galling on:

[Wikipedia]

[Google]

[Amazon]

Galling is a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of

Galling is a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of

''Surface Hardening of Stainless Steels by Kolsterising'' by Gümpel P. -- University of Applied Science, Konstanz Germany AIJSTPME (2012) 5(1): 11-18 (PDF)

/ref> * Less cohesive or chemical attraction between surface atoms or molecules. * Avoid continuous plastic deformation and plastic flow, for example, through a thicker oxide layer on the subject material in sheet-metal forming (SMF). *

Galling is a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of

Galling is a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of t ...

and adhesion

Adhesion is the tendency of dissimilar particles or interface (matter), surfaces to cling to one another. (Cohesion (chemistry), Cohesion refers to the tendency of similar or identical particles and surfaces to cling to one another.)

The ...

between the surfaces, followed by slipping and tearing of crystal structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat ...

beneath the surface. This will generally leave some material stuck or even friction welded to the adjacent surface, whereas the galled material will appear worn, chipped, or even gouged and may have balled-up or torn lumps of material stuck to its surface.

Galling is most commonly found in metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

surfaces that are in sliding contact with each other. It is especially common where there is inadequate lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

Lubrication mechanisms such as fluid-lubr ...

between the surfaces. However, certain metals will generally be more prone to galling, due to the atomic structure of their crystals. For example, aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

will gall very easily, whereas annealed (softened) steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

is slightly more resistant to galling. Steel that is fully hardened is very resistant to galling.

Galling is a common problem in most applications where metals slide in contact with other metals. This can happen regardless of whether the metals are the same or different. Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

s such as brass

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve different colours and mechanical, electrical, acoustic and chemical properties, but copper typically has the larger proportion, generally copper and zinc. I ...

and bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloid ...

are often chosen for bearings, bushings, and other sliding applications because of their resistance to galling as well as other forms of mechanical abrasion.

Introduction

Galling is adhesivewear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in ...

that is caused by the microscopic transfer of material between metallic surfaces during transverse motion (sliding). It occurs frequently whenever metal surfaces are in contact, sliding against each other, especially with poor lubrication. It often occurs in high-load, low-speed applications, although it also can occur in high-speed applications with very little load. Galling is a common problem in sheet metal forming, bearings and pistons in engine

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power ge ...

s, hydraulic cylinder

A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment ( engineering vehicles ...

s, air motor

A pneumatic motor (air motor), or compressed-air engine, is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors generally convert the compressed-air energy to mechanical work through either linear or rotary ...

s, and many other industrial operations. Galling is distinct from gouging or scratching in that it involves the visible transfer of material as it is adhesively pulled ( mechanically spalled) from one surface, leaving it stuck to the other in the form of a raised lump (gall). Unlike other forms of wear, galling is usually not a gradual process but occurs quickly and spreads rapidly as the raised lumps induce more galling.

It can often occur in screws and bolts, causing the threads to seize and tear free from the fastener or the hole. In extreme cases, the bolt may seize without stripping the threads, which can lead to breakage of the fastener, the tool, or both. Threaded insert

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a t ...

s of hardened steel are often used in metals like aluminium or stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

that can gall easily.

Galling requires two properties common to most metals, cohesion through metallic-bonding attractions and plasticity (the ability to deform without breaking). The tendency of a material to gall is affected by the ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

of the material. Typically, hardened materials are more resistant to galling, whereas softer materials of the same type will gall more readily. The propensity of a material to gall is also affected by the specific arrangement of the atoms, because crystals arranged in a face-centered cubic

In crystallography, the cubic (or isometric) crystal system is a crystal system where the unit cell is in the shape of a cube. This is one of the most common and simplest shapes found in crystals and minerals.

There are three main varieties o ...

(FCC) lattice will usually allow material-transfer to a greater degree than a body-centered cubic

In crystallography, the cubic (or isometric) crystal system is a crystal system where the Crystal structure#Unit cell, unit cell is in the shape of a cube. This is one of the most common and simplest shapes found in crystals and minerals.

There ...

(BCC). This is because a face-centered cubic has a greater tendency to produce dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to sli ...

s in the crystal lattice, which are defects that allow the lattice to shift, or "cross-slip," making the metal more prone to galling. However, if the metal has a high number of stacking faults (a difference in stacking sequence between atomic planes), it will be less apt to cross-slip at the dislocations. Therefore, a material's resistance to galling is primarily determined by its stacking-fault energy. A material with high stacking-fault energy, such as aluminium or titanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

, will be far more susceptible to galling than materials with low stacking-fault energy, like copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

, bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloid ...

, or gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

. Conversely, materials with a hexagonal close packed

In geometry, close-packing of equal spheres is a dense arrangement of congruent spheres in an infinite, regular arrangement (or lattice). Carl Friedrich Gauss proved that the highest average density – that is, the greatest fraction of space occ ...

(HCP) structure and a high ''c/a'' ratio, such as cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. ...

-based alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

s, are extremely resistant to galling.

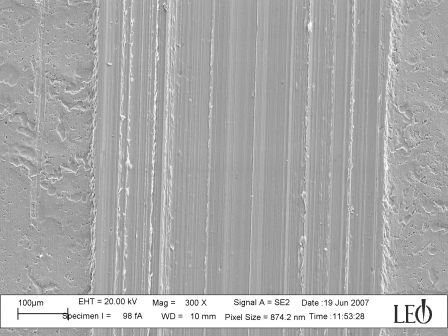

Galling occurs initially with material transfer from individual grains on a microscopic scale, which become stuck or even diffusion welded to the adjacent surface. This transfer can be enhanced if one or both metals form a thin layer of hard oxides with high coefficients of friction, such as those found on aluminum or stainless steel. As the lump grows, it pushes against the adjacent material, forcing them apart and concentrating most of the friction heat energy into a very small area. This, in turn, causes more adhesion and material build-up. The localized heat increases the plasticity of the galled surface, deforming the metal until the lump breaks through the surface and begins plowing up large amounts of material from the galled surface. Methods of preventing galling include the use of lubricant

A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, ...

s like grease and oil

An oil is any nonpolar chemical substance that is composed primarily of hydrocarbons and is hydrophobic (does not mix with water) and lipophilic (mixes with other oils). Oils are usually flammable and surface active. Most oils are unsaturate ...

, low-friction coatings and thin-film deposits like molybdenum disulfide

Molybdenum disulfide (or moly) is an inorganic chemistry, inorganic compound composed of molybdenum and sulfur. Its chemical formula is .

The compound is classified as a transition metal dichalcogenide. It is a silvery black solid that occurs as ...

or titanium nitride

Titanium nitride (TiN; sometimes known as tinite) is an extremely hard ceramic material, often used as a physical vapor deposition (PVD) coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface prop ...

, and increasing the surface hardness of the metals using processes such as case hardening and induction hardening

Induction hardening is a type of surface hardening in which a metal part is induction-heated and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening ...

.

Mechanism

In engineering science and other technical aspects, the term galling is widespread. The influence of acceleration in the contact zone between materials has been mathematically described and correlated to the exhibited friction mechanism found in the tracks during empiric observations of the galling phenomenon. Due to problems with previous incompatible definitions and test methods, better means of measurements in coordination with a greater understanding of the involved frictional mechanisms have led to the attempt to standardize or redefine the term galling to enable a more generalized use.ASTM International

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

has formulated and established a common definition for the technical aspect of the galling phenomenon in the ASTM G40 standard: "Galling is a form of surface damage arising between sliding solids, distinguished by microscopic, usually localized, roughening and creation of protrusions (e.g., lumps) above the original surface".

When two metallic surfaces are pressed against each other, the initial interaction and the mating points are the asperities

In materials science, asperity, defined as "unevenness of surface, roughness, ruggedness" (from the Latin ''asper''—"rough"), has implications (for example) in physics and seismology. Smooth surfaces, even those polished to a mirror finish, ar ...

, or high points, found on each surface. An asperity may penetrate the opposing surface if there is a converging contact and relative movement. The contact between the surfaces initiates friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of t ...

or plastic deformation

In engineering, deformation (the change in size or shape of an object) may be ''elastic'' or ''plastic''.

If the deformation is negligible, the object is said to be ''rigid''.

Main concepts

Occurrence of deformation in engineering application ...

and induces pressure and energy in a small area called the contact zone.

The elevation in pressure increases the energy density

In physics, energy density is the quotient between the amount of energy stored in a given system or contained in a given region of space and the volume of the system or region considered. Often only the ''useful'' or extractable energy is measure ...

and heat level within the deformed area. This leads to greater adhesion

Adhesion is the tendency of dissimilar particles or interface (matter), surfaces to cling to one another. (Cohesion (chemistry), Cohesion refers to the tendency of similar or identical particles and surfaces to cling to one another.)

The ...

between the surfaces, which initiates the material transfer, galling build-up, lump growth, and creation of protrusions above the original surface.

If the lump (or protrusion of transferred material to one surface) grows to a height of several micrometers

The micrometre (Commonwealth English as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American English), also commonly known by the non-SI term micron, is a unit of length in the International System ...

, it may penetrate the opposing surface oxide-layer and cause damage to the underlying material. Damage in the bulk material is a prerequisite for plastic flow found in the deformed volume surrounding the lump. The geometry and speed of the lump define how the flowing material will be transported, accelerated, and decelerated around the lump. This material flow is critical when defining the contact pressure, energy density, and developed temperature during sliding. The mathematical function describing acceleration and deceleration of flowing material is thereby defined by the geometrical constraints, deduced or given by the lump's surface contour.

If the right conditions are met, such as geometric constraints of the lump, an accumulation of energy can cause a clear change in the material's contact and plastic behavior, increasing the friction force required for adhesion and further movement.

In sliding friction, increased compressive stress

Compressive stresses are generated in objects when they are subjected to forces that push inward, causing the material to shorten or compress. These stresses occur when an object is squeezed or pressed from opposite directions. In everyday life, ...

is proportionally equal to a rise in potential energy

In physics, potential energy is the energy of an object or system due to the body's position relative to other objects, or the configuration of its particles. The energy is equal to the work done against any restoring forces, such as gravity ...

and temperature within the contact zone. The energy accumulation during sliding can reduce energy loss from the contact zone due to a small surface area on the surface boundary, thus, low heat conductivity. Another reason is the energy continuously forced into the metals, which is a product of acceleration and pressure. In cooperation, these mechanisms allow constant energy accumulation, causing increased energy density and temperature in the contact zone during sliding.

The process and contact can be compared to cold welding

Cold welding or contact welding is a solid-state welding process in which joining takes place without fusion or heating at the interface of the two parts to be welded. Unlike in fusion welding, no liquid or molten phase is present in the join ...

or friction welding because cold welding is not truly cold, and the fusing points exhibit an increase in temperature and energy density derived from applied pressure and plastic deformation in the contact zone.

Incidence and location

Galling is often found between metallic surfaces where direct contact and relative motion have occurred.Sheet metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Thicknesses can vary significantly; extremely thin sheets are considered foil (metal), foil or Metal leaf, leaf, and pieces thicker than 6 mm (0.25 ...

forming, thread manufacturing, and other industrial operations may include moving parts, or contact surfaces made of stainless steel, aluminium, titanium, and other metals whose natural development of an external oxide layer through passivation increases their corrosion resistance but renders them particularly susceptible to galling.

In metalworking that involves cutting (primarily turning and milling), galling is often used to describe a wear phenomenon that occurs when cutting soft metal. The work material is transferred to the cutter and develops a "lump." The developed lump changes the contact behavior between the two surfaces, which usually increases adhesion, and resistance to further cutting, and, due to created vibrations, can be heard as a distinct sound.

Galling often occurs with aluminium compounds and is a common cause of tool breakdown. Aluminium is a ductile metal, which means it possesses the ability for plastic flow with relative ease, presupposing a relatively consistent and significant plastic zone.

High ductility and flowing material can be considered a general prerequisite for excessive material transfer and galling because frictional heating is closely linked to the structure of plastic zones around penetrating objects.

Galling can occur even at relatively low loads and velocities because it is the real energy density in the system that induces a phase transition, which often leads to an increase in material transfer and higher friction.

Prevention

Generally, two major frictional systems affect adhesive wear or galling: solid surface contact and lubricated contact. In terms of prevention, they work in dissimilar ways and set different demands on the surface structure, alloys, and crystal matrix used in the materials. ''In solid surface contact'' or unlubricated conditions, the initial contact is characterized by the interaction between asperities and the exhibition of two different sorts of attraction: cohesive surface-energy or the molecules connect and adhere the two surfaces together, notably even if a measurable distance separates them. Direct contact and plastic deformation generate another type of attraction through the constitution of a plastic zone with flowing material where induced energy, pressure, and temperature allow bonding between the surfaces on a much larger scale than cohesive surface energy. In metallic compounds and sheet metal forming, the asperities are usually oxides, and the plastic deformation primarily consists ofbrittle fracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity sur ...

, which presupposes a very small plastic zone. The accumulation of energy and temperature is low due to the discontinuity in the fracture mechanism.

However, during the initial asperity/asperity contact, wear debris or bits and pieces from the asperities adhere to the opposing surface, creating microscopic, usually localized, roughening and creation of protrusions (in effect lumps) above the original surface. The transferred wear debris and lumps penetrate the opposing oxide surface layer and cause damage to the underlying bulk material, plowing it forward. This allows continuous plastic deformation, plastic flow, and accumulation of energy and temperature.

The prevention of adhesive material transfer is accomplished by the following or similar approaches:

* Low-temperature carburizing treatments such as Kolsterising can eliminate galling in austenitic stainless steels by increasing surface hardness up to 1200 HV0.05 (depending on the base material and surface conditions)./ref> * Less cohesive or chemical attraction between surface atoms or molecules. * Avoid continuous plastic deformation and plastic flow, for example, through a thicker oxide layer on the subject material in sheet-metal forming (SMF). *

Coating

A coating is a covering that is applied to the surface of an object, or substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. powder coatings.

Paints ...

s deposited on the SMF work tool, such as chemical vapor deposition

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high-quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

In typical CVD, the wafer (electro ...

(CVD) or physical vapor deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polym ...

(PVD) and titanium nitride (TiN) or diamond-like carbon

Diamond-like carbon (DLC) is a class of amorphous carbon material that displays some of the typical properties of diamond. DLC is usually applied as coatings to other materials that could benefit from such properties.

DLC exists in seven dif ...

coatings exhibit low chemical reactivity even in high energy frictional contact, where the subject material's protective oxide layer is breached, and the frictional contact is distinguished by continuous plastic deformation and plastic flow.

''Lubricated contact'' places other demands on the surface structure of the materials involved, and the main issue is to retain the protective lubrication

Lubrication is the process or technique of using a lubricant to reduce friction and wear and tear in a contact between two surfaces. The study of lubrication is a discipline in the field of tribology.

Lubrication mechanisms such as fluid-lubr ...

thickness and avoid plastic deformation. This is important because plastic deformation raises the temperature of the oil or lubrication fluid and changes the viscosity. Any eventual material transfer or creation of protrusions above the original surface will also reduce the ability to retain a protective lubrication thickness. A proper protective lubrication thickness can be assisted or retained by:

* Surface cavities or small holes can create a favorable geometric situation for the oil to retain a protective lubrication thickness in the contact zone.

* Cohesive forces on the surface can increase the chemical attraction between the surface and lubricants and enhance the lubrication thickness.

* Oil additive

Oil additives are chemical compounds that improve the lubricant performance of base oil (or oil "base stock"). The manufacturer of many oils can use the same base stock for each formulation and can choose different additives for each use. Additives ...

s may reduce the tendency for galling or adhesive wear.

See also

* * * *References

{{Reflist Tribology Materials degradation Mechanical engineering Materials science Surface science de:Fressen (Technik)