|

Reflow

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux (metallurgy), flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an Infrared heater, infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil. Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for Through-hole technology, throu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Reflow Oven

A reflow oven is a machine used primarily for reflow soldering of surface mount electronic components to printed circuit boards (PCBs). In commercial high-volume use, reflow ovens take the form of a long tunnel containing a conveyor belt along which PCBs travel. For prototyping or hobbyist use PCBs can be placed in a small oven with a door. Commercial conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a known time and temperature thermal profile, profile. The profile in use may vary depending on the requirements of the PCBs being processed at the time. Types of reflow ovens Infrared and convection ovens In infrared reflow ovens, the heat source is normally ceramic infrared heaters above and below the conveyor, which transfer heat to the PCBs by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Rework (electronics)

In electronics, rework (or re-work) is repair or refinish of a printed circuit board (PCB) assembly, usually involving desoldering and re-soldering of surface-mounted electronic components (SMD). Mass processing techniques are not applicable to single device repair or replacement, and specialized manual techniques by expert personnel using appropriate equipment are required to replace defective components; area array packages such as ball grid array (BGA) devices particularly require expertise and appropriate tools. A hot air gun or hot air station is used to heat devices and melt solder, and specialised tools are used to pick up and position often tiny components. A rework station is a place to do this work—the tools and supplies for this work, typically on a workbench. Other kinds of rework require other tools. Reasons for rework Rework is practiced in many kinds of manufacturing when defective products are found. For electronics, defects may include: * Poor solder joi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Solder Paste

Solder paste is a preparation of powdered solder in sticky Flux (metallurgy), flux paste primarily used to solder surface mount components onto printed circuit boards. It is also possible to solder through-hole pin in paste components by printing solder paste in and over the holes. The sticky paste temporarily holds components in place; the board is then heated, melting the paste and forming a mechanical bond as well as an electrical connection. Use Solder paste is typically used in a Stencil printing, stencil printing process by a solder paste printer, in which paste is deposited over a stainless steel or polyester mask to create the desired pattern on a printed circuit board. The paste may be dispensed Pneumatics, pneumatically, by pin transfer (where a grid of pins is dipped in solder paste and then applied to the board), or by jet printing (where the paste is ejected onto the pads through nozzles, like an inkjet printer). After paste printing, the components are placed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Thermal Profiling

A thermal profile is a complex set of time-temperature data typically associated with the measurement of thermal temperatures in an oven (ex: reflow oven). The thermal profile is often measured along a variety of dimensions such as slope, soak, time above liquidus (TAL), and peak. A thermal profile can be ranked on how it fits in a process window (the specification or tolerance limit). Raw temperature values are normalized in terms of a percentage relative to both the process mean and the window limits. The center of the process window is defined as zero, and the extreme edges of the process window are ±99%. A Process Window Index (PWI) greater than or equal to 100% indicates the profile is outside of the process limitations. A PWI of 99% indicates that the profile is within process limitations, but runs at the edge of the process window. For example, if the process mean is set at 200 °C with the process window calibrated at 180 °C and 220 °C respectively, then ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Tin-silver-copper

Tin-silver-copper ( Sn- Ag- Cu, also known as SAC), is a lead-free (Pb-free) alloy commonly used for electronic solder. It is the main choice for lead-free surface-mount technology (SMT) assembly in the industry,Peter BioccaLead-free SMT Soldering Defects: How to Prevent Them mirrorLead-Free Defects in Reflow Soldering – How to Prevent Them emsnow, Feb 17, 2005 as it is near eutectic, with adequate thermal fatigue properties, strength, and wettability. Lead-free solder is gaining much attention as the environmental effects of lead in industrial products is recognized, and as a result of Europe's RoHS legislation to remove lead and other hazardous materials from electronics. Japanese electronics companies have also looked at Pb-free solder for its industrial advantages. Typical alloys are 3–4% silver, 0.5–0.7% copper, and the balance (95%+) tin. For example, the common "SAC305" solder is 3.0% silver and 0.5% copper. Cheaper alternatives with less silver are used in some appli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

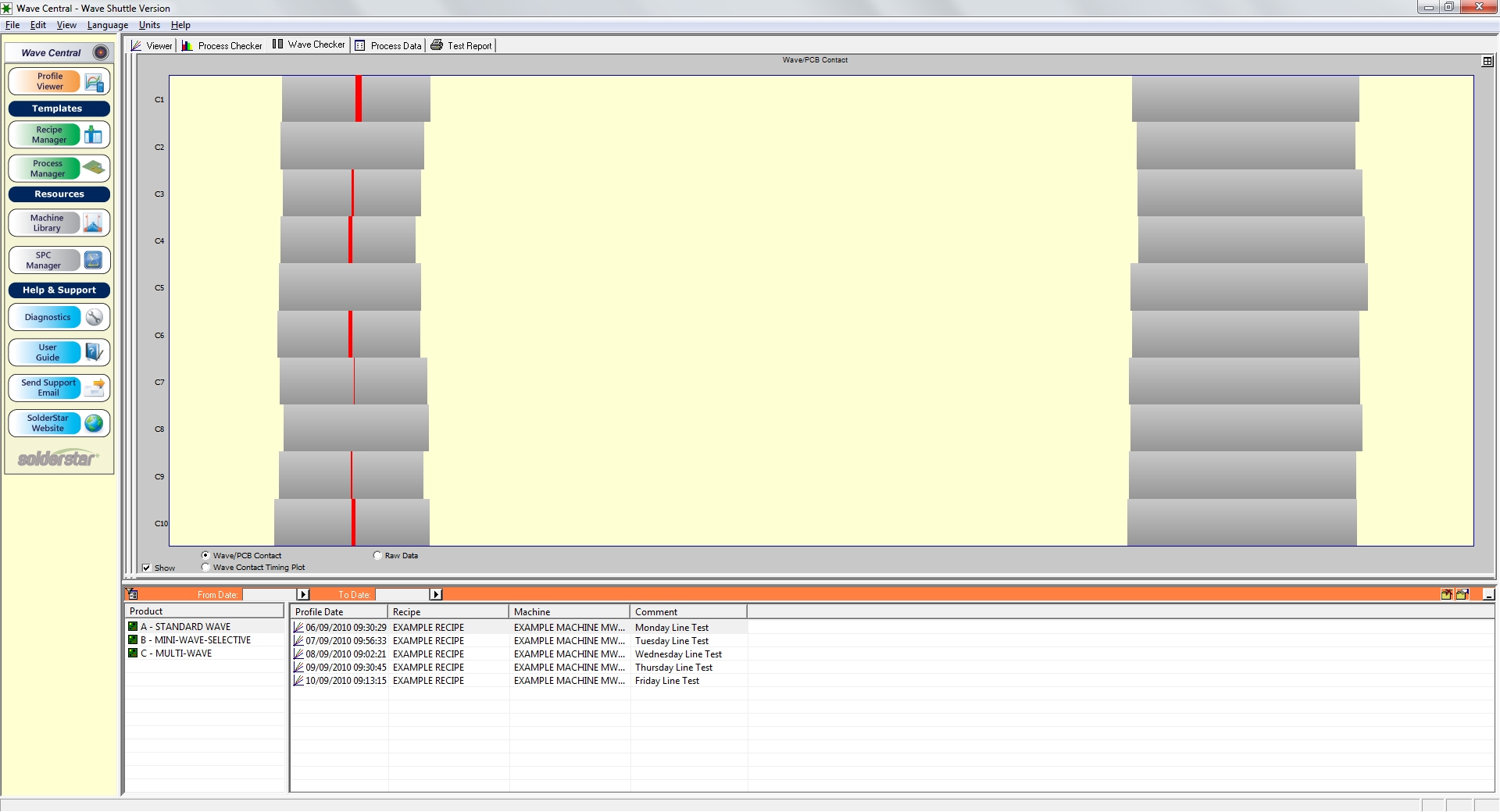

Wave Soldering

Wave soldering is a bulk soldering process used in printed circuit board manufacturing. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board. Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. In the latter case, the components are glued onto the surface of a printed circuit board (PCB) by placement equipment, before being run through the molten solder wave. Wave soldering is mainly used in soldering of through hole components. As through-hole components have been largely replaced by surface mount components, wave soldering has been supplanted by reflow soldering methods in many large-scale electronics applications. However, there is still significant wave soldering where surface-mount technology (SMT) is not suitable (e.g., large power devices and high pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Printed Circuit Board Manufacturing

Printed circuit board manufacturing is the process of manufacturing bare printed circuit board, printed circuit boards (PCBs) and populating them with electronic components. It includes all the processes to produce the full assembly of a board into a functional circuit board. In board manufacturing, multiple PCBs are grouped on a single panel for efficient processing. After assembly, they are separated (depaneled). Various techniques, such as silk screening and photoengraving, replicate the desired copper patterns on the PCB layers. Multi-layer boards are created by laminating different layers under heat and pressure. Holes for Via (electronics), vias (vertical connections between layers) are also drilled. The final assembly involves placing components onto the PCB and soldering them in place. This process can include through-hole technology (in which the component goes through the board) or surface-mount technology (SMT) (in which the component lays on top of the board). Design ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Surface Mount Technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

YouTube

YouTube is an American social media and online video sharing platform owned by Google. YouTube was founded on February 14, 2005, by Steve Chen, Chad Hurley, and Jawed Karim who were three former employees of PayPal. Headquartered in San Bruno, California, it is the second-most-visited website in the world, after Google Search. In January 2024, YouTube had more than 2.7billion monthly active users, who collectively watched more than one billion hours of videos every day. , videos were being uploaded to the platform at a rate of more than 500 hours of content per minute, and , there were approximately 14.8billion videos in total. On November 13, 2006, YouTube was purchased by Google for $1.65 billion (equivalent to $ billion in ). Google expanded YouTube's business model of generating revenue from advertisements alone, to offering paid content such as movies and exclusive content produced by and for YouTube. It also offers YouTube Premium, a paid subs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties that differ from those of the pure elements from which they are made. The vast majority of metals used for commercial purposes are alloyed to improve their properties or behavior, such as increased strength, hardness or corrosion resistance. Metals may also be alloyed to reduce their overall cost, for instance alloys of gold and Copper(II) sulfate, copper. A typical example of an alloy is SAE 304 stainless steel, 304 grade stainless steel which is commonly used for kitchen utensils, pans, knives and forks. Sometime also known as 18/8, it as an alloy consisting broadly of 74% iron, 18% chromium and 8% nickel. The chromium and nickel alloying elements add strength and hardness to the majority iron element, but their main function is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |