

.

Before the Iron Age

Gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile me ...

, silver

Silver is a chemical element with the symbol Ag (from the Latin ', derived from the Proto-Indo-European ''h₂erǵ'': "shiny" or "white") and atomic number 47. A soft, white, lustrous transition metal, it exhibits the highest electrical ...

, and copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

all occur in nature in their native states, as reasonably pure metals humans

Humans (''Homo sapiens'') are the most abundant and widespread species of primate, characterized by bipedalism and exceptional cognitive skills due to a large and complex brain. This has enabled the development of advanced tools, culture, ...

probably worked these metals first. These metals are all quite malleable

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stres ...

, and humans' initial development of hammering techniques was undoubtedly applied to these metals.

During the Chalcolithic

The Copper Age, also called the Chalcolithic (; from grc-gre, χαλκός ''khalkós'', "copper" and ''líthos'', "stone") or (A)eneolithic (from Latin '' aeneus'' "of copper"), is an archaeological period characterized by regular ...

era and the Bronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second prin ...

, humans in the Mideast learned how to smelt, melt, cast

Cast may refer to:

Music

* Cast (band), an English alternative rock band

* Cast (Mexican band), a progressive Mexican rock band

* The Cast, a Scottish musical duo: Mairi Campbell and Dave Francis

* ''Cast'', a 2012 album by Trespassers William

...

, rivet

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the ''tail''. On installation, the rivet is placed in a punched ...

, and (to a limited extent) forge copper and bronze. Bronze is an alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

of copper and approximately 10% to 20% Tin. Bronze is superior to just copper, by being harder, being more resistant to corrosion, and by having a lower melting point (thereby requiring less fuel to melt and cast). Much of the copper used by the Mediterranean World came from the island of Cyprus

Cyprus ; tr, Kıbrıs (), officially the Republic of Cyprus,, , lit: Republic of Cyprus is an island country located south of the Anatolian Peninsula in the eastern Mediterranean Sea. Its continental position is disputed; while it is ge ...

. Most of the tin came from the Cornwall

Cornwall (; kw, Kernow ) is a historic county and ceremonial county in South West England. It is recognised as one of the Celtic nations, and is the homeland of the Cornish people. Cornwall is bordered to the north and west by the Atlantic ...

region of the island of Great Britain

Great Britain is an island in the North Atlantic Ocean off the northwest coast of continental Europe. With an area of , it is the largest of the British Isles, the largest European island and the ninth-largest island in the world. It i ...

, transported by sea-borne Phoenicia

Phoenicia () was an ancient thalassocratic civilization originating in the Levant region of the eastern Mediterranean, primarily located in modern Lebanon. The territory of the Phoenician city-states extended and shrank throughout their histor ...

n and Greek

Greek may refer to:

Greece

Anything of, from, or related to Greece, a country in Southern Europe:

*Greeks, an ethnic group.

*Greek language, a branch of the Indo-European language family.

**Proto-Greek language, the assumed last common ancestor ...

traders.

Copper and bronze cannot be hardened by heat-treatment, they can only be hardened by cold working. To accomplish this, a piece of bronze is lightly hammered for a long period of time. The localized stress-cycling causes work hardening by changing the size and shape of the metal's crystals

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macros ...

. The hardened bronze can then be ground to sharpen it to make edged tools.

Clocksmiths as recently as the 19th century used work hardening techniques to harden the teeth of brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other wit ...

gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic ...

s and ratchets. Tapping on just the teeth produced harder teeth, with superior wear-resistance. By contrast, the rest of the gear was left in a softer and tougher state, more capable of resisting cracking.

Bronze is sufficiently corrosion-resistant that artifacts of bronze may last thousands of years relatively unscathed. Accordingly, museums frequently preserve more examples of Bronze Age metal-work than examples of artifacts from the much younger Iron Age

The Iron Age is the final epoch of the three-age division of the prehistory and protohistory of humanity. It was preceded by the Stone Age ( Paleolithic, Mesolithic, Neolithic) and the Bronze Age ( Chalcolithic). The concept has been mostl ...

. Buried iron artifacts may completely rust

Rust is an iron oxide, a usually reddish-brown oxide formed by the reaction of iron and oxygen in the catalytic presence of water or air moisture. Rust consists of hydrous iron(III) oxides (Fe2O3·nH2O) and iron(III) oxide-hydroxide (FeO( ...

away in less than 100 years. Examples of ancient iron work still extant are very much the exception to the norm.

Iron Age

Concurrent with the advent of alphabetic characters in theIron Age

The Iron Age is the final epoch of the three-age division of the prehistory and protohistory of humanity. It was preceded by the Stone Age ( Paleolithic, Mesolithic, Neolithic) and the Bronze Age ( Chalcolithic). The concept has been mostl ...

, humans became aware of the metal iron

Iron () is a chemical element with Symbol (chemistry), symbol Fe (from la, Wikt:ferrum, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 element, group 8 of the periodic table. It is, Abundanc ...

. However, in earlier ages, iron's qualities, in contrast to those of bronze, were not generally understood. Iron artifacts, composed of meteoric iron

Meteoric iron, sometimes meteoritic iron, is a native metal and early-universe protoplanetary-disk remnant found in meteorites and made from the elements iron and nickel, mainly in the form of the mineral phases kamacite and taenite. Meteoric ir ...

, have the chemical composition containing up to 40% nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

. As this source of this iron is extremely rare and fortuitous, little development of smithing skills peculiar to iron can be assumed to have occurred. That we still possess any such artifacts of meteoric iron may be ascribed to the vagaries of climate, and the increased corrosion-resistance conferred on iron by the presence of nickel.

During the (north) Polar Exploration of the early 20th century, Inughuit

The Inughuit (also spelled Inuhuit), or the Smith Sound Inuit, historically Arctic Highlanders, are Greenlandic Inuit. Formerly known as "Polar Eskimos", they are the northernmost group of Inuit and the northernmost people in North America, livin ...

, northern Greenlandic Inuit

Greenlanders ( kl, Kalaallit / Tunumiit / Inughuit; da, Grønlændere) are people identified with Greenland or the indigenous people, the Greenlandic Inuit (''Grønlansk Inuit''; Kalaallit, Inughuit, and Tunumiit). This connection may be r ...

, were found to be making iron knives from two particularly large nickel-iron meteors. One of these meteors was taken to Washington, D.C.

)

, image_skyline =

, image_caption = Clockwise from top left: the Washington Monument and Lincoln Memorial on the National Mall, United States Capitol, Logan Circle, Jefferson Memorial, White House, Adams Morgan, ...

, where it was remitted to the custody of the Smithsonian Institution

The Smithsonian Institution ( ), or simply the Smithsonian, is a group of museums and education and research centers, the largest such complex in the world, created by the U.S. government "for the increase and diffusion of knowledge". Founded ...

.

The Hittites

The Hittites () were an Anatolian people who played an important role in establishing first a kingdom in Kussara (before 1750 BC), then the Kanesh or Nesha kingdom (c. 1750–1650 BC), and next an empire centered on Hattusa in north-centra ...

of Anatolia

Anatolia, tr, Anadolu Yarımadası), and the Anatolian plateau, also known as Asia Minor, is a large peninsula in Western Asia and the westernmost protrusion of the Asian continent. It constitutes the major part of modern-day Turkey. The ...

first discovered or developed the smelting of iron ores around 1500 BC. They seem to have maintained a near monopoly on the knowledge of iron production for several hundred years, but when their empire collapsed during the Eastern Mediterranean upheavals around 1200 BC, the knowledge seems to have escaped in all directions.

In the Iliad

The ''Iliad'' (; grc, Ἰλιάς, Iliás, ; "a poem about Ilium") is one of two major ancient Greek epic poems attributed to Homer. It is one of the oldest extant works of literature still widely read by modern audiences. As with the '' Odys ...

of Homer

Homer (; grc, Ὅμηρος , ''Hómēros'') (born ) was a Greek poet who is credited as the author of the ''Iliad'' and the ''Odyssey'', two epic poems that are foundational works of ancient Greek literature. Homer is considered one of the ...

(describing the Trojan War

In Greek mythology, the Trojan War was waged against the city of Troy by the Achaeans (Greeks) after Paris of Troy took Helen from her husband Menelaus, king of Sparta. The war is one of the most important events in Greek mythology and ...

and Bronze Age

The Bronze Age is a historic period, lasting approximately from 3300 BC to 1200 BC, characterized by the use of bronze, the presence of writing in some areas, and other early features of urban civilization. The Bronze Age is the second prin ...

Greek and Trojan warriors), most of the armor

Armour (British English) or armor (American English; see spelling differences) is a covering used to protect an object, individual, or vehicle from physical injury or damage, especially direct contact weapons or projectiles during combat, or f ...

and weapons (swords and spears) are stated to have been of bronze. Iron is not unknown, however, as arrowhead

An arrowhead or point is the usually sharpened and hardened tip of an arrow, which contributes a majority of the projectile mass and is responsible for impacting and penetrating a target, as well as to fulfill some special purposes such as sign ...

s are described as iron, and a "ball of iron" is listed as a prize awarded for winning a competition.

The events described probably occurred around 1200 BC, but Homer is thought to have composed this epic poem around 700 BC; so exactitude must remain suspect.

When historical records resume after the 1200 BC upheavals and the ensuing

When historical records resume after the 1200 BC upheavals and the ensuing Greek Dark Age

The term Greek Dark Ages refers to the period of Greek history from the end of the Mycenaean palatial civilization, around 1100 BC, to the beginning of the Archaic age, around 750 BC. Archaeological evidence shows a widespread collapse ...

, iron work (and presumably blacksmiths) seem to have sprung like Athena

Athena or Athene, often given the epithet Pallas, is an ancient Greek religion, ancient Greek goddess associated with wisdom, warfare, and handicraft who was later syncretism, syncretized with the Roman goddess Minerva. Athena was regarded ...

, fully-grown from the head of Zeus

Zeus or , , ; grc, Δῐός, ''Diós'', label= genitive Boeotian Aeolic and Laconian grc-dor, Δεύς, Deús ; grc, Δέος, ''Déos'', label= genitive el, Δίας, ''Días'' () is the sky and thunder god in ancient Greek reli ...

. Very few artifacts remain, due to loss from corrosion, and re-use of iron as a valuable commodity. What information exists indicates that all of the basic operations of blacksmithing were in use as soon as the Iron Age

The Iron Age is the final epoch of the three-age division of the prehistory and protohistory of humanity. It was preceded by the Stone Age ( Paleolithic, Mesolithic, Neolithic) and the Bronze Age ( Chalcolithic). The concept has been mostl ...

reached a particular locality. The scarcity of records and artifacts, and the rapidity of the switch from Bronze Age to Iron Age, is a reason to use evidence of bronze smithing to infer about the early development of blacksmithing.

It is uncertain when Iron weapons replaced Bronze weapons because the earliest Iron swords did not significantly improve on the qualities of existing bronze artifacts. Unalloyed iron is soft, does not hold an edge as well as a properly constructed bronze blade and needs more maintenance. Iron ores are more widely available than the necessary materials to create bronze however, which made iron weapons more economical than comparable bronze weapons. Small amounts of steel are often formed during several of the earliest refining practices, and when the properties of this alloy were discovered and exploited, steel edged weapons greatly outclassed bronze.

Iron is different from most other materials (including bronze), in that it does not immediately go from a solid to a liquid at its melting point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depen ...

. H2O is a solid (ice) at −1 C (31 F), and a liquid (water) at +1 C (33 F). Iron, by contrast, is definitely a solid at , but over the next it becomes increasingly plastic and more "taffy-like" as its temperature increases. This extreme temperature range of variable solidity is the fundamental material property upon which blacksmithing practice depends.

Another major difference between bronze and iron fabrication techniques is that bronze ''can'' be melted. The melting point of iron is much higher than that of bronze. In the western (Europe & the Mideast) tradition, the technology to make fires hot enough to melt iron did not arise until the 16th century, when smelting operations grew large enough to require overly large bellows. These produced blast-furnace temperatures high enough to melt partially refined ores, resulting in ''cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

''. Thus cast iron frying pans and cookware did not become possible in Europe until 3000 years after the introduction of iron smelting. China, in a separate developmental tradition, was producing cast iron at least 1000 years before this.

Although iron is quite abundant, good quality steel remained rare and expensive until the industrial developments of Bessemer process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is removal of impurities from the iron by oxidation ...

''et al.'' in the 1850s. Close examination of blacksmith-made antique tools clearly shows where small pieces of steel were forge-welded into iron to provide the hardened steel cutting edges of tools (notably in axes, adzes, chisels, etc.). The re-use of quality steel is another reason for the lack of artifacts.

The Romans

Roman or Romans most often refers to:

*Rome, the capital city of Italy

* Ancient Rome, Roman civilization from 8th century BC to 5th century AD

*Roman people, the people of ancient Rome

*''Epistle to the Romans'', shortened to ''Romans'', a lette ...

(who ensured that their own weapons were made with good steel) noted (in the 4th century BC) that the Celts

The Celts (, see pronunciation for different usages) or Celtic peoples () are. "CELTS location: Greater Europe time period: Second millennium B.C.E. to present ancestry: Celtic a collection of Indo-European peoples. "The Celts, an ancien ...

of the Po River Valley had iron, but not good steel. The Romans record that during battle, their Celtic opponents could only swing their swords two or three times before having to step on their swords to straighten them.

On the Indian subcontinent

The Indian subcontinent is a list of the physiographic regions of the world, physiographical region in United Nations geoscheme for Asia#Southern Asia, Southern Asia. It is situated on the Indian Plate, projecting southwards into the Indian O ...

, Wootz

Wootz steel, also known as Seric steel, is a crucible steel characterized by a pattern of bands and high carbon content. These bands are formed by sheets of microscopic carbides within a tempered martensite or pearlite matrix in higher carbon st ...

steel was, and continues to be, produced in small quantities.

In southern Asia and western Africa

West Africa or Western Africa is the westernmost region of Africa. The United Nations defines Western Africa as the 16 countries of Benin, Burkina Faso, Cape Verde, The Gambia, Ghana, Guinea, Guinea-Bissau, Ivory Coast, Liberia, Mali, Maurita ...

, blacksmiths form endogenous castes that sometimes speak distinct languages.

Medieval period

In the medieval period, blacksmithing was considered part of the set of '' seven mechanical arts''.

Prior to the

In the medieval period, blacksmithing was considered part of the set of '' seven mechanical arts''.

Prior to the industrial revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

, a "village smithy" was a staple of every town. Factories and mass-production reduced the demand for blacksmith-made tools and hardware.

The original fuel for forge fires was charcoal. Coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

did not begin to replace charcoal until the forests of first Britain (during the AD 17th century), and then the eastern United States of America (during the 19th century) were largely depleted. Coal ''can be'' an inferior fuel for blacksmithing, because much of the world's coal is contaminated with sulfur. Sulfur contamination of iron and steel make them "red short", so that at red heat they become "crumbly" instead of "plastic". Coal sold and purchased for blacksmithing should be largely free of sulfur.

European blacksmiths before and through the medieval era spent a great deal of time heating and hammering iron before forging it into finished articles. Although they were unaware of the chemical basis, they were aware that the quality of the iron was thus improved. From a scientific point of view, the reducing atmosphere of the forge was both removing oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

(rust), and soaking more carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon mak ...

into the iron, thereby developing increasingly higher grades of steel as the process was continued.

Industrial era

During the eighteenth century, agents for theSheffield

Sheffield is a city in South Yorkshire, England, whose name derives from the River Sheaf which runs through it. The city serves as the administrative centre of the City of Sheffield. It is historically part of the West Riding of Yorkshire a ...

cutlery industry scoured the British country-side, offering new carriage springs for old. Springs must be made of hardened steel. At this time, the processes for making steel produced an extremely variable product—quality was not ensured at the initial point of sale. Springs that had survived cracking through hard use over the rough roads of the time, had proven to be of a better quality steel. Much of the fame of Sheffield cutlery (knives, shears, etc.) was due to the extreme lengths the companies took to ensure they used high-grade steel.

During the first half of the nineteenth century, the US government included in their treaties with many Native American tribes, that the US would employ blacksmiths and strikers at

During the first half of the nineteenth century, the US government included in their treaties with many Native American tribes, that the US would employ blacksmiths and strikers at Army

An army (from Old French ''armee'', itself derived from the Latin verb ''armāre'', meaning "to arm", and related to the Latin noun ''arma'', meaning "arms" or "weapons"), ground force or land force is a fighting force that fights primarily on ...

fort

A fortification is a military construction or building designed for the defense of territories in warfare, and is also used to establish rule in a region during peacetime. The term is derived from Latin ''fortis'' ("strong") and ''facere'' ...

s, with the expressed purpose of providing Native Americans with iron tools and repair services.

During the early to mid-nineteenth century, both European armies as well as both the U.S. Federal and Confederate armies employed blacksmiths to shoe horses and repair equipment such as wagons, horse tack, and artillery equipment. These smiths primarily worked at a traveling forge that when combined with a limber, comprised wagons specifically designed and constructed as blacksmith shops on wheels to carry the essential equipment necessary for their work.

Lathes

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to cr ...

, patterned largely on their woodturning

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a simple mechanism that can generate a variety of forms. The operator ...

counterparts, had been used by some blacksmiths since the middle-ages. During the 1790s Henry Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were ...

created the first screw-cutting lathe

A screw-cutting lathe is a machine (specifically, a lathe) capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotatin ...

, a watershed event that signaled the start of blacksmiths being replaced by machinists in factories

A factory, manufacturing plant or a production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. T ...

for the hardware needs of the populace.

Samuel Colt neither invented nor perfected interchangeable parts, but his insistence (and other industrialists at this time) that his firearms be manufactured with this property, was another step towards the obsolescence of metal-working artisans and blacksmiths. (See also Eli Whitney).

As demand for their products declined, many more blacksmiths augmented their incomes by taking in work shoeing horse

The horse (''Equus ferus caballus'') is a domesticated, one-toed, hoofed mammal. It belongs to the taxonomic family Equidae and is one of two extant subspecies of ''Equus ferus''. The horse has evolved over the past 45 to 55 million yea ...

s. A shoer-of-horses was historically known as a farrier

A farrier is a specialist in equine hoof care, including the trimming and balancing of horses' hooves and the placing of shoes on their hooves, if necessary. A farrier combines some blacksmith's skills (fabricating, adapting, and adj ...

in English. With the introduction of automobile

A car or automobile is a motor vehicle with wheels. Most definitions of ''cars'' say that they run primarily on roads, seat one to eight people, have four wheels, and mainly transport people instead of goods.

The year 1886 is regarde ...

s, the number of blacksmiths continued to decrease, many former blacksmiths becoming the initial generation of automobile Mechanics. The nadir of blacksmithing in the United States was reached during the 1960s, when most of the former blacksmiths had left the trade, and few if any new people were entering the trade. By this time, most of the working blacksmiths were those performing farrier

A farrier is a specialist in equine hoof care, including the trimming and balancing of horses' hooves and the placing of shoes on their hooves, if necessary. A farrier combines some blacksmith's skills (fabricating, adapting, and adj ...

work, so the term ''blacksmith'' was effectively co-opted by the farrier trade.

Neoclassicism era

In the final part of the 18th century, forged ironwork continued to decline due to the aforementioned industrial revolution, shapes of the elements in the designs of window grilles and other decorative functional items continued to contradict natural forms, surfaces begin to be covered in paint, cast iron elements are incorporated into the forged designs. Main features of Neoclassicism ironwork (also referred to as Louis XVI style andEmpire style

The Empire style (, ''style Empire'') is an early-nineteenth-century design movement in architecture, furniture, other decorative arts, and the visual arts, representing the second phase of Neoclassicism. It flourished between 1800 and 1815 durin ...

ironwork) include smooth straight bars, decorative geometric elements, double or oval volutes and the usage of elements from Classical antiquity

Classical antiquity (also the classical era, classical period or classical age) is the period of cultural history between the 8th century BC and the 5th century AD centred on the Mediterranean Sea, comprising the interlocking civilizations of ...

( Meander (art), wreaths etc.).

Typical for this kind of ironwork is that the ironwork is painted white with gold (gilded) elements.

20th and 21st centuries

During the 20th century various gases (natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

, acetylene, etc.) have also come to be used as fuels for blacksmithing. While these are fine for blacksmithing iron, special care must be taken when using them to blacksmith steel. Each time a piece of steel is heated, there is a tendency for the carbon content to leave the steel (decarburization

Decarburization (or decarbonization) is the process of decreasing carbon content, which is the opposite of carburization.

The term is typically used in metallurgy, describing the decrease of the content of carbon in metals (usually steel). Decar ...