soldering iron on:

[Wikipedia]

[Google]

[Amazon]

A soldering iron is a

A soldering iron is a

In 1946, Carl E. Weller applied for a patent for his soldering gun that could heat instantaneously and began production of the "Speedy Iron" in Pennsylvania. It was manufactured through the Weller Manufacturing Company, and this product was the first instantaneous thermal soldering gun. Few years later, they released to the market a soldering iron on with self-adjusting temperature. In 1951, the company WEN Products began manufacturing its own instantaneous soldering iron. After a three years trial Weller won for patent infringement.

In 1960 Weller got the patent for the soldering iron "Magnastat", renewed in 1964 and 1971. This iron could control the temperature by using a temperature-sensitive magnetic tip. The "Magnastat" became a best seller and it was included it in the W-TCP soldering station in 1967. In fact, within the patent, as a complementary description, it defines what today has become the " de facto", the redundancy is worth it, " form factor" of the vast majority of current Japanese and Chinese irons: Hakko, Baku, etc... The now-expired patent, which even Weller has stopped using on some models, described an outer tube holding the coated copper tip, clamped with a nut to the handle.

In 1946, Carl E. Weller applied for a patent for his soldering gun that could heat instantaneously and began production of the "Speedy Iron" in Pennsylvania. It was manufactured through the Weller Manufacturing Company, and this product was the first instantaneous thermal soldering gun. Few years later, they released to the market a soldering iron on with self-adjusting temperature. In 1951, the company WEN Products began manufacturing its own instantaneous soldering iron. After a three years trial Weller won for patent infringement.

In 1960 Weller got the patent for the soldering iron "Magnastat", renewed in 1964 and 1971. This iron could control the temperature by using a temperature-sensitive magnetic tip. The "Magnastat" became a best seller and it was included it in the W-TCP soldering station in 1967. In fact, within the patent, as a complementary description, it defines what today has become the " de facto", the redundancy is worth it, " form factor" of the vast majority of current Japanese and Chinese irons: Hakko, Baku, etc... The now-expired patent, which even Weller has stopped using on some models, described an outer tube holding the coated copper tip, clamped with a nut to the handle.

Simple soldering irons reach a temperature determined by thermal equilibrium, dependent upon power input and

Simple soldering irons reach a temperature determined by thermal equilibrium, dependent upon power input and

A soldering station has a

A soldering station has a

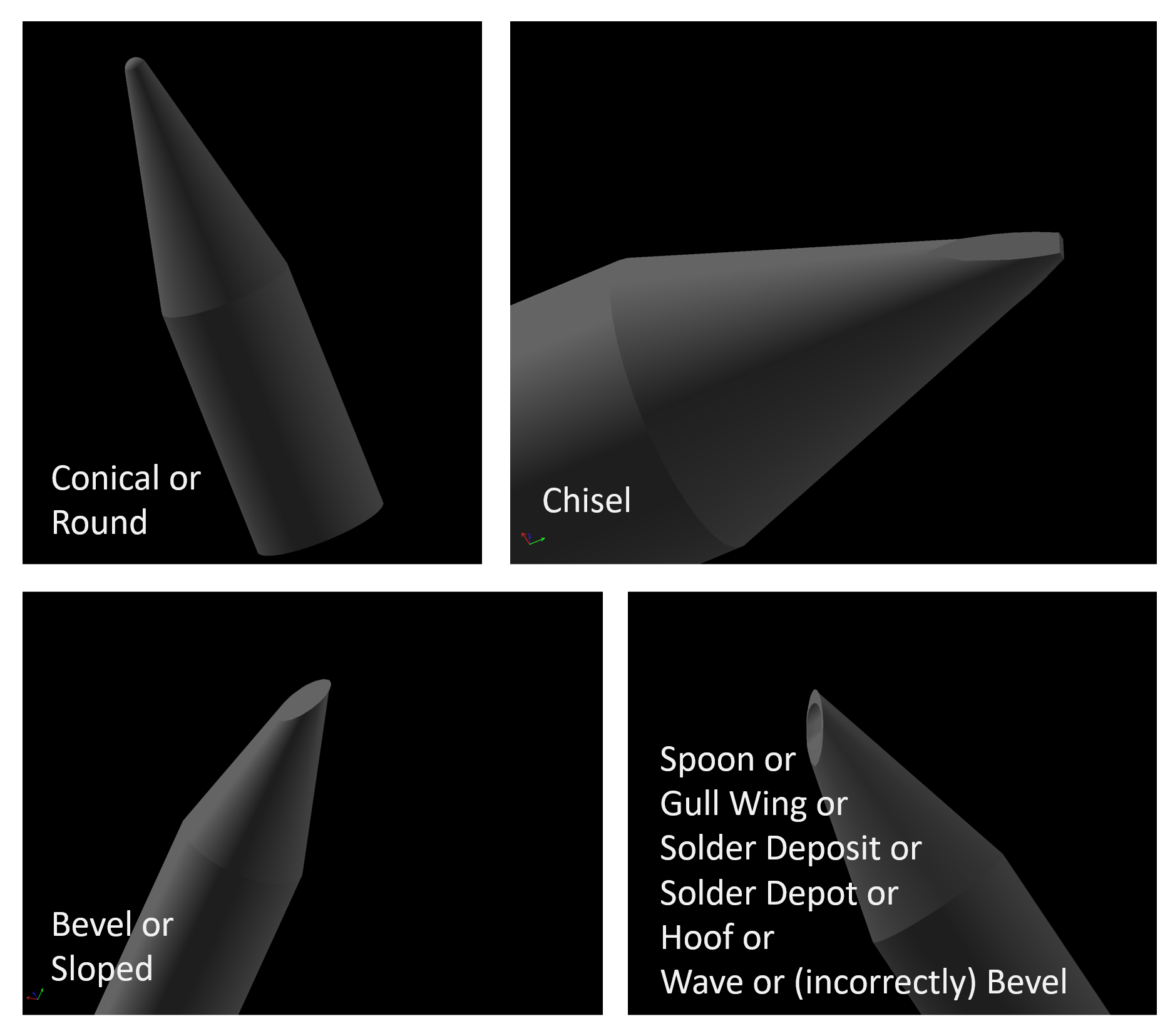

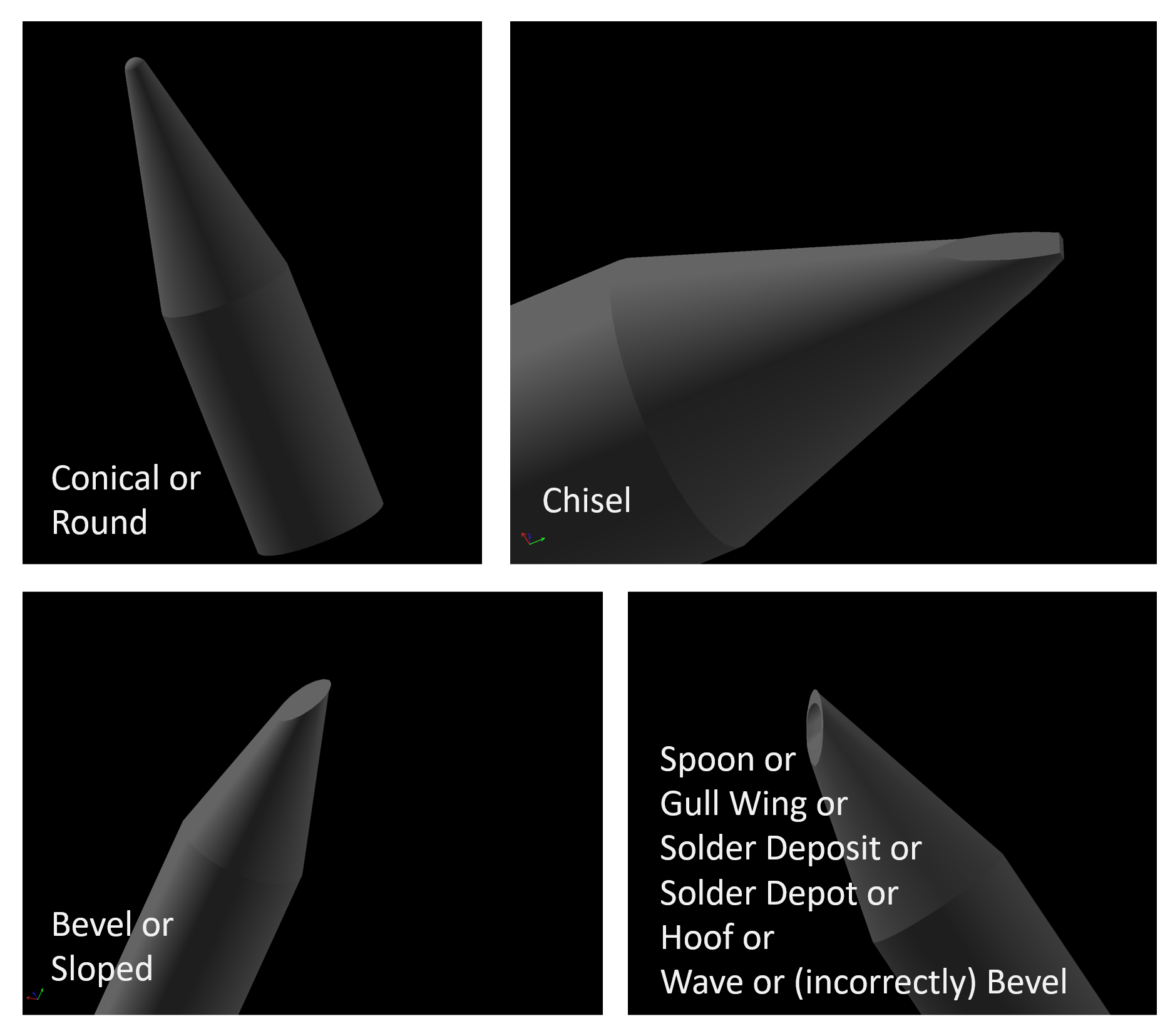

Most soldering irons for electronics have interchangeable tips, also known as ''bits'', that vary in size and shape for different types of work. Common tip shapes include: ''bevel'', ''chisel'', and ''conical''. An example of a more specialist tip is spoon or gull wing, which features concavity. See the image for renderings of a few different tip shapes and some of the names given to them.

Pyramid tips with a triangular flat face and chisel tips with a wide flat face are useful for soldering

Most soldering irons for electronics have interchangeable tips, also known as ''bits'', that vary in size and shape for different types of work. Common tip shapes include: ''bevel'', ''chisel'', and ''conical''. An example of a more specialist tip is spoon or gull wing, which features concavity. See the image for renderings of a few different tip shapes and some of the names given to them.

Pyramid tips with a triangular flat face and chisel tips with a wide flat face are useful for soldering

When the iron tip oxidises and burnt flux accumulates on it, solder no longer wets the tip, impeding heat transfer and making soldering difficult or impossible; tips must be periodically cleaned in use. Such problems happen with all kinds of solder, but are much more severe with the lead-free solders which have become widespread in electronics work, which require higher temperatures than solders containing lead. Exposed iron plating oxidises; if the tip is kept tinned with molten solder oxidation is inhibited. A clean unoxidised tip is tinned by applying a little solder and flux.

A wet small sponge, often supplied with soldering equipment, can be used to wipe the tip. For lead-free solder a slightly more aggressive cleaning, with brass shavings, can be used. Soldering flux will help to remove oxide; the more active the flux the better the cleaning, although acidic flux used on circuit boards that is not carefully cleaned off will cause corrosion. A tip which is cleaned but not retinned is susceptible to oxidation.

Soldering iron tips are made of a copper core plated various metals including iron. The copper is used for heat transfer and the other platings are for durability. Copper is very easily corroded, eating away the tip, particularly in lead-free work; iron is not. Cleaning tips requires the removal of oxide without damaging the iron plating and exposing the copper to rapid corrosion. The use of solder already containing a small amount of copper can slow corrosion of copper tips.

In cases of severe oxidation not removable by gentler methods, abrasion with something hard enough to remove oxide but not so hard as to scratch the iron plating can be used. A brass wire scourer, brush, or wheel on a bench grinder, can be used with care. Sandpaper and other tools may be used but are likely to damage the plating.

When the iron tip oxidises and burnt flux accumulates on it, solder no longer wets the tip, impeding heat transfer and making soldering difficult or impossible; tips must be periodically cleaned in use. Such problems happen with all kinds of solder, but are much more severe with the lead-free solders which have become widespread in electronics work, which require higher temperatures than solders containing lead. Exposed iron plating oxidises; if the tip is kept tinned with molten solder oxidation is inhibited. A clean unoxidised tip is tinned by applying a little solder and flux.

A wet small sponge, often supplied with soldering equipment, can be used to wipe the tip. For lead-free solder a slightly more aggressive cleaning, with brass shavings, can be used. Soldering flux will help to remove oxide; the more active the flux the better the cleaning, although acidic flux used on circuit boards that is not carefully cleaned off will cause corrosion. A tip which is cleaned but not retinned is susceptible to oxidation.

Soldering iron tips are made of a copper core plated various metals including iron. The copper is used for heat transfer and the other platings are for durability. Copper is very easily corroded, eating away the tip, particularly in lead-free work; iron is not. Cleaning tips requires the removal of oxide without damaging the iron plating and exposing the copper to rapid corrosion. The use of solder already containing a small amount of copper can slow corrosion of copper tips.

In cases of severe oxidation not removable by gentler methods, abrasion with something hard enough to remove oxide but not so hard as to scratch the iron plating can be used. A brass wire scourer, brush, or wheel on a bench grinder, can be used with care. Sandpaper and other tools may be used but are likely to damage the plating.

A soldering iron is a

A soldering iron is a hand tool

A hand tool is any tool that is powered manual labour, by hand rather than a motor. Categories of hand tools include wrenches, pliers, cutter (disambiguation), cutters, File (tool), files, hammer, striking tools, chisel, struck or hammered tools, ...

used in soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creatin ...

. It supplies heat to melt solder

Solder (; North American English, NA: ) is a fusible alloy, fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces aft ...

so that it can flow into the joint between two workpieces.

A soldering iron is composed of a heated metal tip (the ''bit'') and an insulated handle. Heating is often achieved electrically, by passing an electric current (supplied through an electrical cord or battery cables) through a resistive heating element

A heating element is a device used for conversion of electric energy into heat, consisting of a heating resistor and accessories. Heat is generated by the passage of electric current through a resistor through a process known as Joule heating. He ...

. Cordless irons can be heated by combustion of gas stored in a small tank, often using a catalytic heater rather than a flame. Simple irons, less commonly used today than in the past, were simply a large copper ''bit'' on a handle, heated in a flame.

Solder melts at approximately . Soldering irons are designed to reach a temperature range of .

Soldering irons are most often used for installation, repairs, and limited production work in electronics

Electronics is a scientific and engineering discipline that studies and applies the principles of physics to design, create, and operate devices that manipulate electrons and other electrically charged particles. It is a subfield of physics and ...

assembly. High-volume production lines use other soldering methods.Bralla, James G. ''Handbook of Manufacturing Processes - How Products, Components and Materials are Made'' Industrial Press, 2007 page 297 Large irons may be used for soldering joints in sheet metal objects. Less common uses include pyrography

Pyrography or pyrogravure is the free handed art of decorating wood or other materials with burn marks resulting from the controlled application of a heated object such as a Fireplace poker, poker. It is also known as pokerwork or wood burning. ...

(burning designs into wood) and plastic welding

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except for Solvent bonding, solvent welding). Welding of thermopl ...

(as an alternative to ultrasonic welding).

History

Before the development of electric soldering irons, the typical soldering iron consisted of acopper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

block, with an appropriately shaped point, supported on an iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

rod and held in a wood handle. Immediately before use, the iron was heated over a fire or in a charcoal brazier

A brazier () is a container used to burn charcoal or other solid fuel for cooking, heating or rituals. It often takes the form of a metal box or bowl with feet, but in some places it is made of terracotta. Its elevation helps circulate air, feed ...

, and it had to be reheated whenever it became too cool for use. Soldering irons were primarily used by tinsmith

A tinsmith is a historical term for a skilled craftsperson who makes and repairs things made of tin or other light metals. The profession was also known as a tinner, tinker, tinman, or tinplate worker; whitesmith may also refer to this profe ...

s and coppersmith

A coppersmith, also known as a brazier, is a person who makes artifacts from copper and brass. Brass is an alloy of copper and zinc. The term "redsmith" is used for a tinsmith that uses tinsmithing tools and techniques to make copper items.

Hi ...

s to work with thin sheet metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Thicknesses can vary significantly; extremely thin sheets are considered foil (metal), foil or Metal leaf, leaf, and pieces thicker than 6 mm (0.25 ...

.

A large copper block was required in order to have sufficient thermal capacity to provide

useful heat after removal from the fire, and copper is expensive. This led to the development of

soldering irons that had a small copper tip attached to an inexpensive cast-iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its car ...

block. Some irons even had removable and replaceable copper tips.

The first electric soldering iron had a very lightweight platinum tip heated by electric current

An electric current is a flow of charged particles, such as electrons or ions, moving through an electrical conductor or space. It is defined as the net rate of flow of electric charge through a surface. The moving particles are called charge c ...

flowing through the tip itself. By 1889, electric soldering irons were being developed with a resistance wire wrapped around the back end of the copper head and enclosed in a protective shell. Alternatively, the heating element

A heating element is a device used for conversion of electric energy into heat, consisting of a heating resistor and accessories. Heat is generated by the passage of electric current through a resistor through a process known as Joule heating. He ...

could be enclosed in a relatively light-weight hollow copper head.

In 1894, the American Electrical Heater Company began manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the

secondary sector of the economy. The term may refer ...

electrical soldering irons on a large scale in Detroit. They started producing them and shortly after American Electrical Heater Company released their line of soldering irons. In 1905, ''Scientific American Magazine,'' published a tutorial on making a soldering iron that

clearly explains how early irons were made.

In 1921, a German company founded by Ernst Sachs developed an electrical soldering iron similar to American Electrical Heater Company iron. in 1926, William Alferink applied for a patent for the first soldering station.

Actual "Form factor" of soldering irons

In 1946, Carl E. Weller applied for a patent for his soldering gun that could heat instantaneously and began production of the "Speedy Iron" in Pennsylvania. It was manufactured through the Weller Manufacturing Company, and this product was the first instantaneous thermal soldering gun. Few years later, they released to the market a soldering iron on with self-adjusting temperature. In 1951, the company WEN Products began manufacturing its own instantaneous soldering iron. After a three years trial Weller won for patent infringement.

In 1960 Weller got the patent for the soldering iron "Magnastat", renewed in 1964 and 1971. This iron could control the temperature by using a temperature-sensitive magnetic tip. The "Magnastat" became a best seller and it was included it in the W-TCP soldering station in 1967. In fact, within the patent, as a complementary description, it defines what today has become the " de facto", the redundancy is worth it, " form factor" of the vast majority of current Japanese and Chinese irons: Hakko, Baku, etc... The now-expired patent, which even Weller has stopped using on some models, described an outer tube holding the coated copper tip, clamped with a nut to the handle.

In 1946, Carl E. Weller applied for a patent for his soldering gun that could heat instantaneously and began production of the "Speedy Iron" in Pennsylvania. It was manufactured through the Weller Manufacturing Company, and this product was the first instantaneous thermal soldering gun. Few years later, they released to the market a soldering iron on with self-adjusting temperature. In 1951, the company WEN Products began manufacturing its own instantaneous soldering iron. After a three years trial Weller won for patent infringement.

In 1960 Weller got the patent for the soldering iron "Magnastat", renewed in 1964 and 1971. This iron could control the temperature by using a temperature-sensitive magnetic tip. The "Magnastat" became a best seller and it was included it in the W-TCP soldering station in 1967. In fact, within the patent, as a complementary description, it defines what today has become the " de facto", the redundancy is worth it, " form factor" of the vast majority of current Japanese and Chinese irons: Hakko, Baku, etc... The now-expired patent, which even Weller has stopped using on some models, described an outer tube holding the coated copper tip, clamped with a nut to the handle.

Types

Simple iron

For electrical and electronics work, a low-power iron, a power rating between 15 and 35watt

The watt (symbol: W) is the unit of Power (physics), power or radiant flux in the International System of Units (SI), equal to 1 joule per second or 1 kg⋅m2⋅s−3. It is used to quantification (science), quantify the rate of Work ...

s, is used. Higher ratings are available, but do not run at higher temperature; instead there is more heat available for making soldered connections to things with large thermal capacity, for example, a metal chassis. Some irons are temperature-controlled, running at a fixed temperature in the same way as a soldering station, with higher power available for joints with large heat capacity. Simple irons run at an uncontrolled temperature determined by thermal equilibrium

Two physical systems are in thermal equilibrium if there is no net flow of thermal energy between them when they are connected by a path permeable to heat. Thermal equilibrium obeys the zeroth law of thermodynamics. A system is said to be in t ...

; when heating something large their temperature drops.

A variation is the Scope soldering iron, common in Australia, which operates from a low-voltage source such as transformer or battery, and heats in seconds when the user pushes the thumb-guard, which then acts as a heat controller.

Cordless iron

Small irons heated by a battery, or by combustion of a gas such asbutane

Butane () is an alkane with the formula C4H10. Butane exists as two isomers, ''n''-butane with connectivity and iso-butane with the formula . Both isomers are highly flammable, colorless, easily liquefied gases that quickly vaporize at ro ...

in a small self-contained tank, can be used when electricity is unavailable or cordless operation is required. The operating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

of these irons is not regulated directly; gas irons may change power by adjusting gas flow. Gas-powered irons may have interchangeable tips including different size soldering tips, hot knife for cutting plastics, miniature blow-torch with a hot flame, and small hot air blower for such applications as shrinking heat shrink tubing.

Temperature-controlled soldering iron

cooling

Cooling is removal of heat, usually resulting in a lower temperature and/or Phase transition, phase change. Temperature lowering achieved by any other means may also be called cooling.

The Heat transfer, transfer of Internal energy, thermal energ ...

by the environment and the materials it comes into contact with. The iron temperature will drop when in contact with a large mass of metal such as a chassis; a small iron will lose too much temperature to solder a large connection. More advanced irons for use in electronics have a mechanism with a temperature sensor and method of temperature control to keep the tip temperature steady; more power is available if a connection is large. Temperature-controlled irons may be free-standing, or may comprise a head with heating element and tip, controlled by a base called a soldering station, with control circuitry and temperature adjustment and sometimes display.

A variety of means are used to control temperature. The simplest of these is a variable power control, much like a light dimmer, which changes the equilibrium temperature of the iron without automatically measuring or regulating the temperature. Another type of system uses a thermostat

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

Thermostats are used in any device or system tha ...

, often inside the iron's tip, which automatically switches power on and off to the element. A thermal sensor such as a thermocouple

A thermocouple, also known as a "thermoelectrical thermometer", is an electrical device consisting of two dissimilar electrical conductors forming an electrical junction. A thermocouple produces a temperature-dependent voltage as a result of the ...

may be used in conjunction with circuitry

An electronic circuit is composed of individual electronic components, such as resistors, transistors, capacitors, inductors and diodes, connected by conductive wires or traces through which electric current can flow. It is a type of electric ...

to monitor the temperature of the tip and adjust power delivered to the heating element to maintain a desired temperature. In some models, the firmware for the control circuitry is free software

Free software, libre software, libreware sometimes known as freedom-respecting software is computer software distributed open-source license, under terms that allow users to run the software for any purpose as well as to study, change, distribut ...

that can be modified by the end-user.

Another approach is to use magnetized soldering tips which lose their magnetic properties at a specific temperature, the Curie point

In physics and materials science, the Curie temperature (''T''C), or Curie point, is the temperature above which certain materials lose their magnet, permanent magnetic properties, which can (in most cases) be replaced by magnetization, induced ...

. As long as the tip is magnetic, it closes a switch to supply power to the heating element. When it exceeds the design temperature it opens the contacts, cooling until the temperature drops enough to restore magnetisation. More complex Curie-point irons circulate a high-frequency AC current through the tip, using magnetic physics to direct heating only where the surface of the tip drops below the Curie point.

Soldering station

A soldering station has a

A soldering station has a temperature

Temperature is a physical quantity that quantitatively expresses the attribute of hotness or coldness. Temperature is measurement, measured with a thermometer. It reflects the average kinetic energy of the vibrating and colliding atoms making ...

control and consists of an electrical power supply, control circuitry with provision for user adjustment of temperature and display, and a soldering iron or soldering head with a tip temperature sensor. The station will normally have a stand for the hot iron when not in use, and a wet sponge for cleaning. It is most commonly used for soldering electronic components. Other functions may be combined; for example a rework station, mainly for surface-mount components may have a hot air gun, vacuum pickup tool, and a soldering head; a desoldering station will have a desoldering head with vacuum pump for desoldering through-hole components, and a soldering iron head.

Soldering tweezers

For soldering and desoldering small surface-mount components with two terminals, such as some links, resistors, capacitors, and diodes, soldering tweezers can be used; they can be either free-standing or controlled from a soldering station. The tweezers have two heated tips mounted on arms whose separation can be manually varied by squeezing gently against spring force, like simpletweezers

Tweezers are small hand tools used for grasping objects too small to be easily handled with the human fingers. Tweezers are thumb-driven forceps most likely derived from tongs used to grab or hold hot objects since the dawn of recorded history. ...

; the tips are applied to the two ends of the component. The main purpose of the soldering tweezers is to melt solder in the correct place; components are usually moved by simple tweezers or vacuum pickup.

Hot knife

A hot knife is a form of soldering iron equipped with a double-edged blade that is situated on a heating element. These tools can reach temperatures of up to 1,000 degrees Fahrenheit (538 degrees Celsius) allowing for cuts of fabric and foam materials without worry of fraying or beading. Hot knives can be utilized in automotive, marine, and carpeting applications, as well as other industrial and personal uses.Stands

A soldering iron stand keeps the iron away from flammable materials, and often also comes with a cellulose sponge and flux pot for cleaning the tip. Some soldering irons for continuous andprofessional

A professional is a member of a profession or any person who work (human activity), works in a specified professional activity. The term also describes the standards of education and training that prepare members of the profession with the partic ...

use come as part of a ''soldering station,'' which allows the exact temperature of the tip to be adjusted, kept constant, and sometimes displayed.

Tips

Most soldering irons for electronics have interchangeable tips, also known as ''bits'', that vary in size and shape for different types of work. Common tip shapes include: ''bevel'', ''chisel'', and ''conical''. An example of a more specialist tip is spoon or gull wing, which features concavity. See the image for renderings of a few different tip shapes and some of the names given to them.

Pyramid tips with a triangular flat face and chisel tips with a wide flat face are useful for soldering

Most soldering irons for electronics have interchangeable tips, also known as ''bits'', that vary in size and shape for different types of work. Common tip shapes include: ''bevel'', ''chisel'', and ''conical''. An example of a more specialist tip is spoon or gull wing, which features concavity. See the image for renderings of a few different tip shapes and some of the names given to them.

Pyramid tips with a triangular flat face and chisel tips with a wide flat face are useful for soldering sheet metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Thicknesses can vary significantly; extremely thin sheets are considered foil (metal), foil or Metal leaf, leaf, and pieces thicker than 6 mm (0.25 ...

. Fine conical or tapered chisel tips are typically used for electronics work. Tips may be straight or have a bend. Concave or wicking tips with a chisel face with a concave well in the flat face to hold a small amount of solder are available. Tip selection depends upon the type of work and access to the joint; soldering of 0.5mm pitch surface-mount ICs, for example, is quite different from soldering a through-hole connection to a large area. A concave tip well is said to help prevent bridging of closely spaced leads; different shapes are recommended to correct bridging that has occurred. Due to patent restrictions not all manufacturers offer concave tips everywhere; in particular there are restrictions in the USA.

Older and very cheap irons typically use a bare copper tip, which is shaped with a file or sandpaper. This dissolves gradually into the solder, suffering pitting and erosion of the shape. Copper tips are sometimes filed when worn down. Iron-plated

Plating is a finishing process in which a metal is deposited on a surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improve solderab ...

copper tips have become increasingly popular since the 1980s. Because iron is not readily dissolved by molten solder, the plated tip is more durable than a bare copper one, though it will eventually wear out and need replacing. This is especially important when working at the higher temperatures needed for modern lead-free solders. Solid iron and steel tips are seldom used because they store less heat, conduct it poorly, and rusting can break the heating element.

Iron-plated tips may feature a layer of nickel between the copper core and the iron surface. A nickel-chrome outer plating may be used further back from the very tip, as solder does not stick well to this material: this avoids solder wetting parts of the tip where it would be unwanted.

Some tips have a heater and a thermocouple-based temperature sensor embedded to facilitate a more precise temperature control (TS100 and T12, for instance).

Cleaning

When the iron tip oxidises and burnt flux accumulates on it, solder no longer wets the tip, impeding heat transfer and making soldering difficult or impossible; tips must be periodically cleaned in use. Such problems happen with all kinds of solder, but are much more severe with the lead-free solders which have become widespread in electronics work, which require higher temperatures than solders containing lead. Exposed iron plating oxidises; if the tip is kept tinned with molten solder oxidation is inhibited. A clean unoxidised tip is tinned by applying a little solder and flux.

A wet small sponge, often supplied with soldering equipment, can be used to wipe the tip. For lead-free solder a slightly more aggressive cleaning, with brass shavings, can be used. Soldering flux will help to remove oxide; the more active the flux the better the cleaning, although acidic flux used on circuit boards that is not carefully cleaned off will cause corrosion. A tip which is cleaned but not retinned is susceptible to oxidation.

Soldering iron tips are made of a copper core plated various metals including iron. The copper is used for heat transfer and the other platings are for durability. Copper is very easily corroded, eating away the tip, particularly in lead-free work; iron is not. Cleaning tips requires the removal of oxide without damaging the iron plating and exposing the copper to rapid corrosion. The use of solder already containing a small amount of copper can slow corrosion of copper tips.

In cases of severe oxidation not removable by gentler methods, abrasion with something hard enough to remove oxide but not so hard as to scratch the iron plating can be used. A brass wire scourer, brush, or wheel on a bench grinder, can be used with care. Sandpaper and other tools may be used but are likely to damage the plating.

When the iron tip oxidises and burnt flux accumulates on it, solder no longer wets the tip, impeding heat transfer and making soldering difficult or impossible; tips must be periodically cleaned in use. Such problems happen with all kinds of solder, but are much more severe with the lead-free solders which have become widespread in electronics work, which require higher temperatures than solders containing lead. Exposed iron plating oxidises; if the tip is kept tinned with molten solder oxidation is inhibited. A clean unoxidised tip is tinned by applying a little solder and flux.

A wet small sponge, often supplied with soldering equipment, can be used to wipe the tip. For lead-free solder a slightly more aggressive cleaning, with brass shavings, can be used. Soldering flux will help to remove oxide; the more active the flux the better the cleaning, although acidic flux used on circuit boards that is not carefully cleaned off will cause corrosion. A tip which is cleaned but not retinned is susceptible to oxidation.

Soldering iron tips are made of a copper core plated various metals including iron. The copper is used for heat transfer and the other platings are for durability. Copper is very easily corroded, eating away the tip, particularly in lead-free work; iron is not. Cleaning tips requires the removal of oxide without damaging the iron plating and exposing the copper to rapid corrosion. The use of solder already containing a small amount of copper can slow corrosion of copper tips.

In cases of severe oxidation not removable by gentler methods, abrasion with something hard enough to remove oxide but not so hard as to scratch the iron plating can be used. A brass wire scourer, brush, or wheel on a bench grinder, can be used with care. Sandpaper and other tools may be used but are likely to damage the plating.

Safety precautions

Electro-static Discharge

Not all soldering irons are ESD-safe. Although some manufacturers' mains-powered models are built with the element shaft (and hence the tip) electrically connected to ground via the iron's mains lead, other models' tips may float at arbitrary voltages unless an additional grounding wire is used.Lead Exposure

Melting the solder can release toxic fumes, particularly solder with higher proportions of lead. It is recommended to work in a well-ventilated area; to avoid inhaling the toxic fumes; and to wash hands with soap after operating with a soldering iron. It is also recommended to use lead-free solder to mitigate the risks of lead exposure.High Temperature

When operating, the iron can reach temperatures in the range of 200-480°C. Never touch the heating element, since doing so while hot will cause one to contract skin burns. Make sure to switch off the device and hold it on the soldering stand when not in use - placing it directly on the workbench may cause it to make contact and damage the surface and nearby objects. Ensure that the cleaning sponge is wet while in operation.Solder Ejection

Sometimes, molten solder can "spit" or spatter, ejecting out from the wire and potentially causing damage to eyes and skin. This is caused by air pockets. Always wear appropriate eye protection, like safety goggles and fireproof clothing (like 100% cotton), covering the arms and legs and wear toe-closed shoes.See also

* Soldering station *Brazing

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

Brazing differs from welding in ...

— Joining metals structurally by the use of a higher temperature joining alloy than solder

* ColdHeat — A resistive "instant heat" soldering iron

* Soldering gun

* Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Co ...

— Melting two objects to be joined into each other

References

{{DEFAULTSORT:Soldering Iron Electronics work tools Soldering 19th-century inventions American inventions German inventions