Shale oil extraction on:

[Wikipedia]

[Google]

[Amazon]

Shale oil extraction is an industrial process for

Shale oil extraction process decomposes oil shale and converts its kerogen into shale oil—a

Shale oil extraction process decomposes oil shale and converts its kerogen into shale oil—a

Wall conduction ''in situ'' technologies use heating elements or heating pipes placed within the oil shale formation. The Shell in situ conversion process (Shell ICP) uses electrical heating elements for heating the oil shale layer to between over a period of approximately four years.

The processing area is isolated from surrounding

Wall conduction ''in situ'' technologies use heating elements or heating pipes placed within the oil shale formation. The Shell in situ conversion process (Shell ICP) uses electrical heating elements for heating the oil shale layer to between over a period of approximately four years.

The processing area is isolated from surrounding  In the CCR Process proposed by American Shale Oil, superheated steam or another heat transfer medium is circulated through a series of pipes placed below the oil shale layer to be extracted. The system combines horizontal wells, through which steam is passed, and vertical wells, which provide both vertical heat transfer through refluxing of converted shale oil and a means to collect the produced hydrocarbons. Heat is supplied by combustion of natural gas or

In the CCR Process proposed by American Shale Oil, superheated steam or another heat transfer medium is circulated through a series of pipes placed below the oil shale layer to be extracted. The system combines horizontal wells, through which steam is passed, and vertical wells, which provide both vertical heat transfer through refluxing of converted shale oil and a means to collect the produced hydrocarbons. Heat is supplied by combustion of natural gas or

Externally generated hot gas ''in situ'' technologies use hot gases heated above-ground and then injected into the oil shale formation. The Chevron CRUSH process, which was researched by Chevron Corporation in partnership with

Externally generated hot gas ''in situ'' technologies use hot gases heated above-ground and then injected into the oil shale formation. The Chevron CRUSH process, which was researched by Chevron Corporation in partnership with

The

The

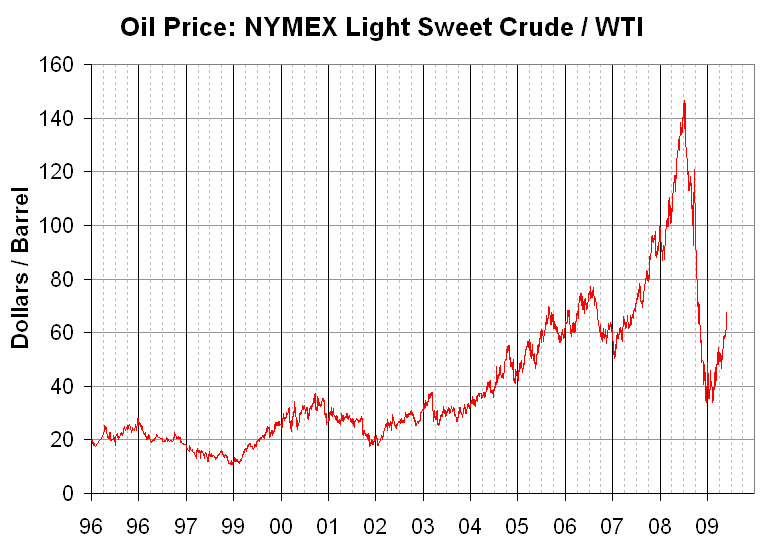

The dominant question for shale oil production is under what conditions shale oil is economically viable. According to the

The dominant question for shale oil production is under what conditions shale oil is economically viable. According to the

Oil-shale extraction can damage the biological and recreational value of land and the ecosystem in the mining area. Combustion and thermal processing generate waste material. In addition, the atmospheric emissions from oil shale processing and combustion include

Oil-shale extraction can damage the biological and recreational value of land and the ecosystem in the mining area. Combustion and thermal processing generate waste material. In addition, the atmospheric emissions from oil shale processing and combustion include

Oil Shale. A Scientific-Technical Journal

()

Oil Shale and Tar Sands Programmatic Environmental Impact Statement (EIS) Information Center.

Concerning potential leases of Federal oil sands lands in Utah and oil shale lands in Utah, Wyoming, and Colorado.

The United States National Oil Shale Association (NOSA)

{{DEFAULTSORT:Shale Oil Extraction Petroleum production Arab inventions

unconventional oil

Unconventional (oil and gas) reservoirs, or unconventional resources (resource plays) are Petroleum geology, accumulations where oil and gas Phase (matter), phases are tightly bound to the rock fabric by strong capillary action, capillary forces, ...

production. This process converts kerogen in oil shale

Oil shale is an organic-rich Granularity, fine-grained sedimentary rock containing kerogen (a solid mixture of Organic compound, organic chemical compounds) from which liquid hydrocarbons can be produced. In addition to kerogen, general compos ...

into shale oil by pyrolysis

Pyrolysis is a process involving the Bond cleavage, separation of covalent bonds in organic matter by thermal decomposition within an Chemically inert, inert environment without oxygen. Etymology

The word ''pyrolysis'' is coined from the Gree ...

, hydrogenation

Hydrogenation is a chemical reaction between molecular hydrogen (H2) and another compound or element, usually in the presence of a catalyst such as nickel, palladium or platinum. The process is commonly employed to redox, reduce or Saturated ...

, or thermal dissolution. The resultant shale oil is used as fuel oil

Fuel oil is any of various fractions obtained from the distillation of petroleum (crude oil). Such oils include distillates (the lighter fractions) and residues (the heavier fractions). Fuel oils include heavy fuel oil (bunker fuel), marine f ...

or upgraded to meet refinery feedstock specifications by adding hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

and removing sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

and nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

impurities.

Shale oil extraction is usually performed above ground (''ex situ'' processing) by mining the oil shale and then treating it in processing facilities. Other modern technologies perform the processing underground (on-site or ''in situ

is a Latin phrase meaning 'in place' or 'on site', derived from ' ('in') and ' ( ablative of ''situs'', ). The term typically refers to the examination or occurrence of a process within its original context, without relocation. The term is use ...

'' processing) by applying heat and extracting the oil via oil wells.

The earliest description of the process dates to the 10th century. In 1684, England granted the first formal extraction process patent. Extraction industries and innovations became widespread during the 19th century. The industry shrank in the mid-20th century following the discovery of large reserves of conventional oil, but high petroleum prices at the beginning of the 21st century have led to renewed interest, accompanied by the development and testing of newer technologies.

As of 2010, major long-standing extraction industries are operating in Estonia

Estonia, officially the Republic of Estonia, is a country in Northern Europe. It is bordered to the north by the Gulf of Finland across from Finland, to the west by the Baltic Sea across from Sweden, to the south by Latvia, and to the east by Ru ...

, Brazil

Brazil, officially the Federative Republic of Brazil, is the largest country in South America. It is the world's List of countries and dependencies by area, fifth-largest country by area and the List of countries and dependencies by population ...

, and China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

. Its economic viability usually requires a lack of locally available crude oil. National energy security

Energy security is the association between national security and the availability of natural resources for energy consumption (as opposed to household energy insecurity). Access to cheaper energy has become essential to the functioning of modern ...

issues have also played a role in its development. Critics of shale oil extraction pose questions about environmental management

Environmental resource management or environmental management is the management of the interaction and impact of human societies on the environment. It is not, as the phrase might suggest, the management of the environment itself. Environment ...

issues, such as waste disposal, extensive water use, waste water management, and air pollution.

History

In the 10th century, the Assyrian physician Masawaih al-Mardini (Mesue the Younger) wrote of his experiments in extracting oil from "some kind of bituminous shale". The first shale oil extraction patent was granted by the English Crown in 1684 to three people who had "found a way to extract and make great quantities of pitch, tarr, and oyle out of a sort of stone". Modern industrial extraction of shale oil originated inFrance

France, officially the French Republic, is a country located primarily in Western Europe. Overseas France, Its overseas regions and territories include French Guiana in South America, Saint Pierre and Miquelon in the Atlantic Ocean#North Atlan ...

with the implementation of a process invented by Alexander Selligue in 1838, improved upon a decade later in Scotland

Scotland is a Countries of the United Kingdom, country that is part of the United Kingdom. It contains nearly one-third of the United Kingdom's land area, consisting of the northern part of the island of Great Britain and more than 790 adjac ...

using a process invented by James Young.

During the late 19th century, plants were built in Australia, Brazil, Canada, and the United States. The 1894 invention of the Pumpherston retort, which was much less reliant on coal heat than its predecessors, marked the separation of the oil shale industry from the coal industry.

China (Manchuria

Manchuria is a historical region in northeast Asia encompassing the entirety of present-day northeast China and parts of the modern-day Russian Far East south of the Uda (Khabarovsk Krai), Uda River and the Tukuringra-Dzhagdy Ranges. The exact ...

), Estonia, New Zealand

New Zealand () is an island country in the southwestern Pacific Ocean. It consists of two main landmasses—the North Island () and the South Island ()—and List of islands of New Zealand, over 600 smaller islands. It is the List of isla ...

, South Africa

South Africa, officially the Republic of South Africa (RSA), is the Southern Africa, southernmost country in Africa. Its Provinces of South Africa, nine provinces are bounded to the south by of coastline that stretches along the Atlantic O ...

, Spain

Spain, or the Kingdom of Spain, is a country in Southern Europe, Southern and Western Europe with territories in North Africa. Featuring the Punta de Tarifa, southernmost point of continental Europe, it is the largest country in Southern Eur ...

, Sweden

Sweden, formally the Kingdom of Sweden, is a Nordic countries, Nordic country located on the Scandinavian Peninsula in Northern Europe. It borders Norway to the west and north, and Finland to the east. At , Sweden is the largest Nordic count ...

, and Switzerland

Switzerland, officially the Swiss Confederation, is a landlocked country located in west-central Europe. It is bordered by Italy to the south, France to the west, Germany to the north, and Austria and Liechtenstein to the east. Switzerland ...

began extracting shale oil in the early 20th century. However, crude oil discoveries in Texas

Texas ( , ; or ) is the most populous U.S. state, state in the South Central United States, South Central region of the United States. It borders Louisiana to the east, Arkansas to the northeast, Oklahoma to the north, New Mexico to the we ...

during the 1920s and in the Middle East

The Middle East (term originally coined in English language) is a geopolitical region encompassing the Arabian Peninsula, the Levant, Turkey, Egypt, Iran, and Iraq.

The term came into widespread usage by the United Kingdom and western Eur ...

in the mid 20th century brought most oil shale industries to a halt.

In 1944, the US recommenced shale oil extraction as part of its Synthetic Liquid Fuels Program. These industries continued until oil prices fell sharply in the 1980s. The last oil shale retort in the US, operated by Unocal Corporation, closed in 1991. The US program was restarted in 2003, followed by a commercial leasing program in 2005 permitting the extraction of oil shale and oil sands on federal lands in accordance with the Energy Policy Act of 2005

The Energy Policy Act of 2005 () is a federal law signed by President George W. Bush on August 8, 2005, at Sandia National Laboratories in Albuquerque, New Mexico. The act, described by proponents as an attempt to combat growing energy problems ...

.

, shale oil extraction is in operation in Estonia, Brazil, and China.

In 2008, their industries produced about 930,000 tonne

The tonne ( or ; symbol: t) is a unit of mass equal to 1,000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton in the United States to distinguish it from the non-metric units of the s ...

s (17,700 barrels per day) of shale oil. Australia, the US, and Canada have tested shale oil extraction techniques via demonstration projects and are planning commercial implementation; Morocco

Morocco, officially the Kingdom of Morocco, is a country in the Maghreb region of North Africa. It has coastlines on the Mediterranean Sea to the north and the Atlantic Ocean to the west, and has land borders with Algeria to Algeria–Morocc ...

and Jordan

Jordan, officially the Hashemite Kingdom of Jordan, is a country in the Southern Levant region of West Asia. Jordan is bordered by Syria to the north, Iraq to the east, Saudi Arabia to the south, and Israel and the occupied Palestinian ter ...

have announced their intent to do the same.

Only four processes are in commercial use: Kiviter, Galoter, Fushun, and Petrosix.

Processing principles

Shale oil extraction process decomposes oil shale and converts its kerogen into shale oil—a

Shale oil extraction process decomposes oil shale and converts its kerogen into shale oil—a petroleum

Petroleum, also known as crude oil or simply oil, is a naturally occurring, yellowish-black liquid chemical mixture found in geological formations, consisting mainly of hydrocarbons. The term ''petroleum'' refers both to naturally occurring un ...

-like synthetic crude oil. The process is conducted by pyrolysis

Pyrolysis is a process involving the Bond cleavage, separation of covalent bonds in organic matter by thermal decomposition within an Chemically inert, inert environment without oxygen. Etymology

The word ''pyrolysis'' is coined from the Gree ...

, hydrogenation

Hydrogenation is a chemical reaction between molecular hydrogen (H2) and another compound or element, usually in the presence of a catalyst such as nickel, palladium or platinum. The process is commonly employed to redox, reduce or Saturated ...

, or thermal dissolution.

The efficiencies of extraction processes are often evaluated by comparing their yields to the results of a Fischer Assay performed on a sample of the shale.

The oldest and the most common extraction method involves pyrolysis (also known as ''retorting'' or destructive distillation

Destructive distillation is a chemical process in which decomposition of unprocessed material is achieved by heating it to a high temperature; the term generally applies to processing of organic material in the absence of air or in the presence o ...

). In this process, oil shale is heated in the absence of oxygen until its kerogen decomposes into condensable shale oil vapors and non-condensable combustible oil shale gas. Oil vapors and oil shale gas are then collected and cooled, causing the shale oil to condense. In addition, oil shale processing produces spent oil shale, which is a solid residue. Spent shale consists of inorganic compound

An inorganic compound is typically a chemical compound that lacks carbon–hydrogen bondsthat is, a compound that is not an organic compound. The study of inorganic compounds is a subfield of chemistry known as ''inorganic chemistry''.

Inorgan ...

s (mineral

In geology and mineralogy, a mineral or mineral species is, broadly speaking, a solid substance with a fairly well-defined chemical composition and a specific crystal structure that occurs naturally in pure form.John P. Rafferty, ed. (2011): Mi ...

s) and char—a carbonaceous residue formed from kerogen. Burning the char off the spent shale produces oil shale ash. Spent shale and shale ash can be used as ingredients in cement or brick manufacture.

The composition of the oil shale may lend added value to the extraction process through the recovery of by-products, including ammonia

Ammonia is an inorganic chemical compound of nitrogen and hydrogen with the chemical formula, formula . A Binary compounds of hydrogen, stable binary hydride and the simplest pnictogen hydride, ammonia is a colourless gas with a distinctive pu ...

, sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

, aromatic compounds, pitch, asphalt, and waxes.

Heating the oil shale to pyrolysis temperature and completing the endothermic

An endothermic process is a chemical or physical process that absorbs heat from its surroundings. In terms of thermodynamics, it is a thermodynamic process with an increase in the enthalpy (or internal energy ) of the system.Oxtoby, D. W; Gillis, ...

kerogen decomposition reactions require a source of energy. Some technologies burn other fossil fuel

A fossil fuel is a flammable carbon compound- or hydrocarbon-containing material formed naturally in the Earth's crust from the buried remains of prehistoric organisms (animals, plants or microplanktons), a process that occurs within geolog ...

s such as natural gas, oil, or coal to generate this heat and experimental methods have used electricity, radio wave

Radio waves (formerly called Hertzian waves) are a type of electromagnetic radiation with the lowest frequencies and the longest wavelengths in the electromagnetic spectrum, typically with frequencies below 300 gigahertz (GHz) and wavelengths g ...

s, microwave

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequency, frequencies between 300&n ...

s, or reactive fluids for this purpose.

Two strategies are used to reduce, and even eliminate, external heat energy requirements: the oil shale gas and char by-products generated by pyrolysis may be burned as a source of energy, and the heat contained in hot spent oil shale and oil shale ash may be used to pre-heat the raw oil shale.

For ''ex situ'' processing, oil shale is crushed into smaller pieces, increasing surface area for better extraction. The temperature at which decomposition of oil shale occurs depends on the time-scale of the process. In ''ex situ'' retorting processes, it begins at and proceeds more rapidly and completely at higher temperatures. The amount of oil produced is the highest when the temperature ranges between . The ratio of oil shale gas to shale oil generally increases along with retorting temperatures.

For a modern ''in situ'' process, which might take several months of heating, decomposition may be conducted at temperatures as low as . Temperatures below are preferable, as this prevents the decomposition of limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

and dolomite in the rock and thereby limits carbon dioxide

Carbon dioxide is a chemical compound with the chemical formula . It is made up of molecules that each have one carbon atom covalent bond, covalently double bonded to two oxygen atoms. It is found in a gas state at room temperature and at norma ...

emissions and energy consumption.

Hydrogenation and thermal dissolution (reactive fluid processes) extract the oil using hydrogen donors, solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

s, or a combination of these. Thermal dissolution involves the application of solvents at elevated temperatures and pressures, increasing oil output by cracking the dissolved organic matter. Different methods produce shale oil with different properties.

Classification of extraction technologies

Industry analysts have created several classifications of the technologies used to extract shale oil from oil shale. ''By process principles'': Based on the treatment of raw oil shale by heat and solvents the methods are classified as pyrolysis, hydrogenation, or thermal dissolution. ''By location'': A frequently used distinction considers whether processing is done above or below ground, and classifies the technologies broadly as ''ex situ'' (displaced) or ''in situ'' (in place). In ''ex situ'' processing, also known as above-ground retorting, the oil shale is mined either underground or at the surface and then transported to a processing facility. In contrast, ''in situ'' processing converts the kerogen while it is still in the form of an oil shale deposit, following which it is then extracted via oil wells, where it rises in the same way as conventional crude oil. Unlike ''ex situ'' processing, it does not involve mining or spent oil shale disposal aboveground as spent oil shale stays underground. ''By heating method'': The method of transferring heat from combustion products to the oil shale may be classified as direct or indirect. While methods that allow combustion products to contact the oil shale within the retort are classified as ''direct'', methods that burn materials external to the retort to heat another material that contacts the oil shale are described as ''indirect'' ''By heat carrier'': Based on the material used to deliver heat energy to the oil shale, processing technologies have been classified into gas heat carrier, solid heat carrier, wall conduction, reactive fluid, and volumetric heating methods. Heat carrier methods can be sub-classified as direct or indirect. The following table shows extraction technologies classified by heating method, heat carrier and location (''in situ'' or ''ex situ''). ''By raw oil shale particle size'': The various ''ex situ'' processing technologies may be differentiated by the size of the oil shale particles that are fed into the retorts. As a rule, gas heat carrier technologies process oil shale lumps varying in diameter from , while solid heat carrier and wall conduction technologies process fines which are particles less than in diameter. ''By retort orientation'': "Ex-situ" technologies are sometimes classified as vertical or horizontal. Vertical retorts are usually shaft kilns where a bed of shale moves from top to bottom by gravity. Horizontal retorts are usually horizontal rotating drums or screws where shale moves from one end to the other. As a general rule, vertical retorts process lumps using a gas heat carrier, while horizontal retorts process fines using solid heat carrier. ''By complexity of technology'': ''In situ'' technologies are usually classified either as ''true in situ'' processes or ''modified in situ'' processes. ''True in situ'' processes do not involve mining or crushing the oil shale. ''Modified in situ'' processes involve drilling and fracturing the target oil shale deposit to create voids in the deposit. The voids enable a better flow of gases and fluids through the deposit, thereby increasing the volume and quality of the shale oil produced.''Ex situ'' technologies

Internal combustion

Internal combustion technologies burn materials (typically char and oil shale gas) within a vertical shaft retort to supply heat for pyrolysis. Typically raw oil shale particles between and in size are fed into the top of the retort and are heated by the rising hot gases, which pass through the descending oil shale, thereby causing decomposition of the kerogen at about . Shale oil mist, evolved gases and cooled combustion gases are removed from the top of the retort then moved to separation equipment. Condensed shale oil is collected, while non-condensable gas is recycled and used to carry heat up the retort. In the lower part of the retort, air is injected for the combustion which heats the spent oil shale and gases to between and . Cold recycled gas may enter the bottom of the retort to cool the shale ash. The Union A and Superior Direct processes depart from this pattern. In the Union A process, oil shale is fed through the bottom of the retort and a pump moves it upward. In the Superior Direct process, oil shale is processed in a horizontal, segmented, doughnut-shaped traveling-grate retort. Internal combustion technologies such as the Paraho Direct are thermally efficient, since combustion of char on the spent shale and heat recovered from the shale ash and evolved gases can provide all the heat requirements of the retort. These technologies can achieve 80–90% of Fischer assay yield. Two well-established shale oil industries use internal combustion technologies: Kiviter process facilities have been operated continuously in Estonia since the 1920s, and a number of Chinese companies operate Fushun process facilities. Common drawbacks of internal combustion technologies are that the combustible oil shale gas is diluted by combustion gases and particles smaller than can not be processed. Uneven distribution of gas across the retort can result in blockages when hot spots cause particles to fuse or disintegrate.Hot recycled solids

Hot recycled solids technologies deliver heat to the oil shale by recycling hot solid particles—typically oil shale ash. These technologies usually employ rotating kiln or fluidized bed retorts, fed by fine oil shale particles generally having a diameter of less than ; some technologies use particles even smaller than . The recycled particles are heated in a separate chamber or vessel to about and then mixed with the raw oil shale to cause the shale to decompose at about . Oil vapour and shale oil gas are separated from the solids and cooled to condense and collect the oil. Heat recovered from the combustion gases and shale ash may be used to dry and preheat the raw oil shale before it is mixed with the hot recycle solids. In the Galoter and Enefit processes, the spent oil shale is burnt in a separate furnace and the resulting hot ash is separated from the combustion gas and mixed with oil shale particles in a rotating kiln. Combustion gases from the furnace are used to dry the oil shale in a dryer before mixing with hot ash. The TOSCO II process usesceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

balls instead of shale ash as the hot recycled solids.

The distinguishing feature of the Alberta Taciuk Process (ATP) is that the entire process occurs in a single rotating multi–chamber horizontal vessel.

Because the hot recycle solids are heated in a separate furnace, the oil shale gas from these technologies is not diluted with combustion exhaust gas. Another advantage is that there is no limit on the smallest particles that the retort can process, thus allowing all the crushed feed to be used. One disadvantage is that more water is used to handle the resulting finer shale ash.

Conduction through a wall

These technologies transfer heat to the oil shale by conducting it through the retort wall. The shale feed usually consists of fine particles. Their advantage lies in the fact that retort vapors are not combined with combustion exhaust. The Combustion Resources process uses a hydrogen–fired rotating kiln, where hot gas is circulated through an outer annulus. The Oil-Tech staged electrically heated retort consists of individual inter-connected heating chambers, stacked atop each other. Its principal advantage lies in its modular design, which enhances its portability and adaptability. The Red Leaf Resources EcoShale In-Capsule Process combines surface mining with a lower-temperature heating method similar to ''in situ'' processes by operating within the confines of an earthen structure. A hot gas circulated through parallel pipes heats the oil shale rubble. An installation within the empty space created by mining would permit rapid reclamation of the topography. A general drawback of conduction through a wall technologies is that the retorts are more costly when scaled-up due to the resulting large amount of heat conducting walls made of high-temperature alloys.Externally generated hot gas

In general, externally generated hot gas technologies are similar to internal combustion technologies in that they also process oil shale lumps in vertical shaft kilns. Significantly, though, the heat in these technologies is delivered by gases heated outside the retort vessel, and therefore the retort vapors are not diluted with combustion exhaust. The Petrosix and Paraho Indirect employ this technology. In addition to not accepting fine particles as feed, these technologies do not utilize the potential heat of combusting the char on the spent shale and thus must burn more valuable fuels. However, due to the lack of combustion of the spent shale, the oil shale does not exceed and significant carbonate mineral decomposition and subsequent CO2 generation can be avoided for some oil shales. Also, these technologies tend to be the more stable and easier to control than internal combustion or hot solid recycle technologies.Reactive fluids

Kerogen is tightly bound to the shale and resists dissolution by mostsolvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

s. Despite this constraint, extraction using especially reactive fluids has been tested, including those in a supercritical state. Reactive fluid technologies are suitable for processing oil shales with a low hydrogen content. In these technologies, hydrogen gas (H2) or hydrogen donors (chemicals that donate hydrogen during chemical reactions) react with coke precursors (chemical structures in the oil shale that are prone to form char during retorting but have not yet done so).

Reactive fluid technologies include the IGT Hytort (high-pressure H2) process, donor solvent processes, and the Chattanooga fluidized bed reactor. In the IGT Hytort oil shale is processed in a high-pressure hydrogen environment.

The Chattanooga process uses a fluidized bed reactor and an associated hydrogen-fired heater for oil shale thermal cracking and hydrogenation.

Laboratory results indicate that these technologies can often obtain significantly higher oil yields than pyrolysis processes. Drawbacks are the additional cost and complexity of hydrogen production

Hydrogen gas is produced by several industrial methods. Nearly all of the world's current supply of hydrogen is created from fossil fuels. Article in press. Most hydrogen is ''gray hydrogen'' made through steam methane reforming. In this process, ...

and high-pressure retort vessels.

Plasma gasification

Several experimental tests have been conducted for the oil-shale gasification by using plasma technologies. In these technologies, oil shale is bombarded by radicals ( ions). The radicals crack kerogenmolecule

A molecule is a group of two or more atoms that are held together by Force, attractive forces known as chemical bonds; depending on context, the term may or may not include ions that satisfy this criterion. In quantum physics, organic chemi ...

s forming synthetic gas and oil. Air, hydrogen or nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

are used as plasma gas and processes may operate in an arc, plasma arc, or plasma electrolysis mode.

The main benefit of these technologies is processing without using water.

''In situ'' technologies

''In situ

is a Latin phrase meaning 'in place' or 'on site', derived from ' ('in') and ' ( ablative of ''situs'', ). The term typically refers to the examination or occurrence of a process within its original context, without relocation. The term is use ...

'' technologies heat oil shale underground by injecting hot fluids into the rock formation, or by using linear or planar heating sources followed by thermal conduction

Thermal conduction is the diffusion of thermal energy (heat) within one material or between materials in contact. The higher temperature object has molecules with more kinetic energy; collisions between molecules distributes this kinetic energy ...

and convection

Convection is single or Multiphase flow, multiphase fluid flow that occurs Spontaneous process, spontaneously through the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoy ...

to distribute heat through the target area. Shale oil is then recovered through vertical wells drilled into the formation. These technologies are potentially able to extract more shale oil from a given area of land than conventional '' ex situ'' processing technologies, as the wells can reach greater depths than surface mines. They present an opportunity to recover shale oil from low-grade deposits that traditional mining techniques could not extract.

John Fell experimented with ''in situ'' extraction, at Newnes, In Australia, during 1921, with some success, but his ambitions were well ahead of technologies available at the time.

During World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

a modified ''in situ'' extraction process was implemented without significant success in Germany. One of the earliest successful ''in situ'' processes was underground gasification by electrical energy ( Ljungström method)—a process exploited between 1940 and 1966 for shale oil extraction at Kvarntorp in Sweden.

Prior to the 1980s, many variations of the ''in situ'' process were explored in the United States. The first modified ''in situ'' oil shale experiment in the United States was conducted by Occidental Petroleum in 1972 at Logan Wash, Colorado. Newer technologies are being explored that use a variety of heat sources and heat delivery systems.

Wall conduction

Wall conduction ''in situ'' technologies use heating elements or heating pipes placed within the oil shale formation. The Shell in situ conversion process (Shell ICP) uses electrical heating elements for heating the oil shale layer to between over a period of approximately four years.

The processing area is isolated from surrounding

Wall conduction ''in situ'' technologies use heating elements or heating pipes placed within the oil shale formation. The Shell in situ conversion process (Shell ICP) uses electrical heating elements for heating the oil shale layer to between over a period of approximately four years.

The processing area is isolated from surrounding groundwater

Groundwater is the water present beneath Earth's surface in rock and Pore space in soil, soil pore spaces and in the fractures of stratum, rock formations. About 30 percent of all readily available fresh water in the world is groundwater. A unit ...

by a freeze wall consisting of wells filled with a circulating super-chilled fluid.

Disadvantages of this process are large electrical power consumption, extensive water use, and the risk of groundwater pollution.

The process was tested since the early 1980s at the Mahogany test site in the Piceance Basin. of oil were extracted in 2004 at a testing area.

In the CCR Process proposed by American Shale Oil, superheated steam or another heat transfer medium is circulated through a series of pipes placed below the oil shale layer to be extracted. The system combines horizontal wells, through which steam is passed, and vertical wells, which provide both vertical heat transfer through refluxing of converted shale oil and a means to collect the produced hydrocarbons. Heat is supplied by combustion of natural gas or

In the CCR Process proposed by American Shale Oil, superheated steam or another heat transfer medium is circulated through a series of pipes placed below the oil shale layer to be extracted. The system combines horizontal wells, through which steam is passed, and vertical wells, which provide both vertical heat transfer through refluxing of converted shale oil and a means to collect the produced hydrocarbons. Heat is supplied by combustion of natural gas or propane

Propane () is a three-carbon chain alkane with the molecular formula . It is a gas at standard temperature and pressure, but becomes liquid when compressed for transportation and storage. A by-product of natural gas processing and petroleum ref ...

in the initial phase and by oil shale gas at a later stage.

The Geothermic Fuels Cells Process (IEP GFC) proposed by Independent Energy Partners extracts shale oil by exploiting a high-temperature stack of fuel cell

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen fuel, hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most bat ...

s. The cells, placed in the oil shale formation, are fueled by natural gas during a warm-up period and afterward by oil shale gas generated by its own waste heat.

Externally generated hot gas

Los Alamos National Laboratory

Los Alamos National Laboratory (often shortened as Los Alamos and LANL) is one of the sixteen research and development Laboratory, laboratories of the United States Department of Energy National Laboratories, United States Department of Energy ...

, injects heated carbon dioxide into the formation via drilled wells and to heat the formation through a series of horizontal fractures through which the gas is circulated.

General Synfuels International has proposed the Omnishale process involving injection of super-heated air into the oil shale formation. Mountain West Energy's In Situ Vapor Extraction process uses similar principles of injection of high-temperature gas.

ExxonMobil Electrofrac

ExxonMobil

Exxon Mobil Corporation ( ) is an American multinational List of oil exploration and production companies, oil and gas corporation headquartered in Spring, Texas, a suburb of Houston. Founded as the Successors of Standard Oil, largest direct s ...

's ''in situ'' technology ( ExxonMobil Electrofrac) uses electrical heating with elements of both wall conduction and volumetric heating methods. It injects an electrically conductive material such as calcined petroleum coke into the hydraulic fractures created in the oil shale formation which then forms a heating element.

Heating wells are placed in a parallel row with a second horizontal well intersecting them at their toe. This allows opposing electrical charges to be applied at either end.

Volumetric heating

Illinois Institute of Technology

The Illinois Institute of Technology, commonly referred to as Illinois Tech and IIT, is a Private university, private research university in Chicago, Illinois, United States. Tracing its history to 1890, the present name was adopted upon the m ...

developed the concept of oil shale volumetric heating using radio waves

Radio waves (formerly called Hertzian waves) are a type of electromagnetic radiation with the lowest frequencies and the longest wavelengths in the electromagnetic spectrum, typically with frequencies below 300 gigahertz (GHz) and wavelengths ...

(radio frequency processing) during the late 1970s. This technology was further developed by Lawrence Livermore National Laboratory

Lawrence Livermore National Laboratory (LLNL) is a Federally funded research and development centers, federally funded research and development center in Livermore, California, United States. Originally established in 1952, the laboratory now i ...

. Oil shale is heated by vertical electrode arrays. Deeper volumes could be processed at slower heating rates by installations spaced at tens of meters. The concept presumes a radio frequency at which the skin depth is many tens of meters, thereby overcoming the thermal diffusion times needed for conductive heating.

Its drawbacks include intensive electrical demand and the possibility that groundwater or char would absorb undue amounts of the energy. Radio frequency processing in conjunction with critical fluids is being developed by Raytheon

Raytheon is a business unit of RTX Corporation and is a major U.S. defense contractor and industrial corporation with manufacturing concentrations in weapons and military and commercial electronics. Founded in 1922, it merged in 2020 with Unite ...

together with CF Technologies and tested by Schlumberger.

Microwave heating technologies are based on the same principles as radio wave heating, although it is believed that radio wave heating is an improvement over microwave heating because its energy can penetrate farther into the oil shale formation.

The microwave heating process was tested by Global Resource Corporation.

Electro-Petroleum proposes electrically enhanced oil recovery by the passage of direct current

Direct current (DC) is one-directional electric current, flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor (material), conductor such as a wire, but can also flow throug ...

between cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device such as a lead-acid battery. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. Conventional curren ...

s in producing wells and anode

An anode usually is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, which is usually an electrode of the device through which conventional current leaves the devic ...

s located either at the surface or at depth in other wells. The passage of the current through the oil shale formation results in resistive Joule heating.

Shale oil

The properties of raw shale oil vary depending on the composition of the parent oil shale and the extraction technology used. Like conventional oil, shale oil is a complex mixture of hydrocarbons, and it is characterized using bulk properties of the oil. Shale oil usually contains large quantities of olefinic andaromatic

In organic chemistry, aromaticity is a chemical property describing the way in which a conjugated system, conjugated ring of unsaturated bonds, lone pairs, or empty orbitals exhibits a stabilization stronger than would be expected from conjugati ...

hydrocarbons. Shale oil can also contain significant quantities of heteroatoms. A typical shale oil composition includes 0.5–1% of oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

, 1.5–2% of nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

and 0.15–1% of sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

, and some deposits contain more heteroatoms. Mineral particles and metals are often present as well.

Generally, the oil is less fluid than crude oil, becoming pourable at temperatures between , while conventional crude oil is pourable at temperatures between ; this property affects shale oil's ability to be transported in existing pipelines.

Shale oil contains polycyclic aromatic hydrocarbons which are carcinogenic

A carcinogen () is any agent that promotes the development of cancer. Carcinogens can include synthetic chemicals, naturally occurring substances, physical agents such as ionizing and non-ionizing radiation, and Biological agent, biologic agent ...

. It has been described that raw shale oil has a mild carcinogenic potential which is comparable to some intermediate refinery products, while upgraded shale oil has lower carcinogenic potential as most of the polycyclic aromatics are believed to broken down by hydrogenation.

Although raw shale oil can be immediately burnt as a fuel oil, many of its applications require that it be upgraded. The differing properties of the raw oils call for correspondingly various pre-treatments before it can be sent to a conventional oil refinery

An oil refinery or petroleum refinery is an industrial processes, industrial process Factory, plant where petroleum (crude oil) is transformed and refining, refined into products such as gasoline (petrol), diesel fuel, Bitumen, asphalt base, ...

.

Particulates in the raw oil clog downstream processes; sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

and nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

create air pollution

Air pollution is the presence of substances in the Atmosphere of Earth, air that are harmful to humans, other living beings or the environment. Pollutants can be Gas, gases like Ground-level ozone, ozone or nitrogen oxides or small particles li ...

. Sulfur and nitrogen, along with the arsenic

Arsenic is a chemical element; it has Symbol (chemistry), symbol As and atomic number 33. It is a metalloid and one of the pnictogens, and therefore shares many properties with its group 15 neighbors phosphorus and antimony. Arsenic is not ...

and iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

that may be present, also destroy the catalysts used in refining. Olefins form insoluble sediments and cause instability. The oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

within the oil, present at higher levels than in crude oil, lends itself to the formation of destructive free radical

A daughter category of ''Ageing'', this category deals only with the biological aspects of ageing.

Ageing

Biogerontology

Biological processes

Causes of death

Cellular processes

Gerontology

Life extension

Metabolic disorders

Metabolism

...

s. Hydrodesulfurization and hydrodenitrogenation can address these problems and result in a product comparable to benchmark crude oil.

Phenols

In organic chemistry, phenols, sometimes called phenolics, are a class of chemical compounds consisting of one or more hydroxyl groups (− O H) bonded directly to an aromatic hydrocarbon group. The simplest is phenol, . Phenolic compounds ar ...

can be first be removed by water extraction. Upgrading shale oil into transport fuels requires adjusting hydrogen–carbon ratios by adding hydrogen ( hydrocracking) or removing carbon ( coking).

Before World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

, most shale oil was upgraded for use as transport fuels. Afterwards, it was used as a raw material for chemical intermediates, pure chemicals and industrial resins, and as a railroad wood preservative

A preservative is a substance or a chemical that is added to products such as food products, beverages, pharmaceutical drugs, paints, biological samples, cosmetics, wood, and many other products to prevent decomposition by microbial growth or ...

. As of 2008, it is primarily used as a heating oil and marine fuel, and to a lesser extent in the production of various chemicals.

Shale oil's concentration of high-boiling point compounds is suited for the production of middle distillates such as kerosene

Kerosene, or paraffin, is a combustibility, combustible hydrocarbon liquid which is derived from petroleum. It is widely used as a fuel in Aviation fuel, aviation as well as households. Its name derives from the Greek (''kērós'') meaning " ...

, jet fuel

Jet fuel or aviation turbine fuel (ATF, also abbreviated avtur) is a type of aviation fuel designed for use in aircraft powered by Gas turbine, gas-turbine engines. It is colorless to straw-colored in appearance. The most commonly used fuels for ...

and diesel fuel

Diesel fuel, also called diesel oil, heavy oil (historically) or simply diesel, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a re ...

.

Additional cracking can create the lighter hydrocarbons used in gasoline.

Economics

United States Department of Energy

The United States Department of Energy (DOE) is an executive department of the U.S. federal government that oversees U.S. national energy policy and energy production, the research and development of nuclear power, the military's nuclear w ...

, the capital costs of a ''ex-situ'' processing complex are $3–10 billion.

The various attempts to develop oil shale deposits have succeeded only when the shale-oil production cost in a given region is lower than the price of petroleum or its other substitutes. According to a survey conducted by the RAND Corporation

The RAND Corporation, doing business as RAND, is an American nonprofit global policy think tank, research institute, and public sector consulting firm. RAND engages in research and development (R&D) in several fields and industries. Since the ...

, the cost of producing shale oil at a hypothetical surface retorting complex in the United States (comprising a mine, retorting plant, upgrading plant, supporting utilities, and spent oil shale reclamation), would be in a range of $70–95 per barrel ($440–600/m3), adjusted to 2005 values. Assuming a gradual increase in output after the start of commercial production, the analysis projects a gradual reduction in processing costs to $30–40 per barrel ($190–250/m3) after achieving the milestone of .

The United States Department of Energy estimates that the ''ex-situ'' processing would be economic at sustained average world oil prices above $54 per barrel and ''in-situ'' processing would be economic at prices above $35 per barrel. These estimates assume a return rate of 15%. Royal Dutch Shell announced in 2006 that its Shell ICP technology would realize a profit when crude oil prices are higher than $30 per barrel ($190/m3), while some technologies at full-scale production assert profitability at oil prices even lower than $20 per barrel ($130/m3).

To increase the efficiency of oil shale retorting and by this the viability of the shale oil production, researchers have proposed and tested several co-pyrolysis processes, in which other materials such as biomass

Biomass is a term used in several contexts: in the context of ecology it means living organisms, and in the context of bioenergy it means matter from recently living (but now dead) organisms. In the latter context, there are variations in how ...

, peat

Peat is an accumulation of partially Decomposition, decayed vegetation or organic matter. It is unique to natural areas called peatlands, bogs, mires, Moorland, moors, or muskegs. ''Sphagnum'' moss, also called peat moss, is one of the most ...

, waste bitumen

Bitumen ( , ) is an immensely viscosity, viscous constituent of petroleum. Depending on its exact composition, it can be a sticky, black liquid or an apparently solid mass that behaves as a liquid over very large time scales. In American Engl ...

, or rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds.

Types of polyisoprene ...

and plastic

Plastics are a wide range of synthetic polymers, synthetic or Semisynthesis, semisynthetic materials composed primarily of Polymer, polymers. Their defining characteristic, Plasticity (physics), plasticity, allows them to be Injection moulding ...

wastes are retorted along with the oil shale.

Some modified technologies propose combining a fluidized bed retort with a circulated fluidized bed furnace for burning the by-products of pyrolysis (char and oil shale gas) and thereby improving oil yield, increasing throughput, and decreasing retorting time.

Other ways of improving the economics of shale oil extraction could be to increase the size of the operation to achieve economies of scale

In microeconomics, economies of scale are the cost advantages that enterprises obtain due to their scale of operation, and are typically measured by the amount of Productivity, output produced per unit of cost (production cost). A decrease in ...

, use oil shale that is a by-product of coal mining such as at Fushun China, produce specialty chemicals as by Viru Keemia Grupp in Estonia, co-generate electricity from the waste heat and process high grade oil shale that yields more oil per shale processed.

A possible measure of the viability of oil shale as an energy source lies in the ratio of the energy in the extracted oil to the energy used in its mining and processing (Energy Returned on Energy Invested, or EROEI). A 1984 study estimated the EROEI of the various known oil shale deposits as varying between 0.7 and 13.3;

Some companies and newer technologies assert an EROEI between 3 and 10. According to the World Energy Outlook 2010, the EROEI of ''ex-situ'' processing is typically 4 to 5 while of ''in-situ'' processing it may be even as low as 2.

To increase the EROEI, several combined technologies were proposed. These include the usage of process waste heat, e.g. gasification or combustion of the residual carbon (char), and the usage of waste heat from other industrial processes, such as coal gasification

In industrial chemistry, coal gasification is the process of producing syngas—a mixture consisting primarily of carbon monoxide (CO), hydrogen (), carbon dioxide (), methane (), and water vapour ()—from coal and water, air and/or oxygen.

H ...

and nuclear power

Nuclear power is the use of nuclear reactions to produce electricity. Nuclear power can be obtained from nuclear fission, nuclear decay and nuclear fusion reactions. Presently, the vast majority of electricity from nuclear power is produced by ...

generation.

The water requirements of extraction processes are an additional economic consideration in regions where water is a scarce resource.

Environmental considerations

Mining oil shale involves a number of environmental impacts, more pronounced in surface mining than in underground mining. These include acid drainage induced by the sudden rapid exposure and subsequentoxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

of formerly buried materials, the introduction of metals including mercury into surface-water and groundwater, increased erosion

Erosion is the action of surface processes (such as Surface runoff, water flow or wind) that removes soil, Rock (geology), rock, or dissolved material from one location on the Earth's crust#Crust, Earth's crust and then sediment transport, tran ...

, sulfur-gas emissions, and air pollution caused by the production of particulates

Particulate matter (PM) or particulates are microscopic particles of solid or liquid matter suspension (chemistry), suspended in the atmosphere of Earth, air. An ''aerosol'' is a mixture of particulates and air, as opposed to the particulate ...

during processing, transport, and support activities.

In 2002, about 97% of air pollution, 86% of total waste and 23% of water pollution in Estonia came from the power industry, which uses oil shale as the main resource for its power production.

Oil-shale extraction can damage the biological and recreational value of land and the ecosystem in the mining area. Combustion and thermal processing generate waste material. In addition, the atmospheric emissions from oil shale processing and combustion include

Oil-shale extraction can damage the biological and recreational value of land and the ecosystem in the mining area. Combustion and thermal processing generate waste material. In addition, the atmospheric emissions from oil shale processing and combustion include carbon dioxide

Carbon dioxide is a chemical compound with the chemical formula . It is made up of molecules that each have one carbon atom covalent bond, covalently double bonded to two oxygen atoms. It is found in a gas state at room temperature and at norma ...

, a greenhouse gas

Greenhouse gases (GHGs) are the gases in the atmosphere that raise the surface temperature of planets such as the Earth. Unlike other gases, greenhouse gases absorb the radiations that a planet emits, resulting in the greenhouse effect. T ...

. Environmentalists oppose production and usage of oil shale, as it creates even more greenhouse gases than conventional fossil fuels.

Experimental ''in situ'' conversion processes and carbon capture and storage technologies may reduce some of these concerns in the future, but at the same time they may cause other problems, including groundwater

Groundwater is the water present beneath Earth's surface in rock and Pore space in soil, soil pore spaces and in the fractures of stratum, rock formations. About 30 percent of all readily available fresh water in the world is groundwater. A unit ...

pollution.

Among the water contaminants commonly associated with oil shale processing are oxygen and nitrogen heterocyclic hydrocarbons. Commonly detected examples include quinoline derivatives, pyridine, and various alkyl homologues of pyridine ( picoline, lutidine).

Water concerns are sensitive issues in arid regions, such as the western US and Israel's Negev Desert

The Negev ( ; ) or Naqab (), is a desert and semidesert region of southern Israel. The region's largest city and administrative capital is Beersheba (pop. ), in the north. At its southern end is the Gulf of Aqaba and the resort town, resort city ...

, where plans exist to expand oil-shale extraction despite a water shortage. Depending on technology, above-ground retorting uses between one and five barrels of water per barrel of produced shale-oil.

A 2008 programmatic environmental impact statement issued by the US Bureau of Land Management

The Bureau of Land Management (BLM) is an agency within the United States Department of the Interior responsible for administering federal lands, U.S. federal lands. Headquartered in Washington, D.C., the BLM oversees more than of land, or one ...

stated that surface mining and retort operations produce of waste water per of processed oil shale. ''In situ'' processing, according to one estimate, uses about one-tenth as much water.

Environmental activists, including members of Greenpeace

Greenpeace is an independent global campaigning network, founded in Canada in 1971 by a group of Environmental movement, environmental activists. Greenpeace states its goal is to "ensure the ability of the Earth to nurture life in all its biod ...

, have organized strong protests against the oil shale industry. In one result, Queensland Energy Resources put the proposed Stuart Oil Shale Project in Australia on hold in 2004.

See also

*Oil shale in China

Oil shale in China is an important source of unconventional oil. A total Chinese oil shale reserves, oil shale resource amounts of 720 billion tonnes, located in 80 deposits of 47 oil shale basins. This is equal to 48 billion t ...

* Oil shale in Estonia

* Oil shale in Jordan

* Oil shale geology

* Oil shale reserves

References

External links

Oil Shale. A Scientific-Technical Journal

()

Oil Shale and Tar Sands Programmatic Environmental Impact Statement (EIS) Information Center.

Concerning potential leases of Federal oil sands lands in Utah and oil shale lands in Utah, Wyoming, and Colorado.

The United States National Oil Shale Association (NOSA)

{{DEFAULTSORT:Shale Oil Extraction Petroleum production Arab inventions