Safety Lamp on:

[Wikipedia]

[Google]

[Amazon]

A safety lamp is any of several types of lamp that provides illumination in places such as

A safety lamp is any of several types of lamp that provides illumination in places such as

In Europe and Britain dried fish skins which emitted a faint

In Europe and Britain dried fish skins which emitted a faint

In the

In the

A safety lamp is any of several types of lamp that provides illumination in places such as

A safety lamp is any of several types of lamp that provides illumination in places such as coal mine

Coal mining is the process of resource extraction, extracting coal from the ground or from a mine. Coal is valued for its Energy value of coal, energy content and since the 1880s has been widely used to Electricity generation, generate electr ...

s where the air may carry coal dust

Coal dust is a fine-powdered form of coal which is created by the crushing, grinding, or pulverizer, pulverization of coal rock. Because of the brittle nature of coal, coal dust can be created by mining, transporting, or mechanically handling it. ...

or a build-up of flammable gases, which may explode if ignited, possibly by an electric spark. Until the development of effective electric lamps in the early 1900s, miners used flame lamps to provide illumination. Open flame lamps could ignite flammable gases which collected in mines, causing explosions; safety lamps were developed to enclose the flame to prevent it from igniting the explosive gases. Flame safety lamps have been replaced for lighting in mining with sealed explosion-proof electric lights, but continue to be used to detect gases.

Background

Damps or gases

Miners have traditionally referred to the various gases encountered during mining as damps, from theMiddle Low German

Middle Low German is a developmental stage of Low German. It developed from the Old Saxon language in the Middle Ages and has been documented in writing since about 1225–34 (). During the Hanseatic period (from about 1300 to about 1600), Mid ...

word ''dampf'' (meaning "vapour

In physics, a vapor (American English) or vapour (Commonwealth English; see spelling differences) is a substance in the gas phase at a temperature lower than its critical temperature,R. H. Petrucci, W. S. Harwood, and F. G. Herring, ''General ...

"). Damps are variable mixtures and are historic terms.

* '' Firedamp'' Naturally occurring flammable mixtures, principally methane.

* '' Blackdamp'' or ''Chokedamp'' Nitrogen and carbon dioxide with no oxygen. Formed by complete combustion of firedamp or occurring naturally. Coal in contact with air will oxidize slowly and, if unused workings are not ventilated, pockets of blackdamp may develop. Also referred to as ''azotic air'' in some 19th-century papers.

* '' Whitedamp'' Formed by the incomplete combustion of coal, or firedamp. The mixture may contain significant amounts of carbon monoxide, which is toxic and potentially explosive.

* ''Stinkdamp

Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hydride gas, and is toxic, corrosive, and flammable. Trace amounts in ambient atmosphere have a characteristic foul odor of rotten eggs. Swedish chemist Car ...

'' Naturally occurring hydrogen sulphide

Hydrogen sulfide is a chemical compound with the formula . It is a colorless chalcogen-hydride gas, and is toxic, corrosive, and flammable. Trace amounts in ambient atmosphere have a characteristic foul odor of rotten eggs. Swedish chemist Ca ...

and other gases. The hydrogen sulphide is highly toxic, but easily detected by smell. The other gases with it may be firedamp or blackdamp.

* ''Afterdamp

Afterdamp is the toxic mixture of gases left in a mine following an explosion caused by methane-rich firedamp, which itself can initiate a much larger explosion of coal dust. The term is etymologically and practically related to other terms for ...

'' The gas from an explosion of firedamp or coal dust. Contains varying proportions of blackdamp and whitedamp and is therefore suffocating, toxic, or explosive, or any combination of these. Afterdamp may also contain stinkdamp. Afterdamp may be a bigger killer following an explosion than the explosion itself.

Open-flame illumination

Before the invention of safety lamps, miners used candles with open flames. This gave rise to frequentexplosions

An explosion is a rapid expansion in volume of a given amount of matter associated with an extreme outward release of energy, usually with the generation of high temperatures and release of high-pressure gases. Explosions may also be generate ...

. For example, at one colliery (Killingworth) in the north east of England, 10 miners were killed in 1806 and 12 in 1809. In 1812, 90 men and boys were suffocated or burnt to death in the Felling Pit near Gateshead and 22 in the following year.

describes the testing of a mine for firedamp. A candle is prepared by being trimmed and excess fat removed. It is held at arm's length at floor level in one hand, the other hand shielding out all except the tip of the flame. As the candle is raised the tip is observed and if unchanged the atmosphere is safe. If however the tip turns bluish-gray increasing in height to a thin extended point becoming a deeper blue, then firedamp is present. Upon detecting firedamp the candle is lowered and arrangements made for the ventilating of the area or the deliberate firing of the firedamp after the end of a shift. To fire the gas, a man edged forward with a lit candle on the end of a stick. He kept his head down to allow the explosion to pass over him, but as soon as the explosion had occurred stood as upright as possible to avoid the afterdamp. Officially known as a fireman, he was also referred to as a penitent or monk from the hooded garb he wore as protection. The protective clothing was made of well-dampened wool or leather. This was a job with risk of injury, or to life.

When they came into regular use, barometer

A barometer is a scientific instrument that is used to measure air pressure in a certain environment. Pressure tendency can forecast short term changes in the weather. Many measurements of air pressure are used within surface weather analysis ...

s were used to tell if atmospheric pressure

Atmospheric pressure, also known as air pressure or barometric pressure (after the barometer), is the pressure within the atmosphere of Earth. The standard atmosphere (symbol: atm) is a unit of pressure defined as , which is equivalent to 1,013. ...

was low, which could lead to more firedamp seeping out of the coal seams into the mine galleries. This continued to be essential information even after the introduction of safety lamps; at Trimdon Grange there was an accident involving pressure.

The lack of good lighting was a major cause of the eye affliction nystagmus

Nystagmus is a condition of involuntary (or voluntary, in some cases) Eye movement (sensory), eye movement. People can be born with it but more commonly acquire it in infancy or later in life. In many cases it may result in visual impairment, re ...

. Miners working in thin seams or when undercutting the coal had to lie on their side in cramped conditions. The pick was swung horizontally to a point beyond the top of their head. In order to see where they were aiming (and accurate blows were needed), the eyes needed to be straining in what would normally be the upwards and slightly to one side direction. This straining led first to temporary nystagmus and then to a permanent disability. Mild nystagmus would self-correct if a miner ceased to perform this work, but if left untreated would force a man to give up mining. The lower levels of light emitted by safety lamps caused an increase in the incidence of nystagmus.

First attempts at safe lamps

bioluminescence

Bioluminescence is the emission of light during a chemiluminescence reaction by living organisms. Bioluminescence occurs in multifarious organisms ranging from marine vertebrates and invertebrates, as well as in some Fungus, fungi, microorgani ...

(often called phosphorescence) were used.

Flint and steel mills introduced by Carlisle Spedding (1696–1755) before 1733 had been tried with limited success. An example of a Spedding steel mill may be seen in the museum at Whitehaven

Whitehaven is a town and civil parish in the Cumberland (unitary authority), Cumberland district of Cumbria, England. It is a port on the north-west coast, and lies outside the Lake District National parks of England and Wales, National Park. ...

where Spedding was manager of the collieries of Sir James Lowther, 4th Baronet

Sir James Lowther, 4th Baronet, FRS (1673 – 2 January 1755) was an English landowner, industrialist and Whig politician who sat in the House of Commons for 54 years between 1694 and 1755. His ownership and development of coal mines around W ...

. A steel disk was rotated at high speed by a crank mechanism. Pressing a flint

Flint, occasionally flintstone, is a sedimentary cryptocrystalline form of the mineral quartz, categorized as the variety of chert that occurs in chalk or marly limestone. Historically, flint was widely used to make stone tools and start ...

against the disk produced a shower of sparks and dim illumination. These mills were troublesome to use and were often worked by a boy, whose only task was to provide light for a group of miners. It was assumed that the sparks had insufficient energy to ignite firedamp until a series of explosions at Wallsend

Wallsend () is a town in North Tyneside, Tyne and Wear, England, at the eastern end of Hadrian's Wall. It has a population of 43,842 and lies east of Newcastle upon Tyne.

History Roman Wallsend

In Roman times, this was the site of the fort of ...

colliery in 1784; a further explosion in June 1785, which the operator of the mill survived, showed that ignition was possible.

The first safety lamp made by William Reid Clanny used a pair of bellows to pump air through water to a candle burning in a metal case with a glass window. Exhaust gases passed out through water. The lamp was intrinsically safe provided it was kept upright, but gave out only a weak light. It was heavy and ungainly and required a man to pump it continuously. It was not a practical success, and Clanny subsequently changed the basis of operation of later lamps in the light of the Davy and Stephenson lamps.

Oil lamps

Principles of operation

Safety lamps have to address the following issues: * Provide adequate light * Do not trigger explosions * Warn of a dangerous atmosphere Fire requires three elements to burn: fuel, oxidant and heat; the triangle of fire. Remove one element of this triangle and the burning will stop. A safety lamp has to ensure that the triangle of fire is maintained inside the lamp, but cannot pass to the outside. Since any breathable atmosphere contains oxygen, and a safety lamp's ''raison d'être'' is to operate in an atmosphere also containing fuel (firedamp or coal dust), the element which must be blocked is heat. The key to manufacturing a successful safety lamp is to control the transfer of heat while still allowing air (the necessary oxidant) to enter and leave the lamp. There are three main paths by which heat must be prevented from leaving the lamp: * convection of the exhaust gases, * conduction through the lamp body, and * burning of the incoming firedamp passing back through the inlet. In the Geordie lamp, the inlet and exhausts are kept separate. Restrictions in the inlet ensure that only just enough air for combustion passes through the lamp. A tall chimney contains the spent gases above the flame. If the percentage of firedamp starts to rise, less oxygen is available in the air and combustion is diminished or extinguished. Early Geordie lamps had a simple pierced copper cap over the chimney to further restrict the flow and to ensure that the vital spent gas did not escape too quickly. Later designs used metal mesh or gauze for the same purpose, and also as a barrier in itself. The inlet is through a number of fine tubes (early) or through a gallery (later). In the case of the gallery system air passes through a number of small holes into the gallery and through wire gauze to the lamp. The tubes both restrict the flow and ensure that any back flow is cooled. The flame front travels more slowly in narrow tubes (a key Stephenson observation) and allows the tubes to effectively stop such a flow. In the Davy system, a metal gauze surrounds the flame and extends for a distance above forming a cage; flames do not pass through a fine enough mesh. All except the very earliest Davy lamps have a double layer at the top of the cage. Rising hot gases are cooled by the gauze, the metal conducting the heat away and being itself cooled by the incoming air. There is no restriction on the air entering the lamp; if firedamp is present it will get through the mesh and burn within the lamp itself, but without igniting gas outside. As the lamp burns brighter in dangerous atmospheres it acts as a warning to miners of rising firedamp levels. The Clanny configuration uses a short glass section around the flame with a gauze cylinder above it. Air is drawn in and descends just inside the glass, passing up through the flame in the centre of the lamp. The outer casings of lamps are made of materials such as brass or tinned steel, which do not make a spark if they strike rock.History and development

