|

Molding Sand

Molding sand, also known as foundry sand, is a sand that when moistened and compressed or oiled or heated tends to pack well and hold its shape. It is used in the process of sand casting for preparing the mold cavity. Green sand Green sand is an aggregate of sand, bentonite clay, pulverized coal and water. Its principal use is in making molds for metal casting. The largest portion of the aggregate is a sand, either most-commonly silica or sometimes olivine. There are many recipes for the proportion of clay, but they all strike different balances between moldability, surface finish, and ability of the hot molten metal to degas. The coal, typically referred to in as sea-coal, which is present at a ratio of less than 5%, partially combusts in the surface of the molten metal leading to offgassing of organic vapors. Sand casting is one of the earliest forms of casting practiced due to the simplicity of materials involved. It still remains one of the cheapest ways to cast metals beca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural class of soil or soil type; i.e., a soil containing more than 85 percent sand-sized particles by mass. The composition of sand varies, depending on the local rock sources and conditions, but the most common constituent of sand in inland continental settings and non- tropical coastal settings is silica (silicon dioxide, or SiO2), usually in the form of quartz. Calcium carbonate is the second most common type of sand, for example, aragonite, which has mostly been created, over the past 500million years, by various forms of life, like coral and shellfish. For example, it is the primary form of sand apparent in areas where reefs have dominated the ecosystem for millions of years like the Caribbean. Somewhat more rarely, sand may be composed of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cope And Drag

In foundry work, the terms cope and drag refer respectively to the top and bottom parts of a two-part casting flask, used in sand casting. The flask is a wood or metal frame, which contains the molding sand, providing support to the sand as the metal is poured into the mold. In flaskless molding, the same terms are used, cope for the top or upper piece and drag for the bottom or lower piece. In the simplest sand casting procedure, the drag is placed upside down on a board, around a pattern of the part to be cast. The pattern is a model of the desired casting. Talcum powder is often dusted over the pattern to aid in the removal of the pattern. Sand is sifted over the pattern until the model is covered by a few inches of sand. More sand is then dumped into the drag, and rammed with a wooden wedge, or mechanically vibrated to pack the sand down. The sand is then struck level with the top edge of the drag, using a wooden or metal strake. A board is then placed on top of the drag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

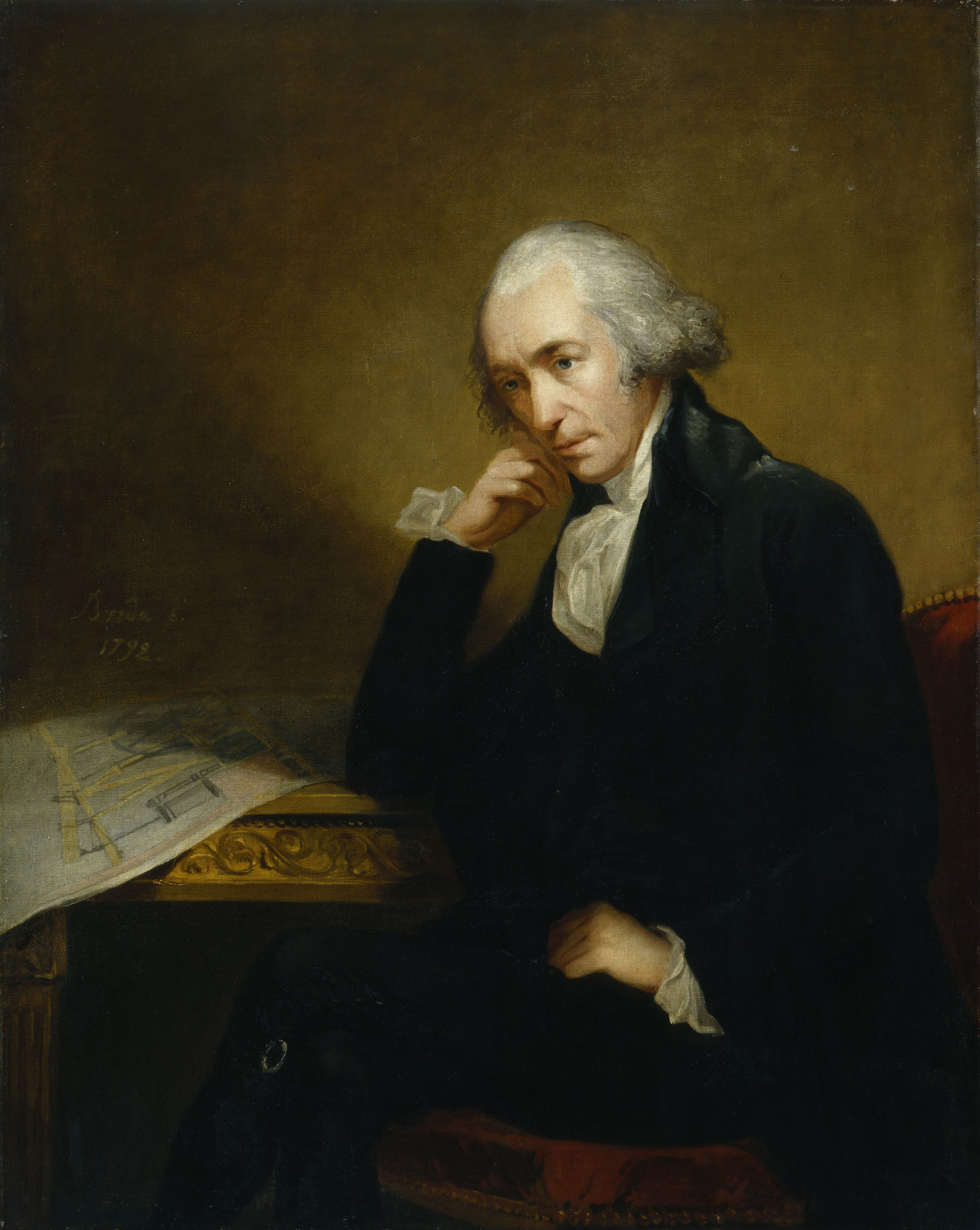

Humphry Davy

Sir Humphry Davy, 1st Baronet, (17 December 177829 May 1829) was a British chemist and inventor who invented the Davy lamp and a very early form of arc lamp. He is also remembered for isolating, by using electricity, several elements for the first time: potassium and sodium in 1807 and calcium, strontium, barium, magnesium and boron the following year, as well as for discovering the elemental nature of chlorine and iodine. Davy also studied the forces involved in these separations, inventing the new field of electrochemistry. Davy is also credited to have been the first to discover clathrate hydrates in his lab. In 1799 he experimented with nitrous oxide and was astonished at how it made him laugh, so he nicknamed it "laughing gas" and wrote about its potential anaesthetic properties in relieving pain during surgery. Davy was a baronet, President of the Royal Society (PRS), Member of the Royal Irish Academy (MRIA), Fellow of the Geological Society (FGS), and a mem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramsite Sand

Ceramsite sand is an artificial foundry sand originating in China. It is a substitute for chromite sand and zircon sand in the foundry and petroleum industries. Ceramsite sand has been used in 3D printing 3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer co ... to produce molds, but the printed layer is prone to deviation from the location of the original object, known as pushing dislocation. References Metalworking {{metalworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sand Rammer

A sand rammer is a piece of equipment used in foundry sand testing to make test specimen of molding sand by compacting bulk material by free fixed height drop of fixed weight for 3 times. It is also used to determine compactibility of sands by using special specimen tubes and a linear scale. Mechanism Sand rammer consists of calibrated sliding weight actuated by cam, a shallow cup to accommodate specimen tube below ram head, a specimen stripper to strip compacted specimen out of specimen tube, a specimen tube to prepare the standard specimen of 50 mm diameter by 50 mm height or 2 inch diameter by 2 inch height for an AFS standard specimen.AFS Mould & core test hand book Specimen preparation The cam is actuated by a user by rotating the handle, causing a cam to lift the weight and let it fall freely on the frame attached to the ram head. This produces a standard compacting action to a pre-measured amount of sand. Demonstration of this apparatus can be seen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sand Casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via sand casting process. Molds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. The mold cavities and gate system are created by compacting the sand around models called patterns, by carving directly into the sand, or by 3D printing. Basic pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hand Mould

A hand mold is a simple mold used for low quantity work. It is used in the injection molding and the printing industry. It is made by a hand injection molding machine. It is a simple machine which contains a barrel, handle, nozzle, mold and heaters. Printing In the printing industry, a hand mold specifically refers to a two-part mold used for casting hand-made type. Inside the mold is a matrix. In particular, it refers to a system for casting movable type, pioneered by Johannes Gutenberg, which was widely used in the early era of printing in Europe (15th-16th century). In this method, the type was made by punching a letter-shaped cavity in a matrix made of some soft metal (typically copper). Then this matrix would be held in the lower part of the mold, the upper part would close on it, and molten type metal would be poured into the cavity. Using the hand mold, the printer could quickly make any additional type he might need.Meggs, Philip B. ''A History of Graphic Design.'' Joh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Foundry Sand Testing

Foundry sand testing is a process used to determine if the foundry sand has the correct properties for a certain casting process. The sand is used to make moulds and cores via a pattern. In a sand casting foundry there are broadly two reasons for rejection of the casting — metal and sand — each of which has a large number of internal variables. The defects arising from the sand can be prevented by using sand testing equipment to measure the various properties of the sand. Process The testing process is divided into four stages: sampling of the bulk material, sample sand preparation, specimen preparation and testing. It is done at three different points of the process: upon first arrival from the supplier, en transport for processing (usually on a conveyor), and after processing. In each situation it is important to take a representative sample by mixing the sand or by taking multiple samples in different locations. Also, the sample must be stored in an airtight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DISAMATIC

DISAMATIC is an automatic production line used for fast manufacturing of sand molds for sand casting. This process is commonly used to mass manufacture of metal castings for the automotive and machine industries. History In 1957, Vagn Aage Jeppesen, professor at the Technical University of Denmark, claimed a patent for a device producing flaskless molds of sand mixtures with vertical parting lines for casting metal parts. In 1960, the Danish company Dansk Industri Syndikat A/S (DISA) acquired the patent and started working on its implementation. In 1962, a half scale prototype of a sand molding machine with flaskless and vertically parted molds under the name of DISAMATIC was ready to be disclosed. During the International Foundry Trade Fair (GIFA) in 1962 in Düsseldorf, the scale model was demonstrated on DISA's stand. This resulted in sales of two first DISAMATICs to European foundries. The first automatic DISAMATIC molding lines could produce up to 240 complete sand mold ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Born Bronze - Bronze Casts

Born may refer to: * Childbirth * Born (surname), a surname (see also for a list of people with the name) * ''Born'' (comics), a comic book limited series Places * Born, Belgium, a village in the German-speaking Community of Belgium * Born, Luxembourg, a village in Luxembourg * Born auf dem Darß, a municipality in Mecklenburg-Vorpommern, Germany * Born, Netherlands, a town in the Netherlands * Born, Saxony-Anhalt, a municipality in Saxony-Anhalt, Germany * Born (crater), a small lunar impact crater located near the eastern edge of the Moon, to the northeast of the prominent crater Langrenus Music * ''Born'' (Bond album), 2001 * ''Born'' (Boom Crash Opera album), 1995 * ''Born'' (EP), a 2004 EP by D'espairsRay * "Born" (song), a 1970 song by Barry Gibb * "Born", a song by the metal band Nevermore from '' This Godless Endeavor'' * "Born", a song by the pop-rock band OneRepublic from '' Oh My My'' * "Born", a song by the Ohio-based band Over the Rhine from '' Drunkard's ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sand Casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via sand casting process. Molds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. The mold cavities and gate system are created by compacting the sand around models called patterns, by carving directly into the sand, or by 3D printing. Basic pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flask (casting)

A flask is a type of tooling used to contain a mold in metal casting. A flask has only sides, and no top or bottom, and forms a frame around the mold, which is typically made of molding sand. The shape of a flask may be square, rectangular, round or any convenient shape. A flask can have any size so long as it is larger than the pattern being used to make the sand mold. Flasks are commonly made of steel, aluminum or even wood. A simple flask has two parts: the cope and the drag. More elaborate flasks may have three or even four parts. Flask design Flasks are often designed with bars that extend to span two opposite sides. The bars act as reinforcement to the molding sand, which is relatively weak in tensile strength. The bars help support the sand through the molding and pouring operation. Flasks are designed with an alignment or registration feature, so that the two flasks can be aligned to one another to ensure a casting can be more dimensionally accurate and also in sm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |