Basic Oxygen Furnace on:

[Wikipedia]

[Google]

[Amazon]

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary

Basic oxygen steelmaking is a primary steelmaking process for converting molten pig iron into steel by blowing oxygen through a lance over the molten pig iron inside the converter. Exothermic heat is generated by the oxidation reactions during blowing.

The basic oxygen steel-making process is as follows:

# Molten

Basic oxygen steelmaking is a primary steelmaking process for converting molten pig iron into steel by blowing oxygen through a lance over the molten pig iron inside the converter. Exothermic heat is generated by the oxidation reactions during blowing.

The basic oxygen steel-making process is as follows:

# Molten

Transforming the twentieth century: technical innovations and their consequences, Volume 2

'. Oxford University Press US. . *Brock, James W.; Elzinga, Kenneth G. (1991).

Antitrust, the market, and the state: the contributions of Walter Adams

'. M. E. Sharpe. . *Tweraser, Kurt (2000). ''The Marshall Plan and the Reconstruction of the Austrian Steel Industry 1945–1953''. in: Bischof, Gunther et al. (2000).

The Marshall Plan in Austria

'.

Basic Oxygen Steelmaking module

at steeluniversity.org, including a fully interactive simulation (archived)

showing typical cost structure for liquid steel {{Authority control Austrian inventions Metallurgical processes Steelmaking Swiss inventions

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking

Steelmaking is the process of producing steel from iron ore and carbon/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (the most important impurity) are removed from the sourced iron, and alloy ...

in which carbon-rich molten pig iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with ...

is made into steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistan ...

. Blowing oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements ...

through molten pig iron lowers the carbon content of the alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductili ...

and changes it into low-carbon steel. The process is known as ''basic'' because flux

Flux describes any effect that appears to pass or travel (whether it actually moves or not) through a surface or substance. Flux is a concept in applied mathematics and vector calculus which has many applications to physics. For transport ...

es of burnt lime or dolomite Dolomite may refer to:

*Dolomite (mineral), a carbonate mineral

*Dolomite (rock), also known as dolostone, a sedimentary carbonate rock

*Dolomite, Alabama, United States, an unincorporated community

*Dolomite, California, United States, an unincor ...

, which are chemical '' bases'', are added to promote the removal of impurities and protect the lining of the converter.

The process was invented in 1948 by Swiss engineer Robert Durrer and commercialized in 1952–1953 by the Austrian steelmaking company VOEST and ÖAMG. The LD converter, named after the Austria

Austria, , bar, Östareich officially the Republic of Austria, is a country in the southern part of Central Europe, lying in the Eastern Alps. It is a federation of nine states, one of which is the capital, Vienna, the most populous ...

n towns Linz

Linz ( , ; cs, Linec) is the capital of Upper Austria and third-largest city in Austria. In the north of the country, it is on the Danube south of the Czech border. In 2018, the population was 204,846.

In 2009, it was a European Capital ...

and Donawitz (a district of Leoben) is a refined version of the Bessemer converter

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is removal of impurities from the iron by oxidation ...

where blowing of air is replaced with blowing oxygen. It reduced capital cost of the plants and smelting time, and increased labor productivity. Between 1920 and 2000, labor requirements in the industry decreased by a factor of 1,000, from more than three man-hours per metric ton to just 0.003.Smil, p. 99. The majority of steel manufactured in the world is produced using the basic oxygen furnace. In 2000, it accounted for 60% of global steel output.

Modern furnaces will take a charge of iron of up to 400 tons and convert it into steel in less than 40 minutes, compared to 10–12 hours in an open hearth furnace.

History

The basic oxygen process developed outside of traditional "big steel" environment. It was developed and refined by a single man, Swiss engineer Robert Durrer, and commercialized by two small steel companies inallied-occupied Austria

The Allied occupation of Austria started on 8 May 1945 with the fall of Nazi Germany and ended with the Austrian State Treaty on 27 July 1955.

After the in 1938, Austria under National Socialism, Austria had generally been recognized as part ...

, which had not yet recovered from the destruction of World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the World War II by country, vast majority of the world's countries—including all of the great power ...

.Smil, p. 97.

In 1856, Henry Bessemer

Sir Henry Bessemer (19 January 1813 – 15 March 1898) was an English inventor, whose steel-making process would become the most important technique for making steel in the nineteenth century for almost one hundred years from 1856 to 1950. He ...

had patented a steelmaking process involving oxygen blowing for decarbonizing molten iron (UK Patent No. 2207). For nearly 100 years commercial quantities of oxygen were not available or were too expensive, and the invention remained unused. During WWII German (Karl Valerian Schwarz), Belgian (John Miles) and Swiss (Durrer and Heinrich Heilbrugge) engineers proposed their versions of oxygen-blown steelmaking, but only Durrer and Heilbrugge brought it to mass-scale production.

In 1943, Durrer, formerly a professor at the Berlin Institute of Technology

The Technical University of Berlin (official name both in English and german: link=no, Technische Universität Berlin, also known as TU Berlin and Berlin Institute of Technology) is a public research university located in Berlin, Germany. It wa ...

, returned to Switzerland

). Swiss law does not designate a ''capital'' as such, but the federal parliament and government are installed in Bern, while other federal institutions, such as the federal courts, are in other cities (Bellinzona, Lausanne, Luzern, Neuchâtel ...

and accepted a seat on the board of Roll AG

Von Roll Holding AG is a Swiss industrial group that operates worldwide. It was founded in 1803. As one of Switzerland’s longest-established industrial companies, Von Roll focuses today on products and systems for electrical applications such ...

, the country's largest steel mill. In 1947 he purchased the first small 2.5-ton experimental converter from the US, and on April 3, 1948 the new converter produced its first steel. The new process could conveniently process large amounts of scrap metal

Scrap consists of recyclable materials, usually metals, left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap has monetary value, especially recovered m ...

with only a small proportion of primary metal necessary. In the summer of 1948 Roll AG and two Austrian state-owned companies, VÖEST and ÖAMG, agreed to commercialize the Durrer process.Smil, pp. 97–98.

By June 1949, VÖEST developed an adaptation of Durrer's process, known as the LD (Linz-Donawitz) process.Tweraser, p. 313.Smil, p. 98. In December 1949, VÖEST and ÖAMG committed to building their first 30-ton oxygen converters. They were put into operation in November 1952 (VÖEST in Linz) and May 1953 (ÖAMG, Donawitz) and temporarily became the leading edge of the world's steelmaking, causing a surge in steel-related research.Brock and Elzinga, p. 39. Thirty-four thousand businesspeople and engineers visited the VÖEST converter by 1963. The LD process reduced processing time and capital costs per ton of steel, contributing to the competitive advantage

In business, a competitive advantage is an attribute that allows an organization to outperform its competitors.

A competitive advantage may include access to natural resources, such as high-grade ores or a low-cost power source, highly skilled ...

of Austrian steel. VÖEST eventually acquired the rights to market the new technology. Errors by the VÖEST and the ÖAMG management in licensing their technology made control over its adoption in Japan

Japan ( ja, 日本, or , and formally , ''Nihonkoku'') is an island country in East Asia. It is situated in the northwest Pacific Ocean, and is bordered on the west by the Sea of Japan, while extending from the Sea of Okhotsk in the n ...

impossible. By the end of the 1950s, the Austrians lost their competitive edge.

In the original LD process, oxygen was blown over the top of the molten iron through the water-cooled nozzle of a vertical lance. In the 1960s, steelmakers introduced bottom-blown converters and introduced inert gas

An inert gas is a gas that does not readily undergo chemical reactions with other chemical substances and therefore does not readily form chemical compounds. The noble gases often do not react with many substances and were historically referred to ...

blowing for stirring the molten metal and removing phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ea ...

impurities.

In the Soviet Union, some experimental production of steel using the process was done in 1934, but industrial use was hampered by lack of efficient technology to produce liquid oxygen.

In 1939, the Russian physicist Pyotr Kapitsa perfected the design of the centrifugal turboexpander. The process was put to use in 1942-1944. Most turboexpanders in industrial use since then have been based on Kapitsa's design and centrifugal turboexpanders have taken over almost 100% of industrial gas liquefaction, and in particular the production of liquid oxygen for steelmaking.

Big American steelmakers were late adopters of the new technology. The first oxygen converters in the US were launched at the end of 1954 by McLouth Steel in Trenton, Michigan, which accounted for less than 1% of the national steel market. U.S. Steel and Bethlehem Steel

The Bethlehem Steel Corporation was an American steelmaking company headquartered in Bethlehem, Pennsylvania. For most of the 20th century, it was one of the world's largest steel producing and shipbuilding companies. At the height of its succ ...

introduced the oxygen process in 1964. By 1970, half of the world's and 80% of Japan's steel output was produced in oxygen converters. In the last quarter of the 20th century, use of basic oxygen converters for steel production was gradually, partially replaced by the electric arc furnace

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc.

Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundries for producing cast iron products) up to ...

using scrap steel and iron. In Japan the share of LD process decreased from 80% in 1970 to 70% in 2000; worldwide share of the basic oxygen process stabilized at 60%.

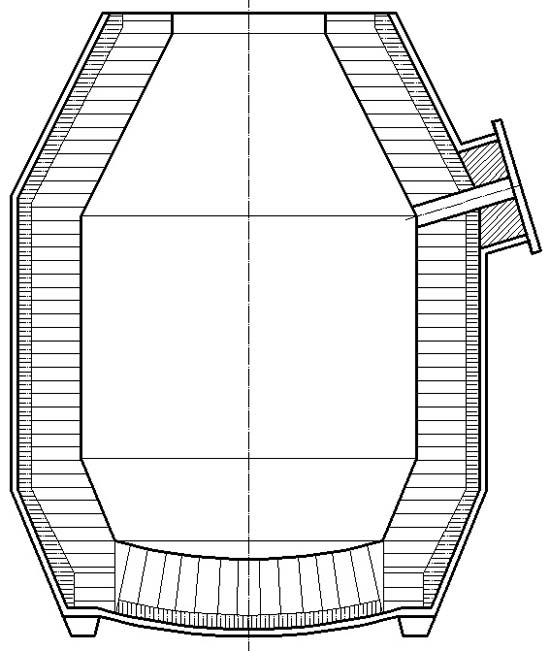

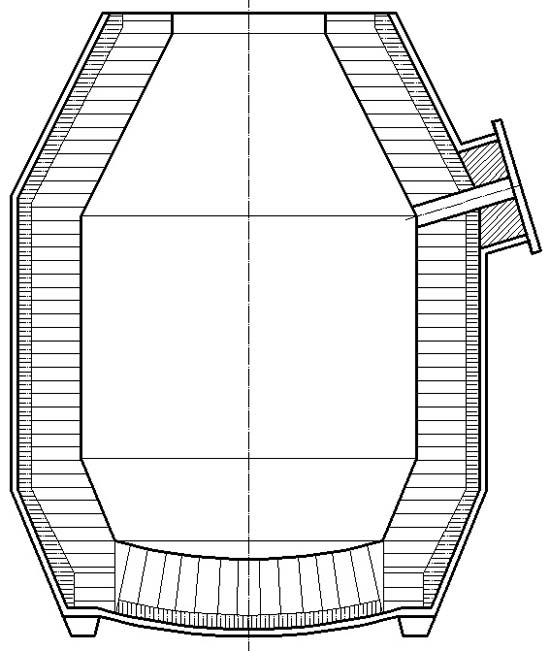

Process

Basic oxygen steelmaking is a primary steelmaking process for converting molten pig iron into steel by blowing oxygen through a lance over the molten pig iron inside the converter. Exothermic heat is generated by the oxidation reactions during blowing.

The basic oxygen steel-making process is as follows:

# Molten

Basic oxygen steelmaking is a primary steelmaking process for converting molten pig iron into steel by blowing oxygen through a lance over the molten pig iron inside the converter. Exothermic heat is generated by the oxidation reactions during blowing.

The basic oxygen steel-making process is as follows:

# Molten pig iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with ...

(sometimes referred to as "hot metal") from a blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheri ...

is poured into a large refractory-lined container called a ladle.

# The metal in the ladle is sent directly for basic oxygen steelmaking or to a pretreatment stage. Pretreatment of the blast furnace hot metal is done externally to reduce sulfur

Sulfur (or sulphur in British English) is a chemical element with the symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with a chemical formul ...

, silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ...

, and phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ea ...

before charging the hot metal into the converter. In external desulfurising pretreatment, a lance is lowered into the molten iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in ...

in the ladle and several hundred kilograms of powdered magnesium

Magnesium is a chemical element with the symbol Mg and atomic number 12. It is a shiny gray metal having a low density, low melting point and high chemical reactivity. Like the other alkaline earth metals (group 2 of the periodic ...

are added and the sulfur impurities are reduced to magnesium sulfide

Magnesium sulfide is an inorganic compound with the formula Mg S. It is a white crystalline material but often is encountered in an impure form that is brown and non-crystalline powder. It is generated industrially in the production of metallic ...

in a violent exothermic

In thermodynamics, an exothermic process () is a thermodynamic process or reaction that releases energy from the system to its surroundings, usually in the form of heat, but also in a form of light (e.g. a spark, flame, or flash), electricity ...

reaction. The sulfide is then raked off. Similar pretreatments are possible for external desiliconisation and external dephosphorisation using mill scale (iron oxide) and lime as fluxes. The decision to pretreat depends on the quality of the hot metal and the required final quality of the steel.

# Filling the furnace with the ingredients is called ''charging''. The BOS process is autogenous, i.e. the required thermal energy is produced during the oxidation process. Maintaining the proper ''charge balance'', the ratio of hot metal from melt to cold scrap is important. The BOS vessel can be tilted up to 360° and is tilted towards the deslagging side for charging scrap and hot metal. The BOS vessel is charged with steel or iron scrap (25–30%),if required. Molten iron from the ladle is added as required for the charge balance. A typical chemistry of hotmetal charged into the BOS vessel is: 4% C, 0.2–0.8% Si, 0.08%–0.18% P, and 0.01–0.04% S, all of which can be oxidised by the supplied oxygen except sulfur (which requires reducing conditions).

# The vessel is then set upright and a water-cooled, copper tipped lance with 3–7 nozzles is lowered into it to within a few feet of the surface of the bath and high-purity oxygen at a pressure of is introduced at supersonic speed. The lance "blows" 99% pure oxygen over the hot metal, igniting the carbon dissolved in the steel, to form carbon monoxide

Carbon monoxide ( chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simpl ...

and carbon dioxide

Carbon dioxide ( chemical formula ) is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature. In the air, carbon dioxide is t ...

, causing the temperature to rise to about 1700 °C. This melts the scrap, lowers the carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

content of the molten iron and helps remove unwanted chemical element

A chemical element is a species of atoms that have a given number of protons in their atomic nucleus, nuclei, including the pure Chemical substance, substance consisting only of that species. Unlike chemical compounds, chemical elements canno ...

s. It is this use of pure oxygen (instead of air) that improves upon the Bessemer process, as the nitrogen (an undesirable element) and other gases in air do not react with the charge, and decrease efficiency of furnace.McGannon, p 486

# Fluxes ( burnt lime or dolomite Dolomite may refer to:

*Dolomite (mineral), a carbonate mineral

*Dolomite (rock), also known as dolostone, a sedimentary carbonate rock

*Dolomite, Alabama, United States, an unincorporated community

*Dolomite, California, United States, an unincor ...

) are fed into the vessel to form slag

Slag is a by-product of smelting ( pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-p ...

, to maintain basicity of the slag – the ratio of calcium oxide to silicon oxide - at a level to minimise refractory wear and absorb impurities during the steelmaking process. During "blowing", churning of metal and fluxes in the vessel forms an emulsion

An emulsion is a mixture of two or more liquids that are normally immiscible (unmixable or unblendable) owing to liquid-liquid phase separation. Emulsions are part of a more general class of two-phase systems of matter called colloids. Alth ...

that facilitates the refining process. Near the end of the blowing cycle, which takes about 20 minutes, the temperature is measured and samples are taken. A typical chemistry of the blown metal is 0.3–0.9% C, 0.05–0.1% Mn, 0.001–0.003% Si, 0.01–0.03% S and 0.005–0.03% P.

# The BOS vessel is tilted towards the slagging side and the steel is poured through a tap hole into a steel ladle with basic refractory lining. This process is called ''tapping'' the steel. The steel is further refined in the ladle furnace, by adding alloying materials to impart special properties required by the customer. Sometimes argon

Argon is a chemical element with the symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third-most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice a ...

or nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

is bubbled into the ladle to make the alloys mix correctly.

# After the steel is poured off from the BOS vessel, the slag is poured into the slag pots through the BOS vessel mouth and dumped.

Variants

Earlier converters, with a false bottom that can be detached and repaired, are still in use. Modern converters have a fixed bottom with plugs for argon purging. The Energy Optimization Furnace (EOF) is a BOF variant associated with a scrap preheater where the sensible heat in the off-gas is used for preheating scrap, located above the furnace roof. The lance used for blowing has undergone changes. Slagless lances, with a long tapering copper tip, have been employed to avoid jamming of the lance during blowing. Post-combustion lance tips burn the CO generated during blowing into CO2 and provide additional heat. For slag-free tapping, darts, refractory balls, and slag detectors are employed. Modern converters are fully automated with automatic blowing patterns and sophisticated control systems.See also

*AJAX furnace

The AJAX furnace was a modification of the tilting open hearth furnace that used blown oxygen to improve productivity. The process was used in the UK during the 1960s at a time of transition from open hearth to oxygen based steel making.

History a ...

, transitional oxygen-based open hearth technology

References

Bibliography

*McGannon, Harold E. editor (1971). ''The Making, Shaping and Treating of Steel: Ninth Edition''. Pittsburgh, Pennsylvania: United States Steel Corporation. *Smil, Vaclav (2006).Transforming the twentieth century: technical innovations and their consequences, Volume 2

'. Oxford University Press US. . *Brock, James W.; Elzinga, Kenneth G. (1991).

Antitrust, the market, and the state: the contributions of Walter Adams

'. M. E. Sharpe. . *Tweraser, Kurt (2000). ''The Marshall Plan and the Reconstruction of the Austrian Steel Industry 1945–1953''. in: Bischof, Gunther et al. (2000).

The Marshall Plan in Austria

'.

Transaction Publishers

Transaction Publishers was a New Jersey-based publishing house that specialized in social science books and journals. It was located on the Livingston Campus of Rutgers University. Transaction was sold to Taylor & Francis in 2016 and merged wit ...

. . pp. 290–322.

External links

Basic Oxygen Steelmaking module

at steeluniversity.org, including a fully interactive simulation (archived)

showing typical cost structure for liquid steel {{Authority control Austrian inventions Metallurgical processes Steelmaking Swiss inventions