A composite material (also called a composition material or shortened to composite, which is the common name) is a

material

Material is a substance or mixture of substances that constitutes an object. Materials can be pure or impure, living or non-living matter. Materials can be classified on the basis of their physical and chemical properties, or on their geolo ...

which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from

mixtures and

solid solutions.

Typical

engineered

Engineering is the use of scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad range of more speciali ...

composite materials include:

*

Reinforced concrete and

masonry

*

Composite wood such as

plywood

*

Reinforced plastic

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibr ...

s, such as

fibre-reinforced polymer or

fiberglass

Fiberglass ( American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cl ...

*

Ceramic matrix composites (

composite ceramic and metal matrices)

*

Metal matrix composites

*and other

advanced composite materials

There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with common materials, as well as composite materials inspired from animals and natural sources with low carbon footprint.

More recently researchers have also begun to actively include sensing, actuation, computation and communication into composites, which are known as

robotic materials.

Composite materials are generally used for

building

A building, or edifice, is an enclosed structure with a roof and walls standing more or less permanently in one place, such as a house or factory (although there's also portable buildings). Buildings come in a variety of sizes, shapes, and func ...

s,

bridge

A bridge is a structure built to span a physical obstacle (such as a body of water, valley, road, or rail) without blocking the way underneath. It is constructed for the purpose of providing passage over the obstacle, which is usually someth ...

s, and

structure

A structure is an arrangement and organization of interrelated elements in a material object or system, or the object or system so organized. Material structures include man-made objects such as buildings and machines and natural objects such a ...

s such as

boat hulls,

swimming pool panels,

racing car bodies,

shower stalls,

bathtub

A bathtub, also known simply as a bath or tub, is a container for holding water in which a person or animal may bathe. Most modern bathtubs are made of thermoformed acrylic, porcelain-enameled steel or cast iron, or fiberglass-reinforced pol ...

s,

storage tanks,

imitation

Imitation (from Latin ''imitatio'', "a copying, imitation") is a behavior whereby an individual observes and replicates another's behavior. Imitation is also a form of that leads to the "development of traditions, and ultimately our culture. I ...

granite

Granite () is a coarse-grained ( phaneritic) intrusive igneous rock composed mostly of quartz, alkali feldspar, and plagioclase. It forms from magma with a high content of silica and alkali metal oxides that slowly cools and solidifies un ...

and

cultured marble sinks and countertops. They are also being increasingly used in general automotive applications.

The most advanced examples perform routinely on

spacecraft

A spacecraft is a vehicle or machine designed to fly in outer space. A type of artificial satellite, spacecraft are used for a variety of purposes, including communications, Earth observation, meteorology, navigation, space colonization, ...

and

aircraft

An aircraft is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or by using the Lift (force), dynamic lift of an airfoil, or in ...

in demanding environments.

History

The earliest composite materials were made from

straw and

mud combined to form

bricks for

building

A building, or edifice, is an enclosed structure with a roof and walls standing more or less permanently in one place, such as a house or factory (although there's also portable buildings). Buildings come in a variety of sizes, shapes, and func ...

construction

Construction is a general term meaning the art and science to form objects, systems, or organizations,"Construction" def. 1.a. 1.b. and 1.c. ''Oxford English Dictionary'' Second Edition on CD-ROM (v. 4.0) Oxford University Press 2009 and ...

. Ancient

brick-making

A brickworks, also known as a brick factory, is a factory for the manufacturing of bricks, from clay or shale. Usually a brickworks is located on a clay bedrock (the most common material from which bricks are made), often with a quarry for cl ...

was documented by

Egyptian tomb paintings.

Wattle and daub is one of the oldest composite materials, at over 6000 years old.

Concrete is also a composite material, and is used more than any other synthetic material in the world. , about 7.5 billion cubic metres of concrete are made each year

* Woody

plant

Plants are predominantly photosynthetic eukaryotes of the kingdom Plantae. Historically, the plant kingdom encompassed all living things that were not animals, and included algae and fungi; however, all current definitions of Plantae excl ...

s, both true

wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin ...

from

trees and such plants as

palms and

bamboo

Bamboos are a diverse group of evergreen perennial flowering plants making up the subfamily Bambusoideae of the grass family Poaceae. Giant bamboos are the largest members of the grass family. The origin of the word "bamboo" is uncertain, ...

, yield natural composites that were used prehistorically by mankind and are still used widely in construction and scaffolding.

*

Plywood

Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured ...

, 3400 BC,

by the Ancient Mesopotamians; gluing wood at different angles gives better properties than natural wood.

*

Cartonnage, layers of linen or papyrus soaked in plaster dates to the

First Intermediate Period of Egypt

The First Intermediate Period, described as a 'dark period' in ancient Egyptian history, spanned approximately 125 years, c. 2181–2055 BC, after the end of the Old Kingdom. It comprises the Seventh (although this is mostly considered spuriou ...

c. 2181–2055 BC

and was used for

death masks.

*

Cob mud bricks, or mud walls, (using mud (clay) with straw or gravel as a binder) have been used for thousands of years.

*

Concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most wid ...

was described by

Vitruvius

Vitruvius (; c. 80–70 BC – after c. 15 BC) was a Roman architect and engineer during the 1st century BC, known for his multi-volume work entitled '' De architectura''. He originated the idea that all buildings should have three attribut ...

, writing around 25 BC in his

''Ten Books on Architecture'', distinguished types of aggregate appropriate for the preparation of

lime mortars. For ''structural mortars'', he recommended ''

pozzolana

Pozzolana or pozzuolana ( , ), also known as pozzolanic ash ( la, pulvis puteolanus), is a natural siliceous or siliceous- aluminous material which reacts with calcium hydroxide in the presence of water at room temperature (cf. pozzolanic react ...

'', which were volcanic sands from the sandlike beds of

Pozzuoli brownish-yellow-gray in colour near

Naples

Naples (; it, Napoli ; nap, Napule ), from grc, Νεάπολις, Neápolis, lit=new city. is the regional capital of Campania and the third-largest city of Italy, after Rome and Milan, with a population of 909,048 within the city's adm ...

and reddish-brown at

Rome

, established_title = Founded

, established_date = 753 BC

, founder = King Romulus ( legendary)

, image_map = Map of comune of Rome (metropolitan city of Capital Rome, region Lazio, Italy).svg

, map_caption ...

. Vitruvius specifies a ratio of 1 part lime to 3 parts pozzolana for cements used in buildings and a 1:2 ratio of lime to pulvis Puteolanus for underwater work, essentially the same ratio mixed today for concrete used at sea.

Natural cement-stones, after burning, produced cements used in concretes from post-Roman times into the 20th century, with some properties superior to manufactured

Portland cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19t ...

.

*

Papier-mâché

upright=1.3, Mardi Gras papier-mâché masks, Haiti

upright=1.3, Papier-mâché Catrinas, traditional figures for day of the dead celebrations in Mexico

Papier-mâché (, ; , literally "chewed paper") is a composite material consisting of p ...

, a composite of paper and glue, has been used for hundreds of years.

* The first artificial

fibre reinforced plastic

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibr ...

was a combination of fiber glass and

bakelite

Polyoxybenzylmethylenglycolanhydride, better known as Bakelite ( ), is a thermosetting phenol formaldehyde resin, formed from a condensation reaction of phenol with formaldehyde. The first plastic made from synthetic components, it was developed ...

, performed in 1935 by Al Simison and Arthur D Little in Owens Corning Company

* One of the most common and familiar composite is

fibreglass, in which small glass fibre are embedded within a polymeric material (normally an epoxy or polyester). The glass fibre is relatively strong and stiff (but also brittle), whereas the polymer is ductile (but also weak and flexible). Thus the resulting fibreglass is relatively stiff, strong, flexible, and ductile.

Examples

Composite materials

Concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most wid ...

is the most common artificial composite material of all and typically consists of loose stones (aggregate) held with a matrix of

cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixe ...

. Concrete is an inexpensive material, and will not compress or shatter even under quite a large compressive force. However, concrete cannot survive tensile loading (i.e., if stretched it will quickly break apart). Therefore, to give concrete the ability to resist being stretched, steel bars, which can resist high stretching (tensile) forces, are often added to concrete to form

reinforced concrete

Reinforced concrete (RC), also called reinforced cement concrete (RCC) and ferroconcrete, is a composite material in which concrete's relatively low ultimate tensile strength, tensile strength and ductility are compensated for by the inclusion ...

.

Fibre-reinforced polymers include

carbon fiber reinforced polymer

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

and

glass-reinforced plastic

Fiberglass (American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass clo ...

. If classified by matrix then there are

thermoplastic composites,

short fibre thermoplastics,

long fibre thermoplastics or long fibre-reinforced thermoplastics. There are numerous

thermoset

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer ( resin). Curing is induced by heat or suitable radiation ...

composites, including

paper composite panels. Many advanced

thermoset polymer matrix

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as gla ...

systems usually incorporate

aramid

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, mar ...

fibre

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate ...

and

carbon fibre

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

in an

epoxy resin

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional ...

matrix.

Shape memory polymer composites are high-performance composites, formulated using fibre or fabric reinforcements and shape memory polymer resin as the matrix. Since a shape memory polymer resin is used as the matrix, these composites have the ability to be easily manipulated into various configurations when they are heated above their activation temperatures and will exhibit high strength and stiffness at lower temperatures. They can also be reheated and reshaped repeatedly without losing their material properties. These composites are ideal for applications such as lightweight, rigid, deployable structures; rapid manufacturing; and dynamic reinforcement.

High strain composites are another type of high-performance composites that are designed to perform in a high deformation setting and are often used in deployable systems where structural flexing is advantageous. Although high strain composites exhibit many similarities to shape memory polymers, their performance is generally dependent on the fibre layout as opposed to the resin content of the matrix.

Composites can also use metal fibres reinforcing other metals, as in

metal matrix composites (MMC) or

ceramic matrix composites (CMC), which includes

bone

A bone is a rigid organ that constitutes part of the skeleton in most vertebrate animals. Bones protect the various other organs of the body, produce red and white blood cells, store minerals, provide structure and support for the body, ...

(

hydroxyapatite

Hydroxyapatite, also called hydroxylapatite (HA), is a naturally occurring mineral form of calcium apatite with the formula Ca5(PO4)3(OH), but it is usually written Ca10(PO4)6(OH)2 to denote that the crystal unit cell comprises two entities. ...

reinforced with

collagen

Collagen () is the main structural protein in the extracellular matrix found in the body's various connective tissues. As the main component of connective tissue, it is the most abundant protein in mammals, making up from 25% to 35% of the whol ...

fibres),

cermet (ceramic and metal) and

concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most wid ...

. Ceramic matrix composites are built primarily for

fracture toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a ...

, not for strength. Another class of composite materials involve woven fabric composite consisting of longitudinal and transverse laced yarns. Woven fabric composites are flexible as they are in form of fabric.

Organic matrix/ceramic aggregate composites include

asphalt concrete

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and tarmac, bitumen macadam, or rolled asphalt in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface roads, parki ...

,

polymer concrete

Polymer concrete, also known as Epoxy Granite, is a type of concrete that uses a polymer to replace lime-type cements as a binder. In some cases the polymer is used in addition to Portland cement to form Polymer Cement Concrete (PCC) or Polymer M ...

,

mastic asphalt

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and tarmac, bitumen macadam, or rolled asphalt in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface roads, parki ...

,

mastic roller hybrid,

dental composite

Dental composite resins (better referred to as "resin-based composites" or simply "filled resins") are dental cements made of synthetic resins. Synthetic resins evolved as restorative materials since they were insoluble, of good tooth-like appea ...

,

syntactic foam and

mother of pearl.

Chobham armour

Chobham armour is the informal name of a composite armour developed in the 1960s at the British tank research centre on Chobham Common, Surrey. The name has since become the common generic term for composite ceramic vehicle armour. Other name ...

is a special type of

composite armour

Composite armour is a type of vehicle armour consisting of layers of different material such as metals, plastics, ceramics or air. Most composite armours are lighter than their all-metal equivalent, but instead occupy a larger volume for the sa ...

used in military applications.

Additionally, thermoplastic composite materials can be formulated with specific metal powders resulting in materials with a density range from 2 g/cm

3 to 11 g/cm

3 (same density as lead). The most common name for this type of material is "high gravity compound" (HGC), although "lead replacement" is also used. These materials can be used in place of traditional materials such as aluminium, stainless steel, brass, bronze, copper, lead, and even tungsten in weighting, balancing (for example, modifying the centre of gravity of a tennis

racquet), vibration damping, and radiation shielding applications. High density composites are an economically viable option when certain materials are deemed hazardous and are banned (such as lead) or when secondary operations costs (such as machining, finishing, or coating) are a factor.

There have been several studies indicating that interleaving stiff and brittle epoxy based

carbon fiber reinforced polymer

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

laminates with flexible thermoplastic laminates can help to make highly toughened composites that show improved impact resistance. Another interesting aspect of such interleaved composites is that they are able to have shape memory behaviour without needing any

shape memory polymers or

shape memory alloys e.g. balsa plies interleaved with hot glue, aluminium plies interleaved with

acrylic polymers or

PVC and

carbon fiber reinforced polymer

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

laminates interleaved with

polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the Aromatic hydrocarbon, aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin pe ...

.

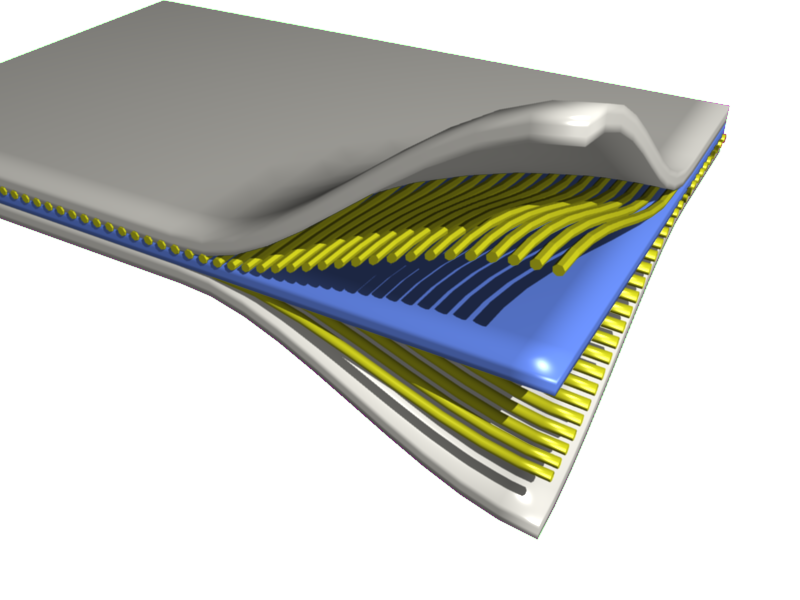

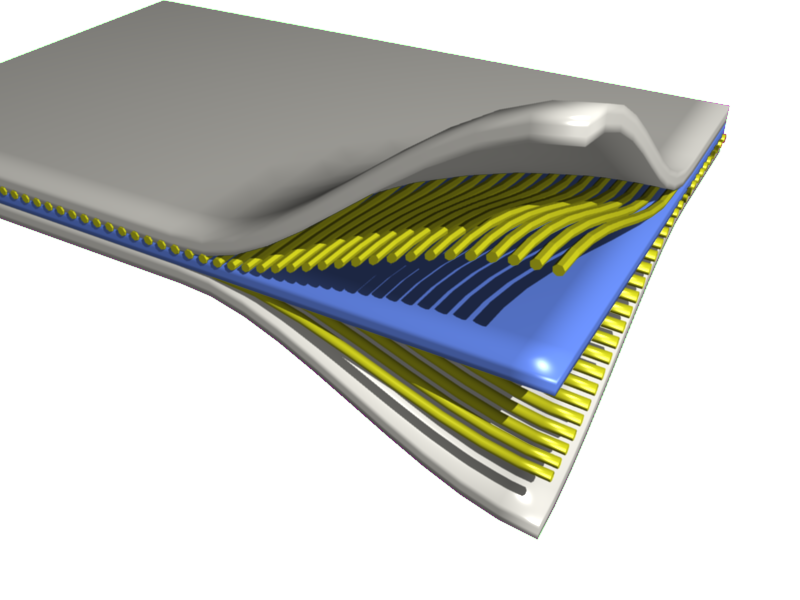

A

sandwich-structured composite is a special class of composite material that is fabricated by attaching two thin but stiff skins to a lightweight but thick core. The core material is normally low strength material, but its higher thickness provides the sandwich composite with high

bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element.

The structural element is assumed to ...

stiffness

Stiffness is the extent to which an object resists deformation in response to an applied force.

The complementary concept is flexibility or pliability: the more flexible an object is, the less stiff it is.

Calculations

The stiffness, k, of a ...

with overall low

density

Density (volumetric mass density or specific mass) is the substance's mass per unit of volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' can also be used. Mathematicall ...

.

Wood is a naturally occurring composite comprising cellulose fibres in a

lignin

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity a ...

and

hemicellulose matrix.

Engineered wood includes a wide variety of different products such as wood fibre board,

plywood,

oriented strand board,

wood plastic composite (recycled wood fibre in polyethylene matrix),

Pykrete

Pykrete is a frozen ice composite, originally made of approximately 14% sawdust or some other form of wood pulp (such as paper) and 86% ice by weight (6 to 1 by weight). During World War II, Geoffrey Pyke proposed it as a candidate material ...

(sawdust in ice matrix), Plastic-impregnated or

laminated paper or textiles,

Arborite

Arborite is the leading Canadian manufacturer of high-pressure decorative plastic laminates (HPL). Best known as a counter top surfacing material, laminate is a durable decorative veneer applied to cabinetry, furniture, and other horizontal and ...

,

Formica (plastic)

Formica Laminate is a laminated composite material invented at the Westinghouse Electric Corporation in the United States in 1912. Originally used to replace mica in electrical applications, it has since been manufactured for multiple applica ...

and

Micarta. Other engineered laminate composites, such as

Mallite

Mallite is a type of laminate composite material, formerly manufactured by the ''William Mallinson & Sons'' company. The material is formed of a core sheet of end grain balsa wood, faced by duralumin sheets. This construction endows the finished m ...

, use a central core of end grain

balsa wood

''Ochroma pyramidale'', commonly known as the balsa tree, is a large, fast-growing tree native to the Americas. It is the sole member of the genus ''Ochroma''. The tree is famous for its wide usage in woodworking, with the name ''balsa'' bei ...

, bonded to surface skins of light

alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductili ...

or GRP. These generate low-weight, high rigidity materials.

Particulate composites have particle as filler material dispersed in matrix, which may be nonmetal, such as glass, epoxy. Automobile tire is an example of particulate composite.

Advanced diamond-like carbon (DLC) coated polymer composites have been reported

where the coating increases the surface hydrophobicity, hardness and wear resistance.

Ferromagnetic composites, including those with a polymer matrix consisting, for example, of nanocrystalline filler of Fe-based powders and polymers matrix. Amorphous and nanocrystalline powders obtained, for example, from metallic glasses can be used. Their use makes it possible to obtain ferromagnetic nanocomposites with controlled magnetic properties.

Products

Fibre-reinforced composite materials have gained popularity (despite their generally high cost) in high-performance products that need to be lightweight, yet strong enough to take harsh loading conditions such as

aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and ast ...

components (

tail

The tail is the section at the rear end of certain kinds of animals’ bodies; in general, the term refers to a distinct, flexible appendage to the torso. It is the part of the body that corresponds roughly to the sacrum and coccyx in mammal ...

s,

wing

A wing is a type of fin that produces lift while moving through air or some other fluid. Accordingly, wings have streamlined cross-sections that are subject to aerodynamic forces and act as airfoils. A wing's aerodynamic efficiency is e ...

s,

fuselage

The fuselage (; from the French ''fuselé'' "spindle-shaped") is an aircraft's main body section. It holds crew, passengers, or cargo. In single-engine aircraft, it will usually contain an engine as well, although in some amphibious aircraft t ...

s,

propeller

A propeller (colloquially often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon ...

s), boat and

scull hulls,

bicycle

A bicycle, also called a pedal cycle, bike or cycle, is a human-powered or motor-powered assisted, pedal-driven, single-track vehicle, having two wheels attached to a frame, one behind the other. A is called a cyclist, or bicyclist.

B ...

frames and

racing car bodies. Other uses include

fishing rod

A fishing rod is a long, thin rod used by anglers to catch fish by manipulating a line ending in a hook (formerly known as an ''angle'', hence the term "angling"). At its most basic form, a fishing rod is a straight rigid stick/pole with ...

s,

storage tank

Storage tanks are containers that hold liquids, compressed gases (gas tank; or in U.S.A "pressure vessel", which is not typically labeled or regulated as a storage tank) or mediums used for the short- or long-term storage of heat or cold. The t ...

s, swimming pool panels, and

baseball bats

A baseball bat is a smooth wooden or metal club used in the sport of baseball to hit the ball after it is thrown by the pitcher. By regulation it may be no more than in diameter at the thickest part and no more than in length. Although histori ...

. The

Boeing 787

The Boeing 787 Dreamliner is an American wide-body jet airliner developed and manufactured by Boeing Commercial Airplanes.

After dropping its unconventional Sonic Cruiser project, Boeing announced the conventional 7E7 on January 29, 2003, ...

and

Airbus A350 structures including the wings and fuselage are composed largely of composites. Composite materials are also becoming more common in the realm of

orthopedic surgery

Orthopedic surgery or orthopedics ( alternatively spelt orthopaedics), is the branch of surgery concerned with conditions involving the musculoskeletal system. Orthopedic surgeons use both surgical and nonsurgical means to treat musculoskeletal ...

, and it is the most common hockey stick material.

Carbon composite is a key material in today's launch vehicles and

heat shield

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is al ...

s for the

re-entry phase of

spacecraft

A spacecraft is a vehicle or machine designed to fly in outer space. A type of artificial satellite, spacecraft are used for a variety of purposes, including communications, Earth observation, meteorology, navigation, space colonization, ...

. It is widely used in solar panel substrates, antenna reflectors and yokes of spacecraft. It is also used in payload adapters, inter-stage structures and heat shields of

launch vehicle

A launch vehicle or carrier rocket is a rocket designed to carry a payload ( spacecraft or satellites) from the Earth's surface to outer space. Most launch vehicles operate from a launch pads, supported by a launch control center and sys ...

s. Furthermore,

disk brake systems of

airplane

An airplane or aeroplane (informally plane) is a fixed-wing aircraft that is propelled forward by thrust from a jet engine, propeller, or rocket engine. Airplanes come in a variety of sizes, shapes, and wing configurations. The broad ...

s and racing cars are using

carbon/carbon material, and the

composite material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or ...

with

carbon fibre

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

s and

silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal s ...

matrix has been introduced in

luxury vehicle

A luxury car is a car that provides increased levels of comfort, equipment, amenities, quality, performance, and associated status compared to moderately priced cars.

The term is subjective and reflects both the qualities of the car and t ...

s and

sports car

A sports car is a car designed with an emphasis on dynamic performance, such as handling, acceleration, top speed, the thrill of driving and racing capability. Sports cars originated in Europe in the early 1900s and are currently produced by ...

s.

In 2006, a fibre-reinforced composite pool panel was introduced for in-ground swimming pools, residential as well as commercial, as a non-corrosive alternative to galvanized steel.

In 2007, an all-composite military

Humvee

The High Mobility Multipurpose Wheeled Vehicle (HMMWV; colloquial: Humvee) is a family of light, four-wheel drive, military trucks and utility vehicles produced by AM General. It has largely supplanted the roles previously performed by the or ...

was introduced by TPI Composites Inc and Armor Holdings Inc, the first all-composite

military vehicle

A military vehicle is any vehicle for land-based military transport and activity, including combat vehicles; both specifically designed for, or significantly used by military and armed forces. Most military vehicles require off-road capabil ...

. By using composites the vehicle is lighter, allowing higher payloads. In 2008, carbon fibre and

DuPont

DuPont de Nemours, Inc., commonly shortened to DuPont, is an American multinational chemical company first formed in 1802 by French-American chemist and industrialist Éleuthère Irénée du Pont de Nemours. The company played a major role in ...

Kevlar (five times stronger than steel) were combined with enhanced thermoset resins to make military transit cases by ECS Composites creating 30-percent lighter cases with high strength.

Pipes and fittings for various purpose like transportation of potable water, fire-fighting, irrigation, seawater, desalinated water, chemical and industrial waste, and sewage are now manufactured in glass reinforced plastics.

