Rigid Chain Actuator on:

[Wikipedia]

[Google]

[Amazon]

A rigid chain actuator, known variously as a linear chain actuator, push-pull chain actuator, electric chain actuator or column-forming chain actuator, is a specialized mechanical

A rigid chain actuator, known variously as a linear chain actuator, push-pull chain actuator, electric chain actuator or column-forming chain actuator, is a specialized mechanical

Modified roller chain has been used extensively in material handling equipment, but could only be used in push-pull applications when a continuous loop of chain was used (with the exception of chain encapsulated in a guide channel). The development of efficient rigid chain actuators broadened the use of chain actuation for industrial applications. Small scale rigid chain actuators are used as building hardware, incorporated into windows, door and hatches as motorized open/close mechanisms. Rigid chain actuators are also used as the lifting columns in performing arts facilities, incorporated in stage, orchestra and seating platform lift systems.

Increasingly rigid chain systems are being incorporated into scissor lift tables or platform lifts as the method of actuation, replacing hydraulic cylinders. They are also used for production line automation and die changing.

The

Modified roller chain has been used extensively in material handling equipment, but could only be used in push-pull applications when a continuous loop of chain was used (with the exception of chain encapsulated in a guide channel). The development of efficient rigid chain actuators broadened the use of chain actuation for industrial applications. Small scale rigid chain actuators are used as building hardware, incorporated into windows, door and hatches as motorized open/close mechanisms. Rigid chain actuators are also used as the lifting columns in performing arts facilities, incorporated in stage, orchestra and seating platform lift systems.

Increasingly rigid chain systems are being incorporated into scissor lift tables or platform lifts as the method of actuation, replacing hydraulic cylinders. They are also used for production line automation and die changing.

The

Rigid chain actuators were developed from “ chain rammers” that used a single “ram chain” thrust from a magazine to load heavy-caliber ordnance into the breech of a cannon. Robert Matthews received a US patent for his “Mechanical Rammer” in 1901 which used a roller on the leading end of the chain to guide it and allow thrust without deflection. Developed more than a century ago, his rammer still bears a strong resemblance to many modern rigid chain actuators. In 1908 Oscar Knoch was awarded a US patent for his “Chain Rammer for Guns”. By orienting the folding side of the chain upward his ram chain acted as a self-supporting telescoping beam with negligible sag. Used in this manner the need for a separate guide was eliminated.

An early conception of chain used as a telescoping column instead a horizontal rammer was by Eldridge E. Long, who was awarded a US patent for his “Lifting Jack” in 1933, which he believed was “particularly adapted for use upon automobiles”. It used a double chain configuration, each chain linking solid bearing blocks that were stacked to resist compressive loads. In 1951, Yaichi Hayakawa was awarded a US patent for his “Interlocking Chain Stanchion” which eliminated bearing blocks by integrating the compressive path of force into the interlocking links of two roller-like chains. The zipper action of back-to-back interlocking chains provided guideless chain travel regardless of orientation and path of travel.

In 1941, prior to the double chain configuration, Karl Bender received a US patent for "Compression Resistant Chain" using three interlocking chains. In addition to the back-to-back arrangement of the typical interlocking chain actuator, a third chain was interlocked between the other two at a right angle. Perhaps due to their relative complexity, triple-chain actuators are not common.

Rigid chain actuators were developed from “ chain rammers” that used a single “ram chain” thrust from a magazine to load heavy-caliber ordnance into the breech of a cannon. Robert Matthews received a US patent for his “Mechanical Rammer” in 1901 which used a roller on the leading end of the chain to guide it and allow thrust without deflection. Developed more than a century ago, his rammer still bears a strong resemblance to many modern rigid chain actuators. In 1908 Oscar Knoch was awarded a US patent for his “Chain Rammer for Guns”. By orienting the folding side of the chain upward his ram chain acted as a self-supporting telescoping beam with negligible sag. Used in this manner the need for a separate guide was eliminated.

An early conception of chain used as a telescoping column instead a horizontal rammer was by Eldridge E. Long, who was awarded a US patent for his “Lifting Jack” in 1933, which he believed was “particularly adapted for use upon automobiles”. It used a double chain configuration, each chain linking solid bearing blocks that were stacked to resist compressive loads. In 1951, Yaichi Hayakawa was awarded a US patent for his “Interlocking Chain Stanchion” which eliminated bearing blocks by integrating the compressive path of force into the interlocking links of two roller-like chains. The zipper action of back-to-back interlocking chains provided guideless chain travel regardless of orientation and path of travel.

In 1941, prior to the double chain configuration, Karl Bender received a US patent for "Compression Resistant Chain" using three interlocking chains. In addition to the back-to-back arrangement of the typical interlocking chain actuator, a third chain was interlocked between the other two at a right angle. Perhaps due to their relative complexity, triple-chain actuators are not common.

Tsubaki Zip Chain Lifter

Video showing rigid chain actuation of a stage lift

Actuators

A rigid chain actuator, known variously as a linear chain actuator, push-pull chain actuator, electric chain actuator or column-forming chain actuator, is a specialized mechanical

A rigid chain actuator, known variously as a linear chain actuator, push-pull chain actuator, electric chain actuator or column-forming chain actuator, is a specialized mechanical linear actuator

A linear actuator is an actuator that creates linear motion (i.e., in a straight line), in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer perip ...

used in window operating, push-pull material handling and lift applications. The actuator is a chain

A chain is a serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression but linear, rigid, and load-bearing in tension. A ...

and pinion

A pinion is a round gear—usually the smaller of two meshed gears—used in several applications, including drivetrain and rack and pinion systems.

Applications Drivetrain

Drivetrains usually feature a gear known as the pinion, which may v ...

device that forms an articulated telescoping member to transmit traction and thrust. High-capacity rigid chain lifting columns ( jacks) can move dynamic loads exceeding over more than of travel.

Principle of operation

Rigid chain actuators function asrack and pinion

rack and pinion is a type of linear actuator that comprises a circular gear (the '' pinion'') engaging a linear gear (the ''rack''). Together, they convert between rotational motion and linear motion: rotating the pinion causes the rack to be d ...

linear actuators that use articulated racks. Rigid chain actuators use limited-articulation chains, usually resembling a roller chain

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, pr ...

, that engage with pinions mounted on a drive shaft within a housing. The links of the actuating member, the “rigid chain”, are articulated in a manner that they deflect from a straight line to one side only. As the pinions spin, the links of the chain are rotated 90 degrees through the housing, which guides and locks the chain into a rigid linear form effective at resisting tension and compression (buckling). Because the actuating member can fold on itself, it can be stored relatively compactly in a storage magazine, either in an overlapping or coiled arrangement. Rigid chain actuators are generally driven by electric motors. Most rigid chains are manufactured from steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

.

Use

Modified roller chain has been used extensively in material handling equipment, but could only be used in push-pull applications when a continuous loop of chain was used (with the exception of chain encapsulated in a guide channel). The development of efficient rigid chain actuators broadened the use of chain actuation for industrial applications. Small scale rigid chain actuators are used as building hardware, incorporated into windows, door and hatches as motorized open/close mechanisms. Rigid chain actuators are also used as the lifting columns in performing arts facilities, incorporated in stage, orchestra and seating platform lift systems.

Increasingly rigid chain systems are being incorporated into scissor lift tables or platform lifts as the method of actuation, replacing hydraulic cylinders. They are also used for production line automation and die changing.

The

Modified roller chain has been used extensively in material handling equipment, but could only be used in push-pull applications when a continuous loop of chain was used (with the exception of chain encapsulated in a guide channel). The development of efficient rigid chain actuators broadened the use of chain actuation for industrial applications. Small scale rigid chain actuators are used as building hardware, incorporated into windows, door and hatches as motorized open/close mechanisms. Rigid chain actuators are also used as the lifting columns in performing arts facilities, incorporated in stage, orchestra and seating platform lift systems.

Increasingly rigid chain systems are being incorporated into scissor lift tables or platform lifts as the method of actuation, replacing hydraulic cylinders. They are also used for production line automation and die changing.

The autoloader

An autoloader or auto-loader is a mechanical aid or replacement for the personnel that load ammunition into crew-served weapons without being an integrated part of the gun itself. The term is generally only applied to larger weapons, such as na ...

s used in Soviet/Russian tanks such as the T-64

The T-64 is a Soviet tank manufactured in Kharkiv, and designed by Alexander Morozov. The tank was introduced in the early 1960s. It was a more advanced counterpart to the T-62: the T-64 served in tank divisions, while the T-62 supported i ...

, T-80

The T-80 is a main battle tank (MBT) that was designed and manufactured in the former Soviet Union and manufactured in Russia. The T-80 is based on the T-64, while incorporating features from the later T-72 and changing the engine to a gas turbi ...

, T-72

The T-72 is a family of Soviet Union, Soviet main battle tanks that entered production in 1973. The T-72 was a development based on the T-64 using thought and design of the previous Object 167M. About 25,000 T-72 tanks have been built, and refu ...

and T-90

The T-90 is a third-generation Russian main battle tank developed from, and designed to replace the T-72. It uses a 125mm 2A46 smoothbore main gun, the 1A45T fire-control system, an upgraded engine, and gunner's thermal sight. Standard p ...

use rigid chain systems to push the two-part ammunition (projectile and propellant

A propellant (or propellent) is a mass that is expelled or expanded in such a way as to create a thrust or another motive force in accordance with Newton's third law of motion, and "propel" a vehicle, projectile, or fluid payload. In vehicle ...

) into the tank's gun

A gun is a device that Propulsion, propels a projectile using pressure or explosive force. The projectiles are typically solid, but can also be pressurized liquid (e.g. in water guns or water cannon, cannons), or gas (e.g. light-gas gun). So ...

.

Types

The primary distinction between types of rigid chain actuator is whether the actuating member is formed from a single chain or from a pair of interlocking chains in a back-to-back arrangement, like azipper

A zipper (N. America), zip, zip fastener (UK), formerly known as a clasp locker, is a commonly used device for binding together two edges of textile, fabric or other flexible material. Used in clothing (e.g. jackets and jeans), luggage and oth ...

. Interlocking chain actuators have the advantages over single-chain actuators of improved resistance to buckling and that the actuating member does not require lateral restraint at its leading end in order to resist a modicum of transverse loads on any edge of the member. For example, it may function as a relatively stable telescoping pole.

The design of the chain varies significantly depending on application and manufacturer. Variants have been designed to, among other things:

* Simplify manufacture

* Reduce friction and maintenance

* Limit size and weight

* Increase speed, travel, capacity, efficiency and stability

Development

Rigid chain actuators were developed from “ chain rammers” that used a single “ram chain” thrust from a magazine to load heavy-caliber ordnance into the breech of a cannon. Robert Matthews received a US patent for his “Mechanical Rammer” in 1901 which used a roller on the leading end of the chain to guide it and allow thrust without deflection. Developed more than a century ago, his rammer still bears a strong resemblance to many modern rigid chain actuators. In 1908 Oscar Knoch was awarded a US patent for his “Chain Rammer for Guns”. By orienting the folding side of the chain upward his ram chain acted as a self-supporting telescoping beam with negligible sag. Used in this manner the need for a separate guide was eliminated.

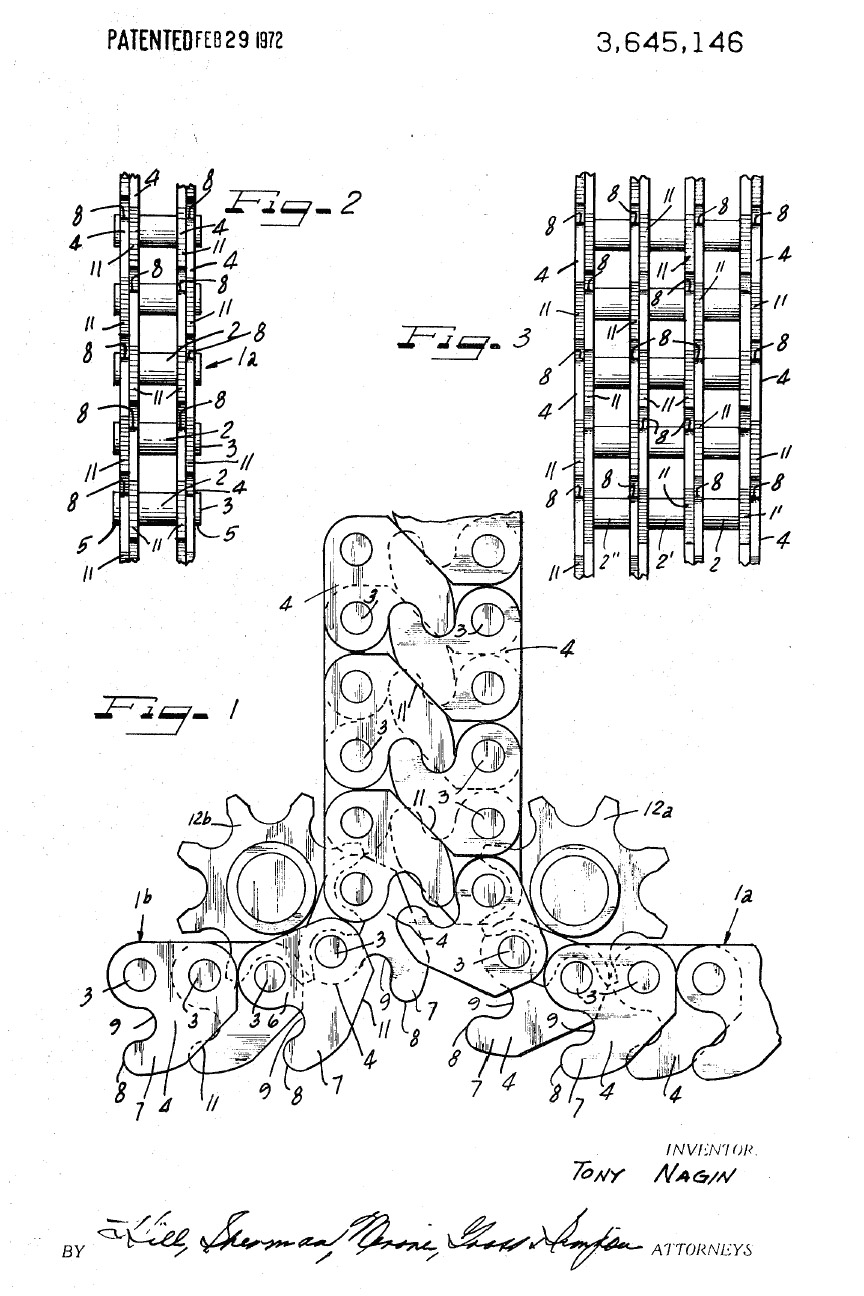

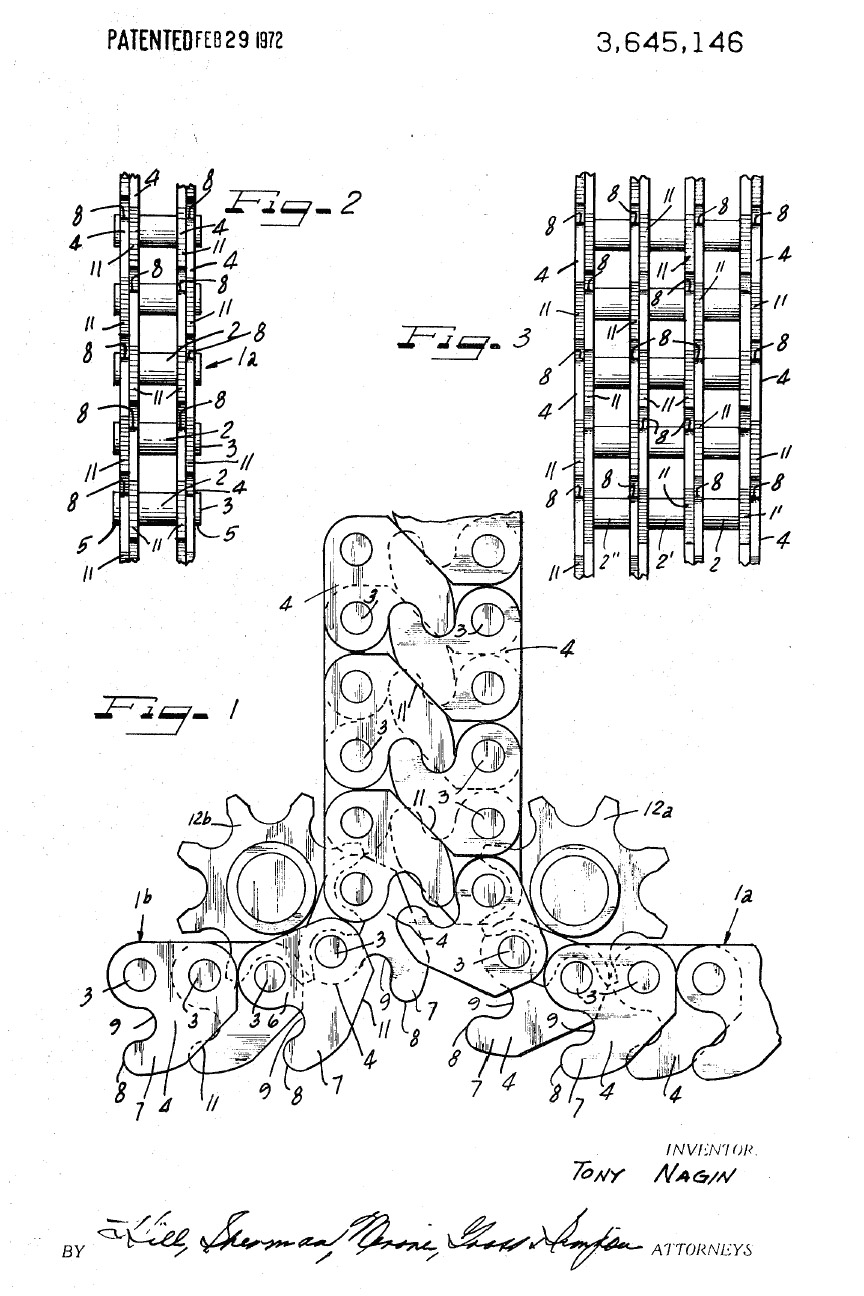

An early conception of chain used as a telescoping column instead a horizontal rammer was by Eldridge E. Long, who was awarded a US patent for his “Lifting Jack” in 1933, which he believed was “particularly adapted for use upon automobiles”. It used a double chain configuration, each chain linking solid bearing blocks that were stacked to resist compressive loads. In 1951, Yaichi Hayakawa was awarded a US patent for his “Interlocking Chain Stanchion” which eliminated bearing blocks by integrating the compressive path of force into the interlocking links of two roller-like chains. The zipper action of back-to-back interlocking chains provided guideless chain travel regardless of orientation and path of travel.

In 1941, prior to the double chain configuration, Karl Bender received a US patent for "Compression Resistant Chain" using three interlocking chains. In addition to the back-to-back arrangement of the typical interlocking chain actuator, a third chain was interlocked between the other two at a right angle. Perhaps due to their relative complexity, triple-chain actuators are not common.

Rigid chain actuators were developed from “ chain rammers” that used a single “ram chain” thrust from a magazine to load heavy-caliber ordnance into the breech of a cannon. Robert Matthews received a US patent for his “Mechanical Rammer” in 1901 which used a roller on the leading end of the chain to guide it and allow thrust without deflection. Developed more than a century ago, his rammer still bears a strong resemblance to many modern rigid chain actuators. In 1908 Oscar Knoch was awarded a US patent for his “Chain Rammer for Guns”. By orienting the folding side of the chain upward his ram chain acted as a self-supporting telescoping beam with negligible sag. Used in this manner the need for a separate guide was eliminated.

An early conception of chain used as a telescoping column instead a horizontal rammer was by Eldridge E. Long, who was awarded a US patent for his “Lifting Jack” in 1933, which he believed was “particularly adapted for use upon automobiles”. It used a double chain configuration, each chain linking solid bearing blocks that were stacked to resist compressive loads. In 1951, Yaichi Hayakawa was awarded a US patent for his “Interlocking Chain Stanchion” which eliminated bearing blocks by integrating the compressive path of force into the interlocking links of two roller-like chains. The zipper action of back-to-back interlocking chains provided guideless chain travel regardless of orientation and path of travel.

In 1941, prior to the double chain configuration, Karl Bender received a US patent for "Compression Resistant Chain" using three interlocking chains. In addition to the back-to-back arrangement of the typical interlocking chain actuator, a third chain was interlocked between the other two at a right angle. Perhaps due to their relative complexity, triple-chain actuators are not common.

See also

* * *References

{{ReflistExternal links

Tsubaki Zip Chain Lifter

Video showing rigid chain actuation of a stage lift

Actuators