|

Rack

Rack or racks may refer to: Storage, support and transportation * Amp rack, a piece of furniture in which amplifiers are mounted * Autorack or auto carrier, for transporting vehicles in freight trains * Baker's rack, for bread and other baked goods * Bicycle rack: ** Bicycle parking rack ** Bicycle stand, for holding bicycles in service, storage, or transport ** The luggage carrier of a bicycle * Bustle rack, a type of storage bin mounted on armored fighting vehicles * Clothes rack, or clothes horse * hatstand, also known as a coat rack, hall rack, or hat rack * Drum rack, part of a drum kit * Drying rack, for clothing * Ejector rack or hardpoint for attaching external loads to an aircraft * Firearm rack * Flat rack container, a type of railroad freight car * Hay rack, for feeding animals * Laboratory drying rack, a for hanging and draining glassware * Music rack or music stand, to hold sheet music for performance * Newspaper rack, a newspaper vending machine * Pallet r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Amp Rack

A 19-inch rack is a standardized frame or enclosure for mounting multiple electronic equipment modules. Each module has a front panel that is wide. The 19 inch dimension includes the edges or ''ears'' that protrude from each side of the equipment, allowing the module to be fastened to the rack frame with screws or bolts. Common uses include computer servers, telecommunications equipment and networking hardware, audiovisual production gear, professional audio equipment, and scientific equipment. Overview and history Equipment designed to be placed in a rack is typically described as rack-mount, rack-mount instrument, a rack-mounted system, a rack-mount chassis, subrack, rack cabinet, rack-mountable, or occasionally simply shelf. The height of the electronic modules is also standardized as multiples of or one rack unit or U (less commonly RU). The industry-standard rack cabinet is 42U tall; however, many data centers have racks taller than this. The term relay rack app ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rack Railway

A rack railway (also rack-and-pinion railway, cog railway, or cogwheel railway) is a steep grade railway with a toothed rack rail, usually between the running rails. The trains are fitted with one or more cog wheels or pinions that mesh with this rack rail. This allows the trains to operate on steep gradients of 100% (45 degrees) or more, well above the 10% maximum for friction-based rail. The rack and pinion mechanism also provides more controlled braking and reduces the effects of snow or ice on the rails. Most rack railways are mountain railways, although a few are transit railways or tramways built to overcome a steep gradient in an urban environment. The first cog railway was the Middleton Railway between Middleton and Leeds in West Yorkshire, England, United Kingdom, where the first commercially successful steam locomotive, ''Salamanca'', ran in 1812. This used a rack and pinion system designed and patented in 1811 by John Blenkinsop. The first mountain cog railw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Parking Rack

A bicycle parking rack, usually shortened to bike rack and also called a bicycle stand, is a device to which bicycles can be securely attached for Bicycle parking, parking purposes. It may be freestanding, or securely attached to the ground or a stationary object, such as a building. Indoor racks are commonly used for private bicycle parking, while outdoor racks are often used in commercial areas. General styles of racks include the Inverted U, Serpentine, Bollard, Grid, and Decorative. The most effective and secure bike racks are those that can secure both wheels and the frame of the bicycle, using a bicycle lock. Bike racks can be constructed from a number of materials, including stainless steel, steel, recycled plastic, and thermoplastic. Durability, weather resistance, appearance and functionality are important factors when choosing this material. The visibility of the bike rack, adequate spacing from automobile parking and pedestrian traffic, weather coverage, and proximi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pallet Racking

Pallet rack is a material handling storage aid system designed to store materials on pallets (or “skids”). Although there are many varieties of pallet racking, all types allow for the storage of palletized materials in horizontal rows with multiple levels. Forklift trucks are usually required to place the loaded pallets onto the racks for storage. Since the Second World War, pallet racks have become a ubiquitous element of most modern warehouses, manufacturing facilities, retail centers, and other storage and distribution facilities. All types of pallet racking increase storage density of the stored goods. Costs associated with the racking increases with increasing storage density. Selective pallet racking systems Selective pallet racking is a common pallet racking system in use today. Selective pallet racking systems typically come in one of two configurations: a roll formed, or clip-in configuration, and a structural bolt-together configuration. #Roll formed selective r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Autorack

An autorack, also known as an auto carrier (also Flat wagon#Car transporters, car transporter outside the US), is a specialized piece of railroad rolling stock used to transport automobiles and light trucks. Autoracks are used to transport new vehicles from factories to automotive distributors, and to transport passengers' vehicles in car shuttle train, car shuttles and motorail services, such as Amtrak's ''Auto Train'' route. History In the early 20th century, when automobiles were still new technology, their production levels were low enough that they could be shipped in sufficient quantities in boxcars. Two to four automobiles would usually fit into one boxcar. But as the automobile industry grew in size, railroads found that they needed to modify the boxcars for more efficient loading. Some modifications included longer boxcars, larger sliding double side doors located near one end of the boxcar, or doors located on the boxcar ends. These modifications helped, but the deman ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roof Rack

A roof rack is a set of bars secured to the roof of an automobile. It is used to carry bulky items such as luggage, bicycles, canoes, kayaks, skis, or various carriers and containers. They allow users of an automobile to transport objects on the roof of the vehicle without reducing interior space for occupants or the cargo area volume limits, such as in the typical car's trunk design. These include car top weatherproof containers; some are designed for specific cargo such as skis or luggage. History There is a long history of the use of roof racks and their designs. Until the late 1970s, almost all regular passenger automobiles had rain gutters. These gutters are formed by the welded flange (raised rim or lip) on the left and right sides of the car's metal roof panel. This made attaching an accessory or aftermarket roof rack a relatively simple process. The first mass production cars without any visible rain gutters were the 1975 AMC Pacer and Chevrolet Monza. Other v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rack And Pinion

rack and pinion is a type of linear actuator that comprises a circular gear (the '' pinion'') engaging a linear gear (the ''rack''). Together, they convert between rotational motion and linear motion: rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate. The rack and pinion mechanism is used in rack railways, where the pinion mounted on a locomotive or a railroad car engages a rack usually placed between the rails, and helps to move the train up a steep gradient. It is also used in arbor presses and drill presses, where the pinion is connected to a lever and displaces a vertical rack (the ram). In pipelines and other industrial piping systems, a rack displaced by a linear actuator turns a pinion to open or close a valve. Stairlifts, lock gates, electric gates, and the mechanical steering mechanism of cars are other notable applications. The term "rack and pinion" may be used also when the rac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pot Rack

A pot rack is a functional piece of kitchen furniture that is used to hang or store cooking pot Cookware and bakeware is food preparation equipment, such as cooking pots, pans, baking sheets etc. used in kitchens. Cookware is used on a Kitchen stove, stove or range cooktop, while bakeware is used in an oven. Some utensils are considere ...s and pans. Steel, wood, wrought iron, and a few other metals are the most common types of materials used for pot racks. Pot racks also usually have some type of finish or stain to help them match pots and decor. In addition, pot racks can range in size from less than a foot to over fifteen feet long. These larger pot racks are capable of supporting dozens of pots and pans. Benefits Pot racks are often purchased for convenience, saving storage space, and for decorative value. Using a pot rack delivers convenience because a person is able to find the pots and pans quickly and easily when they are needed. Pot racks also save storage s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laboratory Drying Rack

Laboratory drying rack is a pegboard for hanging and draining glassware in a laboratory. It is available in different varieties and sizes. It can be used for different materials of glassware in the laboratory room such as funnels, pipettes, mixing balls, slides, bottle stoppers, tubing and so on.Lab Drying Racks. (2016). ''M2 Scientifics.'' Retrieved from: https://www.m2scientifics.com/100-lab-drying-racks In addition to that, the pegs on the drying rack are easily removable and replaceable in order to maintain the cleaning of the lab racks to avoid contamination with other apparatus used on the same rack. Any common laboratory needs to have at least two or three drying racks per lab.Mallapaty G.(2001). Equipment Requirements for a PHC Centre Laboratory. ''The Public Health Care Laboratory.'' Retrieved from: http://www.phclab.com/images/phc.pdf Types Laboratory drying rack can be mainly categorized into three major types including stainless steel laboratory drying racks, epoxy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

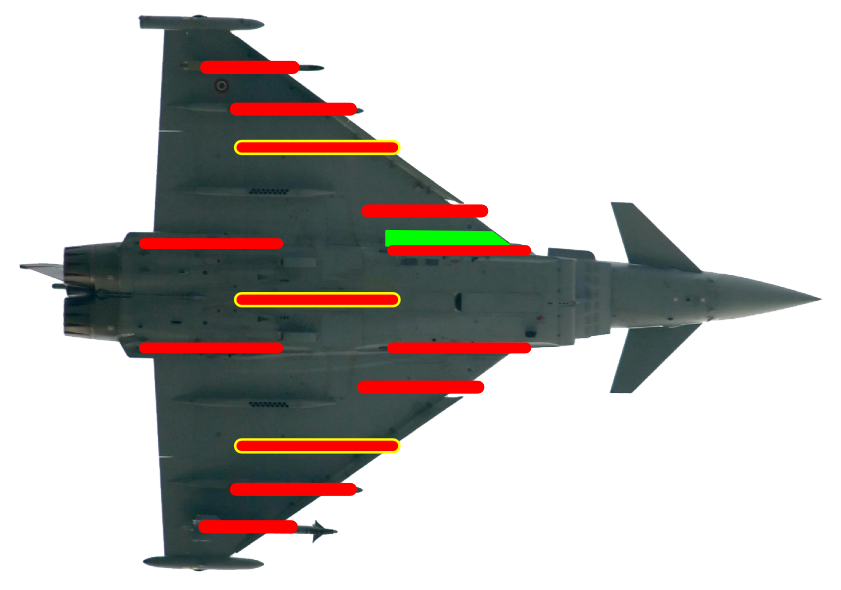

Ejector Rack

A hardpoint is an attachment location on a structural frame designed to transfer force and carry an external or internal structural load, load. The term is usually used to refer to the mounting points (more formally known as a weapon station or station) on the airframe of military aircraft that carry list of aircraft weapons, weapons (e.g. gun pods and rocket pods), aircraft ordnance, ordnances (aerial bomb, bombs and guided missile, missiles) and support equipment (e.g. flare (countermeasure), flares and electronic countermeasure, countermeasures, targeting pods or drop tanks), and also include hardpoints (also known as pylons) on the wings or fuselage of a military transport aircraft, commercial airliner or private jet where external turbofan jet engines are often mounted. Aircraft In aeronautics, the term ''station'' is used to refer to a point of carriage on the frame of an aircraft. A station is usually rated to carry a certain amount of payload. It is a design number whi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bustle Rack

A bustle rack is a type of storage bin mounted on combat vehicles, usually on the sides and/or rear of the turret. These racks are used to carry extra gear and supplies for the vehicle in the field, as well as give the crew a place to store their belongings so that they don't take up the already cramped space inside the vehicle. On the U.S. Abrams Main Battle Tank The original rack design for the XM1 and first production M1 Abrams tanks was blueprinted by then 1LT John A. Baker III, XO and Company Maintenance Officer, H Co, 2/6 CAV, Ft. Knox, KY. Baker had previously developed the standard combat load plan for M60A1 tanks for the Rapid Deployment Force (RDF), 194th Armored Brigade in the early 1980s. Upon joining the Army's first XM1/M1 unit, H Co, 2/6 CAV, Baker and his platoon tested every aspect of the XM1 seven days a week for months on end, putting the Army's newest battle tank through its paces. Baker and his men became painfully aware that the vehicle's stowage would be s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |