Computer-Aided Engineering on:

[Wikipedia]

[Google]

[Amazon]

Computer-aided engineering (CAE) is the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

Computer-aided engineering (CAE) is the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

Why do we need a CAE Software or Numerical Simulations?

Computer Aided Engineering Journal WP:LINKROT

(FEA, CAD, ...)

Integrated Computer Aided Engineering Journal

Computer-Aided Civil and Infrastructure Engineering

Predictive engineering analytics

{{Authority control Computer-aided engineering software Product lifecycle management Engineering disciplines

Computer-aided engineering (CAE) is the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

Computer-aided engineering (CAE) is the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

Overview

Following alongside the consistent improvement in computer graphics and speed, computer aid assists engineers with once complicated and time consuming tasks with the input of information and a press of a button. It includesfinite element method

Finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat tran ...

or analysis (FEA), computational fluid dynamics

Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems that involve fluid dynamics, fluid flows. Computers are used to perform the calculations required ...

(CFD), multibody dynamics

Multibody system is the study of the dynamic behavior of interconnected rigid or flexible bodies, each of which may undergo large translational and rotational displacements.

Introduction

The systematic treatment of the dynamic behavior of ...

(MBD), durability and optimization. It is included with computer-aided design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve c ...

(CAD) and computer-aided manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most ...

(CAM) in a collective term and abbreviation computer-aided technologies (CAx).

The term CAE has been used to describe the use of computer technology within engineering in a broader sense than just engineering analysis. It was in this context that the term was coined by Jason Lemon, founder of Structural Dynamics Research Corporation ( SDRC) in the late 1970s. However, this definition is better known today by the terms CAx and product lifecycle

In Industry (economics), industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the Product engineering, engineering, Product design, design, and Manufacturing, ma ...

management (PLM).

CAE systems are individually considered a single node

In general, a node is a localized swelling (a "knot") or a point of intersection (a vertex).

Node may refer to:

In mathematics

* Vertex (graph theory), a vertex in a mathematical graph

*Vertex (geometry), a point where two or more curves, lines ...

on a total information network and each node may interact with other nodes on the network.

CAE fields and phases

CAE areas covered include: *Stress analysis

Stress may refer to:

Science and medicine

* Stress (biology)

Stress, whether physiological, biological or psychological, is an organism's response to a stressor, such as an environmental condition or change in life circumstances. When s ...

on components and assemblies using finite element analysis (FEA);

*Thermal and fluid flow analysis computational fluid dynamics (CFD);

*Multibody dynamics (MBD) and kinematics

In physics, kinematics studies the geometrical aspects of motion of physical objects independent of forces that set them in motion. Constrained motion such as linked machine parts are also described as kinematics.

Kinematics is concerned with s ...

;

*Analysis tools for process simulation for operations such as casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or ...

, molding, and die press forming;

*Optimization

Mathematical optimization (alternatively spelled ''optimisation'') or mathematical programming is the selection of a best element, with regard to some criteria, from some set of available alternatives. It is generally divided into two subfiel ...

of the product or process.

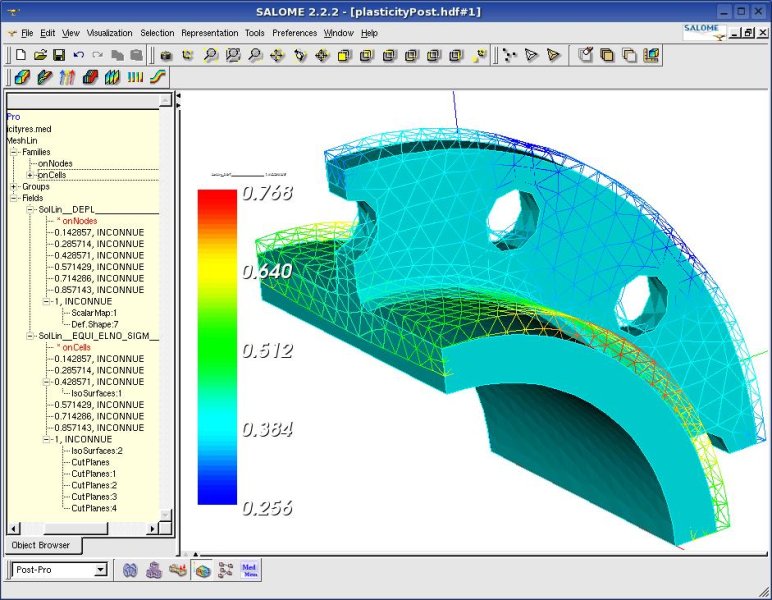

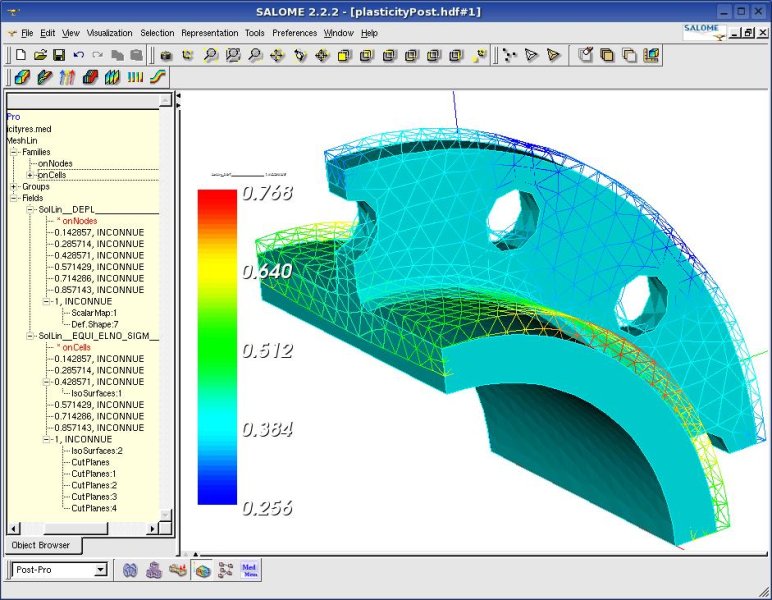

In general, there are three phases in any computer-aided engineering task:

*Pre-processing – defining the model and environmental factors to be applied to it (typically a finite element model, but facet, voxel

In computing, a voxel is a representation of a value on a three-dimensional regular grid, akin to the two-dimensional pixel. Voxels are frequently used in the Data visualization, visualization and analysis of medical imaging, medical and scient ...

, and thin sheet methods are also used);

*Analysis solver (usually performed on high powered computers);

*Post-processing of results (using visualization tools).

This cycle is iterated, often many times, either manually or with the use of commercial optimization software.

CAE in the automotive industry

CAE tools are widely used in theautomotive industry

The automotive industry comprises a wide range of company, companies and organizations involved in the design, Business development, development, manufacturing, marketing, selling, Maintenance, repairing, and Custom car, modification of motor ve ...

. Their use has enabled automakers to reduce product development costs and time while improving the safety, comfort, and durability of the vehicles they produce. The predictive capability of CAE tools has progressed to the point where much of the design verification is done using computer simulations (diagnosis) rather than physical prototype

A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and Software prototyping, software programming. A prototype ...

testing. CAE dependability is based upon all proper assumptions as inputs and must identify critical inputs (BJ). Even though there have been many advances in CAE, and it is widely used in the engineering field, physical testing is still a must. It is used for verification and model updating, to accurately define loads and boundary conditions, and for final prototype sign-off.

The future of CAE in the product development process

Even though CAE has built a strong reputation as a verification, troubleshooting and analysis tool, there is still a perception that sufficiently accurate results come rather late in thedesign cycle

A decision cycle or decision loop is a sequence of steps used by an entity on a repeated basis to Decision making, reach and implement decisions and to learn from the results. The "decision cycle" phrase has a history of use to broadly categorize v ...

to really drive the design. This can be expected to become a problem as modern products become ever more complex. They include smart systems, which leads to an increased need for multi-physics analysis including controls, and contain new lightweight materials, with which engineers are often less familiar.

CAE software companies and manufacturers are constantly looking for tools and process improvements to change this situation.

On the software side, they are constantly looking to develop more powerful solvers, to better utilize computer resources, and to include engineering knowledge in pre and post-processing. Recent developments have seen the integration of artificial intelligence and machine learning into CAE tools, enabling real-time simulations and predictive modeling. On the process side, they try to achieve a better alignment between 3D CAE, 1D system simulation, and physical testing. This should increase modeling realism and calculation speed.

CAE software companies and manufacturers try to better integrate CAE in the overall product lifecycle management

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design, and manufacture, as well as the service and disposal of manufactured products. ...

. In this way they can connect product design with product use, which is needed for smart products. This enhanced engineering process is also referred to as predictive engineering analytics

A prediction (Latin ''præ-'', "before," and ''dictum'', "something said") or forecast is a statement about a future event or about future data. Predictions are often, but not always, based upon experience or knowledge of forecasters. There ...

.

See also

References

Further reading

* B. Raphael and I.F.C. Smith (2003).'' Fundamentals of computer aided engineering.'' John Wiley. .External links

Why do we need a CAE Software or Numerical Simulations?

Computer Aided Engineering Journal WP:LINKROT

(FEA, CAD, ...)

Integrated Computer Aided Engineering Journal

Computer-Aided Civil and Infrastructure Engineering

Predictive engineering analytics

{{Authority control Computer-aided engineering software Product lifecycle management Engineering disciplines