Surface finish on:

[Wikipedia]

[Google]

[Amazon]

Surface finish, also known as surface texture or surface topography, is the nature of a

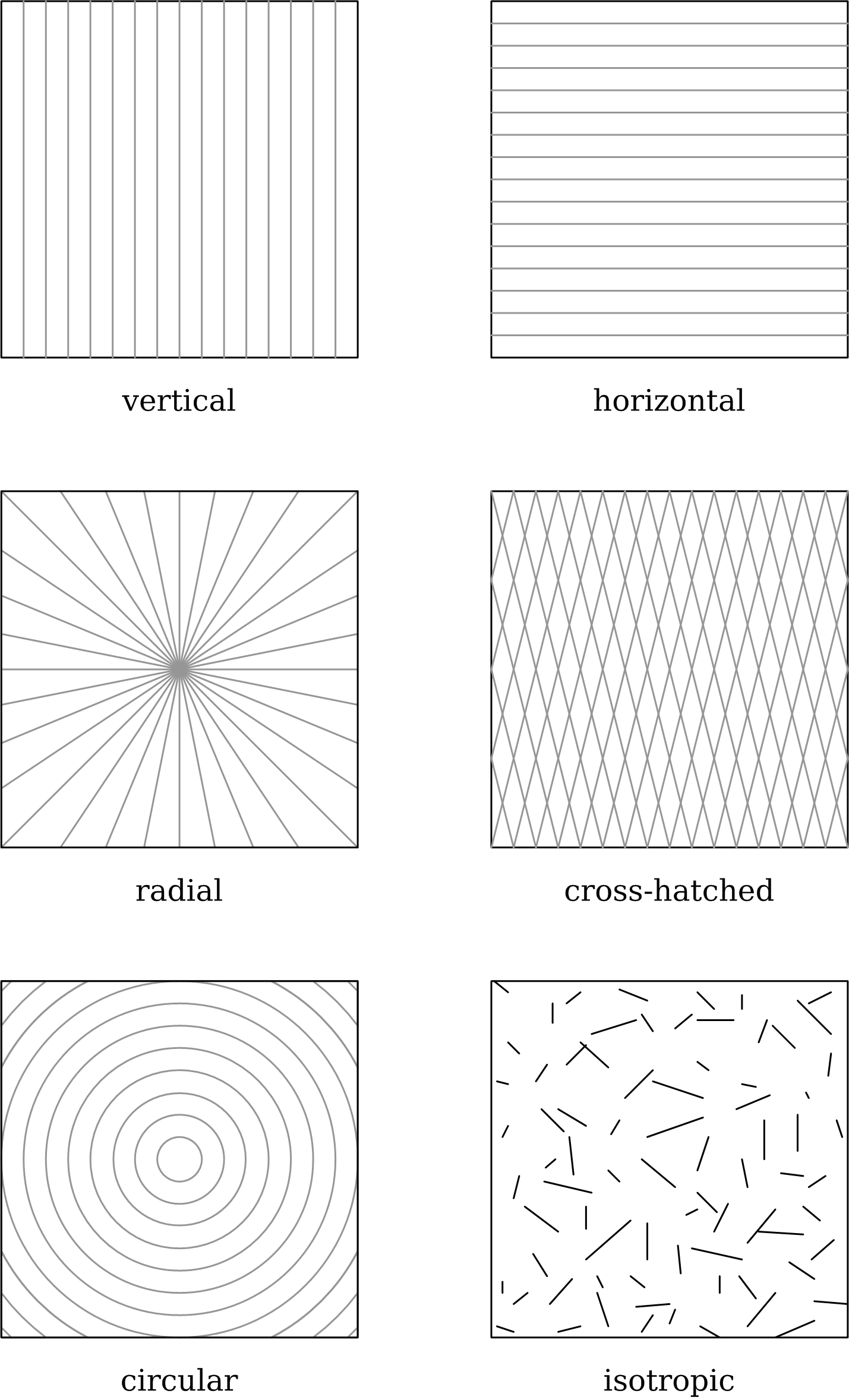

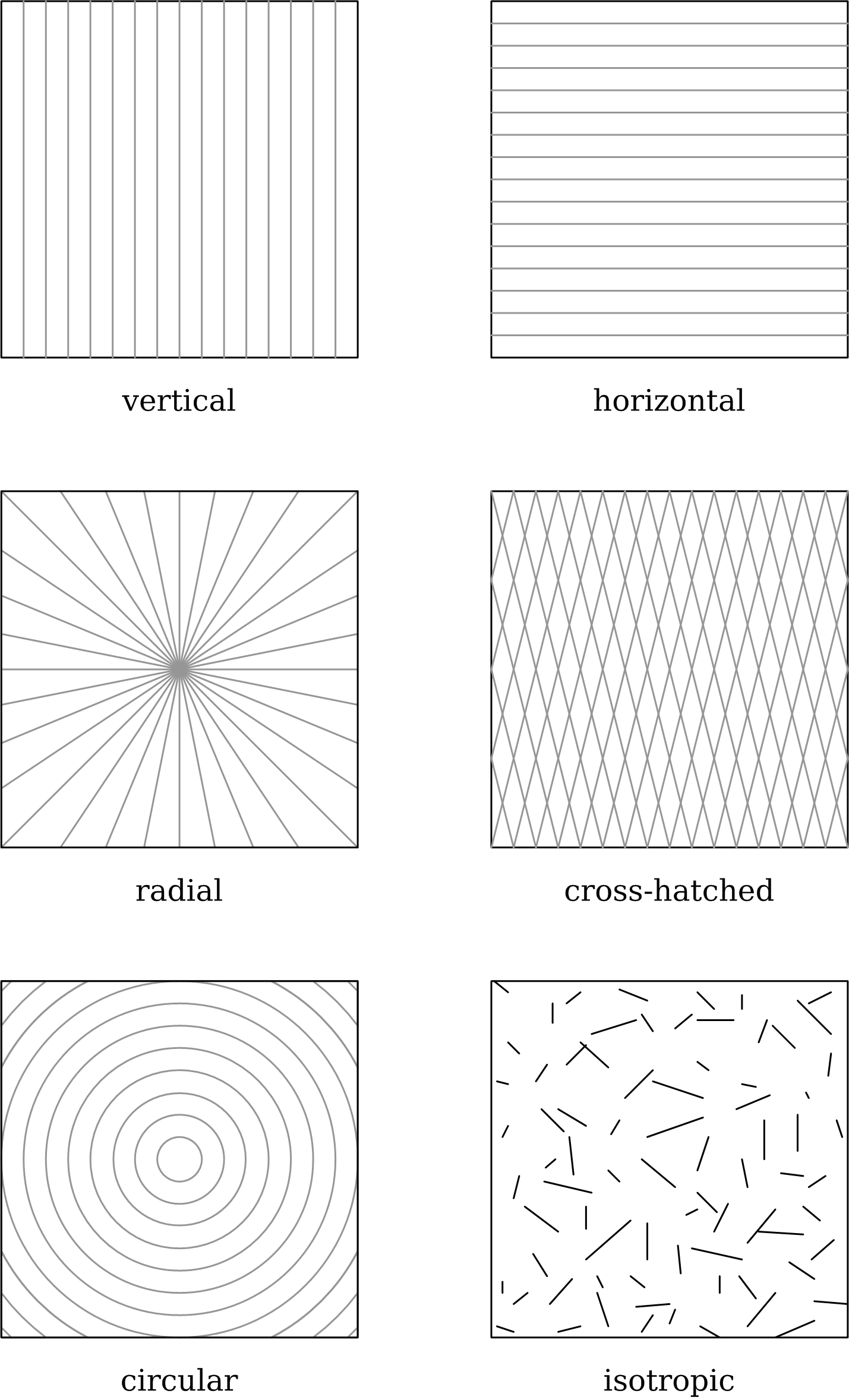

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a

Surface finish may be measured in two ways: ''contact'' and ''non-contact'' methods. Contact methods involve dragging a measurement

Surface finish may be measured in two ways: ''contact'' and ''non-contact'' methods. Contact methods involve dragging a measurement

surface

A surface, as the term is most generally used, is the outermost or uppermost layer of a physical object or space. It is the portion or region of the object that can first be perceived by an observer using the senses of sight and touch, and is ...

as defined by the three characteristics of lay, surface roughness

Surface roughness or simply roughness is the quality of a surface of not being smooth and it is hence linked to human ( haptic) perception of the surface texture. From a mathematical perspective it is related to the spatial variability structure ...

, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane).

Surface texture is one of the important factors that control friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of t ...

and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic

In physics and geometry, isotropy () is uniformity in all orientations. Precise definitions depend on the subject area. Exceptions, or inequalities, are frequently indicated by the prefix ' or ', hence '' anisotropy''. ''Anisotropy'' is also ...

or anisotropic

Anisotropy () is the structural property of non-uniformity in different directions, as opposed to isotropy. An anisotropic object or pattern has properties that differ according to direction of measurement. For example, many materials exhibit ver ...

. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture.

Each manufacturing process

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the

secondary sector of the economy. The term may refer to ...

(such as the many kinds of machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool.

A wide variety of machines are used for grinding, best classified as portable or stationary:

* Portable power tools such as angle grinders, die gri ...

, polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by the index of refraction of the material accordi ...

, lapping

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first ste ...

, abrasive blasting

Sandblasting, sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove sur ...

, honing, electrical discharge machining

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal

fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is ...

(EDM), milling

Milling may refer to:

* Milling (minting), forming narrow ridges around the edge of a coin

* Milling (grinding), breaking solid materials into smaller pieces by grinding, crushing, or cutting in a mill

* Milling (machining), a process of using ro ...

, lithography

Lithography () is a planographic method of printing originally based on the miscibility, immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by ...

, industrial etching/ chemical milling, laser texturing, or other processes.

Lay

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a

Lay is the direction of the predominant surface pattern, ordinarily determined by the production method used. The term is also used to denote the winding direction of fibers and strands of a rope

A rope is a group of yarns, Plying, plies, fibres, or strands that are plying, twisted or braided together into a larger and stronger form. Ropes have high tensile strength and can be used for dragging and lifting. Rope is thicker and stronger ...

.

Surface roughness

Surface roughness, commonly shortened to ''roughness,'' is a measure of the total spaced surface irregularities. In engineering, this is what is usually meant by "surface finish." A Lower number constitutes finer irregularities, i.e., a smoother surface.Waviness

Waviness is the measure of surface irregularities with a spacing greater than that of surface roughness. These irregularities usually occur due to warping, vibrations, or deflection during machining.Measurement

stylus

A stylus is a writing utensil or tool for scribing or marking into softer materials. Different styluses were used to write in cuneiform by pressing into wet clay, and to scribe or carve into a wax tablet. Very hard styluses are also used to En ...

across the surface; these instruments are called profilometers. Non-contact methods include: interferometry

Interferometry is a technique which uses the ''interference (wave propagation), interference'' of Superposition principle, superimposed waves to extract information. Interferometry typically uses electromagnetic waves and is an important inves ...

, confocal microscopy

Confocal microscopy, most frequently confocal laser scanning microscopy (CLSM) or laser scanning confocal microscopy (LSCM), is an optical imaging technique for increasing optical resolution and contrast (vision), contrast of a micrograph by me ...

, focus variation, structured light, electrical capacitance, electron microscopy

An electron microscope is a microscope that uses a beam of electrons as a source of illumination. It uses electron optics that are analogous to the glass lenses of an optical light microscope to control the electron beam, for instance focusing i ...

, atomic force microscopy

Atomic force microscopy (AFM) or scanning force microscopy (SFM) is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the opti ...

and photogrammetry

Photogrammetry is the science and technology of obtaining reliable information about physical objects and the environment through the process of recording, measuring and interpreting photographic images and patterns of electromagnetic radiant ima ...

.

Non-contact methods

Optical metrology plays a key role in non-contact surface roughness measurements, offering high-resolution and non-destructive analysis of complex or delicate surfaces. These techniques are particularly useful in environments where contact-based methods may damage the material or provide limited accessibility. Common optical techniques include: * White Light Interferometry (WLI), which uses the interference of broadband light to achieve nanometer-level vertical resolution in surface profiling. * Confocal Microscopy, which relies on spatial filtering and point illumination to generate precise topographical maps of a surface. * Chromatic confocal sensing, which determines the height of surface points based on the wavelength at which light is focused. It allows for in situ and inline roughness measurements, often producing parameters like Ra and Rz. These optical methods are widely implemented in industries such as aerospace, automotive, biomedical engineering, and microelectronics, where precise surface texture control is critical.Specification

In the United States, surface finish is usually specified using the ASME Y14.36M standard. The other common standard isInternational Organization for Standardization

The International Organization for Standardization (ISO ; ; ) is an independent, non-governmental, international standard development organization composed of representatives from the national standards organizations of member countries.

M ...

(ISO) 1302:2002, although the same has been withdrawn in favour of ISO 21920-1:2021.

Many factors contribute to the surface finish in manufacturing. In forming processes, such as molding or metal forming, surface finish of the die determines the surface finish of the workpiece. In machining, the interaction of the cutting edges and the microstructure of the material being cut both contribute to the final surface finish.

In general, the cost of manufacturing a surface increases as the surface finish improves.. Any given manufacturing process is usually optimized enough to ensure that the resulting texture is usable for the part's intended application. If necessary, an additional process will be added to modify the initial texture. The expense of this additional process must be justified by adding value in some way—principally better function or longer lifespan. Parts that have sliding contact with others may work better or last longer if the roughness is lower. Aesthetic improvement may add value if it improves the saleability of the product.

A practical example is as follows. An aircraft maker contracts with a vendor

In a supply chain, a vendor, supplier, provider or a seller, is an enterprise that contributes goods or services. Generally, a supply chain vendor manufactures inventory/stock items and sells them to the next link in the chain. Today, these term ...

to make parts. A certain grade of steel is specified for the part because it is strong

Strong may refer to:

Education

* The Strong, an educational institution in Rochester, New York, United States

* Strong Hall (Lawrence, Kansas), an administrative hall of the University of Kansas

* Strong School, New Haven, Connecticut, United ...

enough and hard enough for the part's function. The steel is machinable although not free-machining. The vendor decides to mill

Mill may refer to:

Science and technology

* Factory

* Mill (grinding)

* Milling (machining)

* Millwork

* Paper mill

* Steel mill, a factory for the manufacture of steel

* Sugarcane mill

* Textile mill

* List of types of mill

* Mill, the arithmetic ...

the parts. The milling can achieve the specified roughness (for example, ≤ 3.2 μm) as long as the machinist uses premium-quality inserts in the end mill

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. They can have several end configurations: round (ball), tapered, or straight are a few popular types. They are most commonly used in "milling machi ...

and replaces the inserts after every 20 parts (as opposed to cutting hundreds before changing the inserts). There is no need to add a second operation (such as grinding or polishing) after the milling as long as the milling is done well enough (correct inserts, frequent-enough insert changes, and clean coolant

A coolant is a substance, typically liquid, that is used to reduce or regulate the temperature of a system. An ideal coolant has high thermal capacity, low viscosity, is low-cost, non-toxic, chemically inert and neither causes nor promotes corr ...

). The inserts and coolant cost money, but the costs that grinding or polishing would incur (more time and additional materials) would cost even more than that. Obviating the second operation results in a lower unit cost

The unit cost is the price incurred by a company

A company, abbreviated as co., is a Legal personality, legal entity representing an association of legal people, whether Natural person, natural, Juridical person, juridical or a mixture ...

and thus a lower price

A price is the (usually not negative) quantity of payment or compensation expected, required, or given by one party to another in return for goods or services. In some situations, especially when the product is a service rather than a ph ...

. The competition

Competition is a rivalry where two or more parties strive for a common goal which cannot be shared: where one's gain is the other's loss (an example of which is a zero-sum game). Competition can arise between entities such as organisms, indi ...

between vendors elevates such details from minor to crucial importance. It was certainly possible to make the parts in a slightly less efficient way (two operations) for a slightly higher price; but only one vendor can get the contract, so the slight difference in efficiency is magnified by competition into the great difference between the prospering and shuttering of firms.

Just as different manufacturing processes produce parts at various tolerances, they are also capable of different roughnesses. Generally, these two characteristics are linked: manufacturing processes that are dimensionally precise create surfaces with low roughness. In other words, if a process can manufacture parts to a narrow dimensional tolerance, the parts will not be very rough.

Due to the abstractness of surface finish parameters, engineers usually use a tool that has a variety of surface roughnesses created using different manufacturing methods.

See also

*Gloss (optics)

Gloss is an optical property which indicates how well a surface reflects light in a specular (mirror-like) direction. It is one of the important parameters that are used to describe the visual appearance of an object. Other categories of visual ...

References

Bibliography

*{{Citation , last1 = Degarmo , first1 = E. Paul , last2 = Black , first2 = J T. , last3 = Kohser , first3 = Ronald A. , title = Materials and Processes in Manufacturing , publisher = Wiley , year = 2003 , edition = 9th , isbn = 0-471-65653-4 , postscript =. Metalworking terminology Tribology F