Piston Pin on:

[Wikipedia]

[Google]

[Amazon]

In internal combustion engines, the

In internal combustion engines, the

p. 28

In very early engine designs, including those driven by steam, and many very large stationary or marine engines, the gudgeon pin is located in a sliding

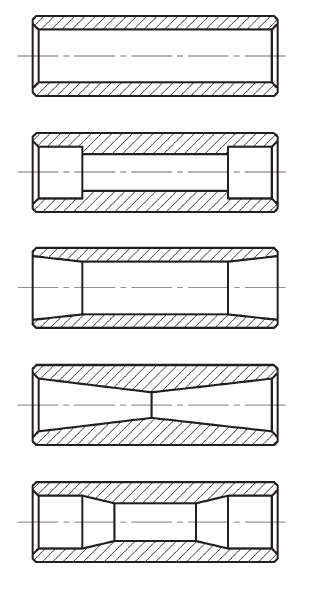

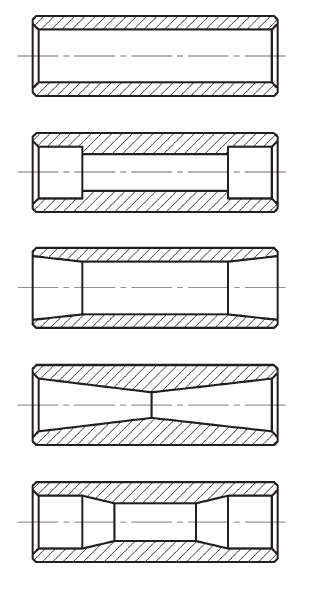

Typical construction of gudgeon pin (wrist pin) is shown on the picture. The design depend on technological and technical effectiveness.

;Semi-floating

:In the semi-floating configuration, the pin is usually fixed relative to the piston by an

Typical construction of gudgeon pin (wrist pin) is shown on the picture. The design depend on technological and technical effectiveness.

;Semi-floating

:In the semi-floating configuration, the pin is usually fixed relative to the piston by an

p. 34

This arrangement is usually more difficult to manufacture and service because two bearing surfaces or inserted sleeves complicate the design. In addition, the pin must be precisely set so that the small end eye is central. Because of thermal expansion considerations, this arrangement was more usual for single-cylinder engines as opposed to multiple cylinder engines with long cylinder blocks and crankcases, until precision manufacturing became more commonplace. ;Fully floating :In the fully floating configuration, a bearing surface is created both between the small end eye and gudgeon pin and the journal in the piston. The gudgeon pins are usually secured with

gudgeon

A gudgeon is a socket-like, cylindrical (i.e., ''female'') fitting attached to one component to enable a pivoting or hinging connection to a second component. The second component carries a pintle fitting, the male counterpart to the gudgeon, e ...

pin (UK, wrist pin or piston pin US) connects the piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tig ...

to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves.Nunney, Malcolm James (2007) "The Reciprocating Piston Petrol Engine: Gudgeon pins and their location" ''Light and heavy vehicle technology'' (4th ed.) Butterworth-Heinemann, Oxford, UKp. 28

In very early engine designs, including those driven by steam, and many very large stationary or marine engines, the gudgeon pin is located in a sliding

crosshead

In mechanical engineering, a crosshead is a mechanical joint used as part of the slider-crank linkages of long reciprocating engines (either internal combustion or steam) and reciprocating compressors to eliminate sideways force on the piston. ...

that connects to the piston via a rod. A gudgeon is a pivot or journal. The origin of the word gudgeon is the Middle English word gojoun, which originated from the Middle French word goujon. Its first known use was in the 15th century.Webster's Seventh New Collegiate Dictionary, G & C Merriam Company, 1963, p. 370

Overview

The gudgeon pin is typically aforged

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which ...

short hollow rod made of a steel alloy of high strength and hardness that may be physically separated from both the connecting rod and piston or crosshead. The design of the gudgeon pin, especially in the case of small, high-revving automotive engines is challenging. The gudgeon pin has to operate under some of the highest temperatures experienced in the engine, with difficulties in lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

Lubrication mechanisms such as fluid-lubrica ...

due to its location, while remaining small and light so as to fit into the piston diameter and not unduly add to the reciprocating mass

Engine balance refers to how the forces (resulting from combustion or rotating/reciprocating components) are balanced within an internal combustion engine or steam engine. The most commonly used terms are ''primary balance'' and ''secondary bala ...

. The requirements for lightness and compactness demand a small diameter rod that is subject to heavy shear and bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element.

The structural element is assumed to ...

loads, with some of the highest pressure loadings of any bearing in the whole engine. To overcome these problems, the materials used to make the gudgeon pin and the way it is manufactured are amongst the most highly engineered of any mechanical component found in internal combustion engines.

Design options

Gudgeon pins use two broad design configurations: semi-floating and fully floating. Typical construction of gudgeon pin (wrist pin) is shown on the picture. The design depend on technological and technical effectiveness.

;Semi-floating

:In the semi-floating configuration, the pin is usually fixed relative to the piston by an

Typical construction of gudgeon pin (wrist pin) is shown on the picture. The design depend on technological and technical effectiveness.

;Semi-floating

:In the semi-floating configuration, the pin is usually fixed relative to the piston by an interference fit

An interference fit, also known as a pressed fit or friction fit is a form of fastening between two ''tight'' fitting mating parts that produces a joint which is held together by friction after the parts are pushed together.

Depending on the am ...

with the journal in the piston. (This replaced the earlier set screw method.) The connecting rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaf ...

small end

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the cranksha ...

bearing thus acts as the bearing alone. In this configuration, only the small end bearing requires a bearing surface, if any. If needed, this is provided by either electroplating the small end bearing journal with a suitable metal, or more usually by inserting a sleeve bearing or needle bearing

A needle roller bearing is a special type of roller bearing which uses long, thin cylindrical rollers resembling needles. Ordinary roller bearings' rollers are only slightly longer than their diameter, but needle bearings typically have rollers ...

into the eye of the small end, which has an interference fit with the aperture of the small end. During overhaul, it is usually possible to replace this bearing sleeve if it is badly worn. The reverse configuration, fixing the gudgeon pin to the connecting rod instead of to the piston, is implemented using an interference fit with the small end eye instead, with the gudgeon pin journals in the piston functioning as bearings.Hillier, Victor Albert Walter and Pittuck, Frank William (1991) "The Petrol Engine: Gudgeon pins" ''Fundamentals of Motor Vehicle Technology'' (4th ed.) Stanley Thornes Pub., Cheltenham, Englandp. 34

This arrangement is usually more difficult to manufacture and service because two bearing surfaces or inserted sleeves complicate the design. In addition, the pin must be precisely set so that the small end eye is central. Because of thermal expansion considerations, this arrangement was more usual for single-cylinder engines as opposed to multiple cylinder engines with long cylinder blocks and crankcases, until precision manufacturing became more commonplace. ;Fully floating :In the fully floating configuration, a bearing surface is created both between the small end eye and gudgeon pin and the journal in the piston. The gudgeon pins are usually secured with

circlip

A circlip (a portmanteau of "circle" and "clip"), also known as a C-clip, Rotor Clip, snap ring or Jesus clip, is a type of fastener or retaining ring consisting of a semi-flexible metal ring with open ends which can be snapped into place, int ...

s. No interference fit is used in any instance and the pin 'floats' entirely on bearing surfaces. The average rubbing speed of each of the three bearings is halved and the load is shared across a bearing that is usually about three times the length of the semi-floating design with an interference fit with the piston.

References

{{Aircraft piston engine components Engine technology Engine components