Francis pump-turbine on:

[Wikipedia]

[Google]

[Amazon]

The Francis turbine is a type of

The Francis turbine is a type of

The Francis turbine is a type of reaction turbine, a category of turbine in which the working fluid comes to the turbine under immense pressure and the energy is extracted by the turbine blades from the working fluid. A part of the energy is given up by the fluid because of pressure changes occurring on the blades of the turbine, quantified by the expression of

The Francis turbine is a type of reaction turbine, a category of turbine in which the working fluid comes to the turbine under immense pressure and the energy is extracted by the turbine blades from the working fluid. A part of the energy is given up by the fluid because of pressure changes occurring on the blades of the turbine, quantified by the expression of

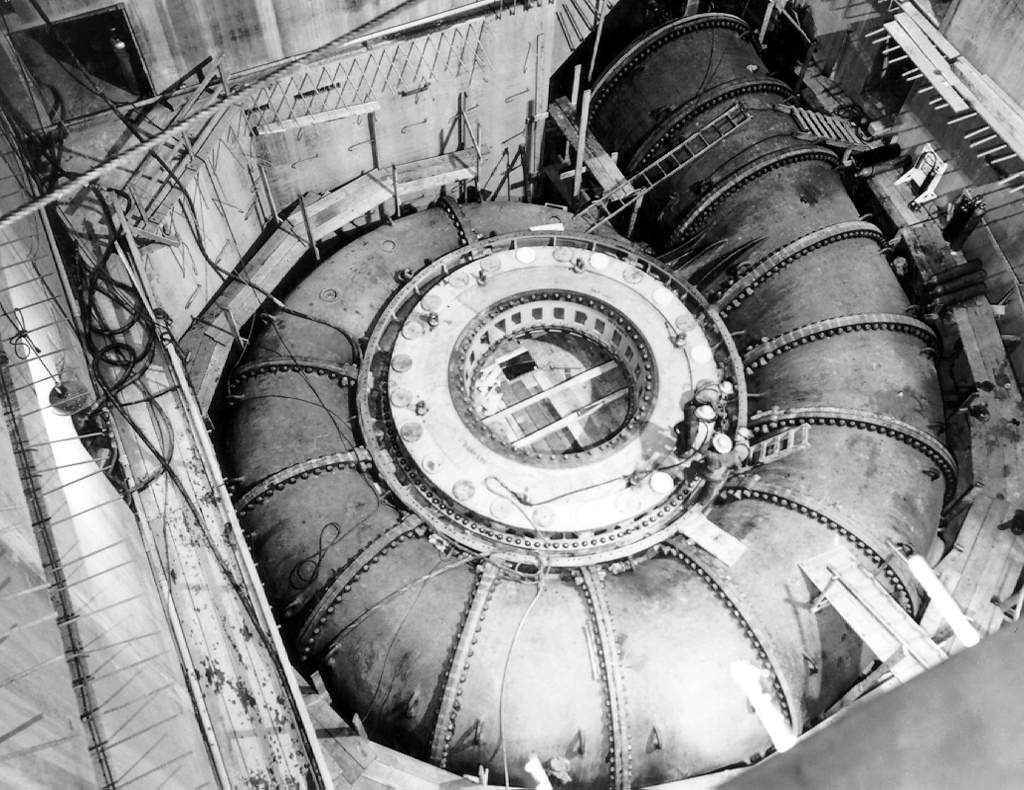

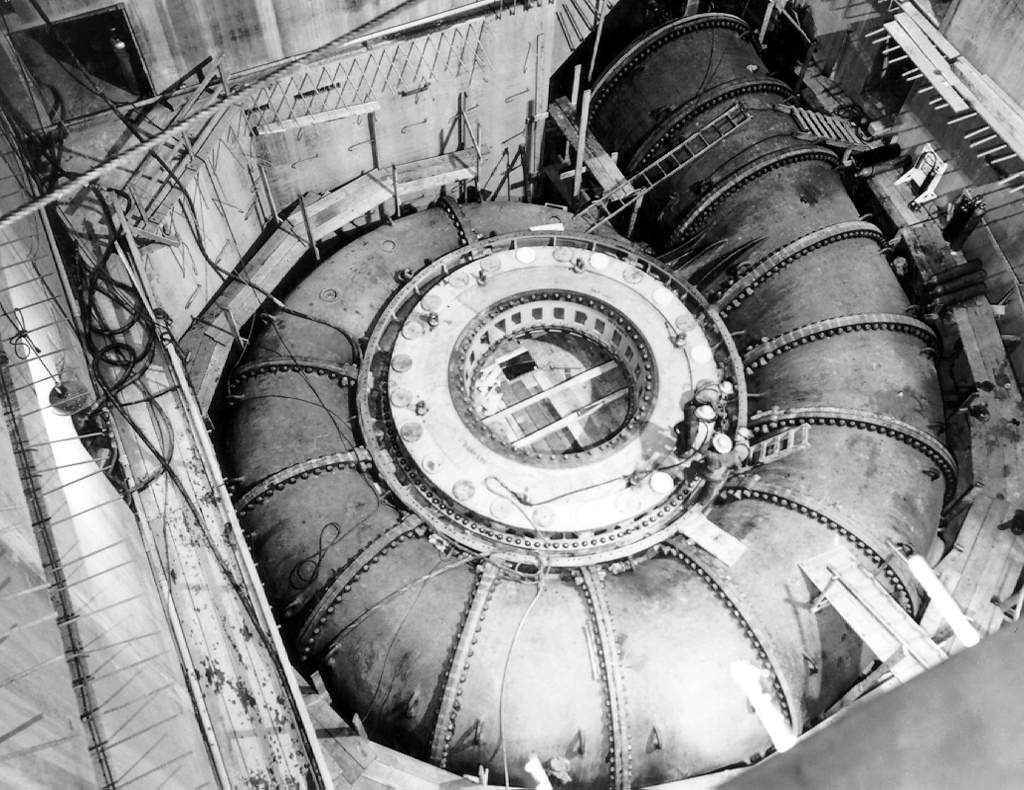

Francis Turbine complete.jpg, Francis turbine (exterior view) attached to a generator

Francis Turbine Low flow.jpg, Cut-away view, with wicket gates (yellow) at minimum flow setting

Francis Turbine High flow.jpg, Cut-away view, with wicket gates (yellow) at full flow setting

Usually the flow velocity (velocity perpendicular to the tangential direction) remains constant throughout, i.e. and is equal to that at the inlet to the draft tube. Using the Euler turbine equation,

, where ''e'' is the energy transfer to the rotor per unit mass of the fluid. From the inlet velocity triangle,

:

and

:

Therefore

:

The loss of kinetic energy per unit mass at the outlet is . Therefore, neglecting friction, the blade efficiency becomes

:

i.e.

:

Usually the flow velocity (velocity perpendicular to the tangential direction) remains constant throughout, i.e. and is equal to that at the inlet to the draft tube. Using the Euler turbine equation,

, where ''e'' is the energy transfer to the rotor per unit mass of the fluid. From the inlet velocity triangle,

:

and

:

Therefore

:

The loss of kinetic energy per unit mass at the outlet is . Therefore, neglecting friction, the blade efficiency becomes

:

i.e.

:

Degree of reaction can be defined as the ratio of pressure energy change in the blades to total energy change of the fluid. This means that it is a ratio indicating the fraction of total change in fluid pressure energy occurring in the blades of the turbine. The rest of the changes occur in the stator blades of the turbines and the volute casing as it has a varying cross-sectional area. For example, if the degree of reaction is given as 50%, that means that half of the total energy change of the fluid is taking place in the rotor blades and the other half is occurring in the stator blades. If the degree of reaction is zero it means that the energy changes due to the rotor blades is zero, leading to a different turbine design called the

Degree of reaction can be defined as the ratio of pressure energy change in the blades to total energy change of the fluid. This means that it is a ratio indicating the fraction of total change in fluid pressure energy occurring in the blades of the turbine. The rest of the changes occur in the stator blades of the turbines and the volute casing as it has a varying cross-sectional area. For example, if the degree of reaction is given as 50%, that means that half of the total energy change of the fluid is taking place in the rotor blades and the other half is occurring in the stator blades. If the degree of reaction is zero it means that the energy changes due to the rotor blades is zero, leading to a different turbine design called the

Francis turbines may be designed for a wide range of heads and flows. This versatility, along with their high efficiency, has made them the most widely used turbine in the world. Francis type units cover a head range from , and their connected generator output power varies from just a few kilowatts up to 1000 MW. Large Francis turbines are individually designed for each site to operate with the given water flow and water head at the highest possible efficiency, typically over 90% (to 99%L. Suo, ... H. Xie, in Comprehensive Renewable Energy, 2012).

In contrast to the

Francis turbines may be designed for a wide range of heads and flows. This versatility, along with their high efficiency, has made them the most widely used turbine in the world. Francis type units cover a head range from , and their connected generator output power varies from just a few kilowatts up to 1000 MW. Large Francis turbines are individually designed for each site to operate with the given water flow and water head at the highest possible efficiency, typically over 90% (to 99%L. Suo, ... H. Xie, in Comprehensive Renewable Energy, 2012).

In contrast to the

The Francis turbine is a type of

The Francis turbine is a type of water turbine

A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

Water turbines were developed in the 19th century and were widely used for industrial power prior to electrical grids. Now, th ...

. It is an inward-flow reaction turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating e ...

that combines radial

Radial is a geometric term of location which may refer to:

Mathematics and Direction

* Vector (geometric), a line

* Radius, adjective form of

* Radial distance, a directional coordinate in a polar coordinate system

* Radial set

* A bearing from ...

and axial flow

An axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other ...

concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.

The process of arriving at the modern Francis runner design took from 1848 to approximately 1920. It became known as the Francis turbine around 1920, being named after British-American engineer James B. Francis who in 1848 created a new turbine design.

Francis turbines are primarily used for producing electricity. The power output of the electric generator

In electricity generation, a generator is a device that converts motive power (mechanical energy) or fuel-based power ( chemical energy) into electric power for use in an external circuit. Sources of mechanical energy include steam turbines, gas ...

s generally ranges from just a few kilowatts up to 1000 MW, though mini-hydro installations may be lower. The best performance is seen when the head

A head is the part of an organism which usually includes the ears, brain, forehead, cheeks, chin, eyes, nose, and mouth, each of which aid in various sensory functions such as sight, hearing, smell, and taste. Some very simple animals may not ...

height is between . Penstock

A penstock is a sluice or gate or intake structure that controls water flow, or an enclosed pipe that delivers water to hydro turbines and sewerage systems. The term is inherited from the earlier technology of mill ponds and watermills.

H ...

diameters are between . The speeds of different turbine units range from 70 to 1000 rpm

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or with the notation min−1) is a unit of rotational speed or rotational frequency for rotating machines.

Standards

ISO 80000-3:2019 defines a unit of rotation as the dimensi ...

. A wicket gate

A wicket gate, or simply a wicket, is a pedestrian door or gate, particularly one built into a larger door or into a wall or fence.

Use in fortifications

Wickets are typically small, narrow doors either alongside or within a larger castle or ...

around the outside of the turbine's rotating runner controls the rate of water flow through the turbine for different power production rates. Francis turbines are usually mounted with a vertical shaft, to isolate water from the generator. This also facilitates installation and maintenance.

Development

Water wheel

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or bucke ...

s of different types have been used for more than 1,000 years to power mills of all types, but they were relatively inefficient. Nineteenth-century efficiency improvements of water turbine

A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

Water turbines were developed in the 19th century and were widely used for industrial power prior to electrical grids. Now, th ...

s allowed them to replace nearly all water wheel applications and compete with steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be trans ...

s wherever water power was available. After electric generator

In electricity generation, a generator is a device that converts motive power (mechanical energy) or fuel-based power ( chemical energy) into electric power for use in an external circuit. Sources of mechanical energy include steam turbines, gas ...

s were developed in the late 1800s, turbines were a natural source of generator power where potential hydropower sources existed.

In 1826 the French engineer Benoit Fourneyron developed a high-efficiency (80%) outward-flow water turbine. Water was directed tangentially through the turbine runner, causing it to spin. Another French engineer Jean-Victor Poncelet

Jean-Victor Poncelet (; 1 July 1788 – 22 December 1867) was a French engineer and mathematician who served most notably as the Commanding General of the École Polytechnique. He is considered a reviver of projective geometry, and his work ''Tr ...

designed an inward-flow turbine in about 1820 that used the same principles. S. B. Howd obtained a US patent in 1838 for a similar design.

In 1848 James B. Francis, while working as head engineer of the Locks and Canals company in the water wheel-powered textile

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the ...

factory city of Lowell, Massachusetts

Lowell () is a city in Massachusetts, in the United States. Alongside Cambridge, It is one of two traditional seats of Middlesex County. With an estimated population of 115,554 in 2020, it was the fifth most populous city in Massachusetts as of ...

, improved on these designs to create more efficient turbines. He applied scientific principles and testing methods to produce a very efficient turbine design. More importantly, his mathematical and graphical calculation methods improved turbine design and engineering. His analytical methods allowed the design of high-efficiency turbines to precisely match a site's water flow and pressure ( water head).

Components

A Francis turbine consists of the following main parts: Spiral casing: The spiral casing around the runner of the turbine is known as the volute casing or scroll case. Throughout its length, it has numerous openings at regular intervals to allow the working fluid to impinge on the blades of the runner. These openings convert the pressure energy of the fluid into kinetic energy just before the fluid impinges on the blades. This maintains a constant velocity despite the fact that numerous openings have been provided for the fluid to enter the blades, as the cross-sectional area of this casing decreases uniformly along the circumference. Guide and stay vanes: The primary function of the guide and stay vanes is to convert the pressure energy of the fluid into kinetic energy. It also serves to direct the flow at design angles to the runner blades.Draft tube

Draft Tube is a diverging tube fitted at the exit of runner of turbine and used to utilize the kinetic energy available with water at the exit of runner. '.

This draft tube at the end of the turbine increases the pressure of the exiting flu ...

: The draft tube is a conduit that connects the runner exit to the tail race where the water is discharged from the turbine. Its primary function is to reduce the velocity of discharged water to minimize the loss of kinetic energy at the outlet. This permits the turbine to be set above the tail water without appreciable drop of available head.

Theory of operation

The Francis turbine is a type of reaction turbine, a category of turbine in which the working fluid comes to the turbine under immense pressure and the energy is extracted by the turbine blades from the working fluid. A part of the energy is given up by the fluid because of pressure changes occurring on the blades of the turbine, quantified by the expression of

The Francis turbine is a type of reaction turbine, a category of turbine in which the working fluid comes to the turbine under immense pressure and the energy is extracted by the turbine blades from the working fluid. A part of the energy is given up by the fluid because of pressure changes occurring on the blades of the turbine, quantified by the expression of degree of reaction

In turbomachinery, degree of reaction or reaction ratio (R) is defined as the ratio of the static pressure rise in the rotating blades of a compressor (or drop in turbine blades) to the static pressure rise in the compressor stage (or drop in a tur ...

, while the remaining part of the energy is extracted by the volute casing of the turbine. At the exit, water acts on the spinning cup-shaped runner features, leaving at low velocity and low swirl with very little kinetic or potential energy

In physics, potential energy is the energy held by an object because of its position relative to other objects, stresses within itself, its electric charge, or other factors.

Common types of potential energy include the gravitational potentia ...

left. The turbine's exit tube is shaped to help decelerate the water flow and recover the pressure.

Blade efficiency

Usually the flow velocity (velocity perpendicular to the tangential direction) remains constant throughout, i.e. and is equal to that at the inlet to the draft tube. Using the Euler turbine equation,

, where ''e'' is the energy transfer to the rotor per unit mass of the fluid. From the inlet velocity triangle,

:

and

:

Therefore

:

The loss of kinetic energy per unit mass at the outlet is . Therefore, neglecting friction, the blade efficiency becomes

:

i.e.

:

Usually the flow velocity (velocity perpendicular to the tangential direction) remains constant throughout, i.e. and is equal to that at the inlet to the draft tube. Using the Euler turbine equation,

, where ''e'' is the energy transfer to the rotor per unit mass of the fluid. From the inlet velocity triangle,

:

and

:

Therefore

:

The loss of kinetic energy per unit mass at the outlet is . Therefore, neglecting friction, the blade efficiency becomes

:

i.e.

:

Degree of reaction

Degree of reaction can be defined as the ratio of pressure energy change in the blades to total energy change of the fluid. This means that it is a ratio indicating the fraction of total change in fluid pressure energy occurring in the blades of the turbine. The rest of the changes occur in the stator blades of the turbines and the volute casing as it has a varying cross-sectional area. For example, if the degree of reaction is given as 50%, that means that half of the total energy change of the fluid is taking place in the rotor blades and the other half is occurring in the stator blades. If the degree of reaction is zero it means that the energy changes due to the rotor blades is zero, leading to a different turbine design called the

Degree of reaction can be defined as the ratio of pressure energy change in the blades to total energy change of the fluid. This means that it is a ratio indicating the fraction of total change in fluid pressure energy occurring in the blades of the turbine. The rest of the changes occur in the stator blades of the turbines and the volute casing as it has a varying cross-sectional area. For example, if the degree of reaction is given as 50%, that means that half of the total energy change of the fluid is taking place in the rotor blades and the other half is occurring in the stator blades. If the degree of reaction is zero it means that the energy changes due to the rotor blades is zero, leading to a different turbine design called the Pelton Turbine

The Pelton wheel or Pelton Turbine is an impulse-type water turbine invented by American inventor Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse of moving water, as opposed to water's dead weight like the tra ...

.

:

The second equality above holds, since discharge is radial in a Francis turbine. Now, putting in the value of 'e' from above and using (as )

:

Application

Francis turbines may be designed for a wide range of heads and flows. This versatility, along with their high efficiency, has made them the most widely used turbine in the world. Francis type units cover a head range from , and their connected generator output power varies from just a few kilowatts up to 1000 MW. Large Francis turbines are individually designed for each site to operate with the given water flow and water head at the highest possible efficiency, typically over 90% (to 99%L. Suo, ... H. Xie, in Comprehensive Renewable Energy, 2012).

In contrast to the

Francis turbines may be designed for a wide range of heads and flows. This versatility, along with their high efficiency, has made them the most widely used turbine in the world. Francis type units cover a head range from , and their connected generator output power varies from just a few kilowatts up to 1000 MW. Large Francis turbines are individually designed for each site to operate with the given water flow and water head at the highest possible efficiency, typically over 90% (to 99%L. Suo, ... H. Xie, in Comprehensive Renewable Energy, 2012).

In contrast to the Pelton turbine

The Pelton wheel or Pelton Turbine is an impulse-type water turbine invented by American inventor Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse of moving water, as opposed to water's dead weight like the tra ...

, the Francis turbine operates at its best completely filled with water at all times. The turbine and the outlet channel may be placed lower than the lake or sea level outside, reducing the tendency for cavitation

Cavitation is a phenomenon in which the static pressure of a liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, cal ...

.

In addition to electrical production, they may also be used for pumped storage

Pumping may refer to:

* The operation of a pump, for moving a liquid from one location to another

**The use of a breast pump for extraction of milk

* Pumping (audio), a creative misuse of dynamic range compression

* Pumping (computer systems), the ...

, where a reservoir is filled by the turbine (acting as a pump) driven by the generator acting as a large electrical motor during periods of low power demand, and then reversed and used to generate power during peak demand. These pump storage reservoirs act as large energy storage sources to store "excess" electrical energy in the form of water in elevated reservoirs. This is one of a few methods that allow temporary excess electrical capacity to be stored for later utilization.

See also

*Draft tube

Draft Tube is a diverging tube fitted at the exit of runner of turbine and used to utilize the kinetic energy available with water at the exit of runner. '.

This draft tube at the end of the turbine increases the pressure of the exiting flu ...

* Evolution from Francis turbine to Kaplan turbine

*Hydropower

Hydropower (from el, ὕδωρ, "water"), also known as water power, is the use of falling or fast-running water to produce electricity or to power machines. This is achieved by converting the gravitational potential or kinetic energy of a wa ...

* Jonval turbine

*Kaplan turbine

The Kaplan turbine is a propeller-type water turbine which has adjustable blades. It was developed in 1913 by Austrian professor Viktor Kaplan, who combined automatically adjusted propeller blades with automatically adjusted wicket gates to a ...

*Pelton wheel

The Pelton wheel or Pelton Turbine is an impulse-type water turbine invented by American inventor Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse of moving water, as opposed to water's dead weight like the tr ...

* Sensor fish, a device used to study the impact of fish travelling through Francis and Kaplan turbines

Citations

General bibliography

* Layton, Edwin T. ''From Rule of Thumb to Scientific Engineering: James B. Francis and the Invention of the Francis Turbine''. NLA Monograph Series. Stony Brook, NY: Research Foundation of the State University of New York, 1992. . * S. M. Yahya, page number 13, fig. 1.14. {{DEFAULTSORT:Francis Turbine Water turbines English inventions American inventions