|

Thick Film Technology

Thick-film technology is used to produce electronic devices/modules such as surface mount devices modules, hybrid integrated circuits, heating elements, integrated passive devices and sensors. The main manufacturing technique is screen printing (stenciling), which in addition to use in manufacturing electronic devices can also be used for various graphic reproduction targets. It became one of the key manufacturing/miniaturisation techniques of electronic devices/modules during 1950s. Typical film thickness – manufactured with thick film manufacturing processes for electronic devices – is 0.0001 to 0.1 mm. Thick-film circuits/modules are widely used in the automotive industry, both in sensors, e.g. mixture of fuel/air, pressure sensors, engine and gearbox controls, sensor for releasing airbags, ignitors to airbags; common is that high reliability is required, often extended temperature range also along massive thermocycling of circuits without failure. Other application area ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

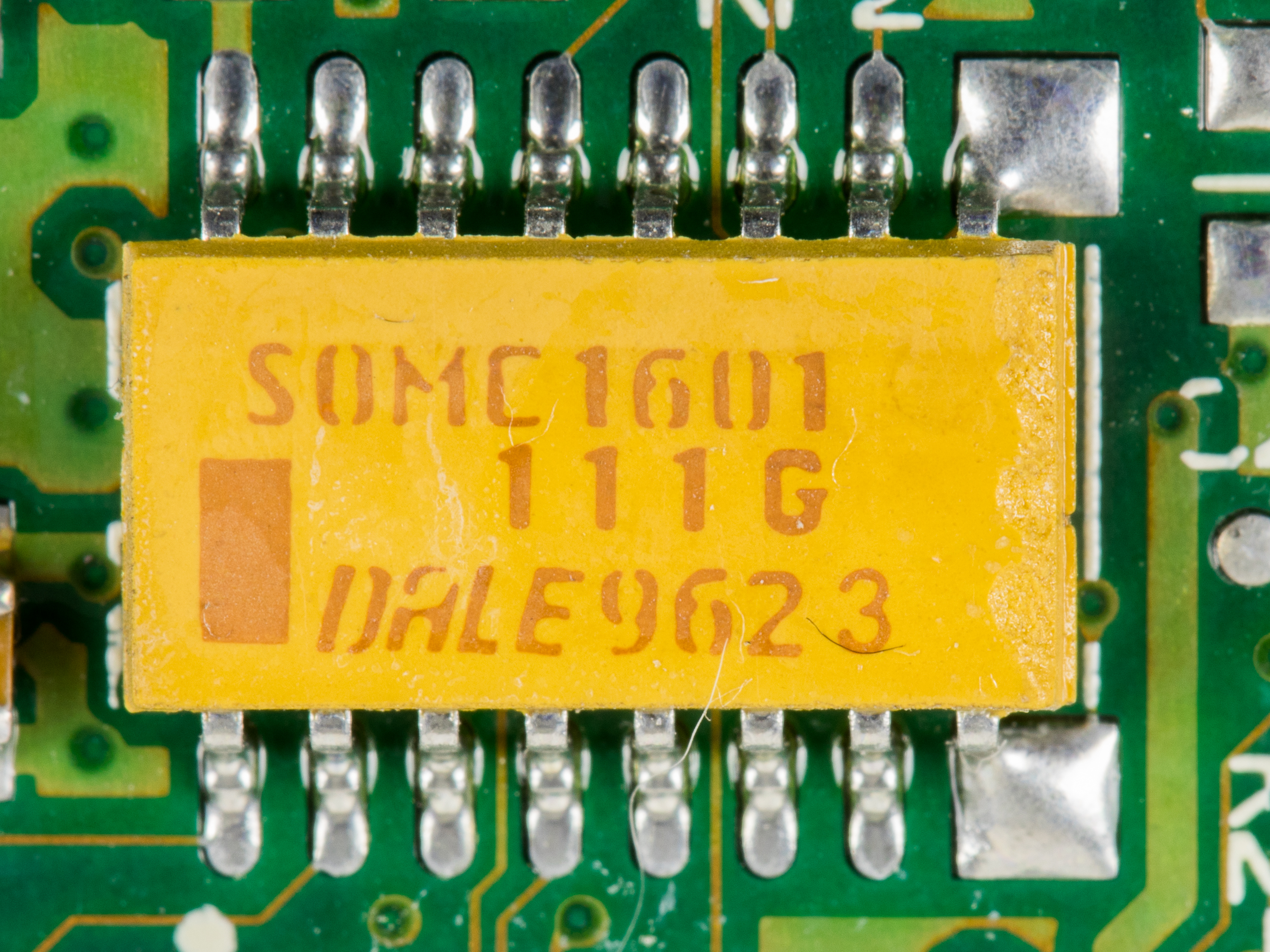

Surface Mount Devices

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminum Nitride

Aluminium nitride ( Al N) is a solid nitride of aluminium. It has a high thermal conductivity of up to 321 W/(m·K) and is an electrical insulator. Its wurtzite phase (w-AlN) has a band gap of ~6 eV at room temperature and has a potential application in optoelectronics operating at deep ultraviolet frequencies. History and physical properties AlN was first synthesized in 1862 by F. Briegleb and A. Geuther. AlN, in the pure (undoped) state has an electrical conductivity of 10−11–10−13 Ω−1⋅cm−1, rising to 10−5–10−6 Ω−1⋅cm−1 when doped. Electrical breakdown occurs at a field of 1.2–1.8 V/mm (dielectric strength). The material exists primarily in the hexagonal wurtzite crystal structure, but also has a metastable cubic zincblende phase, which is synthesized primarily in the form of thin films. It is predicted that the cubic phase of AlN (zb-AlN) can exhibit superconductivity at high pressures. In AlN wurtzite crystal structure, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Passive Devices

Integrated passive devices (IPDs), also known as integrated passive components (IPCs) or embedded passive components (EPC), are electronic components where resistors (R), capacitors (C), inductors (L)/coils/chokes, microstriplines, impedance matching elements, baluns or any combinations of them are integrated in the same package or on the same substrate. Sometimes integrated passives can also be called as embedded passives, and still the difference between integrated and embedded passives is technically unclear. In both cases passives are realized in between dielectric layers or on the same substrate. The earliest form of IPDs are resistor, capacitor, resistor-capacitor (RC) or resistor-capacitor-coil/inductor (RCL) networks. Passive transformers can also be realised as integrated passive devices like by putting two coils on top of each other separated by a thin dielectric layer. Sometimes diodes (PN, PIN, zener etc.) can be integrated on the same substrate with integrated passives ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thin Film

A thin film is a layer of materials ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many applications. A familiar example is the household mirror, which typically has a thin metal coating on the back of a sheet of glass to form a reflective interface. The process of silvering was once commonly used to produce mirrors, while more recently the metal layer is deposited using techniques such as sputtering. Advances in thin film deposition techniques during the 20th century have enabled a wide range of technological breakthroughs in areas such as magnetic recording media, electronic semiconductor devices, integrated passive devices, light-emitting diodes, optical coatings (such as antireflective coatings), hard coatings on cutting tools, and for both energy generation (e.g. thin-film solar cells) and storage ( thin-film bat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronic Design Automation

Electronic design automation (EDA), also referred to as electronic computer-aided design (ECAD), is a category of software tools for designing Electronics, electronic systems such as integrated circuits and printed circuit boards. The tools work together in a Design flow (EDA), design flow that chip designers use to design and analyze entire semiconductor chips. Since a modern semiconductor chip can have billions of components, EDA tools are essential for their design; this article in particular describes EDA specifically with respect to integrated circuits (ICs). History Early days The earliest electronic design automation is attributed to IBM with the documentation of its IBM 700/7000 series, 700 series computers in the 1950s. Prior to the development of EDA, integrated circuits were designed by hand and manually laid out. Some advanced shops used geometric software to generate tapes for a Gerber format, Gerber photoplotter, responsible for generating a monochromatic ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint. Soldering is commonly used in the electronics industry for the manufacture and repair of Printed circuit board, printed circuit boards (PCBs) and other electronic components. It is also used in plumbing and Metalworking, metalwork, as well as in the manufacture of jewelry and other decorative items. The solder used in the process can vary in composition, with different alloys used for different applications. Common solder alloys include tin-lead, tin-silver, and tin-copper, among others. Lead-free solder has also become more widely used in recent years due to health and environmental concerns associated with the use of lead. In addition to the type of solder used, the temperature and method of heating also p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

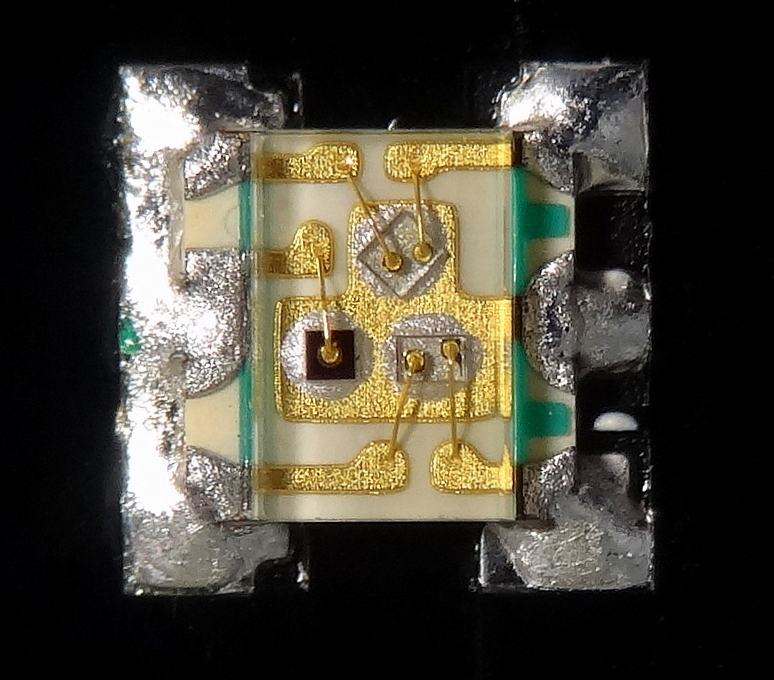

Wire Bonding

Wire bonding is a method of making interconnections between an integrated circuit (IC) or other semiconductor device and its packaging during semiconductor device fabrication. Wire bonding can also be used to connect an IC to other electronics or to connect from one printed circuit board (PCB) to another, although these are less common. Wire bonding is generally considered the most cost-effective and flexible interconnect technology and is used to assemble the vast majority of semiconductor packages. Wire bonding can be used at frequencies above 100 GHz. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wafer Dicing

Die singulation, also called wafer dicing, is the process in semiconductor device fabrication by which dies are separated from a finished wafer of semiconductor. It can involve scribing and breaking, mechanical sawing (normally with a machine called a '' dicing saw'') or laser cutting. All methods are typically automated to ensure precision and accuracy. Following the dicing process the individual silicon chips may be encapsulated into chip carriers which are then suitable for use in building electronic devices such as computers, etc. During dicing, wafers are typically mounted on dicing tape which has a sticky backing that holds the wafer on a thin sheet metal frame. Dicing tape has different properties depending on the dicing application. UV curable tapes are used for smaller sizes and non-UV dicing tape for larger die sizes. Dicing saws may use a dicing blade with diamond particles, rotating at 30,000 RPM and cooled with deionized water. Once a wafer has been diced, the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Trimming

{{Unreferenced, date=June 2015 Laser trimming is the manufacturing process of using a laser to adjust the operating parameters of an electronic circuit. One of the most common applications uses a laser to burn away small portions of resistors, raising their resistance value. The burning operation can be conducted while the circuit is being tested by automatic test equipment, leading to optimum final values for the resistor(s) in the circuit. The resistance value of a film resistor is defined by its geometric dimensions (length, width, height) and the resistor material. A lateral cut in the resistor material by the laser narrows or lengthens the current flow path and increases the resistance value. The same effect is obtained whether the laser changes a thick-film or a thin-film resistor on a ceramic substrate or a surface-mount resistor. The surface-mount resistor is produced with the same technology and may be laser trimmed as well. Trimmable chip capacitors are built up as mult ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultraviolet

Ultraviolet radiation, also known as simply UV, is electromagnetic radiation of wavelengths of 10–400 nanometers, shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight and constitutes about 10% of the total electromagnetic radiation output from the Sun. It is also produced by electric arcs, Cherenkov radiation, and specialized lights, such as mercury-vapor lamps, tanning lamps, and black lights. The photons of ultraviolet have greater energy than those of visible light, from about 3.1 to 12 electron volts, around the minimum energy required to ionize atoms. Although long-wavelength ultraviolet is not considered an ionizing radiation because its photons lack sufficient energy, it can induce chemical reactions and cause many substances to glow or fluoresce. Many practical applications, including chemical and biological effects, are derived from the way that UV radiation can interact with organic molecules. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Curing (chemistry)

Curing is a chemical process employed in polymer chemistry and process engineering that produces the toughening or hardening of a polymer material by cross-linking of polymer chains. Even if it is strongly associated with the production of thermosetting polymers, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC plastisols. Curing process During the curing process, single monomers and oligomers, mixed with or without a curing agent, react to form a tridimensional polymeric network. In the very first part of the reaction Branching (polymer chemistry), branches of molecules with various architectures are formed, and their molecular weight increases in time with the extent of the reaction until the network size is equal to the size of the system. The system has lost its solubility and its viscosity tends to infinite. The remaining molecules start to coexist with the macroscopic network until they react wit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

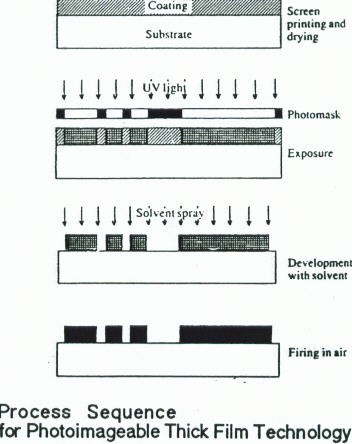

Photoimageable Thick-film Technology

Photoimageable thick-film technology is a combination of conventional thick film technology with elements of thin film technology, and it provides a low cost solution to producing high quality microwave circuits. The ability to directly photoimage the printed layers means that the technology can provide the high line and gap resolution required by high frequency planar components. It provides a feasible fabrication process to produce circuits operating at microwave and millimetre-wave frequencies. Circuits made using this technology meet the modern requirements for high density packaging, whilst yielding the high quality components required for very high frequency applications, including wireless communication, radar, and measurement systems. This technology also enables both single-layer and multi-layer filters to be produced conveniently. Research work has investigated the combination of conventional thick film and fine line photoimageable technologies in order to accommodate f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |