Extruder (3D Printing) on:

[Wikipedia]

[Google]

[Amazon]

A 3D printer extruder is a

A 3D printer extruder is a

With a direct-drive extruder, the motor pushing the filament is installed by the hotend and pushes the filament directly into the nozzle. Direct-drive designs have several advantages, and typically give better extrusion, faster retraction, are able to print more types of filaments, and can use a smaller and lighter motor due to the short distance to the nozzle. One typical disadvantage of direct-drive extruders is the added mass to the hotend, compared to a typical Bowden extruder, which may cause more vibrations so that the direct-drive printhead has to move slower, which can affect print speed. Another typical disadvantage is more complex maintenance due to tight packaging of many components in the hotend.

With a direct-drive extruder, the motor pushing the filament is installed by the hotend and pushes the filament directly into the nozzle. Direct-drive designs have several advantages, and typically give better extrusion, faster retraction, are able to print more types of filaments, and can use a smaller and lighter motor due to the short distance to the nozzle. One typical disadvantage of direct-drive extruders is the added mass to the hotend, compared to a typical Bowden extruder, which may cause more vibrations so that the direct-drive printhead has to move slower, which can affect print speed. Another typical disadvantage is more complex maintenance due to tight packaging of many components in the hotend.

A 3D printer extruder is a

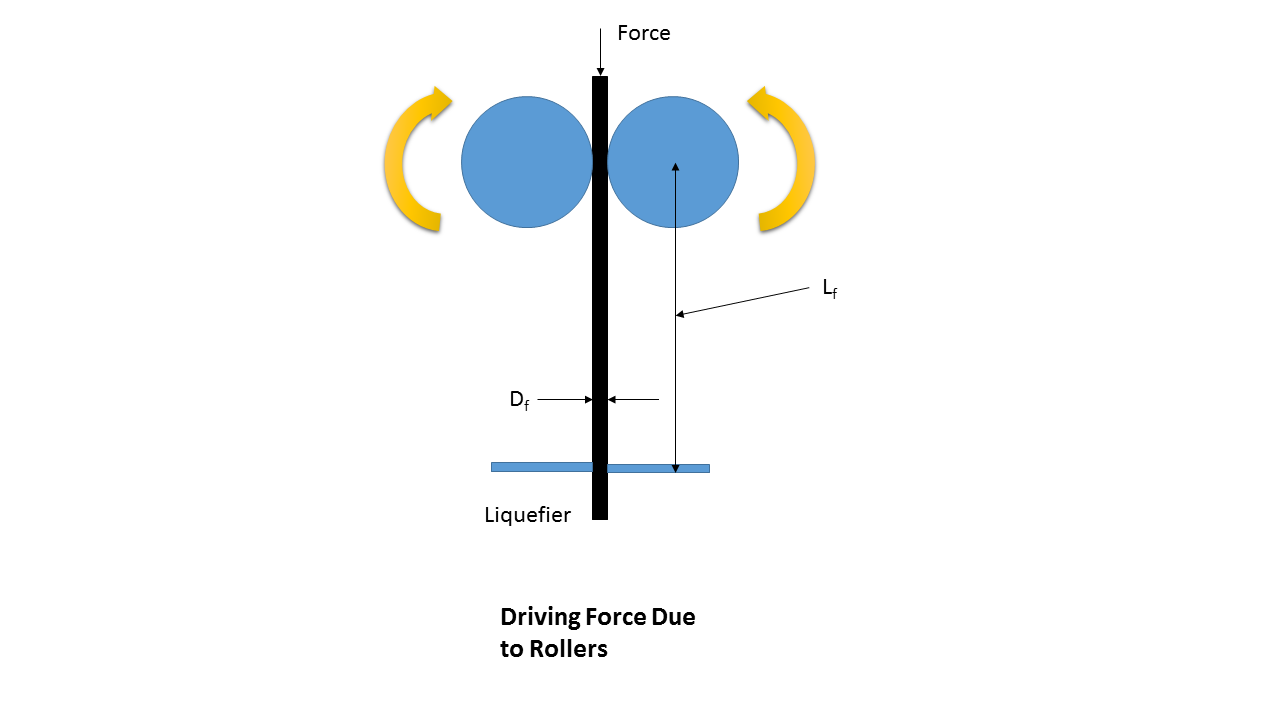

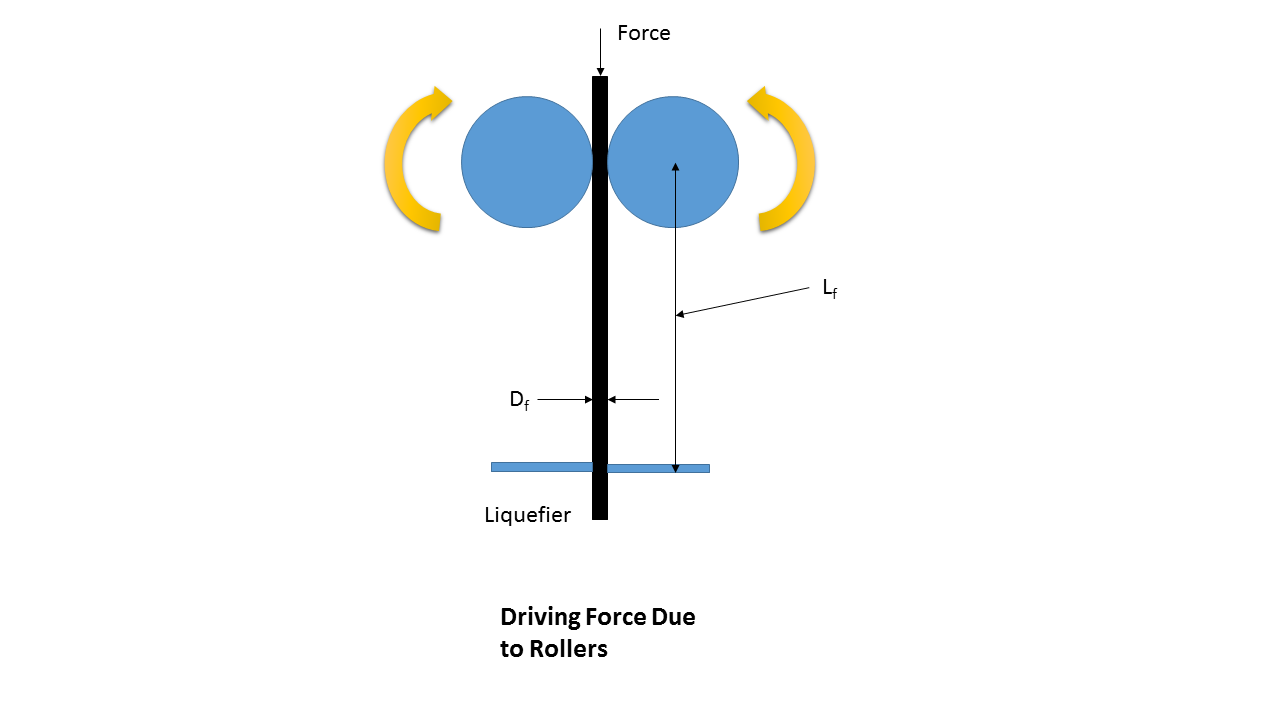

A 3D printer extruder is a filament

The word filament, which is descended from Latin ''filum'' meaning " thread", is used in English for a variety of thread-like structures, including:

Astronomy

* Galaxy filament, the largest known cosmic structures in the universe

* Solar filament ...

feeding mechanism used in many fused filament fabrication

Fused filament fabrication (FFF), also known as fused deposition modeling (with the trademarked acronym FDM), or ''filament freeform fabrication'', is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is ...

(FFF) 3D printer

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

s. There are several types of 3D printer extruders. A Bowden extruder is a type of extruder that pushes filament through a long and flexible PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene, and has numerous applications because it is chemically inert. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off fro ...

(Teflon) tube to the hot end

A hotend is a component used in fused filament deposition 3D printers. Its purpose is to heat up and melt filament material for depositing into the intended shape.

The hotend is usually made of a bulk heat-conductive material with an internal ...

. An alternative type of extruder which is also widely used in filament 3D printers is the direct-drive extruder, which sits closer to the extruder hot end.

Bowden extruder

Bowden type extruders are easier to swap since they are outside the print head. They also have less chance of tangling the filament while it unwinds from the spool. Additionally, they reduce themass

Mass is an Intrinsic and extrinsic properties, intrinsic property of a physical body, body. It was traditionally believed to be related to the physical quantity, quantity of matter in a body, until the discovery of the atom and particle physi ...

of the extrusion carriage because it doesn't have to hold a stepper motor

A stepper motor, also known as step motor or stepping motor,Clarence W. de Silva. Mechatronics: An Integrated Approach (2005). CRC Press. p. 675. "The terms ''stepper motor'', ''stepping motor'', and ''step motor'' are synonymous and are often u ...

. This allows for faster changes in print head movement direction, increased print speed, increased accuracy, and decreased instances of artifacting or ghosting along the x and y axes.

One disadvantage is that because Bowden extruders push filament through a long and curved tube, more friction must be overcome compared with direct drive extruders. To partially mitigate these friction forces, the tube is made of PTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene, and has numerous applications because it is chemically inert. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off fro ...

, which has a low coefficient of friction. Flexible filaments do not print well because the filament flexes inside the tube and clogs up the machine.

Another disadvantage is that the feeding distance is relatively long, and thus the resistance is high, meaning the stepping motor of extrusion is required to have a higher torque. The long distance can also lead to more backlash

Backlash may refer to:

Literature

* '' Backlash: The Undeclared War Against American Women'', a 1991 book by Susan Faludi

* ''Backlash'' (Star Wars novel), a 2010 novel by Aaron Allston

* Backlash (Marc Slayton), a comic book character from ...

.

Direct-drive extruder

Filament compatibility

Bowden extruders: Works better with rigid filaments such as PLA, ABS and PETG which are less likely to buckle while inside the bowden tube. Flexible filaments such as TPU will struggle with bowden extruders since it has a long path to get to the hotend, The friction inside the bowden tube and compressible nature of the filament will make it difficult to use with a bowden extruder. Direct-drive extruder: Works well with both flexible and rigid filaments. Since the extruder sits on top of the hotend, the filament travel distance from the extruder to the hotend is minimal, due to this reason even flexible filaments such as TPU will print well with a direct drive extruder.See also

*Lyman filament extruder

300px, right The Lyman filament extruder is a device for making 3D printing filament suitable for use in 3-D printers like the RepRap. It is named after its developer Hugh Lyman and was the winner of the Desktop Factory Competition.

The goal i ...

, a DIY device for manufacturing new filament from plastic pellets or recycled filament

References

{{DEFAULTSORT:3D printer extruder Fused filament fabrication 3D printing