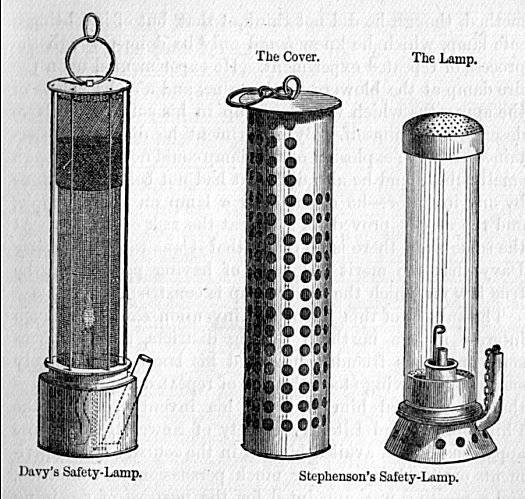

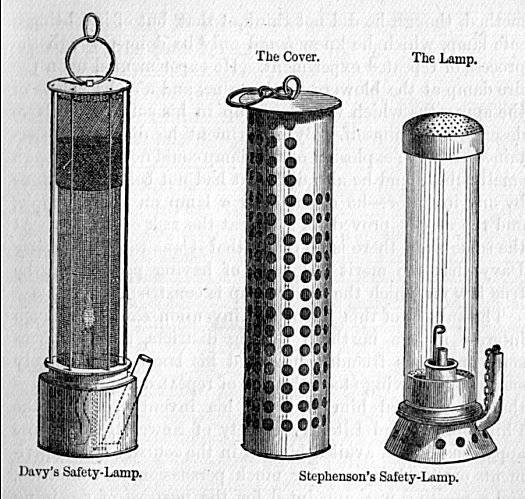

Within months of Clanny's demonstration of his first lamp, two improved designs had been announced: one byGeorge Stephenson

George Stephenson (9 June 1781 – 12 August 1848) was an English civil engineer and Mechanical engineering, mechanical engineer during the Industrial Revolution. Renowned as the "Father of Railways", Stephenson was considered by the Victoria ...

, which later became the Geordie lamp, and the Davy lamp

The Davy lamp is a safety lamp used in flammable atmospheres, invented in 1815 by Sir Humphry Davy.Sir Humphry Davy

Sir Humphry Davy, 1st Baronet (17 December 177829 May 1829) was a British chemist and inventor who invented the Davy lamp and a very early form of arc lamp. He is also remembered for isolating, by using electricity, several Chemical element, e ...

. Subsequently, Clanny incorporated aspects of both lamps and produced the ancestor of all modern oil safety lamps.

George Stephenson came from a mining family and by 1804 had secured the post of brakesman at Killingworth colliery. He was present at both the 1806 and 1809 explosions in the pit. By 1810, he was engineman and responsible for machinery both above and below ground. The pit was a gassy pit and Stephenson took the lead in work to extinguish a fire in 1814. For some years prior to 1815 he had been experimenting on the ''blowers'' or fissures from which gas erupted. He reasoned that a lamp in a chimney could create a sufficient updraft that firedamp would not penetrate down the chimney. Further observations of the speed of flame fronts in fissures and passageways led him to design a lamp with fine tubes admitting the air.

Sir Humphry Davy was asked to consider the problems of a safety lamp following the Felling explosion. Previous experimenters had used coal gas (chiefly carbon monoxide) incorrectly, believing it to be the same as firedamp. Davy, however, performed his experiments with samples of firedamp collected from pits. As an experimental chemist, he was familiar with the inability of flames to pass through mesh; his experiments enabled him to determine the correct size and fineness for a miner's lamp.

Davy was awarded the Rumford Medal and £1,000 by the Royal Society

The Royal Society, formally The Royal Society of London for Improving Natural Knowledge, is a learned society and the United Kingdom's national academy of sciences. The society fulfils a number of roles: promoting science and its benefits, re ...

in 1816 and a £2,000 prize by the country's colliery owners, who also awarded 100 guineas

The guinea (; commonly abbreviated gn., or gns. in plural) was a coin, minted in Great Britain between 1663 and 1814, that contained approximately one-quarter of an ounce of gold. The name came from the Guinea region in West Africa, from where m ...

(£105) to Stephenson. The Newcastle committee also awarded Stephenson a £1,000 prize collected by subscription. Clanny was awarded a medal by the Royal Society of Arts in 1816.

Both the Davy and Stephenson lamps were fragile. The gauze in the Davy lamp rusted in the damp air of a coal pit and became unsafe, while the glass in the Stephenson lamp was easily broken, and allowed the flame to ignite firedamp in the mine; later Stephenson designs also incorporated a gauze screen as a protection against glass breakage. Developments, including the Gray, Mueseler and Marsaut lamps, tried to overcome these problems by using multiple gauze cylinders, but glass remained a problem until toughened glass became available.

Improper use of safety lamps defeated the purpose of the safety lamp and caused risk. When the flame went out in a lamp there was a temptation for the collier to open and relight it. Some opened the lamps to light tobacco pipes underground. Both of these practices were strictly forbidden. The miner was expected to return to the shaft, a round trip of up to a few miles, to relight an extinguished lamp. For men on piece work

Piece work or piecework is any type of employment in which a worker is paid a fixed piece rate for each unit produced or action performed, regardless of time.

Context

When paying a worker, employers can use various methods and combinations of m ...

paid for what they produced, a relighting could cost them perhaps 10% of their day's pay, encouraging them to take the risk. Miners would also damage the mesh to make the lamp brighter. To prevent dangerous relighting (or opening the lamp to light a pipe), from the mid-century onwards, and particularly after the 1872 act, lamps had to have a lock mechanism which prevented the miner opening the lamp. Two schemes existed: either a special tool was required which was kept at the pit head, or else opening the lamp extinguished the flame. The latter mechanism can be seen in the Mueseler, Landau, and Yates lamps below. Such a lamp was known as a ''protector'' lamp, a term picked up and used as a company name. Only on the return to the bank could the lamp man open the lamp for refilling and service. Various different locking mechanisms were developed; miners tended to be ingenious in finding ways of circumventing them. A number of additional lit lamps were supposed to accompany each gang of men, but restricting the number was an obvious economy for the pit owners.

The light given out by these lamps was poor (particularly Davy's, obscured by the gauze); early lamps gave less light than candles. This was not resolved until the introduction of electric lighting around 1900, and the introduction of battery-powered helmet lamps in 1930. The poor light provided yet another reason for miners to try to circumvent the locks.

The gauze in early lamps (the Davy, Geordie and Clanny) was exposed to air currents. It was quickly discovered that an air current could cause the flame, in effect, to pass through the gauze: the flame playing directly on the mesh heats it faster than the heat can be conducted away, increasing its temperature until sufficient to ignite the gas outside the lamp.

The following data is compiled from :

Following accidents such as Wallsend (1818), Trimdon Grange (1882) and the Bedford Colliery Disaster (1886), lamps had to be shielded against such currents. In the case of the Davy, a "Tin-can Davy" was developed which had a metal cylinder with perforations at the bottom and a glass window for the light from the gauze. Clanny derived lamps had a metal "bonnet" (typically of tinned iron) in the shape of a truncated cone covering the gauze above the glass cylinder. The important point was that no direct current of air could impinge on the gauze itself. The shields had the disadvantage of not allowing the collier or the deputy to check that the gauze was in place and clean. Lamps were therefore made so that they could be inspected and then the bonnet placed on and locked.

Davy used a fine wire gauze with a mesh of 784 holes per square inch (28 mesh). The required fineness of the mesh was scrutinised by the Miners' Lamp Committee in 1924, 109 years after Davy's work, and a recommendation to use a coarser mesh of 400 holes/sq in (20 mesh) of 27 SWG wire was made. Lamps tested were as safe, and illumination increased, depending on lamp type, by between 16% and 32%.

Timeline of development

Examples of lamps

Davy lamp

In the

In the Davy lamp

The Davy lamp is a safety lamp used in flammable atmospheres, invented in 1815 by Sir Humphry Davy. The poor light compared to either the Geordie or Clanny eventually led to the Davy being regarded as "not a lamp but a scientific instrument for detecting the presence of firedamp". Some pits continued to use candles for illumination, relying on the Davy to warn men when to extinguish them.

In the earlier Geordie lamps an oil lamp is surrounded by glass. The top of the glass has a perforated copper cap with a metal gauze screen above that. The glass is surrounded by a perforated metal tube to protect it. Air ingress was via a series of tubes at the base.

Later versions used a metal gauze, instead of the perforated metal tube, to surround and protect the glass. Air intake was via an annular chamber around the base of the lamp (instead of previous tubes) into which air entered through small (") holes then passed through gauze into the lamp. If the glass surrounding the lamp was broken, the Geordie became a Davy.

A strong enough current of air could travel through the tubes (later holes and gallery) and enlarge the flame, eventually leading to it becoming red-hot. The lamp becomes unsafe in a current of from 8 to 12 feet per second, about twice that of the Davy.

In the earlier Geordie lamps an oil lamp is surrounded by glass. The top of the glass has a perforated copper cap with a metal gauze screen above that. The glass is surrounded by a perforated metal tube to protect it. Air ingress was via a series of tubes at the base.

Later versions used a metal gauze, instead of the perforated metal tube, to surround and protect the glass. Air intake was via an annular chamber around the base of the lamp (instead of previous tubes) into which air entered through small (") holes then passed through gauze into the lamp. If the glass surrounding the lamp was broken, the Geordie became a Davy.

A strong enough current of air could travel through the tubes (later holes and gallery) and enlarge the flame, eventually leading to it becoming red-hot. The lamp becomes unsafe in a current of from 8 to 12 feet per second, about twice that of the Davy.

The lamp is a modified Clanny designed by the Belgian Mathieu-Louis Mueseler. The flame is surrounded by a glass tube surmounted by a wire gauze-capped cylinder. Air enters from the side above the glass and flows down to the flame before rising to exit at the top of the lamp. So far this is just a Clanny, but there is an internal chimney separating the rising combustion products from the incoming air. The chimney is supported by a gauze shelf through which incoming air must pass, forming a second barrier to back-propagating flames. Some Mueseler lamps were fitted with a mechanism which locked the base of the lamp. Turning down the wick eventually released the base, but by then the flame was extinguished and therefore safe.