Composite materials used in tensile structures for facade application provides the advantage of being translucent. The woven base cloth combined with the appropriate coating allows better light transmission. This provides a very comfortable level of illumination compared to the full brightness of outside.

The wings of wind turbines, in growing sizes in the order of 50 m length are fabricated in composites since several years.

Two-lower-leg-amputees run on carbon-composite spring-like artificial feet as quick as non-amputee athletes.

High pressure gas cylinders typically about 7–9 litre volume x 300 bar pressure for firemen are nowadays constructed from carbon composite. Type-4-cylinders include metal only as boss that carries the thread to screw in the valve.

On 5 September 2019,

HMD Global

HMD Global Oy, branded as HMD and Nokia Mobile, is a Finnish mobile phone manufacturer. The company is made up of the mobile phone business that Nokia sold to Microsoft in 2014, then bought back in 2016. HMD began marketing Nokia-branded smar ...

unveiled the

Nokia 6.2

The Nokia 6.2 is an Android smartphone designed by HMD Global. It was announced at IFA Berlin on 6 September 2019, with two models launching at costs of €199 and €249.

Specifications Design

The Nokia 6.2 has a 6.3-inch display with a 19: ...

and

Nokia 7.2

The Nokia 7.2 is a Nokia branded Android smartphone announced September 6th, 2019 at IFA. At launch, prices started at $349 (£249) for the cheapest model.

Notable changes from the Nokia 7.1

The Nokia 7.2 has three rear cameras, including ...

which are claimed to be using polymer composite for the frames.

Overview

Composite materials are created from individual materials. These individual materials are known as constituent materials, and there are two main categories of it. One is the

matrix

Matrix most commonly refers to:

* ''The Matrix'' (franchise), an American media franchise

** '' The Matrix'', a 1999 science-fiction action film

** "The Matrix", a fictional setting, a virtual reality environment, within ''The Matrix'' (franchi ...

(

binder) and the other

reinforcement

In behavioral psychology, reinforcement is a consequence applied that will strengthen an organism's future behavior whenever that behavior is preceded by a specific antecedent stimulus. This strengthening effect may be measured as a higher fr ...

. A portion of each kind is needed at least. The reinforcement receives support from the matrix as the matrix surrounds the reinforcement and maintains its relative positions. The properties of the matrix are improved as the reinforcements impart their exceptional physical and mechanical properties. The mechanical properties become unavailable from the individual constituent materials by synergism. At the same time, the designer of the product or structure receives options to choose an optimum combination from the variety of matrix and strengthening materials.

To shape the engineered composites, it must be formed. The reinforcement is placed onto the mould surface or into the

mould cavity. Before or after this, the matrix can be introduced to the reinforcement. The matrix undergoes a melding event which sets the part shape necessarily. This melding event can happen in several ways, depending upon the matrix nature, such as solidification from the melted state for a thermoplastic polymer matrix composite or chemical

polymerization

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many f ...

for a

thermoset polymer matrix

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as gla ...

.

According to the requirements of end-item design, various methods of moulding can be used. The natures of the chosen matrix and reinforcement are the key factors influencing the methodology. The gross quantity of material to be made is another main factor. To support high capital investments for rapid and automated manufacturing technology, vast quantities can be used. Cheaper capital investments but higher labour and tooling expenses at a correspondingly slower rate assists the small production quantities.

Many commercially produced composites use a

polymer

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

matrix material often called a resin solution. There are many different polymers available depending upon the starting raw ingredients. There are several broad categories, each with numerous variations. The most common are known as

polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include natura ...

,

vinyl ester,

epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also co ...

,

phenolic,

polyimide

Polyimide (sometimes abbreviated PI) is a polymer containing imide groups belonging to the class of high-performance plastics. With their high heat-resistance, polyimides enjoy diverse applications in roles demanding rugged organic materials, e. ...

,

polyamide

A polyamide is a polymer with repeating units linked by amide bonds.

Polyamides occur both naturally and artificially. Examples of naturally occurring polyamides are proteins, such as wool and silk. Artificially made polyamides can be made th ...

,

polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

Polypropylene

belongs to the group of polyolefins a ...

,

PEEK

Polyether ether ketone (PEEK) is a colourless organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications. The polymer was first developed in November 1978, later being introduced to the market by ...

, and others. The reinforcement materials are often fibres but also commonly ground minerals. The various methods described below have been developed to reduce the resin content of the final product, or the fibre content is increased. As a rule of thumb, lay up results in a product containing 60% resin and 40% fibre, whereas vacuum infusion gives a final product with 40% resin and 60% fibre content. The strength of the product is greatly dependent on this ratio.

Martin Hubbe and Lucian A Lucia consider

wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin ...

to be a natural composite of

cellulose fibres in a

matrix

Matrix most commonly refers to:

* ''The Matrix'' (franchise), an American media franchise

** '' The Matrix'', a 1999 science-fiction action film

** "The Matrix", a fictional setting, a virtual reality environment, within ''The Matrix'' (franchi ...

of

lignin

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity a ...

.

Cores in composites

Several layup designs of composite also involve a co-curing or post-curing of the prepreg with many other media, such as foam or honeycomb. Generally, this is known as a

sandwich structure. This is a more general layup for the production of cowlings, doors, radomes or non-structural parts.

Open- and closed-cell-structured

foam

Foams are materials formed by trapping pockets of gas in a liquid or solid.

A bath sponge and the head on a glass of beer are examples of foams. In most foams, the volume of gas is large, with thin films of liquid or solid separating the ...

s like

polyvinylchloride,

polyurethane

Polyurethane (; often abbreviated PUR and PU) refers to a class of polymers composed of organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane is produced from ...

,

polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including b ...

or

polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the Aromatic hydrocarbon, aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin pe ...

foams,

balsa wood

''Ochroma pyramidale'', commonly known as the balsa tree, is a large, fast-growing tree native to the Americas. It is the sole member of the genus ''Ochroma''. The tree is famous for its wide usage in woodworking, with the name ''balsa'' bei ...

,

syntactic foams, and

honeycombs are generally utilized core materials. Open- and closed-cell

metal foam

Regular foamed aluminium

A metal foam is a cellular structure consisting of a solid metal (frequently aluminium) with gas-filled pores comprising a large portion of the volume. The pores can be sealed (closed-cell foam) or interconnected (open- ...

can also be utilized as core materials. Recently, 3D graphene structures ( also called graphene foam) have also been employed as core structures. A recent review by Khurram and Xu et al., have provided the summary of the state-of-the-art techniques for fabrication of the 3D structure of graphene, and the examples of the use of these foam like structures as a core for their respective polymer composites.

Semi-Crystalline Polymers

Although the two phases are chemically equivalent, semi-crystalline polymers can be described both quantitatively and qualitatively as composite materials. The crystalline portion has a higher elastic modulus and provides reinforcement for the less stiff, amorphous phase. Polymeric materials can range from 0% to 100% crystallinity aka volume fraction depending on molecular structure and thermal history. Different processing techniques can be employed to vary the percent crystallinity in these materials and thus the mechanical properties of these materials as described in the physical properties section. This effect is seen in a variety of places from industrial plastics like polyethylene shopping bags to spiders which can produce silks with different mechanical properties. In many cases these materials act like particle composites with randomly dispersed crystals known as spherulites. However they can also be engineered to be anisotropic and act more like fiber reinforced composites. In the case of spider silk, the properties of the material can even be dependent on the size of the crystals, independent of the volume fraction. Ironically, single component polymeric materials are some of the most easily tunable composite materials known.

Methods of fabrication

Normally, the fabrication of composite includes wetting, mixing or saturating the reinforcement with the matrix. The matrix is then induced to bind together (with heat or a chemical reaction) into a rigid structure. Usually, the operation is done in an open or closed forming mould. However, the order and ways of introducing the constituents alters considerably. Composites fabrication is achieved by a wide variety of methods, including

advanced fibre placement (Automated fibre placement),

fibreglass spray lay-up process,

filament winding

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates arou ...

,

lanxide process

The Lanxide process, also known as pressureless metal infiltration, is a way of producing metal-matrix composite materials by a process of partial reaction; the process involves a careful choice of initial alloy (usually aluminium with about 3% ma ...

,

tailored fibre placement,

tufting and

z-pinning.

Overview of mould

The reinforcing and matrix materials are merged, compacted, and cured (processed) within a mould to undergo a melding event. The part shape is fundamentally set after the melding event. However, under particular process conditions, it can deform. The melding event For a

thermoset polymer matrix

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as gla ...

material is a curing reaction that is caused by the possibility of extra heat or chemical reactivity such as an organic peroxide. The melding event for a thermoplastic polymeric matrix material is a solidification from the melted state. The melding event for a metal matrix material such as titanium foil is a fusing at high pressure and a temperature near the melting point.

It is suitable for many moulding methods to refer to one mould piece as a "lower" mould and another mould piece as an "upper" mould. Lower and upper does not refer to the mould's configuration in space, but the different faces of the moulded panel. There is always a lower mould, and sometimes an upper mould in this convention. Part construction commences by applying materials to the lower mould. Lower mould and upper mould are more generalized descriptors than more common and specific terms such as male side, female side, a-side, b-side, tool side, bowl, hat, mandrel, etc. Continuous manufacturing utilizes a different nomenclature.

Usually, the moulded product is referred to as a panel. It can be referred to as casting for certain geometries and material combinations. It can be referred to as a profile for certain continuous processes. Some of the processes are

autoclave moulding,

vacuum bag moulding,

pressure bag moulding Pressure bag moulding is a process for moulding reinforced plastics. This process is related to vacuum bag molding.

Procedure

A solid female mold is used along with a flexible male mold. The reinforcement is placed inside the female mold with jus ...

,

resin transfer moulding Resin transfer moulding is a process for producing high performance composite components.

Procedure

It is a process using a rigid two-sided mould set that forms both surfaces of the panel. Usually, the mould is formed from aluminum or steel, but ...

and

light resin transfer moulding.

Other fabrication methods

Other types of fabrication include

casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejecte ...

, centrifugal casting,

braiding

A braid (also referred to as a plait) is a complex structure or pattern formed by interlacing two or more strands of flexible material such as textile yarns, wire, or hair.

The simplest and most common version is a flat, solid, three-strande ...

(onto a

former

A former is an object, such as a template, gauge or cutting die, which is used to form something such as a boat's hull. Typically, a former gives shape to a structure that may have complex curvature.

A former may become an integral part of the ...

),

continuous casting

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the ...

,

filament winding

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates arou ...

, press moulding,

transfer moulding,

pultrusion moulding and

slip forming. There are also forming capabilities including

CNC filament winding, vacuum infusion, wet lay-up,

compression moulding, and

thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate ...

moulding, to name a few. The practice of curing ovens and paint booths is also required for some projects.

Finishing methods

The composite parts finishing is also crucial in the final design. Many of these finishes will involve rain-erosion coatings or polyurethane coatings.

Tooling

The mould and mould inserts are referred to as "tooling." The mould/tooling can be built from different materials. Tooling materials include

aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

,

carbon fibre

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

,

invar,

nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow t ...

, reinforced

silicone rubber Silicone rubber is an elastomer (rubber-like material) composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulation ...

and steel. The tooling material selection is normally based on, but not limited to, the

coefficient of thermal expansion, expected number of cycles, end item tolerance, desired or expected surface condition, cure method,

glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or ru ...

of the material being moulded, moulding method, matrix, cost and other various considerations.

Physical properties

Usually, the composite's physical properties are not

isotropic

Isotropy is uniformity in all orientations; it is derived . Precise definitions depend on the subject area. Exceptions, or inequalities, are frequently indicated by the prefix ' or ', hence '' anisotropy''. ''Anisotropy'' is also used to describ ...

(independent of the direction of applied force) in nature. But they are typically

anisotropic

Anisotropy () is the property of a material which allows it to change or assume different properties in different directions, as opposed to isotropy. It can be defined as a difference, when measured along different axes, in a material's physic ...

(different depending on the direction of the applied force or load). For instance, the composite panel's stiffness will usually depend upon the orientation of the applied forces and/or moments. The composite's strength is bounded by two loading conditions, as shown in the plot to the right.

Isostrain rule of mixtures

If both the fibres and matrix are aligned parallel to the loading direction, the deformation of both phases will be the same (assuming there is no delamination at the fibre-matrix interface). This isostrain condition provides the upper bound for composite strength, and is determined by the

rule of mixtures:

where ''E

C'' is the effective composite

Young's modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied ...

, and ''V

i'' and ''E

i'' are the volume fraction and Young's moduli, respectively, of the composite phases.

For example, a composite material made up of α and β phases as shown in the figure to the right under isostrain, the Young's modulus would be as follows:

where V

α and V

β are the respective volume fractions of each phase.

This can be derived by considering that in the isostrain case,

Assuming that the composite has a uniform cross section, the stress on the composite is a weighted average between the two phases,

The stresses in the individual phases are given by Hooke's Law,

Combining these equations gives that the overall stress in the composite is

Then it can be shown that

Isostress rule of mixtures

The lower bound is dictated by the isostress condition, in which the fibres and matrix are oriented perpendicularly to the loading direction:

and now the strains become a weighted average

Rewriting Hooke's Law for the individual phases

This leads to

From the definition of Hooke's Law

and in general

Following the example above, if one had a composite material made up of α and β phases under isostress conditions as shown in the figure to the right, the composition Young's modulus would be:

The isostrain condition implies that under an applied load, both phases experience the same strain but will feel different stress. Comparatively, under isostress conditions both phases will feel the same stress but the strains will differ between each phase. A generalized equation for any loading condition between isostrain and isostress can be written as:

where X is a material property such as modulus or stress, c, m, and r stand for the properties of the composite, matrix, and reinforcement materials respectively, and n is a value between 1 and −1.

The above equation can be further generalized beyond a two phase composite to an m-component system:

Though composite stiffness is maximized when fibres are aligned with the loading direction, so is the possibility of fibre tensile fracture, assuming the tensile strength exceeds that of the matrix. When a fibre has some angle of misorientation θ, several fracture modes are possible. For small values of θ the stress required to initiate fracture is increased by a factor of (cos θ)

−2 due to the increased cross-sectional area (''A'' cos θ) of the fibre and reduced force (''F/''cos θ) experienced by the fibre, leading to a composite tensile strength of ''σ

parallel /''cos

2 θ where ''σ

parallel '' is the tensile strength of the composite with fibres aligned parallel with the applied force.

Intermediate angles of misorientation θ lead to matrix shear failure. Again the cross sectional area is modified but since shear stress is now the driving force for failure the area of the matrix parallel to the fibres is of interest, increasing by a factor of 1/sin θ. Similarly, the force parallel to this area again decreases (''F/''cos θ) leading to a total tensile strength of ''τ

my /''sin θ cos θ where ''τ

my'' is the matrix shear strength.

Finally, for large values of θ (near π/2) transverse matrix failure is the most likely to occur, since the fibres no longer carry the majority of the load. Still, the tensile strength will be greater than for the purely perpendicular orientation, since the force perpendicular to the fibres will decrease by a factor of 1/sin θ and the area decreases by a factor of 1/sin θ producing a composite tensile strength of ''σ

perp /''sin

2θ where ''σ

perp '' is the tensile strength of the composite with fibres align perpendicular to the applied force.

The majority of commercial composites are formed with random dispersion and orientation of the strengthening fibres, in which case the composite Young's modulus will fall between the isostrain and isostress bounds. However, in applications where the strength-to-weight ratio is engineered to be as high as possible (such as in the aerospace industry), fibre alignment may be tightly controlled.

Panel stiffness is also dependent on the design of the panel. For instance, the fibre reinforcement and matrix used, the method of panel build, thermoset versus thermoplastic, and type of weave.

In contrast to composites, isotropic materials (for example, aluminium or steel), in standard wrought forms, possess the same stiffness typically despite the directional orientation of the applied forces and/or moments. The relationship between forces/moments and strains/curvatures for an isotropic material can be described with the following material properties: Young's Modulus, the

Shear Modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain:

:G \ \stackre ...

and the

Poisson's ratio

In materials science and solid mechanics, Poisson's ratio \nu ( nu) is a measure of the Poisson effect, the deformation (expansion or contraction) of a material in directions perpendicular to the specific direction of loading. The value of Po ...

, in relatively simple mathematical relationships. For the anisotropic material, it needs the mathematics of a second-order tensor and up to 21 material property constants. For the special case of orthogonal isotropy, there are three distinct material property constants for each of Young's Modulus, Shear Modulus and Poisson's ratio—a total of 9 constants to express the relationship between forces/moments and strains/curvatures.

Techniques that take benefit of the materials' anisotropic properties involve

mortise and tenon

A mortise and tenon (occasionally mortice and tenon) joint connects two pieces of wood or other material. Woodworkers around the world have used it for thousands of years to join pieces of wood, mainly when the adjoining pieces connect at righ ...

joints (in natural composites such as wood) and

Pi Joints

The number (; spelled out as "pi") is a mathematical constant that is the ratio of a circle's circumference to its diameter, approximately equal to 3.14159. The number appears in many formulas across mathematics and physics. It is an irra ...

in synthetic composites.

Mechanical Properties of Composites

Particle Reinforcement

In general, particle reinforcement is

strengthening

Chinese food therapy (, also called nutrition therapy and dietary therapy) is a mode of dieting rooted in Chinese beliefs concerning the effects of food on the human organism, and centered on concepts such as eating in moderation. Its basic pr ...

the composites less than

fiber

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate ...

reinforcement. It is used to enhance the

stiffness

Stiffness is the extent to which an object resists deformation in response to an applied force.

The complementary concept is flexibility or pliability: the more flexible an object is, the less stiff it is.

Calculations

The stiffness, k, of a ...

of the composites while increasing the

strength and the

toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.[mechanical properties

A materials property is an intensive property of a material, i.e., a physical property that does not depend on the amount of the material. These quantitative properties may be used as a metric by which the benefits of one material versus another ...]

, they are used in applications in which

wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in ...

resistance is required. For example, hardness of

cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixe ...

can be increased by reinforcing gravel particles, drastically. Particle reinforcement a highly advantageous method of tuning mechanical properties of materials since it is very easy implement while being low cost.

The

elastic modulus

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is ...

of particle-reinforced composites can be expressed as,

where E is the

elastic modulus

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is ...

, V is the

volume fraction. The subscripts c, p and m are indicating composite, particle and matrix, respectively.

is a constant can be found empirically.

Similarly, tensile strength of particle-reinforced composites can be expressed as,

where T.S. is the

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

, and

is a constant (not equal to

) that can be found empirically.

Continuous Fiber Reinforcement

In general, continuous

fiber

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate ...

reinforcement is implemented by incorporating a

fiber

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate ...

as the strong phase into a weak phase, matrix. The reason for the popularity of fiber usage is materials with extraordinary strength can be obtained in their fiber form. Non-metallic fibers are usually showing a very high strength to density ratio compared to metal fibers because of the

covalent

A covalent bond is a chemical bond that involves the sharing of electrons to form electron pairs between atoms. These electron pairs are known as shared pairs or bonding pairs. The stable balance of attractive and repulsive forces between atom ...

nature of their

bonds. The most famous example of this is

carbon fibers

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high stren ...

that have many applications extending from

sports gear to

protective equipment

Personal protective equipment (PPE) is protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection. The hazards addressed by protective equipment include physical, ele ...

to

space industries.

The stress on the composite can be expressed in terms of the

volume fraction of the fiber and the matrix.

where

is the stress, V is the

volume fraction. The subscripts c, f and m are indicating composite, fiber and matrix, respectively.

Although the

stress–strain behavior of fiber composites can only be determined by testing, there is an expected trend, three stages of the

stress–strain curve

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress ...

. The first stage is the region of the stress–strain curve where both fiber and the matrix are

elastically deformed. This linearly elastic region can be expressed in the following form.

where

is the stress,

is the strain, E is the

elastic modulus

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is ...

, and V is

the volume fraction. The subscripts c, f, and m are indicating composite, fiber, and matrix, respectively.

After passing the elastic region for both fiber and the matrix, the second region of the stress–strain curve] can be observed. In the second region, the fiber is still elastically deformed while the matrix is plastically deformed since the matrix is the weak phase. The instantaneous

Elastic modulus, modulus can be determined using the slope of the stress–strain curve in the second region. The relationship between

stress

Stress may refer to:

Science and medicine

* Stress (biology), an organism's response to a stressor such as an environmental condition

* Stress (linguistics), relative emphasis or prominence given to a syllable in a word, or to a word in a phrase ...

and strain can be expressed as,

where

is the stress,

is the strain, E is the

elastic modulus

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is ...

, and V is

the volume fraction. The subscripts c, f, and m are indicating composite, fiber, and matrix, respectively. To find the modulus in the second region derivative of this equation can be used since the

slope of the curve is equal to the modulus.

In most cases it can be assumed

since the second term is much less than the first one.

In reality, the

derivative

In mathematics, the derivative of a function of a real variable measures the sensitivity to change of the function value (output value) with respect to a change in its argument (input value). Derivatives are a fundamental tool of calculus. ...

of stress with respect to strain is not always returning the modulus because of the

binding interaction between the fiber and matrix. The strength of the interaction between these two phases can result in changes in the

mechanical properties

A materials property is an intensive property of a material, i.e., a physical property that does not depend on the amount of the material. These quantitative properties may be used as a metric by which the benefits of one material versus another ...

of the composite. The compatibility of the fiber and matrix is a measure of

internal stress

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elonga ...

.

The

covalently bonded high strength fibers (e.g.

carbon fibers

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high stren ...

) experience mostly

elastic deformation before the fracture since the

plastic deformation

In engineering, deformation refers to the change in size or shape of an object. ''Displacements'' are the ''absolute'' change in position of a point on the object. Deflection is the relative change in external displacements on an object. Strain ...

can happen due to

dislocation motion. Whereas,

metallic fiber

Metallic fibers are manufactured fibers composed of metal, metallic alloys, plastic-coated metal, metal-coated plastic, or a core completely covered by metal.

Having their origin in textile and clothing applications, gold and silver fibers have ...

s have more space to plastically deform, so their composites exhibit a third stage where both fiber and the matrix are plastically deforming.

Metallic fiber

Metallic fibers are manufactured fibers composed of metal, metallic alloys, plastic-coated metal, metal-coated plastic, or a core completely covered by metal.

Having their origin in textile and clothing applications, gold and silver fibers have ...

s have

many applications to work at

cryogenic temperatures that is one of the advantages of composites with

metal fibers over nonmetallic. The stress in this region of the

stress–strain curve

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress ...

can be expressed as,

where

is the stress,

is the strain, E is the

elastic modulus

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is ...

, and V is the

volume fraction. The subscripts c, f, and m are indicating composite, fiber, and matrix, respectively.

and

are for fiber and matrix flow stresses respectively. Just after the third region the composite exhibit

necking. The necking strain of composite is happened to be between the necking strain of the fiber and the matrix just like other mechanical properties of the composites. The necking strain of the weak phase is delayed by the strong phase. The amount of the delay depends upon the volume fraction of the strong phase.

Thus, the

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

of the composite can be expressed in terms of the

volume fraction.

where T.S. is the

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

,

is the stress,

is the strain, E is the

elastic modulus

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is ...

, and V is the

volume fraction. The subscripts c, f, and m are indicating composite, fiber, and matrix, respectively. The composite tensile strength can be expressed as

for

is less than or equal to

(arbitrary critical value of volume fraction)

for

is greater than or equal to

The critical value of

volume fraction can be expressed as,

Evidently, the composite

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

can be higher than the matrix if

is greater than

.

Thus, the minimum volume fraction of the fiber can be expressed as,

Although this minimum value is very low in practice, it is very important to know since the reason for the incorporation of continuous fibers is to improve the mechanical properties of the materials/composites, and this value of volume fraction is the threshold of this improvement.

The Effect of Fiber Orientation

Aligned Fibers

A change in the angle between the applied stress and fiber orientation will affect the mechanical properties of fiber-reinforced composites, especially the tensile strength. This angle,

, can be used predict the dominant tensile fracture mechanism.

At small angles,

, the dominant fracture mechanism is the same as with load-fiber alignment, tensile fracture. The resolved force acting upon the length of the fibers is reduced by a factor of

from rotation.

. The resolved area on which the fiber experiences the force is increased by a factor of

from rotation.

. Taking the effective

tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials ...

to be

and the aligned

tensile strength