|

Thermal Wheel

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, energy recovery wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of air-handling units or rooftop units or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel. Description A thermal wheel consists of a circular honeycomb matrix of heat-absorbing material, which is slowly rotated within the supply and exhaust air streams of an air-handling system. As the thermal wheel rotates, heat is captured from the exhaust air stream in one half of the rotation and released to the fresh air stream in the other half of the rotation. Thus waste heat energy from the exhaust air stream is transferred to the matrix material and then from the matrix material to the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Efficiency

Fuel efficiency is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical potential energy contained in a carrier (fuel) into kinetic energy or work. Overall fuel efficiency may vary per device, which in turn may vary per application, and this spectrum of variance is often illustrated as a continuous energy profile. Non-transportation applications, such as industry, benefit from increased fuel efficiency, especially fossil fuel power plants or industries dealing with combustion, such as ammonia production during the Haber process. In the context of transport, fuel economy is the energy efficiency of a particular vehicle, given as a ratio of distance traveled per unit of fuel consumed. It is dependent on several factors including engine efficiency, transmission design, and tire design. In most countries, using the metric system, fuel economy is stated as "fuel consumption" in liters per 100 kilometers (L/100 km) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Preheater

An air preheater is any device designed to heat air before another process (for example, combustion in a boiler With the primary objective of increasing the thermal efficiency of the process. They may be used alone or to replace a recuperative heat system or to replace a steam coil. In particular, this article describes the combustion air preheaters used in large boilers found in thermal power stations producing electric power from e.g. fossil fuels, biomass or waste. (See Chapter 8 by Z.H. Lin) For instance, as the Ljungström air preheater has been attributed worldwide fuel savings estimated to 4,960,000,000 tons of oil, "few inventions have been as successful in saving fuel as the Ljungström Air Preheater", marked as the 44th International Historic Mechanical Engineering Landmark by the American Society of Mechanical Engineers. The purpose of the air preheater is to recover the heat from the boiler flue gas which increases the thermal efficiency of the boiler by red ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Regenerative Heat Exchanger

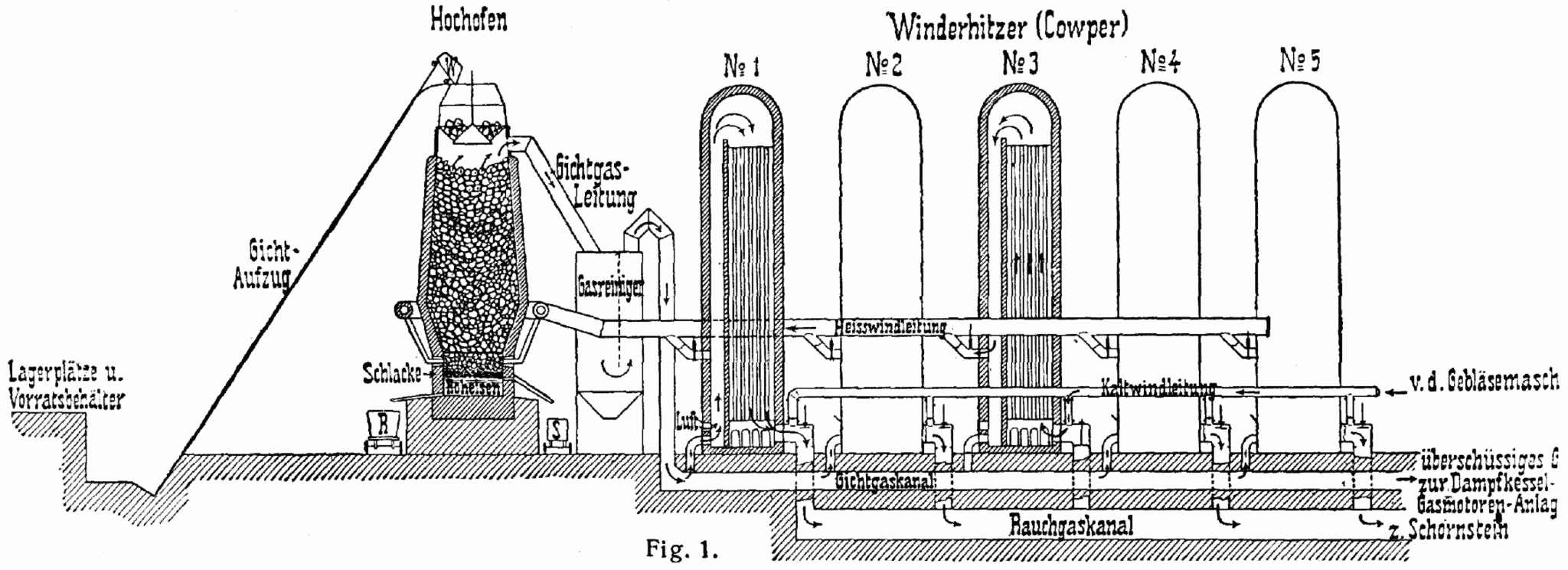

A regenerative heat exchanger, or more commonly a regenerator, is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid. To accomplish this the hot fluid is brought into contact with the heat storage medium, then the fluid is displaced with the cold fluid, which absorbs the heat. In regenerative heat exchangers, the fluid on either side of the heat exchanger can be the same fluid. The fluid may go through an external processing step, and then it is flowed back through the heat exchanger in the opposite direction for further processing. Usually the application will use this process cyclically or repetitively. Regenerative heating was one of the most important technologies developed during the Industrial Revolution when it was used in the hot blast process on blast furnaces. It was later used in glass melting furnaces and steel making, to increase the efficiency of open hearth furnaces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Recovery Ventilation

Heat recovery ventilation (HRV), also known as mechanical ventilation heat recovery (MVHR), is an energy recovery ventilation system which works between two air sources at different temperatures. Heat recovery is a method which is used to reduce the heating and cooling demands of buildings. By recovering the residual heat in the exhaust gas, the fresh air introduced into the air conditioning system is preheated (pre-cooled) and the fresh air enthalpy is increased (reduced) before the fresh air enters the room or the air cooler of the air conditioning unit performs heat and moisture treatment. A typical heat recovery system in buildings consists of a core unit, channels for fresh and exhaust air, and blower fans. Building exhaust air is used as either a heat source or heat sink depending on the climate conditions, time of year and requirements of the building. Heat recovery systems typically recover about 60–95% of the heat in exhaust air and have significantly improved the energ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Energy Recovery Ventilation

Energy recovery ventilation (ERV) is the energy recovery process in residential and commercial HVAC systems that exchanges the energy contained in normally exhausted air of a building or conditioned space, using it to treat (precondition) the incoming outdoor ventilation air. The specific equipment involved may be called an Energy Recovery Ventilator, also abbreviated ''ERV''. During the warmer seasons, an ERV system pre-cools and dehumidifies; During cooler seasons the system humidifies and pre-heats.Dieckmann, John. "Improving Humidity Control with Energy Recovery Ventilation." ''ASHRAE Journal''. 50, no. 8, (2008) An ERV system helps HVAC design meet ventilation and energy standards (e.g., ASHRAE), improves indoor air quality and reduces total HVAC equipment capacity, thereby reducing energy consumption. ERV systems enable an HVAC system to maintain a 40-50% indoor relative humidity, essentially in all conditions. ERV's must use power for a blower to overcome the pressure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HVAC

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. " Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR (as in the designation of HACR-rated circuit breakers). HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels, and senior living facilities; medium to large industrial and office buildings such as skyscrapers and hospitals; vehicles such as cars, trains, airplanes, ships and submarines; and in marine environments, where safe and healthy building conditions are regulated with respect to temperature and humidity, using fres ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Pipe

A heat pipe is a heat-transfer device that employs phase transition to transfer heat between two solid interfaces. At the hot interface of a heat pipe, a volatile liquid in contact with a thermally conductive solid surface turns into a vapor by absorbing heat from that surface. The vapor then travels along the heat pipe to the cold interface and condenses back into a liquid, releasing the latent heat. The liquid then returns to the hot interface through either capillary action, centrifugal force, or gravity and the cycle repeats. Due to the very high heat transfer coefficients for boiling and condensation, heat pipes are highly effective thermal conductors. The effective thermal conductivity varies with heat pipe length, and can approach for long heat pipes, in comparison with approximately for copper. Structure, design and construction A typical heat pipe consists of a sealed pipe or tube made of a material that is compatible with the working fluid such as copper fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recuperator

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat. Generally, they are used to extract heat from the exhaust and use it to preheat air entering the combustion system. In this way they use waste energy to heat the air, offsetting some of the fuel, and thereby improve the energy efficiency of the system as a whole. Description In many types of processes, combustion is used to generate heat, and the recuperator serves to recuperate, or reclaim this heat, in order to reuse or recycle it. The term recuperator refers as well to liquid-liquid counterflow heat exchangers used for heat recovery in the chemical and refinery industries and in closed processes such as ammonia-water or LiBr-water absorption refrigeration cycle. Recuperators are often used in association with the burner portion of a h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Run Around Coil

300px, A run-around coil installation, serving air handling units on the roof of an office building A run-around coil is a type of energy recovery heat exchanger most often positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, to recover the heat energy. Generally, it refers to any intermediate stream used to transfer heat between two streams that are not directly connected for reasons of safety or practicality. It may also be referred to as a run-around loop, a pump-around coil or a liquid coupled heat exchanger.D. A. REAY (1980), A Review of Gas–Gas Heat Recovery Systems, Heat Recovery Systems, Volume 1, No. 1, Pergamon Press Ltd., pgs 18 – 21 Description A typical run-around coil system comprises two or more multi-row finned tube coils connected to each other by a pumped pipework circuit. The pipework is charged with a heat exchange fluid, normally water, which picks up heat from the exhaust air coil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fouling

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms ( biofouling) or a non-living substance (inorganic or organic). Fouling is usually distinguished from other surface-growth phenomena in that it occurs on a surface of a component, system, or plant performing a defined and useful function and that the fouling process impedes or interferes with this function. Other terms used in the literature to describe fouling include deposit formation, encrustation, crudding, deposition, scaling, scale formation, slagging, and sludge formation. The last six terms have a more narrow meaning than fouling within the scope of the fouling science and technology, and they also have meanings outside of this scope; therefore, they should be used with caution. Fouling phenomena are common and diverse, ranging from fouling of ship hulls, natural surfaces in the marine environment ( marine fouling), fouling of heat-transf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adsorption

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the ''adsorbate'' on the surface of the ''adsorbent''. This process differs from absorption, in which a fluid (the ''absorbate'') is dissolved by or permeates a liquid or solid (the ''absorbent''). Adsorption is a '' surface phenomenon'', while absorption involves the whole volume of the material, although adsorption does often precede absorption. The term '' sorption'' encompasses both processes, while '' desorption'' is the reverse of it. Like surface tension, adsorption is a consequence of surface energy. In a bulk material, all the bonding requirements (be they ionic, covalent or metallic) of the constituent atoms of the material are fulfilled by other atoms in the material. However, atoms on the surface of the adsorbent are not wholly surrounded by other adsorbent atoms and therefore can attract adsorbates. The exact nature ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |