Radiographic testing on:

[Wikipedia]

[Google]

[Amazon]

Industrial radiography is a modality of

Industrial radiography is a modality of

Gamma radiography and high-energy X-ray radiography are currently used to scan intermodal freight cargo containers in US and other countries. Also research is being done on adapting other types of radiography like dual-energy X-ray radiography or muon radiography for scanning intermodal cargo containers.

Gamma radiography and high-energy X-ray radiography are currently used to scan intermodal freight cargo containers in US and other countries. Also research is being done on adapting other types of radiography like dual-energy X-ray radiography or muon radiography for scanning intermodal cargo containers.

Industrial radiography is a modality of

Industrial radiography is a modality of non-destructive testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.

The terms nondestructive examination (NDE), n ...

that uses ionizing radiation

Ionizing radiation (or ionising radiation), including nuclear radiation, consists of subatomic particles or electromagnetic waves that have sufficient energy to ionize atoms or molecules by detaching electrons from them. Some particles can travel ...

to inspect materials and components with the objective of locating and quantifying defects and degradation in material properties that would lead to the failure of engineering structures. It plays an important role in the science and technology needed to ensure product quality and reliability. In Australia, industrial radiographic non-destructive testing is colloquially referred to as "bombing" a component with a "bomb".

Industrial Radiography uses either X-rays, produced with X-ray generators, or gamma rays generated by the natural radioactivity of sealed radionuclide

A radionuclide (radioactive nuclide, radioisotope or radioactive isotope) is a nuclide that has excess nuclear energy, making it unstable. This excess energy can be used in one of three ways: emitted from the nucleus as gamma radiation; transfer ...

sources. Neutrons can also be used. After crossing the specimen, photons are captured by a detector, such as a silver halide film, a phosphor plate, flat panel detector or CdTe detector. The examination can be performed in static 2D (named radiography), in real time 2D ( fluoroscopy), or in 3D after image reconstruction (computed tomography

A computed tomography scan (CT scan; formerly called computed axial tomography scan or CAT scan) is a medical imaging technique used to obtain detailed internal images of the body. The personnel that perform CT scans are called radiographers ...

or CT). It is also possible to perform tomography nearly in real time ( 4-dimensionnal computed tomography or 4DCT). Particular techniques such as X-ray fluorescence ( XRF), X-ray diffractometry ( XRD), and several other ones complete the range of tools that can be used in industrial radiography.

Inspection techniques can be portable or stationary. Industrial radiography is used in welding, casting parts or composite pieces inspection, in food inspection and luggage control, in sorting and recycling, in EOD and IED analysis, aircraft maintenance, ballistics

Ballistics is the field of mechanics concerned with the launching, flight behaviour and impact effects of projectiles, especially ranged weapon munitions such as bullets, unguided bombs, rockets or the like; the science or art of designing and a ...

, turbine inspection, in surface characterisation, coating thickness measurement, in counterfeit drug control, etc.

History

Radiography started in 1895 with the discovery of X-rays (later also called Röntgen rays after the man who first described their properties in detail), a type of electromagnetic radiation. Soon after the discovery of X-rays, radioactivity was discovered. By using radioactive sources such as radium, far higher photon energies could be obtained than those from ''normal'' X-ray generators. Soon these found various applications, with one of the earliest users being Loughborough College. X-rays and gamma rays were put to use very early, before the dangers of ionizing radiation were discovered. After World War II new isotopes such as caesium-137, iridium-192 and cobalt-60 became available for industrial radiography, and the use of radium and radon decreased.Applications

Inspection of products

Gamma radiation

A gamma ray, also known as gamma radiation (symbol γ or \gamma), is a penetrating form of electromagnetic radiation arising from the radioactive decay of atomic nuclei. It consists of the shortest wavelength electromagnetic waves, typically s ...

sources, most commonly iridium-192 and cobalt-60, are used to inspect a variety of materials. The vast majority of radiography concerns the testing and grading of welds on piping, pressure vessels, high-capacity storage containers, pipelines, and some structural welds. Other tested materials include concrete (locating rebar

Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a Tension (physics), tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concr ...

or conduit), welder's test coupons, machined parts, plate metal, or pipewall (locating anomalies due to corrosion or mechanical damage). Non-metal components such as ceramics used in the aerospace industries are also regularly tested. Theoretically, industrial radiographers could radiograph any solid, flat material (walls, ceilings, floors, square or rectangular containers) or any hollow cylindrical or spherical object.

Inspection of welding

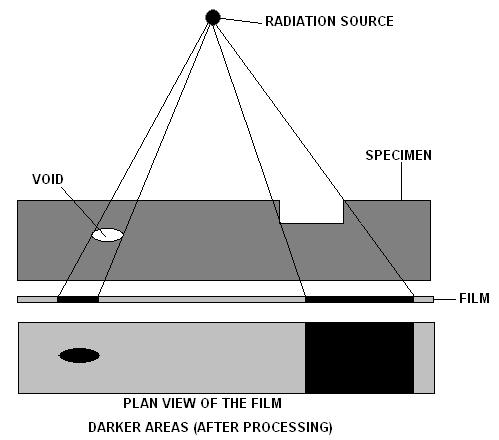

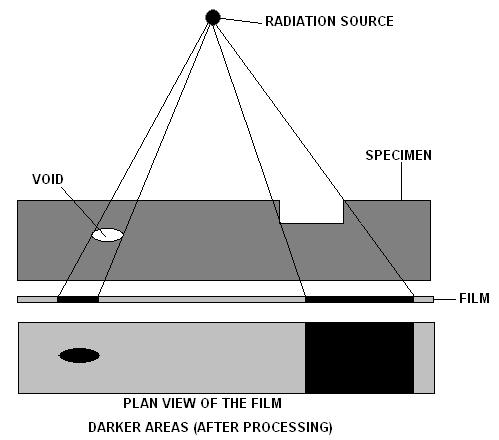

The beam of radiation must be directed to the middle of the section under examination and must be normal to the material surface at that point, except in special techniques where known defects are best revealed by a different alignment of the beam. The length of weld under examination for each exposure shall be such that the thickness of the material at the diagnostic extremities, measured in the direction of the incident beam, does not exceed the actual thickness at that point by more than 6%. The specimen to be inspected is placed between the source of radiation and the detecting device, usually the film in a light tight holder or cassette, and the radiation is allowed to penetrate the part for the required length of time to be adequately recorded. The result is a two-dimensional projection of the part onto the film, producing a latent image of varying densities according to the amount ofradiation

In physics, radiation is the emission or transmission of energy in the form of waves or particles through space or through a material medium. This includes:

* ''electromagnetic radiation'', such as radio waves, microwaves, infrared, visi ...

reaching each area. It is known as a radio graph, as distinct from a photograph produced by light. Because film is cumulative in its response (the exposure increasing as it absorbs more radiation), relatively weak radiation can be detected by prolonging the exposure until the film can record an image that will be visible after development. The radiograph is examined as a negative, without printing as a positive as in photography. This is because, in printing, some of the detail is always lost and no useful purpose is served.

Before commencing a radiographic examination, it is always advisable to examine the component with one's own eyes, to eliminate any possible external defects. If the surface of a weld is too irregular, it may be desirable to grind it to obtain a smooth finish, but this is likely to be limited to those cases in which the surface irregularities (which will be visible on the radio graph) may make detecting internal defects difficult.

After this visual examination, the operator will have a clear idea of the possibilities of access to the two faces of the weld, which is important both for the setting up of the equipment and for the choice of the most appropriate technique.

Defects such as delaminations and planar cracks are difficult to detect using radiography, particularly to the untrained eye.

Without overlooking the negatives of radiographic inspection, radiography does hold many significant benefits over ultrasonics, particularly insomuch that as a 'picture' is produced keeping a semi permanent record for the life cycle of the film, more accurate identification of the defect can be made, and by more interpreters. Very important as most construction standards permit some level of defect acceptance, depending on the type and size of the defect.

To the trained radiographer, subtle variations in visible film density provide the technician the ability to not only accurately locate a defect, but identify its type, size and location; an interpretation that can be physically reviewed and confirmed by others, possibly eliminating the need for expensive and unnecessary repairs.

For purposes of inspection, including weld inspection

Weld quality assurance is the use of technological methods and actions to test or assure the quality of welds, and secondarily to confirm the presence, location and coverage of welds. In manufacturing, welds are used to join two or more metal surf ...

, there exist several exposure arrangements.

First, there is the panoramic, one of the four single-wall exposure/single-wall view (SWE/SWV) arrangements. This exposure is created when the radiographer places the source of radiation at the center of a sphere, cone, or cylinder (including tanks, vessels, and piping). Depending upon client requirements, the radiographer would then place film cassettes on the outside of the surface to be examined. This exposure arrangement is nearly ideal – when properly arranged and exposed, all portions of all exposed film will be of the same approximate density. It also has the advantage of taking less time than other arrangements since the source must only penetrate the total wall thickness (WT) once and must only travel the radius of the inspection item, not its full diameter. The major disadvantage of the panoramic is that it may be impractical to reach the center of the item (enclosed pipe) or the source may be too weak to perform in this arrangement (large vessels or tanks).

The second SWE/SWV arrangement is an interior placement of the source in an enclosed inspection item without having the source centered up. The source does not come in direct contact with the item, but is placed a distance away, depending on client requirements. The third is an exterior placement with similar characteristics. The fourth is reserved for flat objects, such as plate metal, and is also radiographed without the source coming in direct contact with the item. In each case, the radiographic film is located on the opposite side of the inspection item from the source. In all four cases, only one wall is exposed, and only one wall is viewed on the radiograph.

Of the other exposure arrangements, only the contact shot has the source located on the inspection item. This type of radiograph exposes both walls, but only resolves the image on the wall nearest the film. This exposure arrangement takes more time than a panoramic, as the source must first penetrate the WT twice and travel the entire outside diameter of the pipe or vessel to reach the film on the opposite side. This is a double wall exposure/single wall view DWE/SWV arrangement. Another is the superimposure (wherein the source is placed on one side of the item, not in direct contact with it, with the film on the opposite side). This arrangement is usually reserved for very small diameter piping or parts. The last DWE/SWV exposure arrangement is the elliptical, in which the source is offset from the plane of the inspection item (usually a weld in pipe) and the elliptical image of the weld furthest from the source is cast onto the film.

Airport security

Both hold luggage and carry-on hand luggage are normally examined by X-ray machines using X-ray radiography. See airport security for more details.Non-intrusive cargo scanning

Art

The American artist Kathleen Gilje has painted copies ofArtemisia Gentileschi

Artemisia Lomi or Artemisia Gentileschi (, ; 8 July 1593) was an Italian Baroque painter. Gentileschi is considered among the most accomplished seventeenth-century artists, initially working in the style of Caravaggio. She was producing profess ...

's '' Susanna and the Elders'' and Gustave Courbet's '' Woman with a Parrot''.

Before, she painted in lead white similar pictures with differences: Susanna fights the intrusion of the elders;*

* there is a nude Courbet beyond the woman he paints.

Then she painted over reproducing the original.

Gilje's paintings are exhibited with radiographs that show the underpaintings, simulating the study of pentimentos and providing a comment on the old masters' work.

Sources

Many types of ionizing radiation sources exist for use in industrial radiography.X-Ray generators

X-ray generators produce