The lamp was patented in 1840, and in 1864 the Belgian government made this type of lamp compulsory.

In the presence of firedamp the explosive mixture is drawn through two gauzes (cylinder and shelf), burnt and then within the chimney are only burnt gases, not explosive mixture. Like a Clanny, and the Davy before it, it acts as an indicator of firedamp, burning more brightly in its presence. Later models had graduated shields by which the deputy could determine the concentration of firedamp from the heightening of the flame. Whilst the Clanny will continue to burn if laid on its side, potentially cracking the glass; the Mueseler will extinguish itself due to the stoppage of convection currents. The lamp is safe in currents up to 15 feet per second.

The lamp is a modified Clanny designed by the Belgian Mathieu-Louis Mueseler. The flame is surrounded by a glass tube surmounted by a wire gauze-capped cylinder. Air enters from the side above the glass and flows down to the flame before rising to exit at the top of the lamp. So far this is just a Clanny, but there is an internal chimney separating the rising combustion products from the incoming air. The chimney is supported by a gauze shelf through which incoming air must pass, forming a second barrier to back-propagating flames. Some Mueseler lamps were fitted with a mechanism which locked the base of the lamp. Turning down the wick eventually released the base, but by then the flame was extinguished and therefore safe.

The lamp was patented in 1840, and in 1864 the Belgian government made this type of lamp compulsory.

In the presence of firedamp the explosive mixture is drawn through two gauzes (cylinder and shelf), burnt and then within the chimney are only burnt gases, not explosive mixture. Like a Clanny, and the Davy before it, it acts as an indicator of firedamp, burning more brightly in its presence. Later models had graduated shields by which the deputy could determine the concentration of firedamp from the heightening of the flame. Whilst the Clanny will continue to burn if laid on its side, potentially cracking the glass; the Mueseler will extinguish itself due to the stoppage of convection currents. The lamp is safe in currents up to 15 feet per second.

The Marsaut lamp is a Clanny with multiple gauzes. Two or three gauzes are fitted inside each other, which improves the safety in a draught. Multiple gauzes, however, interfere with the air flow. The Marsaut was one of the first lamps to be fitted with a shield, in the illustration (right) the bonnet can be seen surrounding the gauzes. A shielded Marsaut lamp can resist a current of 30 feet per second.

The Marsaut lamp is a Clanny with multiple gauzes. Two or three gauzes are fitted inside each other, which improves the safety in a draught. Multiple gauzes, however, interfere with the air flow. The Marsaut was one of the first lamps to be fitted with a shield, in the illustration (right) the bonnet can be seen surrounding the gauzes. A shielded Marsaut lamp can resist a current of 30 feet per second.

"Miners safety lamps: a guide to resources"

2016. A guide to books, journals, government reports, archival material and other resources on lamps in the Institute Library. *Barrie, D. ''The wand of science: a history of the British flame safety lamp''. Birmingham: D. Barrie Risk Management Ltd, 2006. *Barnard, T.R. ''Miners' safety lamps: their construction and care''. London: Pitman, 1936. *Galloway, R.L. ''Annals of coal mining and the coal trade.'' First series. o 1835London: Colliery Guardian, 1898 (reprinted Newton Abbot: David and Charles, 1971); 420-439. Second series. 835-80London: Colliery Guardian, 1904 (reprinted Newton Abbot: David and Charles, 1971), 304-324. *Hardwick, F.W. & O'Shea, L.T

Notes on the history of the safety lamp

''Transactions, Institution of Mining Engineers'' 51 1915-6, 548-724. History from 1813 to 1913 with many types of lamps described and testing discussed for the UK and other European countries. *James, F.A.J.L. How big is a hole?: the problems of the practical application of science in the invention of the miners’ safety lamp by Humphry Davy and George Stephenson in late Regency England ''Transactions, Newcomen Society'' 75(2) 2005, 175–227 *Kerr, G.L

''Practical coal mining, a manual for managers, under-managers, colliery engineers, and others''

5th ed. London: Griffin, 1914. Ch.XIV *Pohs, H. A.''The miner's flame light book: the story of man's development of underground light.'' Denver: 1995. This has a US emphasis. *Rimmer, D & others ''Clanny, Stephenson and Davy: commemorating the bicentenary of the miners safety lamps''. Miners Lamp Collectors Society, 2015 *Watson, W.F. The invention of the miners safety lamp: a reappraisal ''Transactions, Newcomen Society'' 70(1) 1998-9, 135-141 "to settle the disputed features of the lamps of Clanny, Davy and Stephenson"

Durham Mining MuseumMiners Lamp Collectors Society

*NEIMME

The North of England Institute of Mining and Mechanical EngineersWand of Science

"The website resource for miners safety lamp collectors! If I don't know it I probably know a man who does!!" * {{Authority control History of coal mining Oil lamp Mine safety Mining equipment Safety equipment

Stephenson ("Geordie") lamp

In the earlier Geordie lamps an oil lamp is surrounded by glass. The top of the glass has a perforated copper cap with a metal gauze screen above that. The glass is surrounded by a perforated metal tube to protect it. Air ingress was via a series of tubes at the base.

Later versions used a metal gauze, instead of the perforated metal tube, to surround and protect the glass. Air intake was via an annular chamber around the base of the lamp (instead of previous tubes) into which air entered through small (") holes then passed through gauze into the lamp. If the glass surrounding the lamp was broken, the Geordie became a Davy.

A strong enough current of air could travel through the tubes (later holes and gallery) and enlarge the flame, eventually leading to it becoming red-hot. The lamp becomes unsafe in a current of from 8 to 12 feet per second, about twice that of the Davy.

In the earlier Geordie lamps an oil lamp is surrounded by glass. The top of the glass has a perforated copper cap with a metal gauze screen above that. The glass is surrounded by a perforated metal tube to protect it. Air ingress was via a series of tubes at the base.

Later versions used a metal gauze, instead of the perforated metal tube, to surround and protect the glass. Air intake was via an annular chamber around the base of the lamp (instead of previous tubes) into which air entered through small (") holes then passed through gauze into the lamp. If the glass surrounding the lamp was broken, the Geordie became a Davy.

A strong enough current of air could travel through the tubes (later holes and gallery) and enlarge the flame, eventually leading to it becoming red-hot. The lamp becomes unsafe in a current of from 8 to 12 feet per second, about twice that of the Davy.

Purdy lamp

A development of the Geordie lamp was the Purdy. A galley with wire gauze provided the inlet, above the glass was a chimney with perforated copper cap and gauze outer. A brass tube protected the upper works, shielded them and kept them locked in position. A sprung pin locked the whole together. The pin could only be released by applying a vacuum to a captive hollow screw; not something that a nicotine starved miner could do at the coal face .Improved Clanny lamp

Clanny abandoned his pumps and candles and developed a safety lamp which combined features of both the Davy and Geordie. The oil lamp was surrounded by a glass chimney with no ventilation from below. Above the chimney is a wire gauze cylinder with a double top. Air enters from the side and spent gases exit from the top. In the presence of firedamp the flame intensifies. The flame must be kept fairly high in normal use, a small flame permits the enclosed space to fill with firedamp/air mixture and the subsequent detonation may pass through the gauze. A larger flame will keep the upper part full of burnt gas. The Clanny gives more light than the Davy and can be carried more easily in a draught. Lupton notes however ''it is superior in no other respect'', particularly as a test instrument. The glass on a Clanny was secured by a large diameter brass ring which could be hard to tighten securely. If a splinter occurred at the end of a crack, or indeed any other unevenness, then the seal might be compromised. Such an incident occurred at Nicholson Pit in 1856 on a lamp being used by an overman to test for firedamp. The mines inspector recommended that only Stephenson lamps were used for illumination and Davys for testing. In particular "overmen ... whose lamps are mostly used to detect the presence gas, should avoid such lannylamps".Mueseler lamp

The lamp is a modified Clanny designed by the Belgian Mathieu-Louis Mueseler. The flame is surrounded by a glass tube surmounted by a wire gauze-capped cylinder. Air enters from the side above the glass and flows down to the flame before rising to exit at the top of the lamp. So far this is just a Clanny, but there is an internal chimney separating the rising combustion products from the incoming air. The chimney is supported by a gauze shelf through which incoming air must pass, forming a second barrier to back-propagating flames. Some Mueseler lamps were fitted with a mechanism which locked the base of the lamp. Turning down the wick eventually released the base, but by then the flame was extinguished and therefore safe.

The lamp was patented in 1840, and in 1864 the Belgian government made this type of lamp compulsory.

In the presence of firedamp the explosive mixture is drawn through two gauzes (cylinder and shelf), burnt and then within the chimney are only burnt gases, not explosive mixture. Like a Clanny, and the Davy before it, it acts as an indicator of firedamp, burning more brightly in its presence. Later models had graduated shields by which the deputy could determine the concentration of firedamp from the heightening of the flame. Whilst the Clanny will continue to burn if laid on its side, potentially cracking the glass; the Mueseler will extinguish itself due to the stoppage of convection currents. The lamp is safe in currents up to 15 feet per second.

The lamp is a modified Clanny designed by the Belgian Mathieu-Louis Mueseler. The flame is surrounded by a glass tube surmounted by a wire gauze-capped cylinder. Air enters from the side above the glass and flows down to the flame before rising to exit at the top of the lamp. So far this is just a Clanny, but there is an internal chimney separating the rising combustion products from the incoming air. The chimney is supported by a gauze shelf through which incoming air must pass, forming a second barrier to back-propagating flames. Some Mueseler lamps were fitted with a mechanism which locked the base of the lamp. Turning down the wick eventually released the base, but by then the flame was extinguished and therefore safe.

The lamp was patented in 1840, and in 1864 the Belgian government made this type of lamp compulsory.

In the presence of firedamp the explosive mixture is drawn through two gauzes (cylinder and shelf), burnt and then within the chimney are only burnt gases, not explosive mixture. Like a Clanny, and the Davy before it, it acts as an indicator of firedamp, burning more brightly in its presence. Later models had graduated shields by which the deputy could determine the concentration of firedamp from the heightening of the flame. Whilst the Clanny will continue to burn if laid on its side, potentially cracking the glass; the Mueseler will extinguish itself due to the stoppage of convection currents. The lamp is safe in currents up to 15 feet per second.

Marsaut lamp

The Marsaut lamp is a Clanny with multiple gauzes. Two or three gauzes are fitted inside each other, which improves the safety in a draught. Multiple gauzes, however, interfere with the air flow. The Marsaut was one of the first lamps to be fitted with a shield, in the illustration (right) the bonnet can be seen surrounding the gauzes. A shielded Marsaut lamp can resist a current of 30 feet per second.

The Marsaut lamp is a Clanny with multiple gauzes. Two or three gauzes are fitted inside each other, which improves the safety in a draught. Multiple gauzes, however, interfere with the air flow. The Marsaut was one of the first lamps to be fitted with a shield, in the illustration (right) the bonnet can be seen surrounding the gauzes. A shielded Marsaut lamp can resist a current of 30 feet per second.

Bainbridge lamp

The Bainbridge is a development of the Stephenson. A tapered glass cylinder surrounds the flame, and above that the body is a brass tube. The top of the tube is closed by a horizontal mesh attached to the body of the lamp by small bars to conduct heat away. Air enters through a series of small holes drilled in the lower brass ring supporting the glass.Landau's lamp

The lamp is in part a development of the Geordie. Air enters into a ring near the base which is protected by wire gauze or a perforated plate. The air passes down the side of the lamp passing through a series of gauze-covered holes, and enters the base through another yet another series of gauze-covered holes. Any attempt to unscrew the base causes the lever (shown at ''f'' in the illustration) to extinguish the flame. The gauze-covered holes and passageways restrict the flow to that required for combustion, so if any part of the oxygen is replaced by firedamp, then the flame is extinguished for want of oxidant. The upper portion of the lamp uses a chimney like in Mueseler and Morgan lamps. The rising gases pass up the chimney and through a gauze. At the top of the chimney a dished reflector diverts the gases out sideways through a number of holes in the chimney. The gases then start to rise up the ''intermediate chimney'' before exiting through another gauze. Gas finally passes down between the outermost chimney and the intermediate chimney, exiting a little above the glass. The outer chimney is therefore effectively a shield.Yates' lamp

The Yates lamp is a development of the Clanny. Air enters through the lower part of the gauze top and leaves through the upper part; there is no chimney. The lower glass part of the lamp has seen some development however. It is replaced by a silvered reflector having a ''strong lens or bull's-eye'' in it to allow the light out. The result was a claimed 20 fold improvement in lighting over the Davy. Yates claimed "the temptation to expose the flame to obtain more light is removed". The base also contained an interlocking mechanism to ensure that the wick was lowered and the lamp extinguished by any attempt to open it. The lamp was "much more expensive than the forms of lamp now in general use, but Mr, Yates states that the saving of oil effected by its use will in one year pay the additional cost".Evan Thomas

The lamp devised and manufactured by Evan Thomas of Aberdare is similar to a shielded Clanny, but there is a brass cylinder outside the gauze above the glass. It resists draughts well, but illumination is poor.Morgan

The Morgan is a cross between the Mueseler and the Marsaut. It is a shielded lamp with a series of disks at the top to allow spent fumes out and a series of holes lower down the shield to allow air in. There is an inner and outer shield so that air cannot blow directly on the wire gauze but must first find its way through a slim chamber. There are multiple gauzes, like the Mersaut, and there is an internal chimney like the Mueseler. There is no "shelf" supporting the chimney, instead it hangs from an inverted gauze cone. The Morgan will resist air up to 53 feet per second and is ''"sufficiently safe for every practical purpose"''.Clifford

The Clifford also has a double shield, but with a plain flat top. The chimney is quite narrow with wire gauze covering the top. The bottom of the chimney has a glass bell covering the flame. The chimney is supported on a gauze shelf. Air enters through the lower part of the outer shield, through the passage and into the lamp through the inner shield. It is drawn down through the gauze, then passes the flame and ascends the chimney. At the top it leaves through gauze and the top of the double shield. The inner chimney is made of copper coated with a fusible metal: if the lamp gets too hot the metal melts and closes the air holes, extinguishing the lamp. The lamp has been tested and according to Lupton ''"successfully resisted every effort to explode it up to a velocity of more than 100 feet per second"''.Electric lamps

It was not until tungsten filaments replaced carbon that a portable electric light became a reality. An early pioneer was Joseph Swan who exhibited his first lamp in Newcastle upon Tyne in 1881 and improved ones in subsequent years. The Royal Commission on Accidents in Mines set up in 1881 carried out extensive tests of all types of lamps and the final report in 1886 noted that there had been good progress made in producing electric lamps giving a light superior to that of oil lamps and expected economic and efficient lamps to become available soon. This turned out not to be the case and progress was slow in attaining reliability and economy. The Sussmann lamp was introduced into Britain in 1893 and following trials at Murton Colliery in Durham it became a widely used electric lamp with 3000 or so reported by the company in use in 1900 However, by 1910 there were only 2055 electric lamps of all types in use about 0.25% of all safety lamps. In 1911, an anonymous colliery owner, through the British government, offered a prize of £1000 () for the best lamp to specified requirements. There were 195 entries. It was won by a German engineer with the CEAG lamp, which was hand-held and delivered twice the illumination of oil lamps, with a battery life of 16 hours. Awards were made to 8 other lamps that met the judges' criteria. Clearly this stimulated development and over the next few years there was a marked increase in the use of electric lamps, especially the CEAG, Gray-Sussmann, and Oldham, so by 1922 there were 294,593 in use in Britain. In 1913,Thomas Edison

Thomas Alva Edison (February11, 1847October18, 1931) was an American inventor and businessman. He developed many devices in fields such as electric power generation, mass communication, sound recording, and motion pictures. These inventions, ...

won the ''Ratheman medal'' for inventing a lightweight storage battery that could be carried on the back, powering a parabolic reflector that could be mounted on the miner's helmet. After extensive testing, 70,000 robust designs were in use in the US by 1916.

