|

Supercharged

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a supercharger is a form of forced induction that is mechanically powered (usually by a belt from the engine's crankshaft), as opposed to a turbocharger, which is powered by the kinetic energy of the exhaust gasses. However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. The first supercharged engine was built in 1878, with usage in aircraft engines beginning in the 1910s and usage in car engines beginning in the 1920s. In piston engines used by aircraft, supercharging was often used to compensate for the lower air density at high altitudes. Supercharging is less commonly used in the 21st century, as manufacturers have shifted to turbochargers to reduce fuel consumption and/or increase power outputs. D ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supercharger Animation By Tyroola

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a supercharger is a form of forced induction that is mechanically powered (usually by a belt from the engine's crankshaft), as opposed to a turbocharger, which is powered by the kinetic energy of the exhaust gasses. However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. The first supercharged engine was built in 1878, with usage in aircraft engines beginning in the 1910s and usage in car engines beginning in the 1920s. In piston engines used by aircraft, supercharging was often used to compensate for the lower air density at high altitudes. Supercharging is less commonly used in the 21st century, as manufacturers have shifted to turbochargers to reduce fuel consumption and/or increase power outputs. De ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls-Royce Merlin

The Rolls-Royce Merlin is a British liquid-cooled V-12 piston aero engine of 27-litres (1,650 cu in) capacity. Rolls-Royce designed the engine and first ran it in 1933 as a private venture. Initially known as the PV-12, it was later called '' Merlin'' following the company convention of naming its four-stroke piston aero engines after birds of prey. After several modifications, the first production variants of the PV-12 were completed in 1936. The first operational aircraft to enter service using the Merlin were the Fairey Battle, Hawker Hurricane and Supermarine Spitfire. The Merlin remains most closely associated with the Spitfire and Hurricane, although the majority of the production run was for the four-engined Avro Lancaster heavy bomber. A series of rapidly-applied developments, brought about by wartime needs, markedly improved the engine's performance and durability. Starting at 1,000 hp for the first production models, most late war versions produced ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

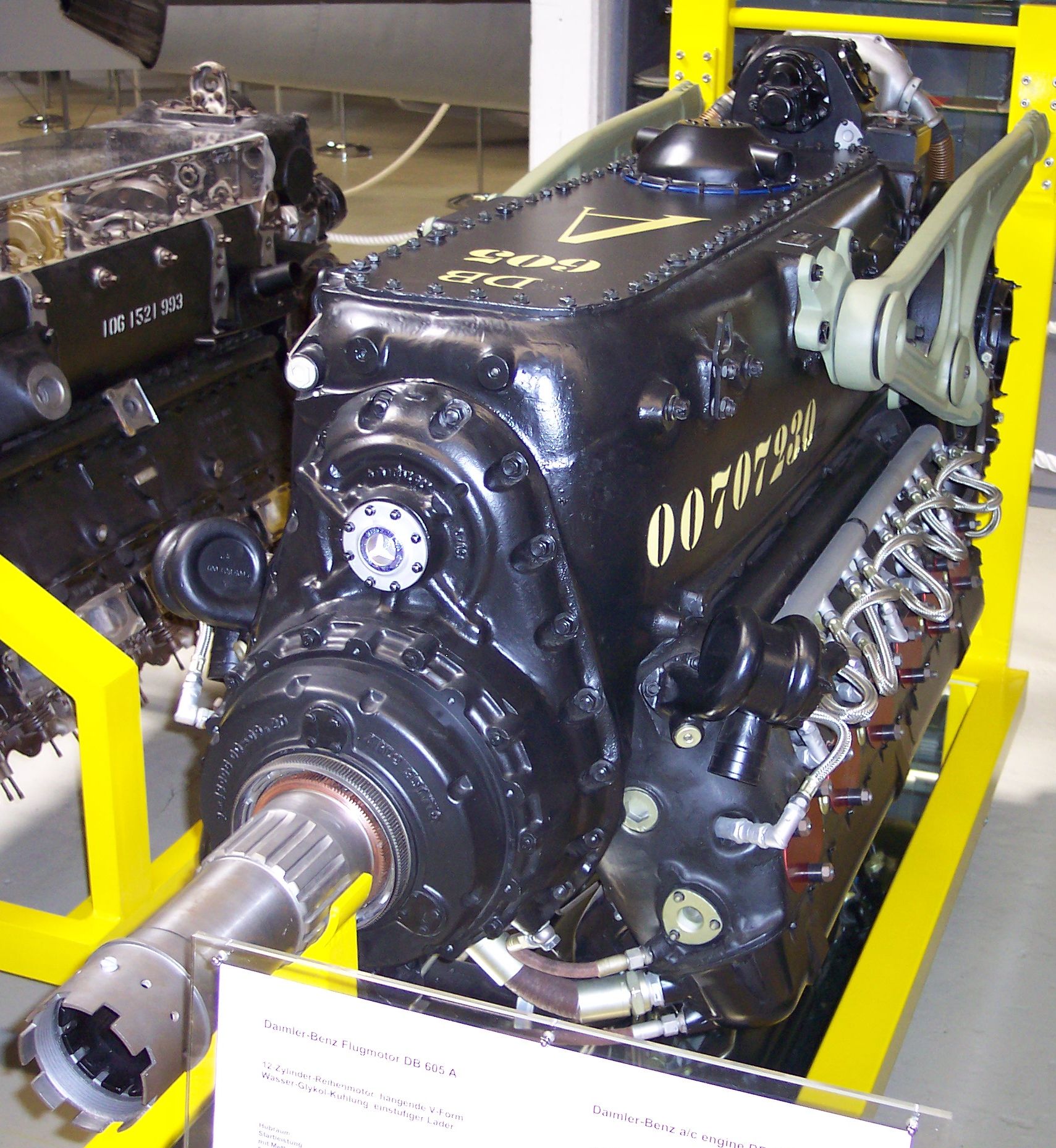

Daimler-Benz DB 605

The Daimler-Benz DB 605 is a German aircraft engine built during World War II. Developed from the DB 601, the DB 605 was used from 1942 to 1945 in the Messerschmitt Bf 109 fighter, and the Bf 110 and Me 210C heavy fighters. The DB 610, a pair of DB 605s geared to turn a single output shaft that replaced the similar DB 606, was used in the A-3 and all A-5 variants of Germany's only operational heavy bomber, the Heinkel He 177A. License-built versions of the DB 605 were used in the Macchi C.205, Fiat G.55, Reggiane 2005 and some other Italian aircraft. It was also used in the Swedish SAAB B 18B and initially in the pusher-design SAAB J 21. Approximately 42,400 DB 605s of all kinds were built. Design and development The primary differences between the 605 and 601 were greater displacement, higher revolutions, higher compression ratio and a more powerful supercharger. Engineers determined that the cylinders could be bored out to a larger diameter without seriously affecting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbo Lag

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Roots-type Supercharger

The Roots-type blower is a positive displacement lobe pump which operates by pumping a fluid with a pair of meshing lobes resembling a set of stretched gears. Fluid is trapped in pockets surrounding the lobes and carried from the intake side to the exhaust. The most common application of the Roots-type blower has been the induction device on two-stroke diesel engines, such as those produced by Detroit Diesel and Electro-Motive Diesel. Roots-type blowers are also used to supercharge four-stroke Otto cycle engines, with the blower being driven from the engine's crankshaft via a toothed or V-belt, a roller chain or a gear train. The Roots-type blower is named after American inventors and brothers Philander and Francis Marion Roots, founders of the Roots Blower Company of Connersville, Indiana USA, who patented the basic design in 1860 as an air pump for use in blast furnaces and other industrial applications. In 1900, Gottlieb Daimler included a Roots-style b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pre-ignition

Pre-ignition (or preignition) in a spark-ignition engine is a technically different phenomenon from engine knocking, and describes the event wherein the air/fuel mixture in the cylinder ignites before the spark plug fires. Pre-ignition is initiated by an ignition source other than the spark, such as hot spots in the combustion chamber, a spark plug that runs too hot for the application, or carbonaceous deposits in the combustion chamber heated to incandescence by previous engine combustion events. The phenomenon is also referred to as 'after-run', or 'run-on' or sometimes dieseling, when it causes the engine to carry on running after the ignition is shut off. This effect is more readily achieved on carbureted gasoline engines, because the fuel supply to the carburetor is typically regulated by a passive mechanical float valve and fuel delivery can feasibly continue until fuel line pressure has been relieved, provided the fuel can be somehow drawn past the throttle plate. The occur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throttle Response

Throttle response or vehicle responsiveness is a measure of how quickly a vehicle's prime mover, such as an internal combustion engine, can increase its power output in response to a driver's request for acceleration. Throttles are not used in diesel engines, but the term throttle can be used to refer to any input that modulates the power output of a vehicle's prime mover. Throttle response is often confused with increased power but is more accurately described as time rate of change of power levels. Gasoline vs diesel Formerly, gasoline/petrol engines exhibited better throttle response than diesel engines. This results from higher specific power output and higher maximum engine power, as well as the fact that lower-powered diesel engines were disproportionately heavier. Recently diesel engines became able to outperform similar-sized petrol engines. Most naturally aspirated gasoline engines have better responsiveness than supercharged or turbocharged engines for engines with simi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Positive Displacement Pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: ''direct lift'', ''displacement'', and ''gravity'' pumps. Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis. When a casing contains only one revolving impeller, it is called a single-stage pump. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Auto Ignition

The autoignition temperature or kindling point of a substance is the lowest temperature in which it spontaneously ignites in a normal atmosphere without an external source of ignition, such as a flame or spark. This temperature is required to supply the activation energy needed for combustion. The temperature at which a chemical ignites decreases as the pressure is increased. *The ignition temperature of a substance is the lowest temperature at which the substance starts combustion. *Substances which spontaneously ignite in a normal atmosphere at naturally ambient temperatures are termed pyrophoric. Autoignition temperatures of liquid chemicals are typically measured using a flask placed in a temperature-controlled oven in accordance with the procedure described in ASTM E659. When measured for plastics, autoignition temperature can be also measured under elevated pressure and at 100% oxygen concentration. The resulting value is used as a predictor of viability for high-oxyg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high- pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |