Oil burner on:

[Wikipedia]

[Google]

[Amazon]

An oil burner is a heating device which burns #1, #2 and #6

An oil burner is a heating device which burns #1, #2 and #6

Fuel is injected into the combustion chamber by a

Fuel is injected into the combustion chamber by a

A

A

This allows fuel to be shut off from the sprayer by electrical control. It helps avoid drips when the valve is closed. It also eases the purging of the burner (and any boiler) of fuel mist during startup, or while restarting after a misfire. If the burner were not purged the oil/air mixture could explode.

This allows fuel to be shut off from the sprayer by electrical control. It helps avoid drips when the valve is closed. It also eases the purging of the burner (and any boiler) of fuel mist during startup, or while restarting after a misfire. If the burner were not purged the oil/air mixture could explode.

Oil-fired burners are fitted with a safety mechanism for determining if the fuel has ignited and a flame present. The terms "primary control", "safety control", "cad cell control", "master control", and "fire-eye control" are variously used to describe a light dependent electrical resistor ( LDR) which detects the flame whose value changes by the amount of

Oil-fired burners are fitted with a safety mechanism for determining if the fuel has ignited and a flame present. The terms "primary control", "safety control", "cad cell control", "master control", and "fire-eye control" are variously used to describe a light dependent electrical resistor ( LDR) which detects the flame whose value changes by the amount of

The motor which drives the fan and the oil pump is usually a

capacitor start motor. It is a single phase, squirrel cage

The motor which drives the fan and the oil pump is usually a

capacitor start motor. It is a single phase, squirrel cage

An oil burner is a heating device which burns #1, #2 and #6

An oil burner is a heating device which burns #1, #2 and #6 heating oil

Heating oil is any petroleum product or other oil used for heating; a fuel oil. Most commonly, it refers to low viscosity grades of fuel oil used for furnaces or boilers use for home heating and in other buildings. Home heating oil is often ab ...

s, diesel fuel

Diesel fuel , also called diesel oil, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a result of compression of the inlet air and ...

or other similar fuels

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but ...

. In the United States ultra low #2 diesel is the common fuel used. It is dyed red to show that it is road-tax exempt. In most markets of the United States heating oil is the same specification of fuel as on-road un-dyed diesel.

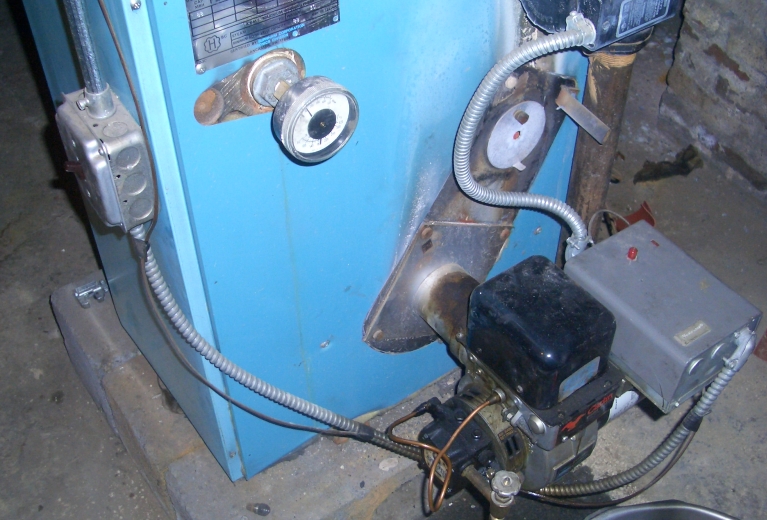

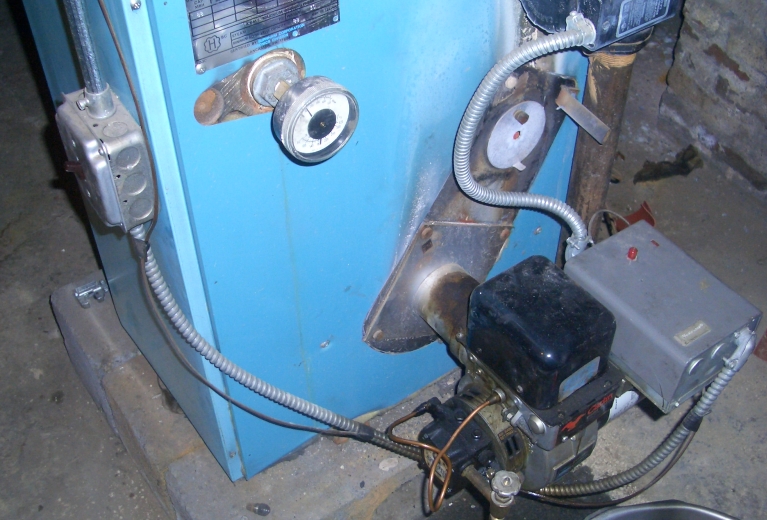

An oil burner is a part attached to an oil furnace, water heater, or boiler. It provides the ignition of heating oil/biodiesel fuel used to heat either air or water via a heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contac ...

. The fuel is atomized into a fine spray usually by forcing it under pressure through a nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe.

A nozzle is often a pipe or tube of varying cross sectional area, a ...

which gives the resulting flame a specific flow rate, angle of spray and pattern (variations of a cone shape). This spray is usually ignited by an electric spark

An electric spark is an abrupt electrical discharge that occurs when a sufficiently high electric field creates an ionized, electrically conductive channel through a normally-insulating medium, often air or other gases or gas mixtures. Michael ...

with the air being forced through around it at the end of a blast tube, by a fan driven by the oil burner motor. The fuel pump is typically driven via a coupling connecting its shaft to that of the motor's. Oil burners also include combustion-proving devices to prevent out-of-control combustion - Primary Control; Safety Control; Cad Cell Control; Master Control; Fire-Eye Control are all common names for the 'combustion safety control'.

In the United States residential home heating oil market the "vaporizing gun burner" is the most common mechanical device used to heat a home or small commercial forced air space with. Depending on the manufacturer these simple burners will see a lifespan if regularly maintained for decades. Currently, old installations from the 1950s and 1960s are still in operation today if they received regular maintenance.

The maintenance involved in a gun burner usually is a replacement of the nozzle used to atomize the fuel, replacing the filter located at the air handler, replacing the fuel filter on the heating oil system from the tank, cleaning out any soot or deposits in the heat exchanger of the furnace, and ensuring the system is in good working order, and also involves checking and adjusting the fuel-air mixture for efficiency with a combustion analyzer.

If a heating oil burner runs out of oil it often must be primed to be restarted. Priming involves purging any air from the fuel lines so that a steady flow of oil can find its way to the burner.

If an oil burner wears out it can usually be upgraded and replaced with a more efficient modern burner. If the heat exchanger wears out that requires a new furnace. Oil furnaces will last nearly forever if maintained regularly ensuring the heat exchanger is vacuumed out and cleaned. Oil burners deposit soot in the heat exchanger which is an un-even insulator. The heat distribution in the heat exchanger is un-even, causing wear on this critical steel part causing an eventual cracking. Annual or every other year tune-ups guarantee this wear is far reduced. Oil furnace lifespans of fifty to seventy-five years with regular service are not uncommon compared to an average wear out of natural gas furnaces every twenty years.

Fuel injection

Fuel is injected into the combustion chamber by a

Fuel is injected into the combustion chamber by a spray nozzle

A spray nozzle is a device that facilitates the dispersion of a liquid by the formation of a spray. The production of a spray requires the fragmentation of liquid structures, such as liquid sheets or ligaments, into droplets, often by using k ...

.

The nozzles are usually supplied with high pressure oil. Because erosion

Erosion is the action of surface processes (such as water flow or wind) that removes soil, rock, or dissolved material from one location on the Earth's crust, and then transports it to another location where it is deposited. Erosion is di ...

from friction with the oil, and possible blockage due to lumps in it, they need replacement when worn. Fuel nozzles are usually rated in fuel volume flow per unit time e.g. USGal/h (U.S. Gallons per hour).

A fuel nozzle is characterized by three features:

* Flow at 100psi pump pressure (e.g. 0.65 USGal/h)

* Spray characteristic (e.g. "S")

* Spray angle (e.g. 60 °)

Alternatively fuel may be passed over a tiny orifice

An orifice is any opening, mouth, hole or vent, as in a pipe, a plate, or a body

* Body orifice, any opening in the body of a human or animal

*Orifice plate, a restriction used to measure flow or to control pressure or flow, sometimes given speci ...

fed with compressed air. This arrangement is referred to as Babington atomiser/nozzle, named after its inventor Robert Babington. As the oil flows over the nozzle, the fuel needn't be under any great pressure. If the pump can handle such the oil may even contain lumps such as scraps of food. Because it is only compressed air that passes through the orifice hole, such nozzles do not suffer much from erosion.

Oil pump

A

A gear pump

A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler.

Gear pumps are also wide ...

of two parts:

Gear pump assembly

This pumps the oil in and increases the pressure in the nozzles to 15 bar maximum (217.5 psi). Usually agerotor

A gerotor is a positive displacement pump. The name ''gerotor'' is derived from "generated rotor". A gerotor unit consists of an inner and outer rotor. The inner rotor has ''n'' teeth, while the outer rotor has ''n''+1 teeth; with ''n'' defined ...

of the sickle type is used. Gear pumps are used frequently in oil burners because of their simplicity, stability and low price.

Pressure regulator

To set the heat output of the burner, the rate of fuel delivery via the nozzle must be adjustable. This is often achieved by an adjustablepressure relief valve

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is re ...

between the pump and the nozzle. When the set pressure is reached (usually 100psi), this valve opens and allows excess oil to flow through a bypass back to the fuel tank or the pump suction side.

Electromagnetic valve

Fan

The fan blows air into the combustion chamber. The rotor of the fan is powered by anelectric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force ...

.

Igniters

Some oil burners use glow bars which operate much like the glow plugs of a diesel engine. Many use high voltage generated by a voltage-step up transformer to create a spark for ignition, somewhat similar to aspark plug

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air ...

.

Original oil burner transformers were copper wire conductors wrapped around an iron core. A standard type of transformer to this day. In the mid-90s electronic igniters replaced the copper and iron transformer, solving many problems related to the old style transformer. This new technology in igniters would soon replace all old style transformers throughout the oil burner industry. The new igniters would run cooler so the output voltage could be increased from 10,000 to 20,000 VAC.

This increase of voltage would be more reliable, reduce delayed ignition, run cooler and all while using less energy. The voltage is high, but a standard igniter will only pull around 35 milliamps.

Safety control

Oil-fired burners are fitted with a safety mechanism for determining if the fuel has ignited and a flame present. The terms "primary control", "safety control", "cad cell control", "master control", and "fire-eye control" are variously used to describe a light dependent electrical resistor ( LDR) which detects the flame whose value changes by the amount of

Oil-fired burners are fitted with a safety mechanism for determining if the fuel has ignited and a flame present. The terms "primary control", "safety control", "cad cell control", "master control", and "fire-eye control" are variously used to describe a light dependent electrical resistor ( LDR) which detects the flame whose value changes by the amount of light

Light or visible light is electromagnetic radiation that can be perceived by the human eye. Visible light is usually defined as having wavelengths in the range of 400–700 nanometres (nm), corresponding to frequencies of 750–420 t ...

it is exposed to. The resistance decreases as the LDR is exposed to more light. The material is usually cadmium

Cadmium is a chemical element with the symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12, zinc and mercury. Like zinc, it demonstrates oxidation state +2 in most of ...

sulfide

Sulfide (British English also sulphide) is an inorganic anion of sulfur with the chemical formula S2− or a compound containing one or more S2− ions. Solutions of sulfide salts are corrosive. ''Sulfide'' also refers to chemical compounds lar ...

, hence the name "cad cell" for this component. In darkness the resistance is around 1 MΩ, while when exposed to light from a properly ignited flame the resistance is significantly lower, around 75–300 Ω.

Older oil burners were equipped with a primary control installed on the exhaust stack with a bimetallic heat sensing element protruding into the stack, such a control was referred to as a "stack relay" or a "stack control". It performed the same function as the newer cad-cell control but instead of sensing light from the burner flame it sensed heat from the flame exhaust gases to prove that ignition took place.

Capacitor start motor

induction motor

An induction motor or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding. An induction motor ...

. The difference with a three-phase motor is in the stator

The stator is the stationary part of a rotary system, found in electric generators, electric motors, sirens, mud motors or biological rotors. Energy flows through a stator to or from the rotating component of the system. In an electric mot ...

. Where the three phase motor has three coils aligned at 120° in the stator, the capacitor start motor holds one main winding and one auxiliary winding aligned at 90°. The phase shift of 90° between the main winding and the auxiliary winding is achieved by a connected capacitor which feeds the auxiliary winding and is connected on the single-phase AC mains. The capacitor will achieve a phase shift of 90° between the main and the auxiliary winding, producing an acceptable initial torque. This motor is intended for continuous operation.

See also

*Boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central h ...

* Central heating

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning (short: HVAC) systems, which can both cool and warm interior spaces.

...

* Coal burner

* Flame lift-off

* Gas burner

* Heater

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HV ...

* Heating oil

Heating oil is any petroleum product or other oil used for heating; a fuel oil. Most commonly, it refers to low viscosity grades of fuel oil used for furnaces or boilers use for home heating and in other buildings. Home heating oil is often ab ...

* Kerosene lamp

A kerosene lamp (also known as a paraffin lamp in some countries) is a type of lighting device that uses kerosene as a fuel. Kerosene lamps have a wick or mantle as light source, protected by a glass chimney or globe; lamps may be used on a ...

* LO-NOx burner

* Passive house

"Passive house" (german: Passivhaus) is a voluntary standard for energy efficiency in a building, which reduces the building's ecological footprint. It results in ultra-low energy buildings that require little energy for space heating or co ...

* Portable stove

A portable stove is a cooking stove specially designed to be portable and lightweight, used in camping, picnicking, backpacking, or other use in remote locations where an easily transportable means of cooking or heating is needed. Portable stove ...

* Rayburn Range

References

{{DEFAULTSORT:Oil Burner Burners Fireplaces Residential heating appliances