Early electric lamps in Britain were hand-held as miners were used to this and helmet lamps became common much later than in countries like the US where helmet (cap) lamps had been the norm.

Nowadays, safety lamps are mainly electric, and traditionally mounted on miners' helmets (such as the Wheat lamp or the Oldham headlamp), sealed to prevent gas penetrating the casing where it might be ignited by an electrical spark.

Although its use as a light source was superseded by electric lighting, the flame safety lamp has continued to be used in mines to detect methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The abundance of methane on Earth makes ...

and blackdamp, although many modern mines now use sophisticated electronic gas detectors for this purpose.

A newer light source, the light-emitting diode

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (corre ...

(LED), has advantages for safety lamps, mainly higher efficiency providing much longer illumination time from the same battery. Batteries too have improved and provide more energy per unit weight; LEDs in conjunction with batteries such as rechargeable lithium units provide much better performance in safety lamp applications.

The Office of Mine Safety and Health (OMSHR), a part of the National Institute for Occupational Safety and Health (NIOSH) (itself part of Centers for Disease Control and Prevention) in the United States has been investigating the benefits of LED headlamps. A problem in mining is that the average age of miners is increasing (43.3 years in the US in 2013), and vision deteriorates with ages. LED technology is physically robust compared to a filament light bulb, and has a longer life: 50,000 hours compared to 1,000 – 3,000. Extended life reduces light maintenance and failures; according to OMSHR an average of 28 accidents per year occur in US mines involving lighting. NIOSH has sponsored the development of cap lamp systems which they say improve the "ability of older subjects to detect moving hazards by 15% and trip hazards by 23.7%, and discomfort glare was reduced by 45%". Conventional lights illuminate a narrow beam; NIOSH LED lamps are designed to produce a wider more diffuse beam which is claimed to improve the perception of objects by 79.5%.

See also

* Canaries as sentinels in coal mines *Headlamp (outdoor)

A headlamp, headlight, or head torch (United Kingdom, UK) is a light source affixed to the head typically for outdoor activities at night or in dark conditions such as caving, orienteering#Night, orienteering, hiking, skiing, backpacking (wilde ...

* List of light sources

This is a list of sources of light, the visible part of the electromagnetic spectrum. Light sources produce photons from another energy source, such as heat, chemical reactions, or conversion of mass or a different frequency of electromagnetic ener ...

* Pellistor

* Wheat lamp

References

Bibliography

* The real author may be Thomas Unthank (NEIMME website). * * * * * * * Publishers note: Portions of the article came from E. Thomas & Williams (see below). * * * * * * * * * * * * * * * * * * * * * * * * * * * Command paper 4699 * (ISBN refers to the David & Charles reprint of 1968 with an introduction by L. T. C. Rolt) * * * (Sykes was the publisher of theNewcastle Courant

Newcastle usually refers to:

*Newcastle upon Tyne, a city and metropolitan borough in Tyne and Wear, England, United Kingdom

*Newcastle-under-Lyme, a town in Staffordshire, England, United Kingdom

*Newcastle, New South Wales, a metropolitan area ...

)

*

*

*

*

*

* (Presidential Lecture)

*

*

Further reading

*North of England Institute of Mining and Mechanical Engineers, Nicholas Wood Memorial Library"Miners safety lamps: a guide to resources"

2016. A guide to books, journals, government reports, archival material and other resources on lamps in the Institute Library. *Barrie, D. ''The wand of science: a history of the British flame safety lamp''. Birmingham: D. Barrie Risk Management Ltd, 2006. *Barnard, T.R. ''Miners' safety lamps: their construction and care''. London: Pitman, 1936. *Galloway, R.L. ''Annals of coal mining and the coal trade.'' First series. o 1835London: Colliery Guardian, 1898 (reprinted Newton Abbot: David and Charles, 1971); 420-439. Second series. 835-80London: Colliery Guardian, 1904 (reprinted Newton Abbot: David and Charles, 1971), 304-324. *Hardwick, F.W. & O'Shea, L.T

Notes on the history of the safety lamp

''Transactions, Institution of Mining Engineers'' 51 1915-6, 548-724. History from 1813 to 1913 with many types of lamps described and testing discussed for the UK and other European countries. *James, F.A.J.L. How big is a hole?: the problems of the practical application of science in the invention of the miners’ safety lamp by Humphry Davy and George Stephenson in late Regency England ''Transactions, Newcomen Society'' 75(2) 2005, 175–227 *Kerr, G.L

''Practical coal mining, a manual for managers, under-managers, colliery engineers, and others''

5th ed. London: Griffin, 1914. Ch.XIV *Pohs, H. A.''The miner's flame light book: the story of man's development of underground light.'' Denver: 1995. This has a US emphasis. *Rimmer, D & others ''Clanny, Stephenson and Davy: commemorating the bicentenary of the miners safety lamps''. Miners Lamp Collectors Society, 2015 *Watson, W.F. The invention of the miners safety lamp: a reappraisal ''Transactions, Newcomen Society'' 70(1) 1998-9, 135-141 "to settle the disputed features of the lamps of Clanny, Davy and Stephenson"

External links and abbreviations

*DMMDurham Mining Museum

*NEIMME

The North of England Institute of Mining and Mechanical Engineers

"The website resource for miners safety lamp collectors! If I don't know it I probably know a man who does!!" * {{Authority control History of coal mining Oil lamp Mine safety Mining equipment Safety equipment